Three-in-one electric driving integrated system of new energy vehicle

A new energy vehicle and integrated system technology, which is applied in the field of new energy vehicle three-in-one electric drive integrated system, can solve the problems of long gearbox space, multiple transfer structures, and insufficient utilization of the space between the reducer and the motor. Achieve the effects of reducing the transfer and fixing structure, improving space utilization, and improving NVH performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

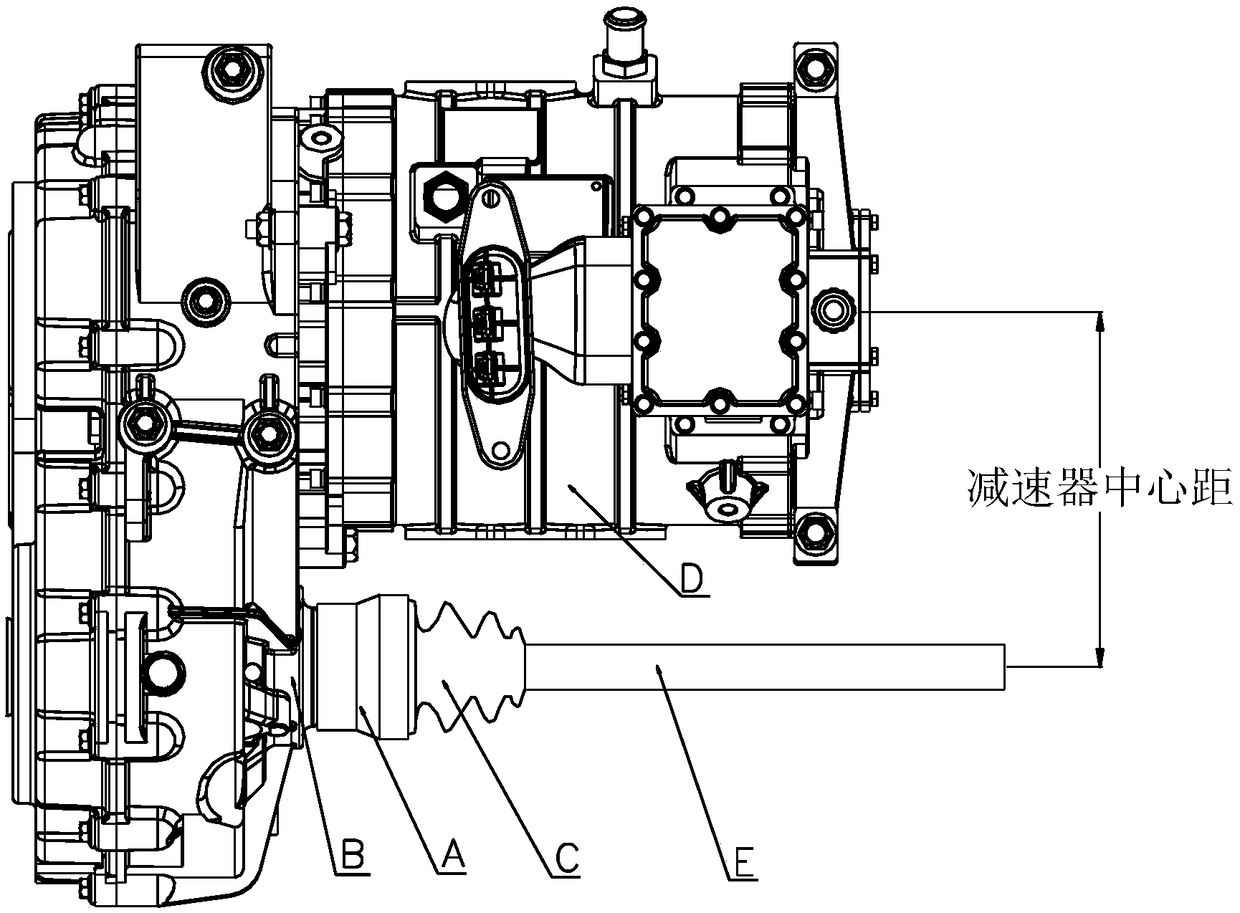

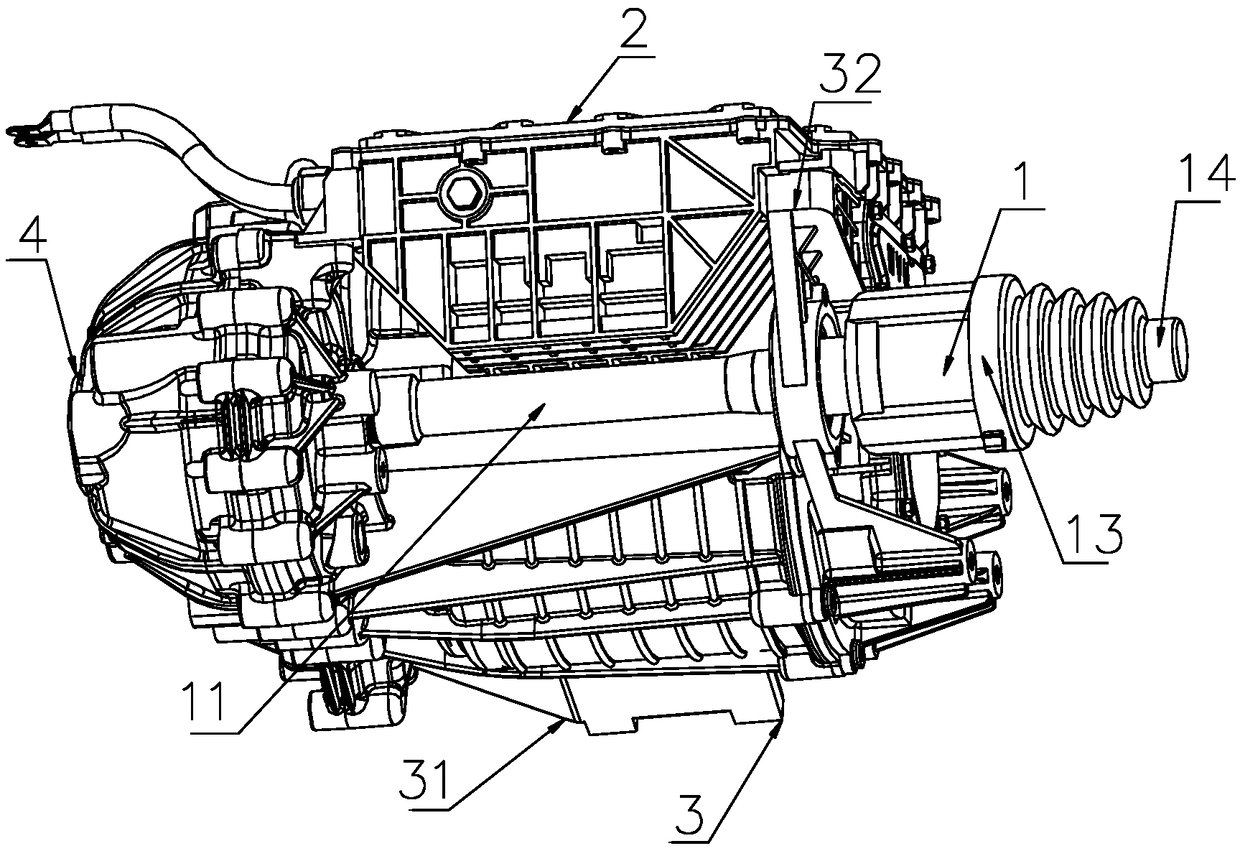

[0045] Such as Figure 2-9 As shown, the three-in-one electric drive integrated system for new energy vehicles of the present invention includes a half shaft mechanism 1, a controller 2, a motor 3 and a gearbox 4, and the motor 3 includes an integrated housing 31 and an integrated housing 31 fixed at one end thereof. The end cover 32; the gearbox 4 is connected to the other end of the integrated housing 31 of the motor 3; the two ends of the half shaft mechanism 1 are fixedly connected to the integrated end cover 32 and the other end of the integrated housing 31 respectively. On the box 4; the integrated housing 31, the integrated end cover 32 and the half-axis mechanism 1 together form a distorted space; the controller 2 is installed in the distorted space and fixed to the motor 3 Integrated housing 31.

[0046]In the three-in-one electric drive integrated system for new energy vehicles in this scheme, the motor housing and the right end cover of the transmission line box ar...

Embodiment 2

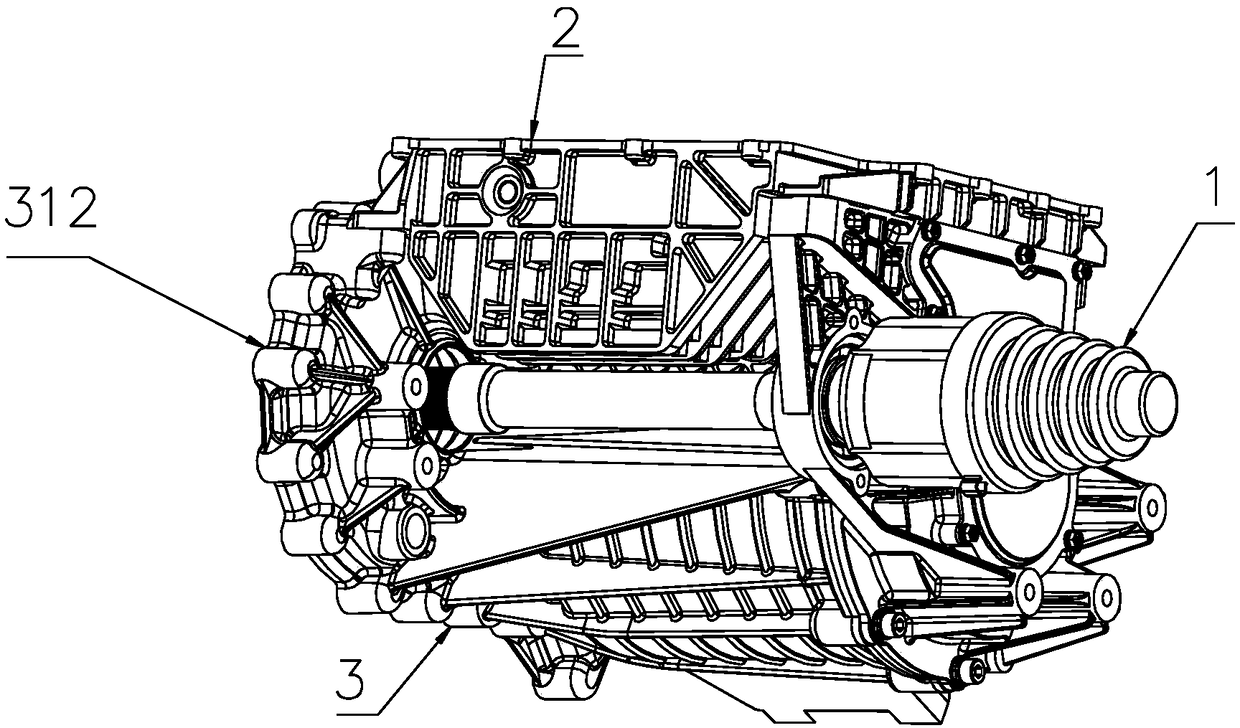

[0053] Such as Figure 10 As shown, another structural form of the integrated end cover 32 is: the integrated end cover 32 has a motor rear end cover 321, a movable bracket 1a and a second positioning hole 323; the motor rear end cover 321 and the movable bracket 1a is a mechanical connection, the movable bracket 1a is installed on the outside of the motor rear end cover 321, and the motor rear end cover 321 is installed on the motor housing 311, and the movable bracket 1a and the half shaft mechanism 1 are connected by bearings 12 fixed. The main difference in the layout of this scheme is that the rear end cover of the motor and the half-shaft fixed bracket are transfer structures, and integrated structures, both of which can improve the space utilization rate of the electric drive system and reduce the space size. The difference is that the transfer structure is relatively convenient to disassemble. , but the vehicle NVH performance is relatively poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com