Self-sealing variable-frequency oil gun and control method thereof

A frequency conversion control and refueling gun technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of unfavorable stability and safety of the hydraulic system, high pressure, energy waste, etc., to reduce processing difficulty and performance requirements , reduce resistance and improve pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

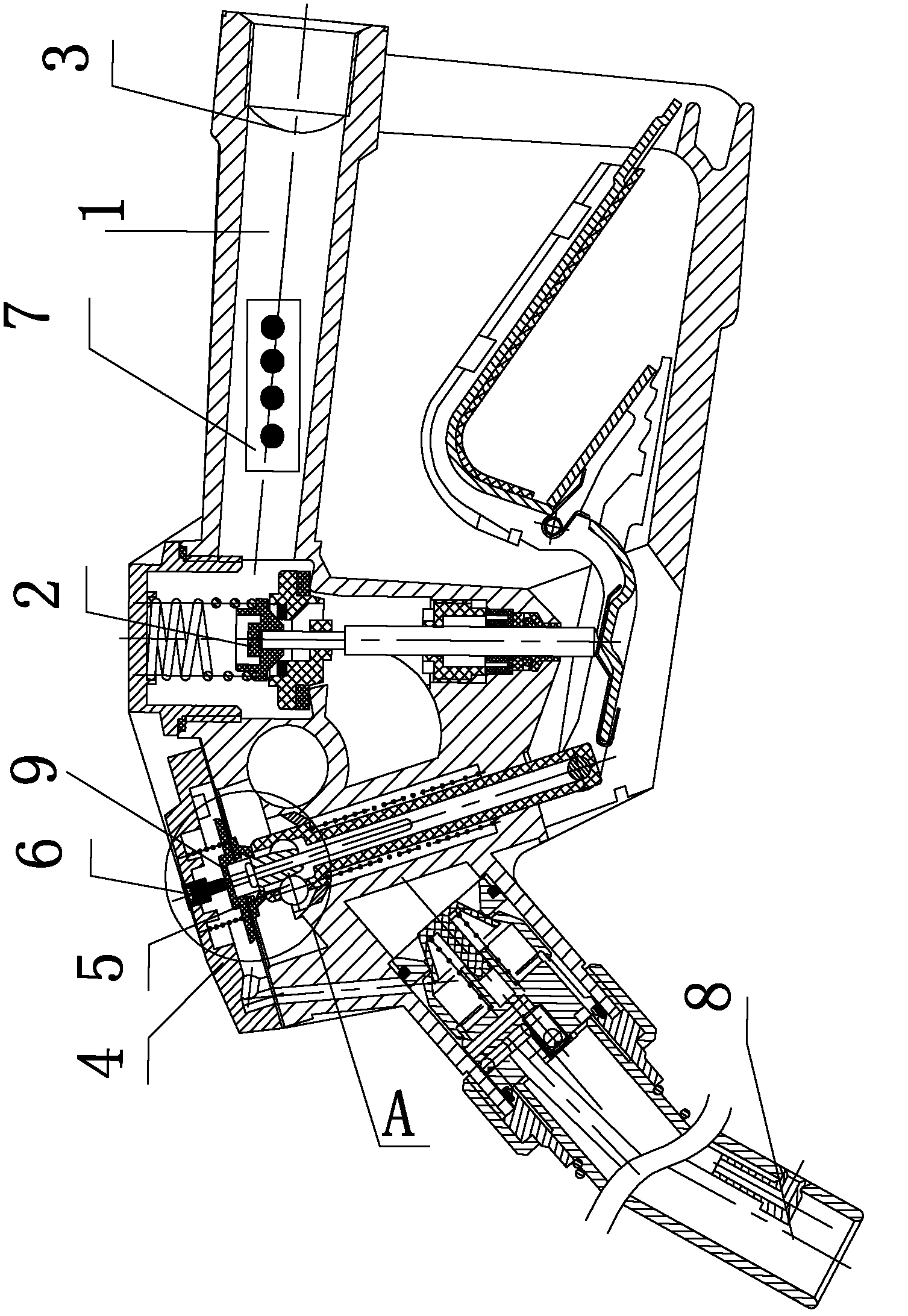

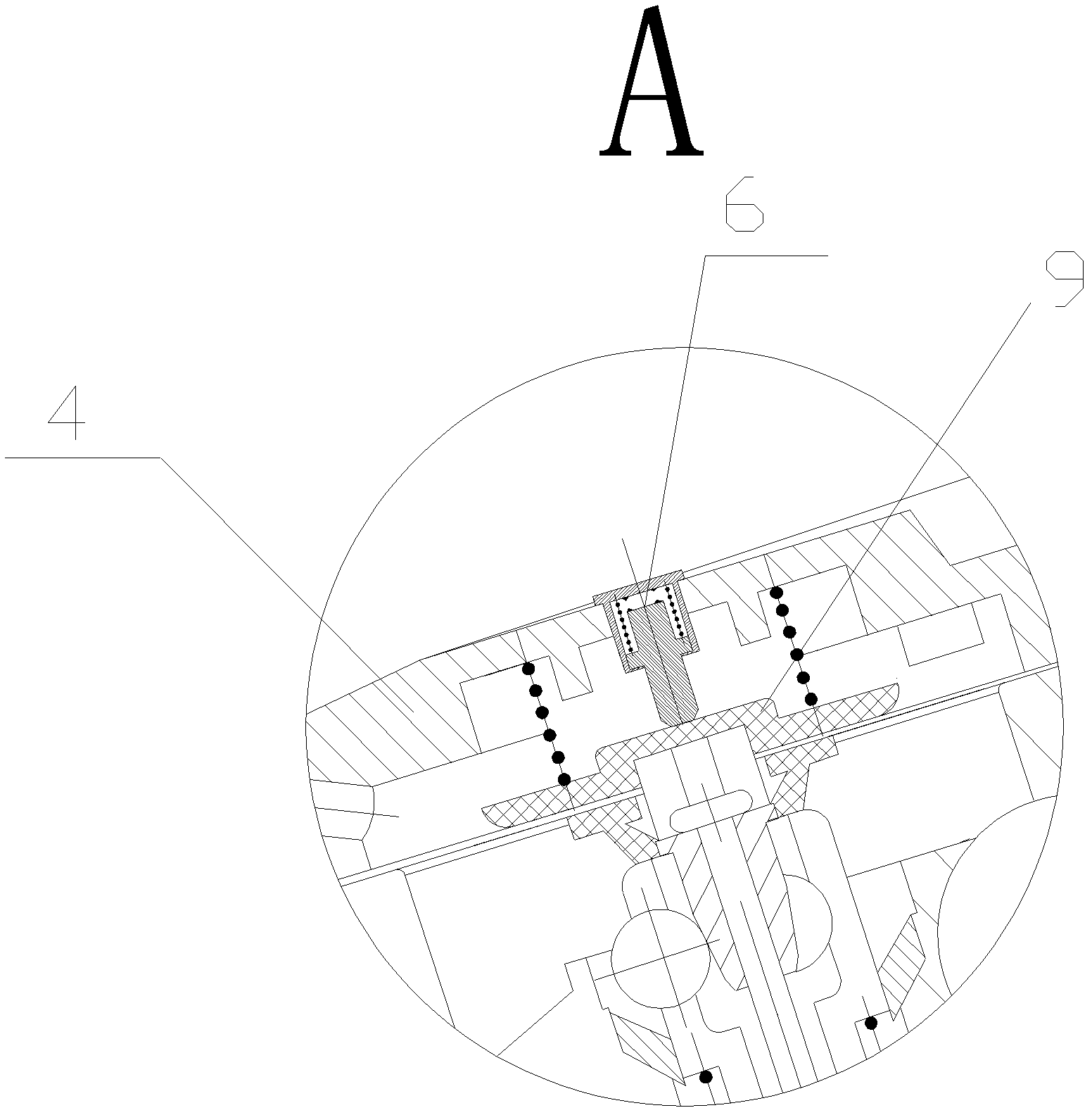

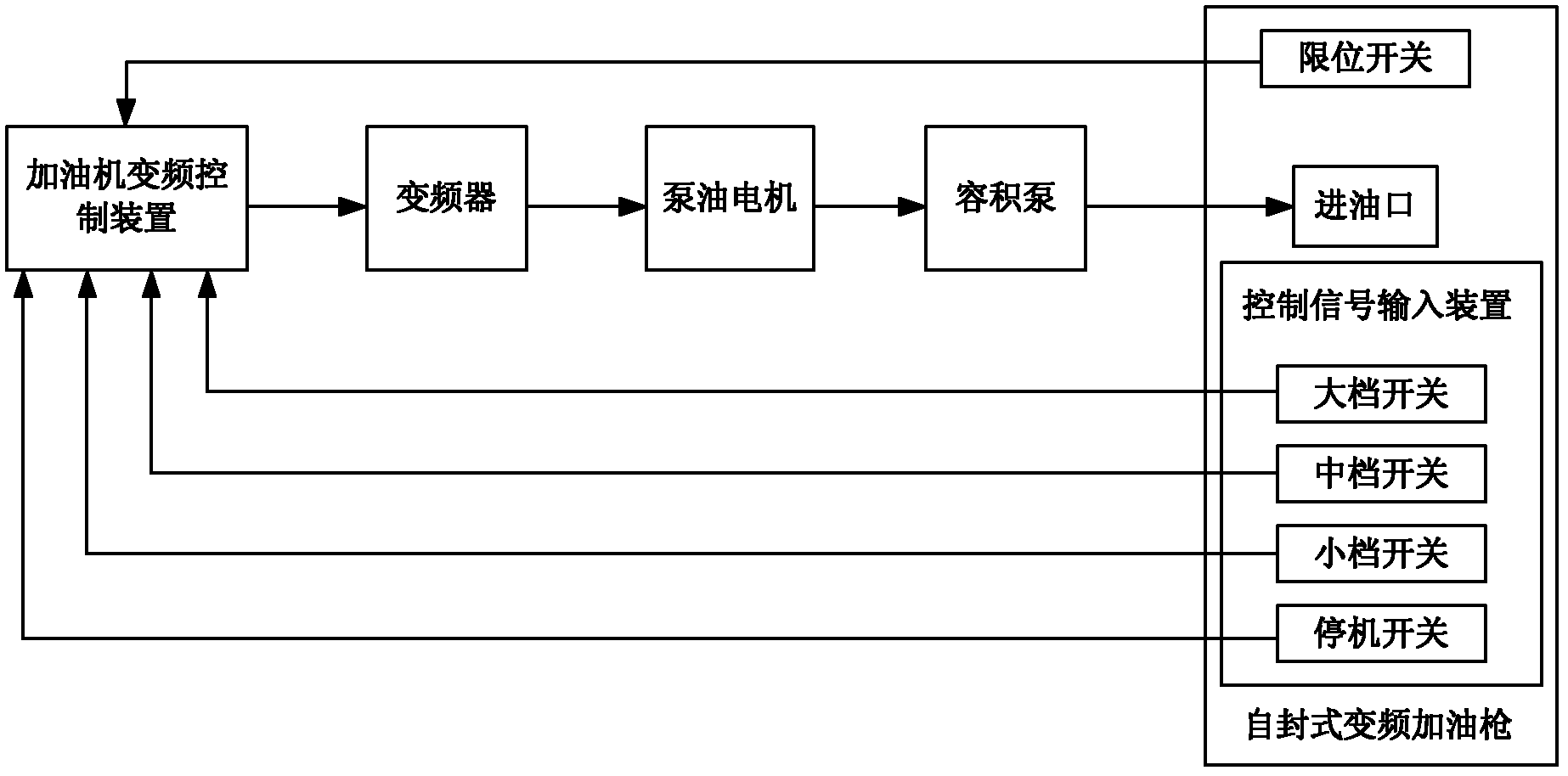

[0027] The structure of the self-styled variable frequency refueling gun of the present invention is as figure 1 and figure 2 As shown, it includes the oil inlet 1 and the self-sealing structure; the self-sealing structure is the same as that of the existing self-sealing fuel gun, and is also composed of a switch film, a self-sealing rod, a self-control rod, a steel ball, etc., and a self-sealing top cover is arranged above the switch film 4. The frequency conversion control device, frequency converter, oil pump motor and displacement pump in the hydraulic system of the fuel dispenser are connected in sequence; the positive displacement pump in the hydraulic system of the fuel dispenser is connected to the oil inlet 3 of the refueling gun to supply oil to the refueling gun. The handle 1 of the refueling gun is provided with a control signal input device 7; the control signal input device 7 includes four key switches of a high-range switch, a middle-range switch, a small-range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com