Compound filter material and preparing method and performance testing method thereof

A composite filter material and performance technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of large particle size and difficult high-efficiency filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

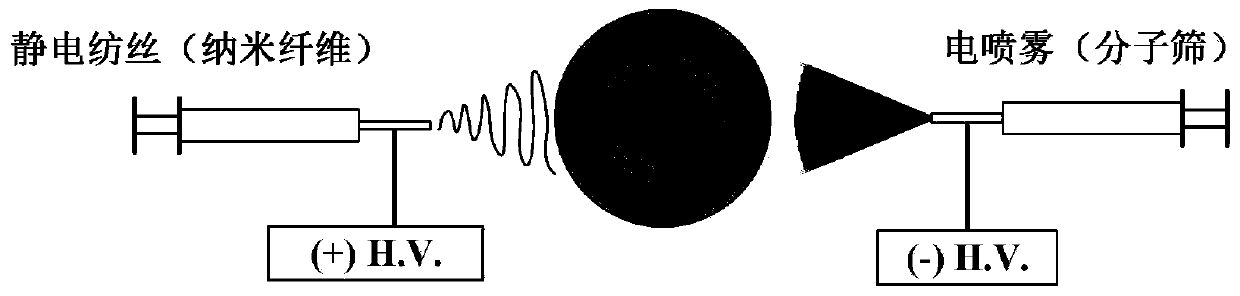

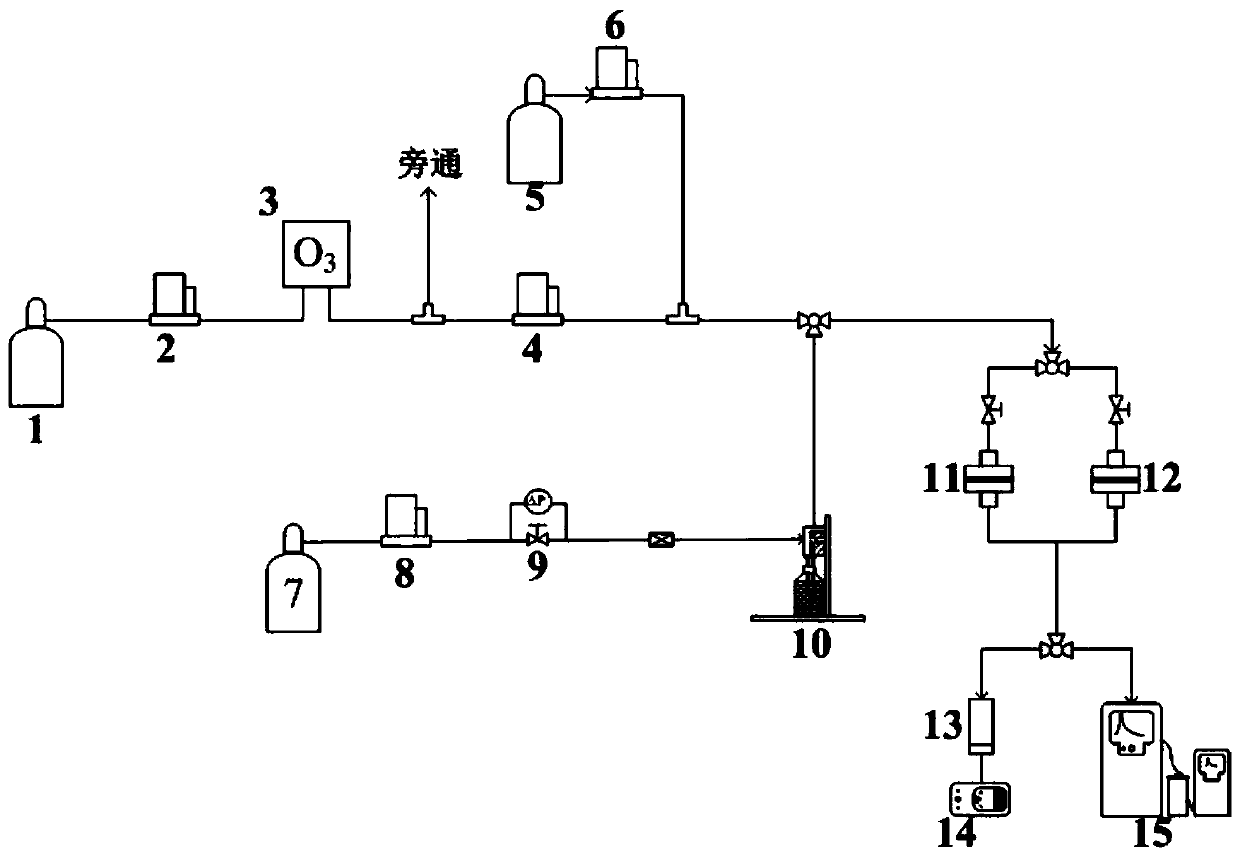

[0138] refer to figure 1 , the present embodiment proposes that the preparation process of the composite filter material containing nanofibers is:

[0139] Fix the load base on the rollers and start the rollers;

[0140] Fill the dimethylformamide solution of polyacrylonitrile into the electrospinning solution cavity, spray it to the roller, and generate nanofibers on the loading base;

[0141] Put the adsorbent solution into the electrospray solution chamber, spray to the roller, and load the adsorbent on the load base until the adsorbent solution is sprayed completely;

[0142] Stop the roller, let it dry, and curve the fiber cloth on the roller to finally obtain the composite filter material containing nanofibers.

[0143] The rotating speed of the roller is 10r / min.

[0144] The mass fraction of polyacrylonitrile in the dimethylformamide solution of polyacrylonitrile is 10%.

[0145] The adsorbent solution is obtained by dissolving the adsorbent in an isopropanol solut...

Embodiment 2

[0168] The preparation method of the composite filter material without nanofibers of the present embodiment is basically the same as that of Example 1, the only difference is:

[0169] The adsorbent used is ZSM-5 molecular sieve.

[0170] Spray 40mg and 10mg of ZSM-5 powdered molecular sieves onto the fiber substrate, respectively, to prepare adsorbents with loading masses per unit area of 0.80 and 0.20mg / cm 2 The loading ratios of samples No. 1 and No. 2 are 85% and 75%, respectively.

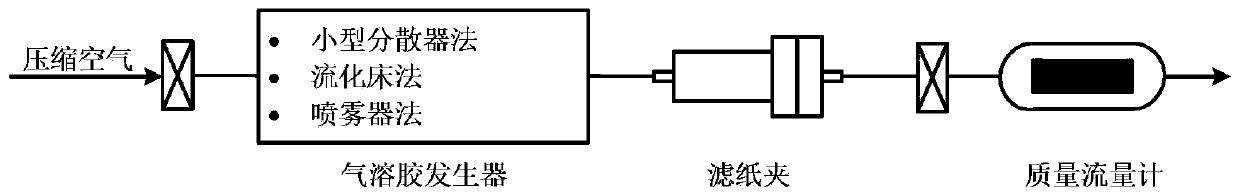

[0171] According to the performance test method of a composite filter material described in Example 1, the performance tests were performed on sample No. 1 and sample No. 2 respectively.

[0172] The test conditions are:

[0173] The gas to be measured is ozone, and the ozone concentration is 600ppb.

[0174] Experimental results such as Figure 9 The comparison chart of the ozone removal efficiency of the two composite filter materials with different adsorbent loading mass is shown, fro...

Embodiment 3

[0176] According to the performance testing method of a kind of composite filter material of implementation case 1, the loading mass per unit area of the adsorbent containing and not containing nanofibers is 0.40 mg / cm 2 (80% load rate,) performance test of the composite filter material, the test conditions are:

[0177] The particle size range of the particle to be measured is 0-300nm.

[0178] Experimental results such as Figure 10 The ozone removal efficiency comparison chart of the two composite filter materials with and without nanofibers is shown. From this figure, it can be obtained that the particulate matter efficiency curve of the composite filter material with nanofibers is above the efficiency curve of the composite filter material without nanofibers , indicating that nanofibers contribute to the removal of particulate matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com