Surface mount type LED (light emitting diode) display screen

A LED display, SMD technology, applied in the field of SMD LED display, can solve the problems of inconvenient transportation and installation, large rectangular box, non-foldable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

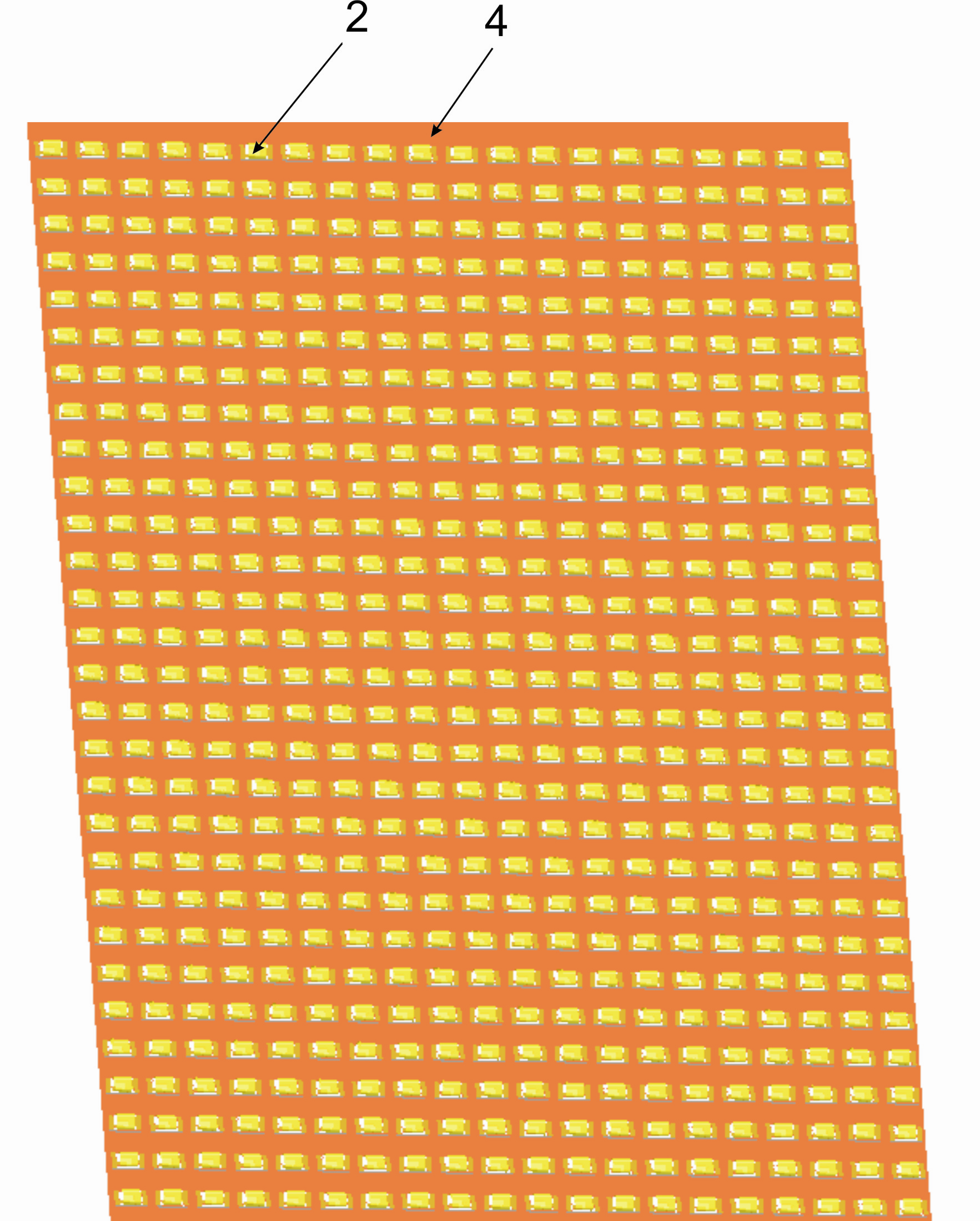

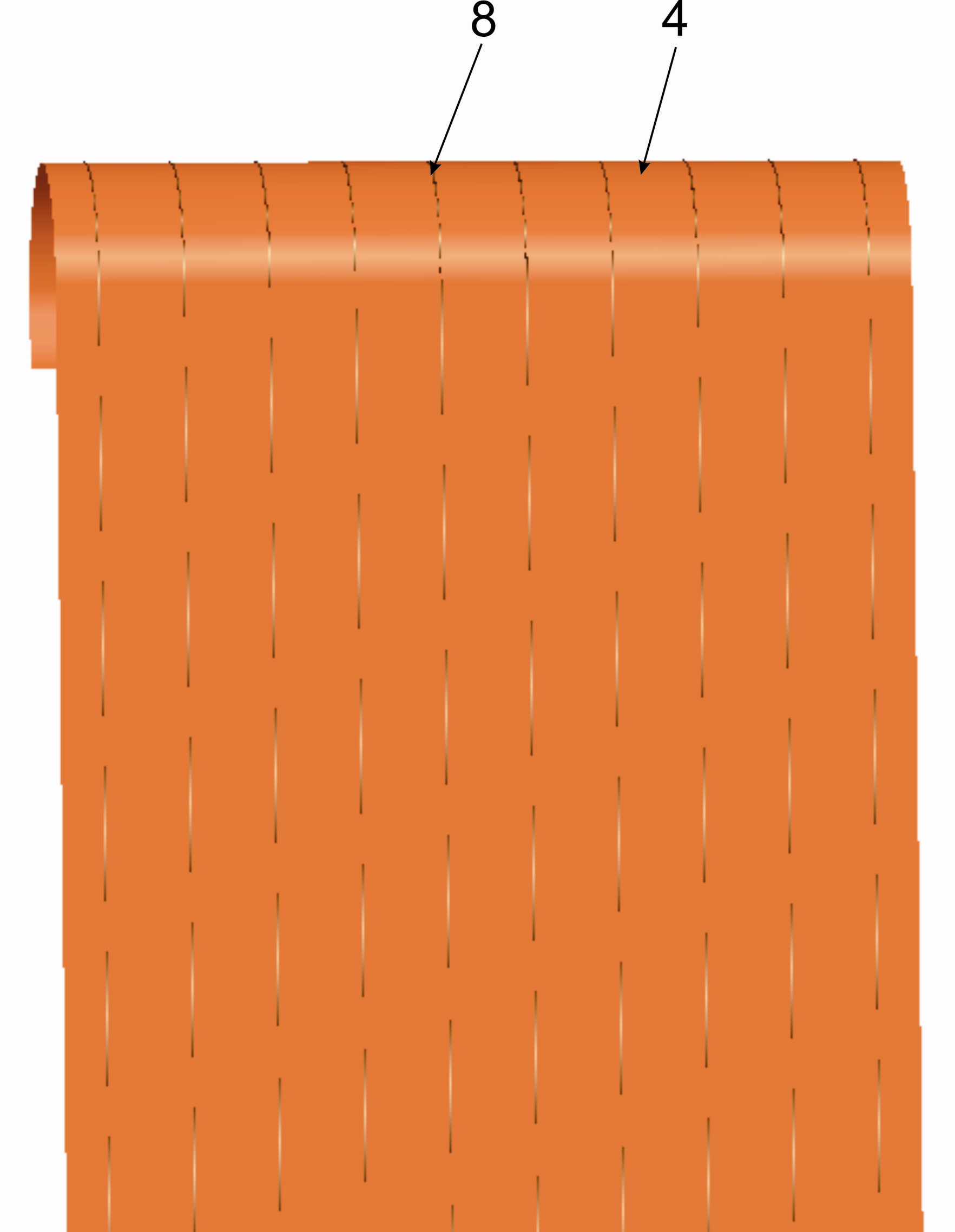

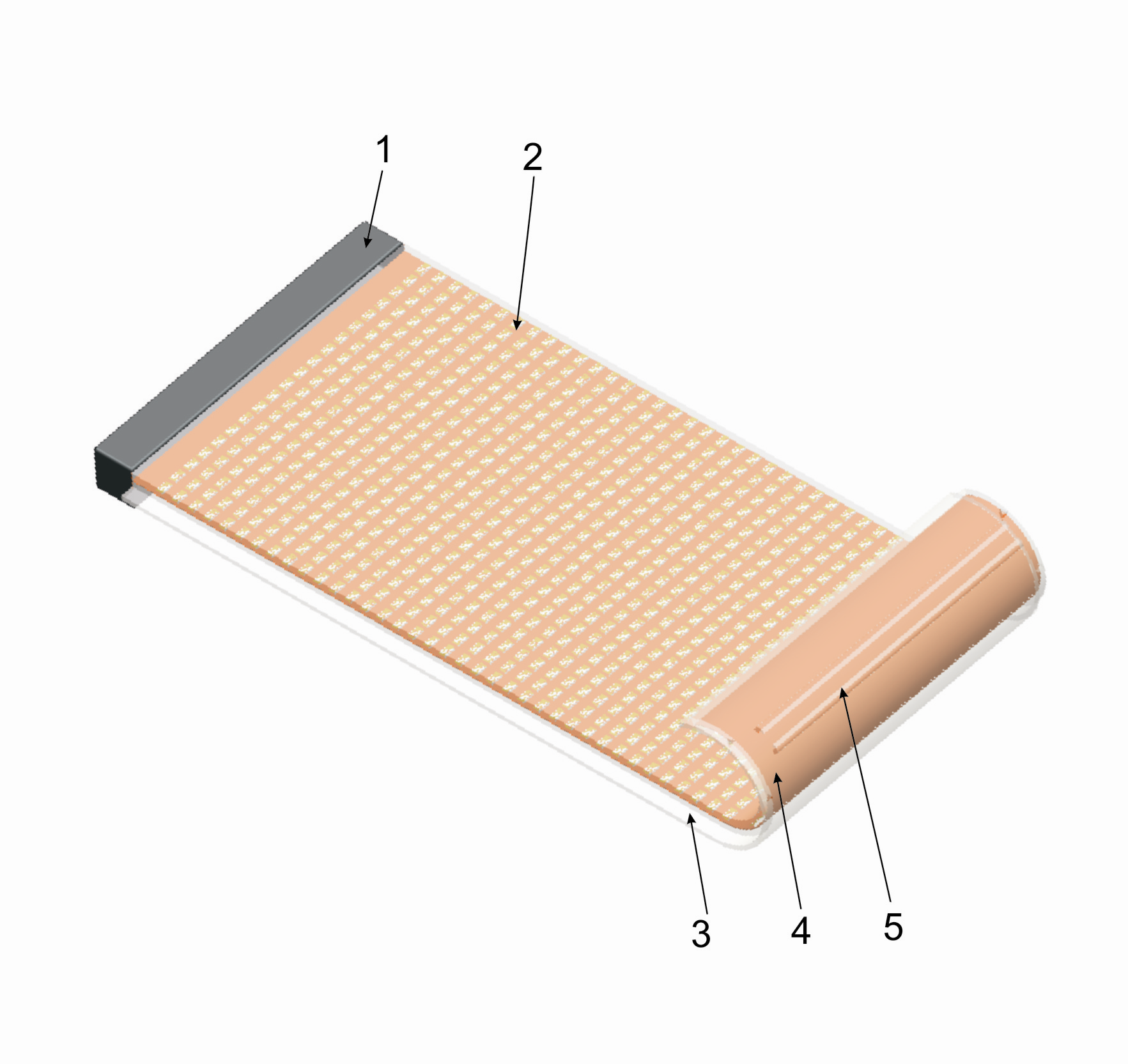

[0014] figure 1 , Paste the LED lamp bead (2) on the FPC (4) by patching. figure 2 , fine steel wires (8) are provided on the back FPC (4) of the independent unit module. image 3 , Paste the LED lamp beads (2) on the FPC (4) and package them with thermally conductive soft silicone (3) to make a unit module. The driver (1) of the free-standing unit module is bolted to the top or bottom of the module. A T-shaped or mushroom-shaped fixing mechanism (5) is provided on the back of the unit module, and the soft LED display screen is fixed on the fixing frame by the fixing mechanism (5) when it needs to be finalized. Figure 4 , there are fast locks (7) and locking holes (6) on the periphery of the combined unit module. When two combined unit modules are connected, the locking block (7) of the unit module is inserted into the into the locking hole (6) of another unit module, and then use the fixing mechanism (5) on the back of the unit module to fix the SMD LED display on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com