Hydraulic coal mine support for low-position roof blasting-down

A technology of hydraulic support and top coal caving, which is applied in the direction of mine roof supports, pillars/supports, mining equipment, etc., can solve the problems of unbalanced force on front and rear columns, achieve favorable intensive management, reduce center distance, and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

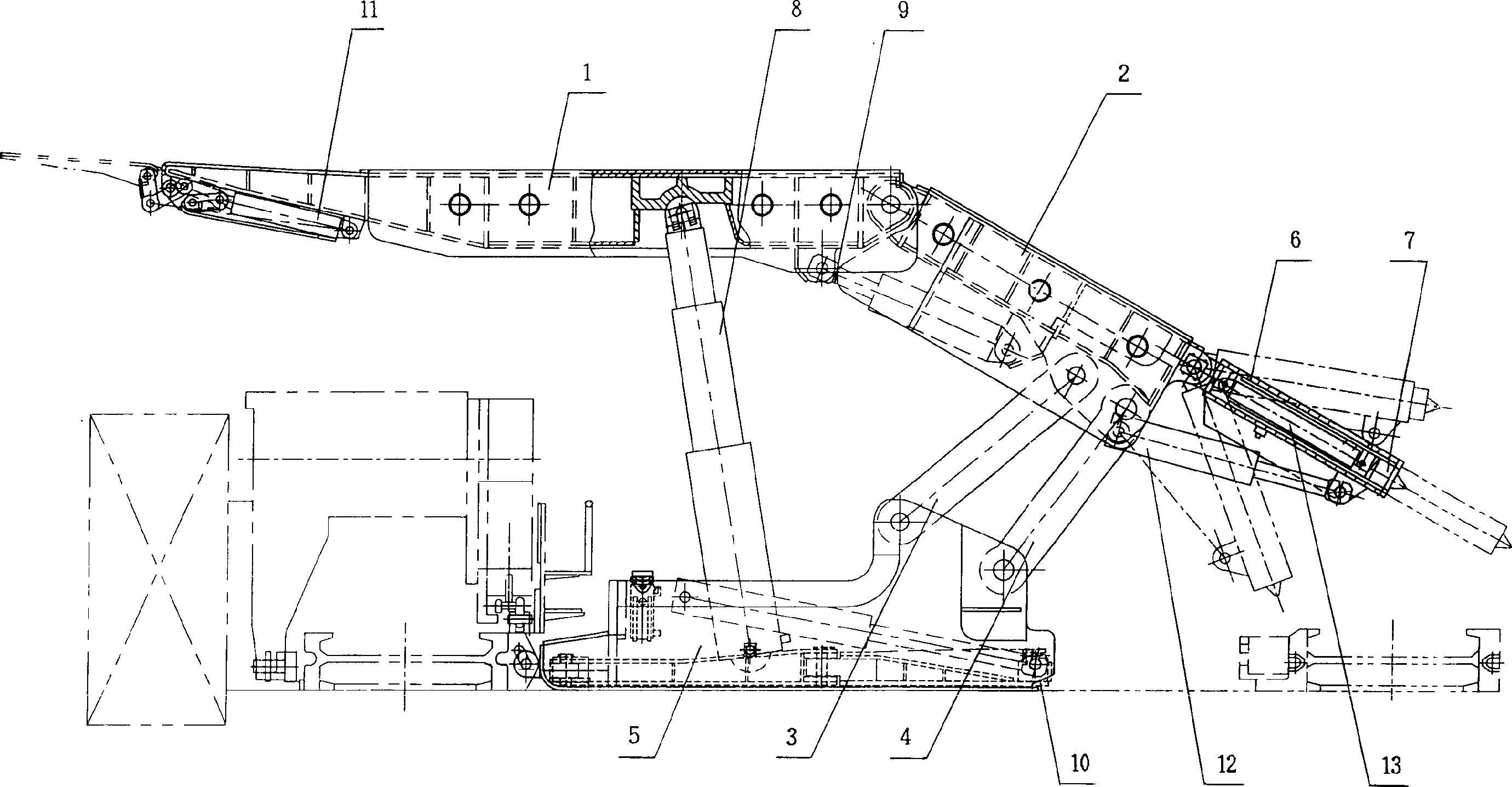

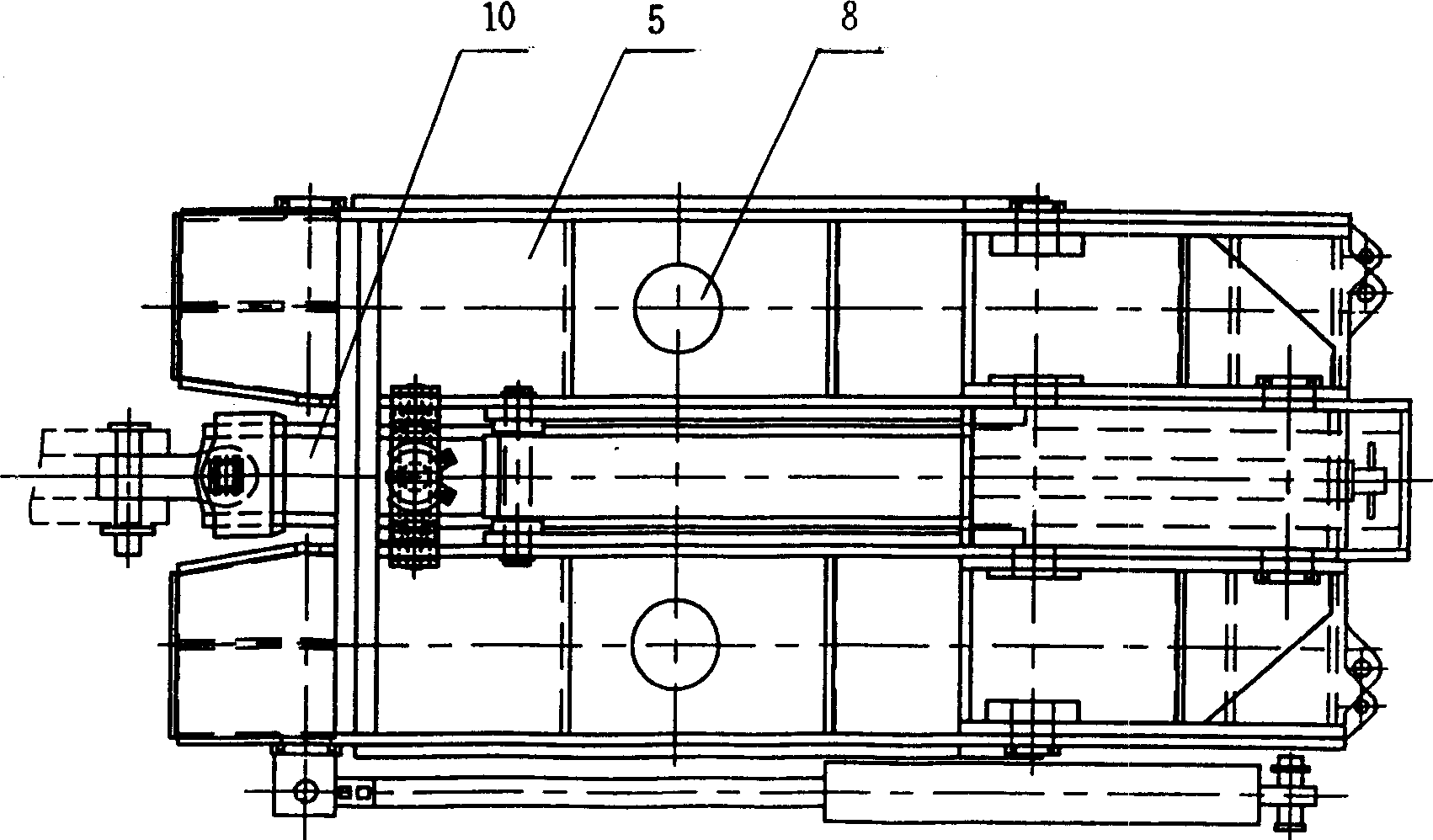

[0041] figure 1 The shown low-level top coal caving hydraulic support of the present invention mainly consists of a top beam (1), a shield beam (2), a front connecting rod (3), a rear connecting rod (4), a base (5), a column (8), Balance jack item (9), pushing mechanism (10), side protection device (11), and the tail beam (6) of coal discharge mechanism, inserting plate (7), tail beam jack (12) form.

[0042] The top beam (1) and the base (5) are hingedly supported by two columns (8), the rear end of the top beam (1) is hinged with the cover beam (2), and the top beam (1) and the cover beam (2) There are two balance jacks (9) hinged between the two below the hinge point, the rear end of the cover beam (2) is hinged with the tail beam (6) of the coal discharge mechanism, and the cover beam (2) and the tail beam (6) are hinged. ) has a tail boom jack (12) hinged between the two below the hinge point. The front connecting rod (3) and the rear connecting rod (4) are hinged betwe...

Embodiment 2

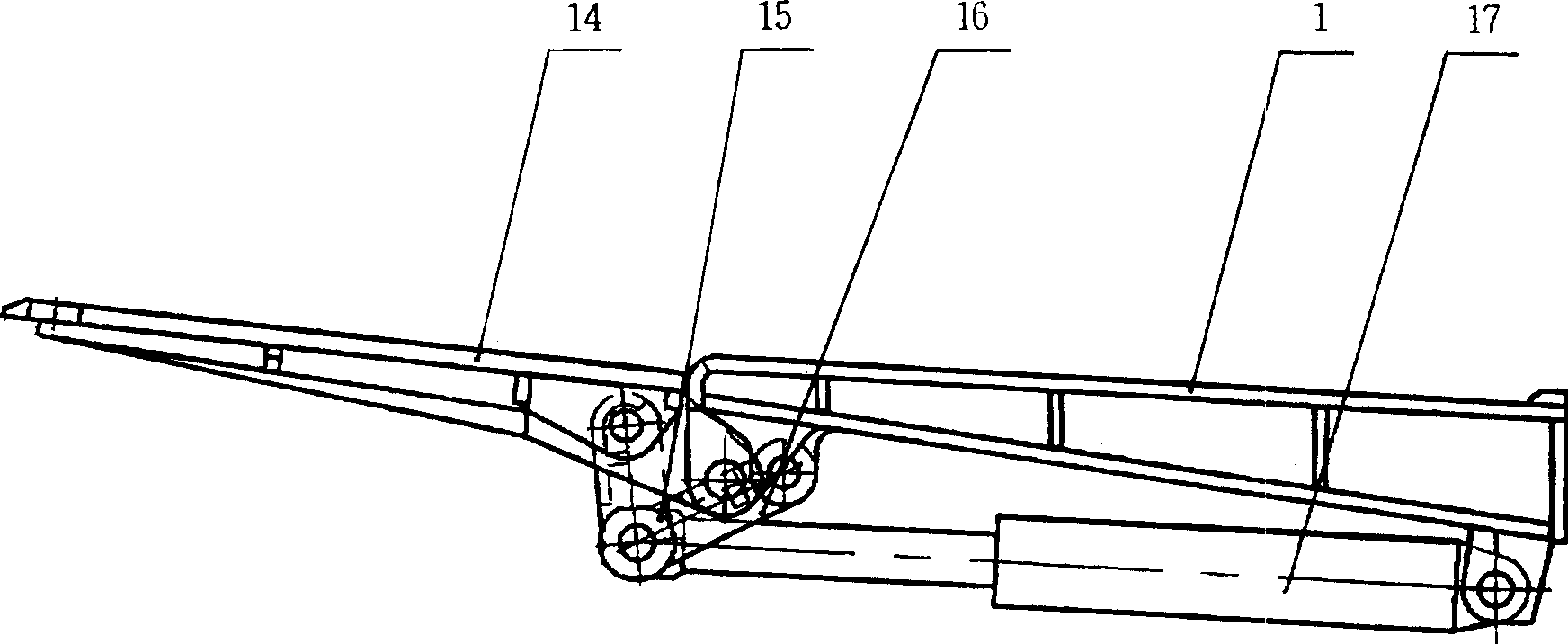

[0058] Figure 8 Another form of the present invention is shown, that is, the two-column shielding type low-level coal caving hydraulic support with a hinged top beam as the top beam. Hinged top beam, or section hinged top beam, is made of top beam (25), front beam (23), front beam jack (24). The front beam (23) is hinged at the front end of the top beam (25), and the front beam jack (24) is hinged between the top beam (25) and the front beam (23). Correspondingly, the side protection device (11) of its four-bar linkage mechanism should be hinged on the front beam (23), that is, the rear end of the side protection plate (17), the long rod (15), and the side protection jack (16) are hinged At the front end of the front beam (23). Apart from this, the rest of this example can be the same as that of Example 1.

[0059] In the above two embodiments: the overall roof beam structure is simple and reliable, and the supporting force at the front end of the roof beam is large; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com