Shunt type air bath duct

A split-flow, air-bath technology, used in cooling/ventilation/heating transformation, photolithographic process exposure devices, microlithography exposure equipment, etc., can solve the problems of affecting flow, large piezoresistance, poor adjustment accuracy, etc. Energy consumption, solving mutual interference, reducing the effect of piezoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

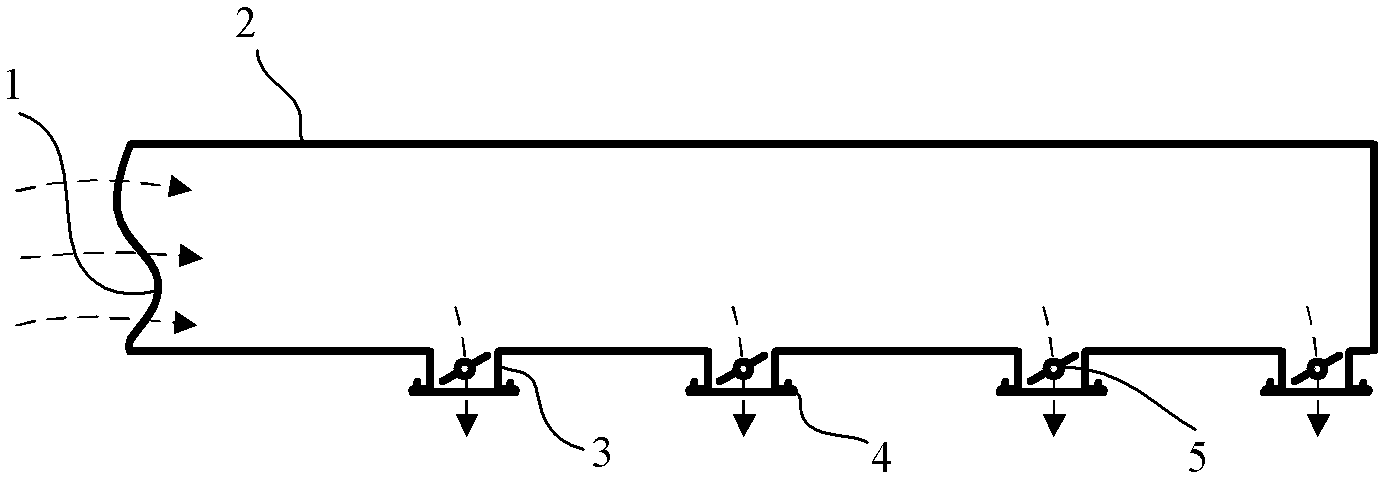

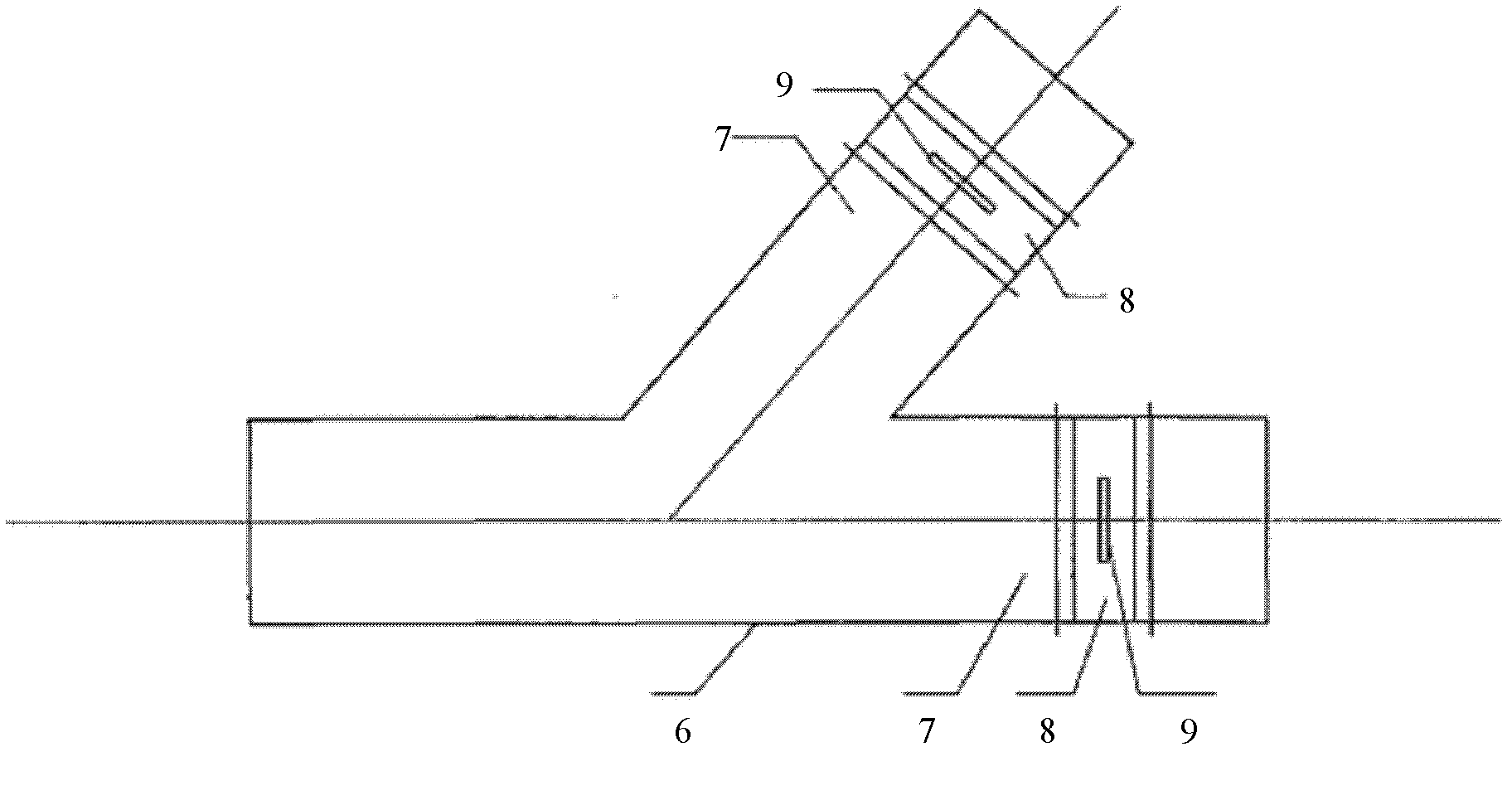

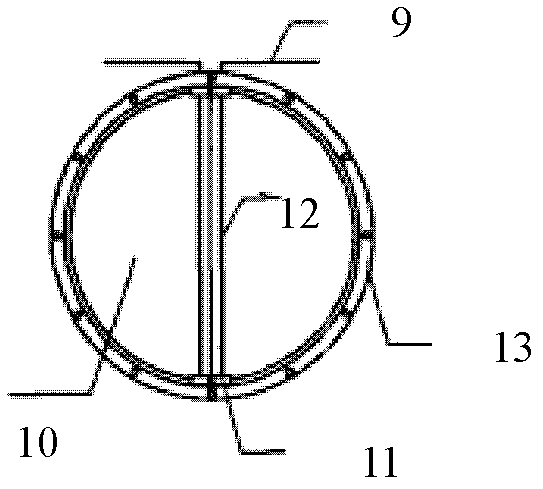

[0024] Figure 4 It is a schematic diagram of a split air bath air duct in a preferred embodiment of the present invention. Please refer to Figure 4 . The split-flow air bath air channel 40 provided in this embodiment can be installed in the overall frame of the photolithography machine to deliver the temperature-controlled air bath gas to various areas and components that require an air bath. Here, the split air bath duct 40 may include a body 400 and at least one split unit 410 . Here, the number of distribution units 410 may be multiple, and the height of the body 400 decreases sequentially with the distribution units 410 . However, the present invention does not impose any limitation thereto. In other embodiments, only on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com