Methanol reforming hydrogen production reactor with flow velocity distribution uniformity

A flow rate distribution, reforming hydrogen production technology, applied in hydrogen, hydrogen/synthesis gas production, chemical instruments and methods, etc., can solve the problem of uneven distribution of reactant flow field and temperature field, and improve the conversion rate and quality of reactants Lightweight, reduce the effect of manufacturing process and material performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

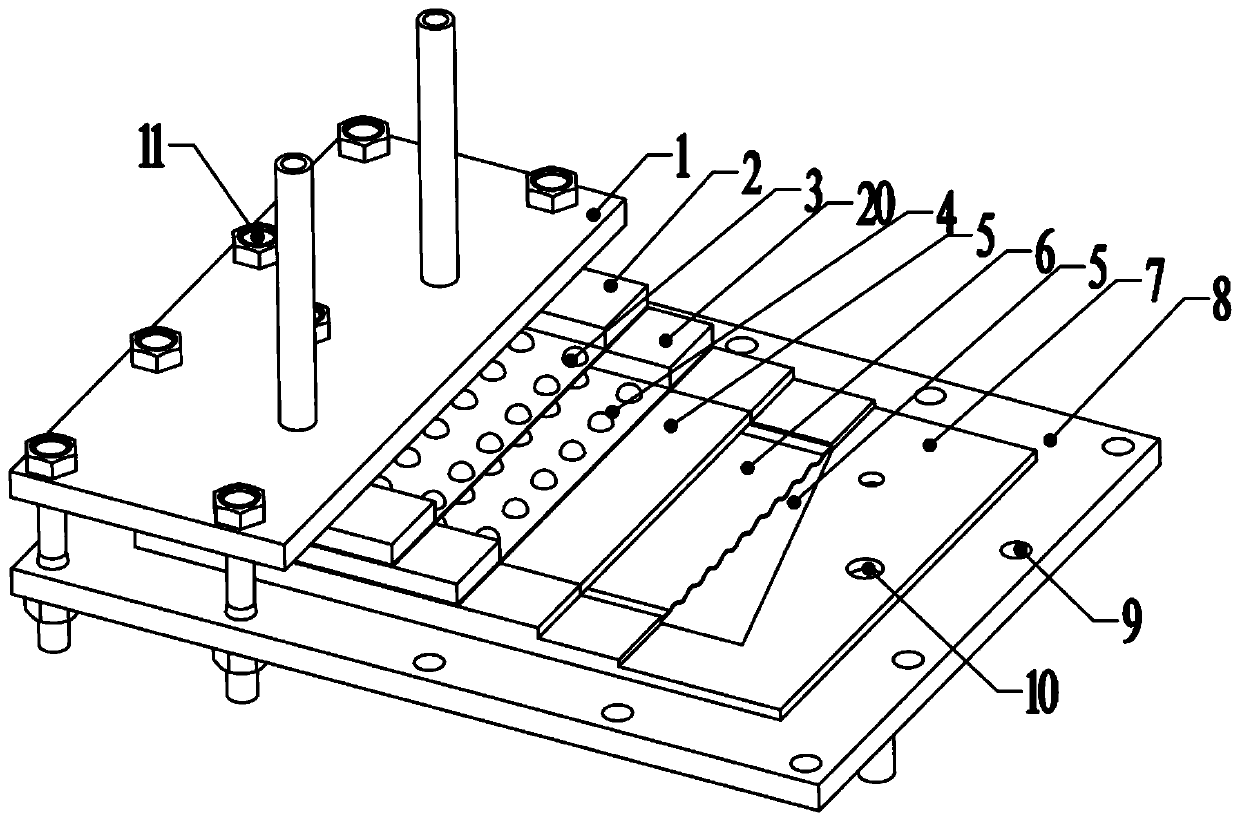

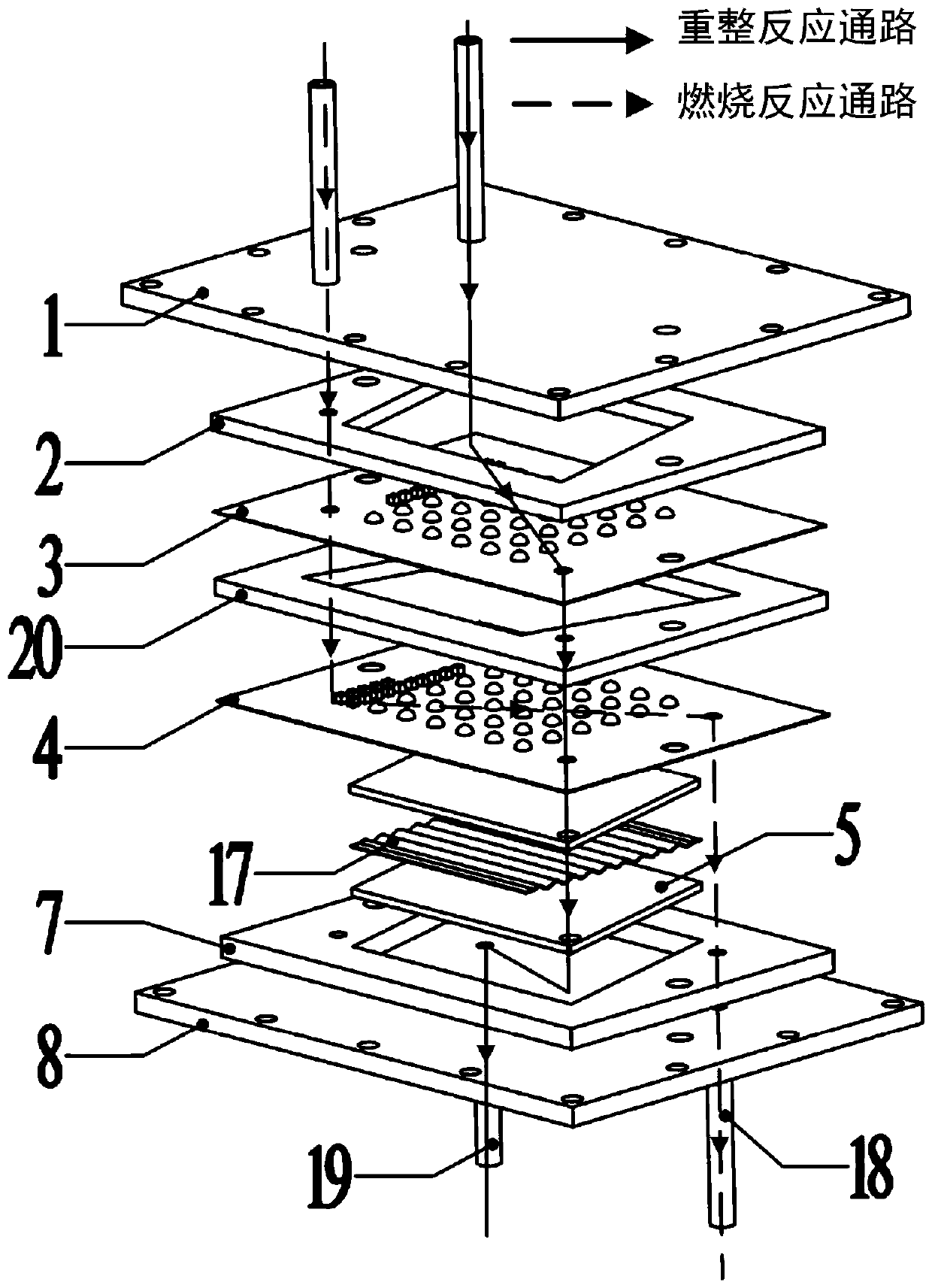

[0035] Such as figure 1 As shown, the present invention includes an upper cover plate 1 and a lower cover plate 8, and an evaporation chamber, a combustion chamber, and a reforming reaction chamber arranged between the upper cover plate 1 and the lower cover plate 8 are sequentially stacked from top to bottom. .

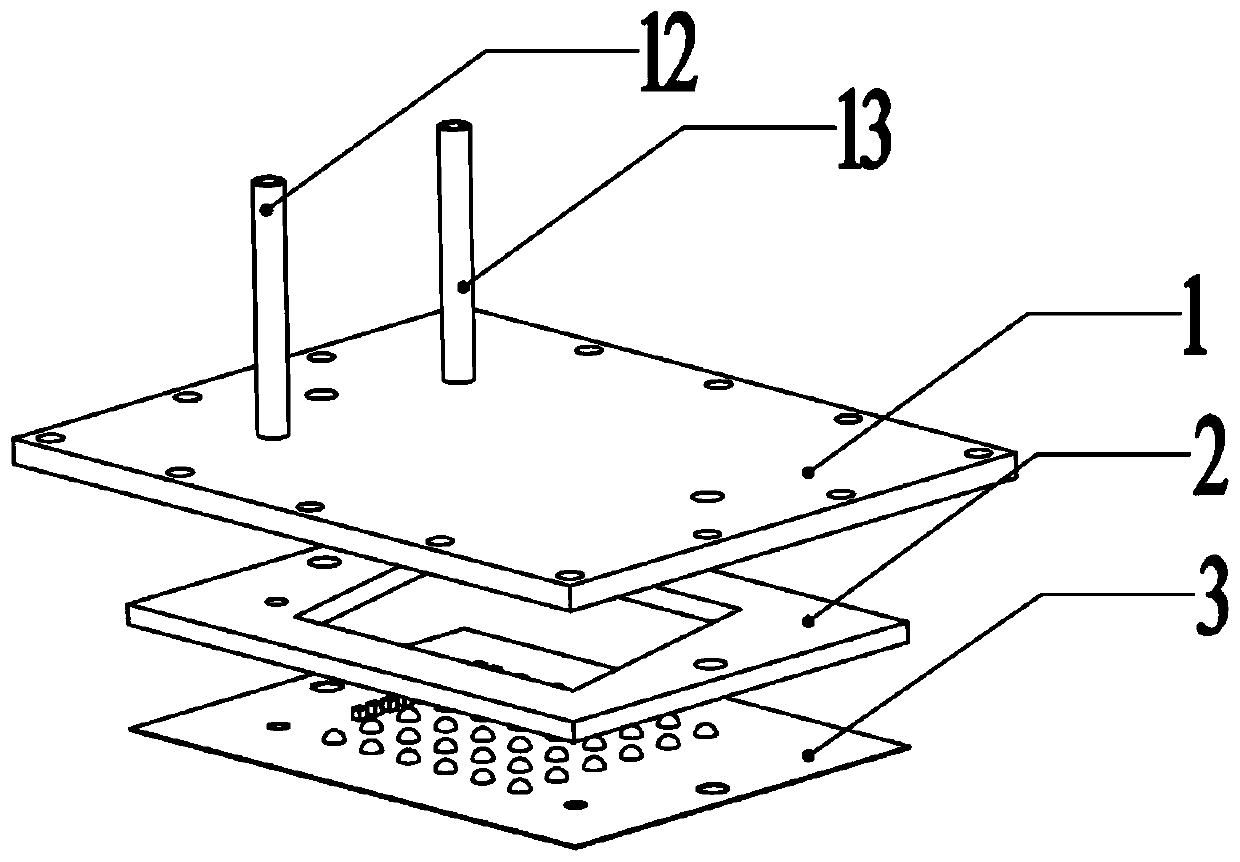

[0036] Such as image 3 As shown, the evaporation chamber includes a first graphite plate 2 and an evaporation plate 3. A parallelogram-shaped through groove is opened in the middle of the first graphite plate 2. The evaporation plate 3 is arranged under the first graphite plate 2. The second graphite plate on the evaporation plate 3 An evaporation cavity is formed in the two through grooves of a graphite plate, and the evaporation cavity is filled with silicon dioxide particles.

[0037] Such as Figure 4 As shown, the combustion chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com