Silicon wafer wire cutting machine

A technology of wire cutting machine and silicon wafer, applied in the direction of working accessories, fine working devices, stone processing equipment, etc., can solve the problems of cumbersome installation, easy chipping of silicon wafers, and easy off-line, etc., so as to improve production efficiency and improve Cutting efficiency and the effect of reducing the probability of wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

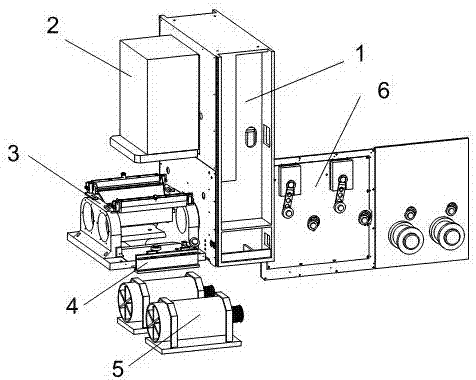

[0017] Such as figure 1 As shown, a silicon wafer wire cutting machine includes a cutting head 3, a feed table 2, a feed table fixing frame 1, a wire take-up tool 4, a wire barrel chamber 6 and a main motor 5, and the feed table 2 is fixed In the feeding table fixing frame 1, the cutting head 3 is located under the feeding table 2, and the cutting head 3 is provided with a wire take-up tooling 4 on one side, and the other side of the feeding table fixing frame 1 is provided with a wire spool chamber 6;

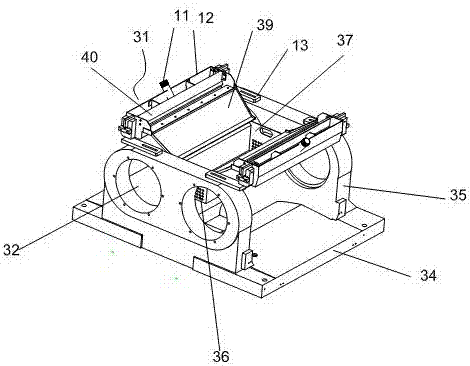

[0018] Such as figure 2 As shown, the cutting head 3 includes a cutting head base 34, a cutting head column 35 positioned at the two ends of the cutting head base 34, a mortar nozzle 31, and a debris box 37. The cutting head column 35 is provided with two The cutting head mounting hole 32 of the bearing of the head bearing box; the mortar nozzle 31 is located in the middle of the cutting head column 35, one on each side, opposite to each other; between the two mortar nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com