Liquid-liquid mixer and working method thereof

A mixer and mixing head technology, applied in mixing methods, fluid mixers, chemical instruments and methods, etc., can solve the problems of high resistance, easy blockage, frequent shutdown and maintenance, etc., and achieve the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

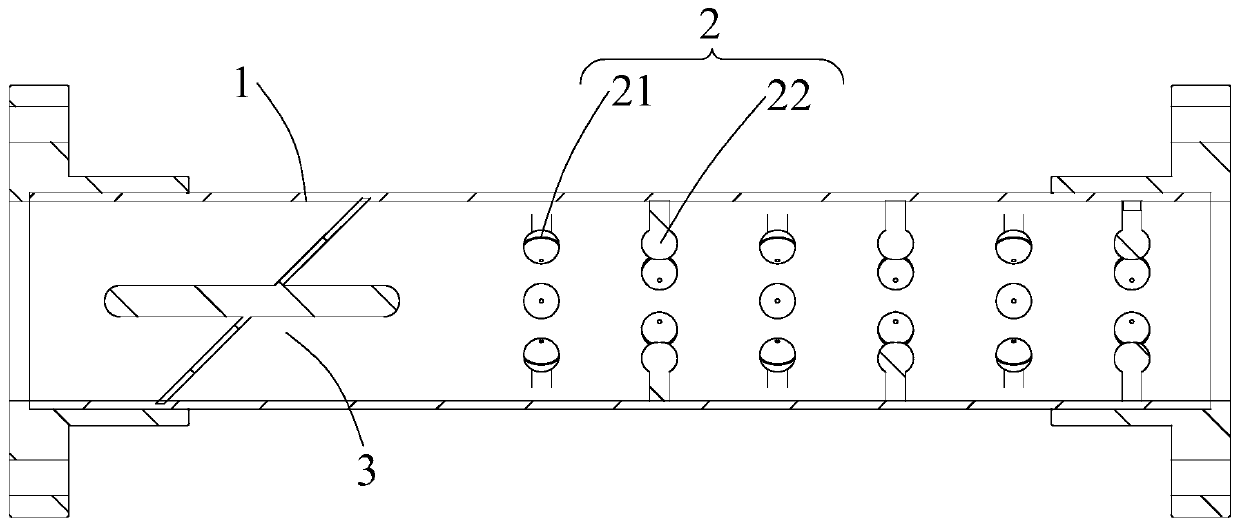

[0057] Such as Figure 1~6 shown

[0058] The invention provides a liquid-liquid mixer, comprising:

[0059] a pipe body 1 and a plurality of mixing units 2 located within said pipe body 1; and

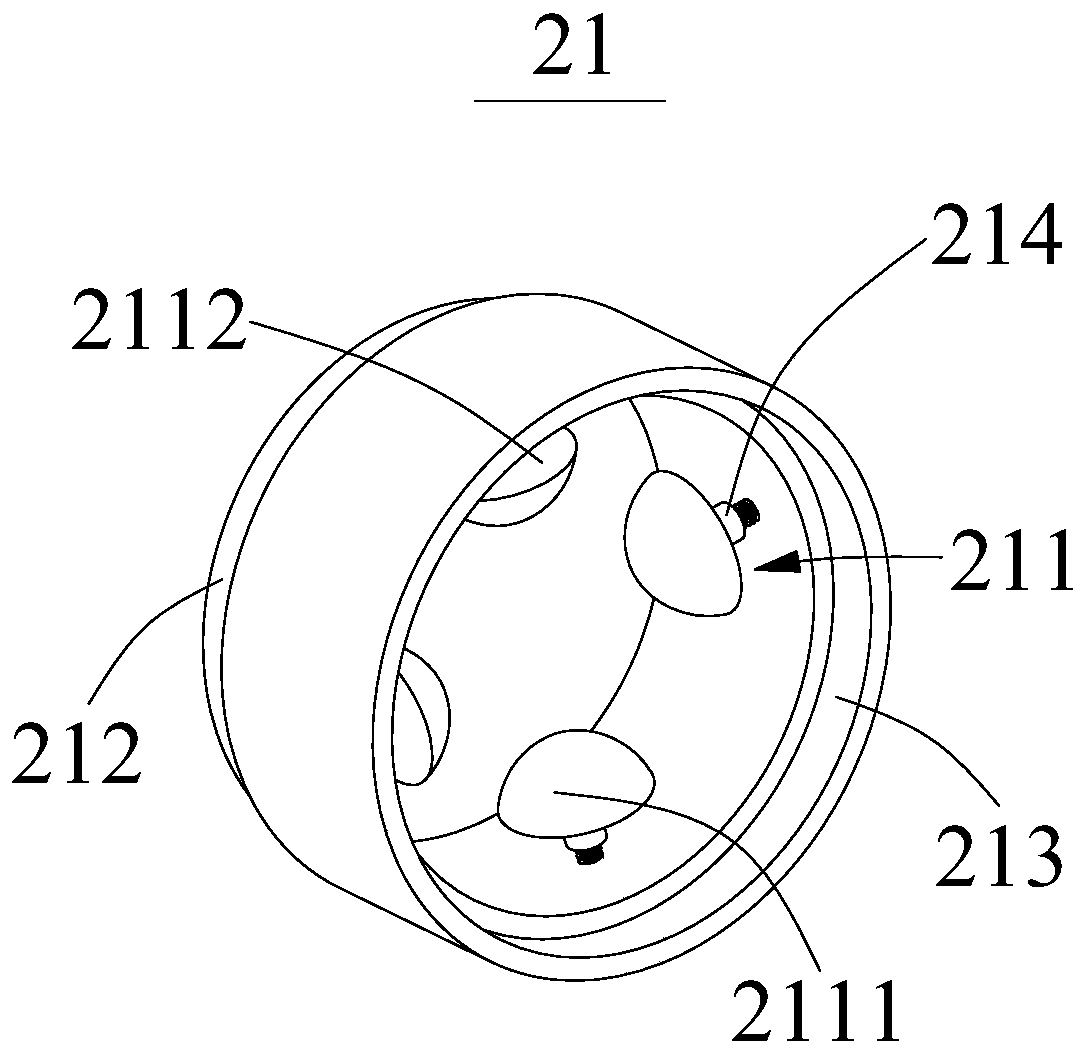

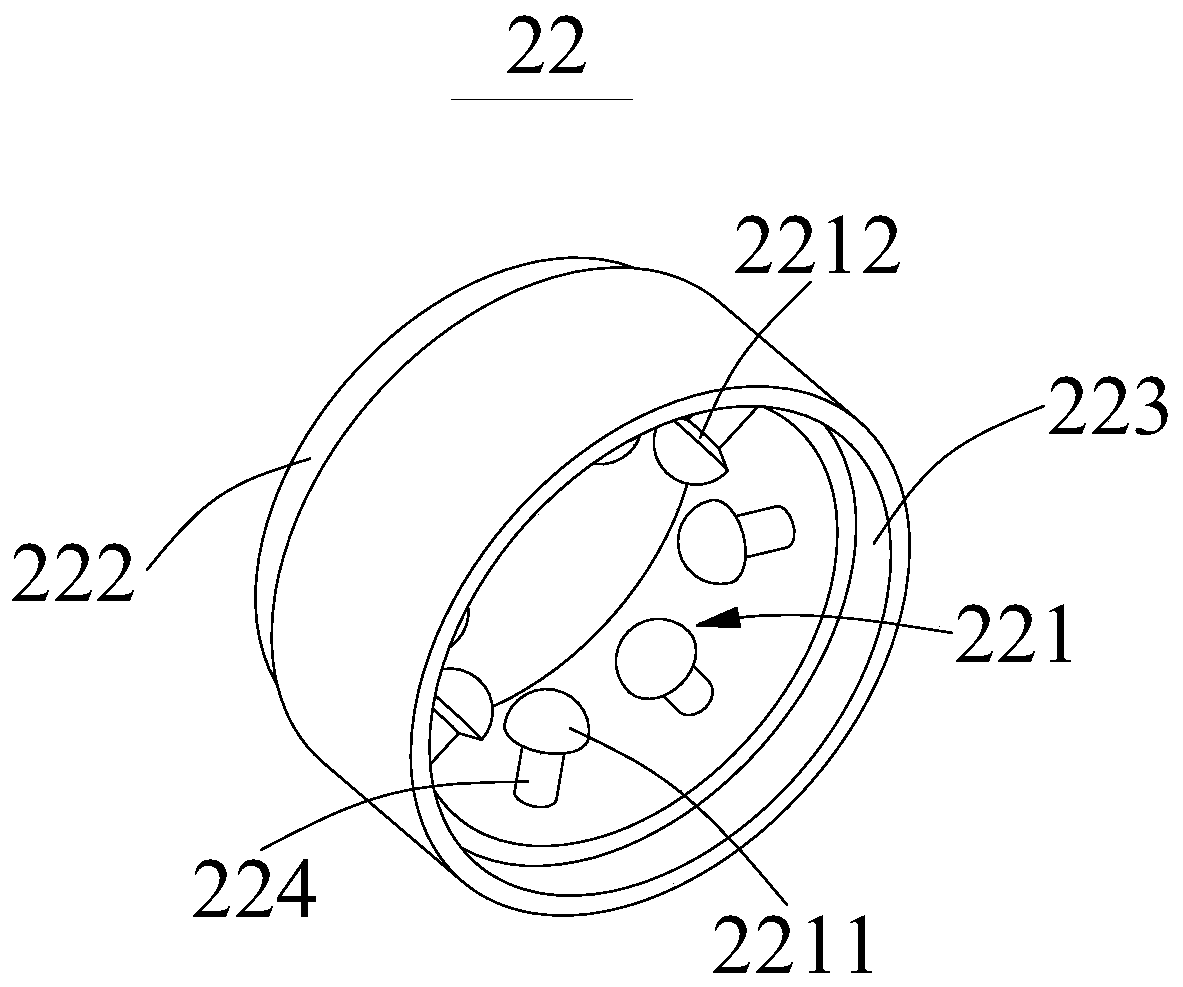

[0060] The mixing unit 2 includes a first mixing part 21 and a second mixing part 22;

[0061] The first mixing part 21 has a plurality of first mixing heads 211, and the second mixing part 22 has a plurality of second mixing heads 221, and each of the first mixing heads 211 is located between two of the second mixing heads. between the axial gaps of the heads 221; the meaning of the axial gap here is the axial gap between the pipeline body 1 and the gap between the two second mixing heads 221, which is the axial gap, and the first mixing head 211 is set At this axial gap, ensure that in each mixing unit 2, the first mixing head 211 and the second mixing head 221 are misplaced. Similarly, in two mixing units 2, the first mixing head 221 in one mixing unit 2 A mixing head 211 is li...

Embodiment 2

[0083] The liquid-liquid mixer of embodiment two is based on the liquid-liquid mixer introduced in embodiment one;

[0084] The working method of this kind of liquid-liquid mixer,

[0085] The liquid-liquid mixer includes a pipeline body 1 and a plurality of mixing units 2 located in the pipeline body 1, the mixing unit 2 includes a first mixing part 21 and a second mixing part 22, and the first mixing part 21 There are a plurality of first mixing heads 211 on the second mixing part 22, and there are several second mixing heads 221 on the second mixing part 22, and each of the first mixing heads 211 is located between two axial gaps of the second mixing heads 221. between;

[0086] The liquid is injected from the liquid inlet of the pipe body 1 , and the dislocation of the first mixing part 21 and the second mixing part 22 disturbs the mixed flow.

[0087] The beneficial effect of the working method of this liquid-liquid mixer is: the form of dislocation disturbing mixed flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com