Patents

Literature

46results about How to "Increase the center distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roller chain sprocket

InactiveUS6375589B1Smooth movementImprove accuracyPortable liftingGearing elementsClosed loopRoller chain

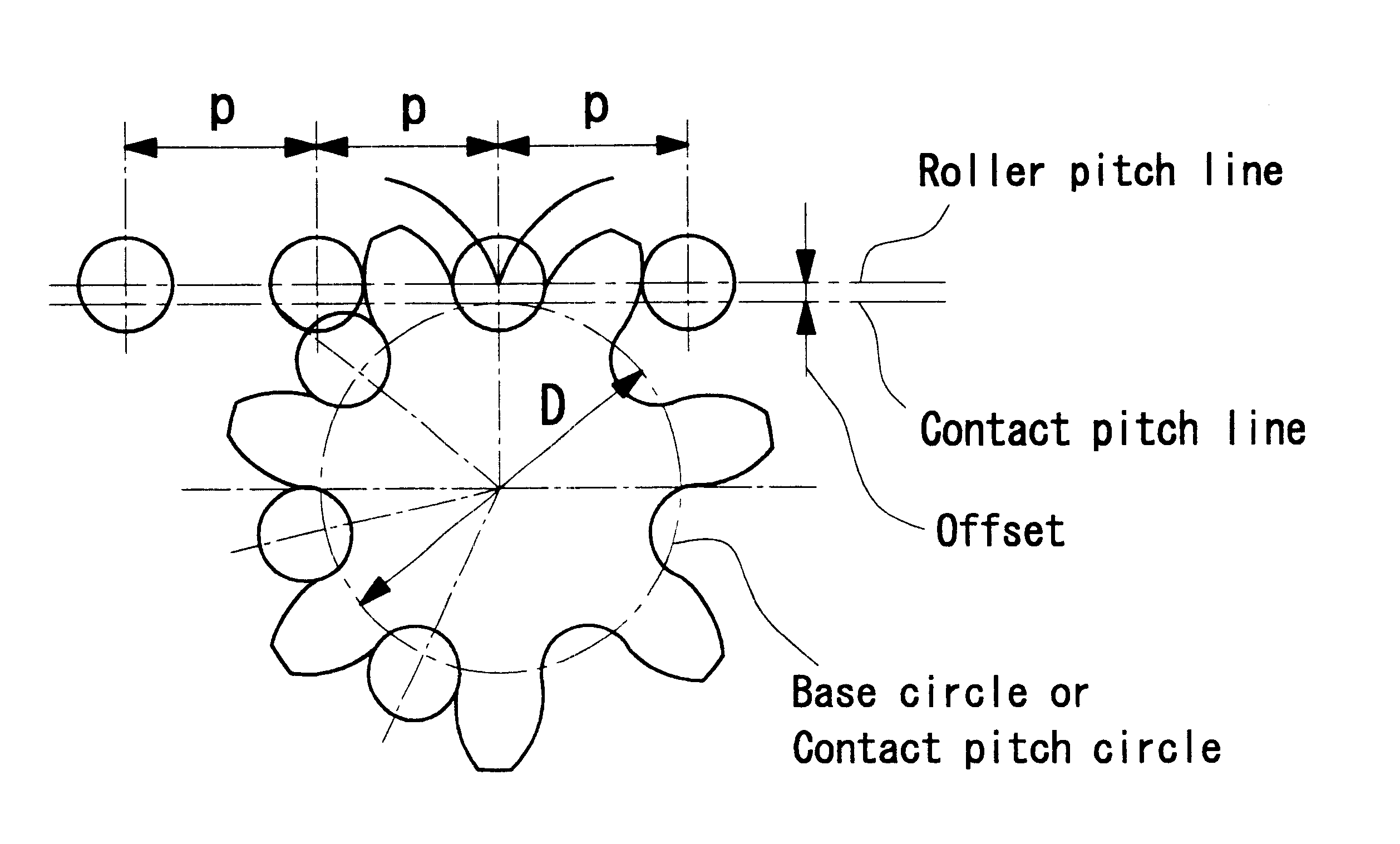

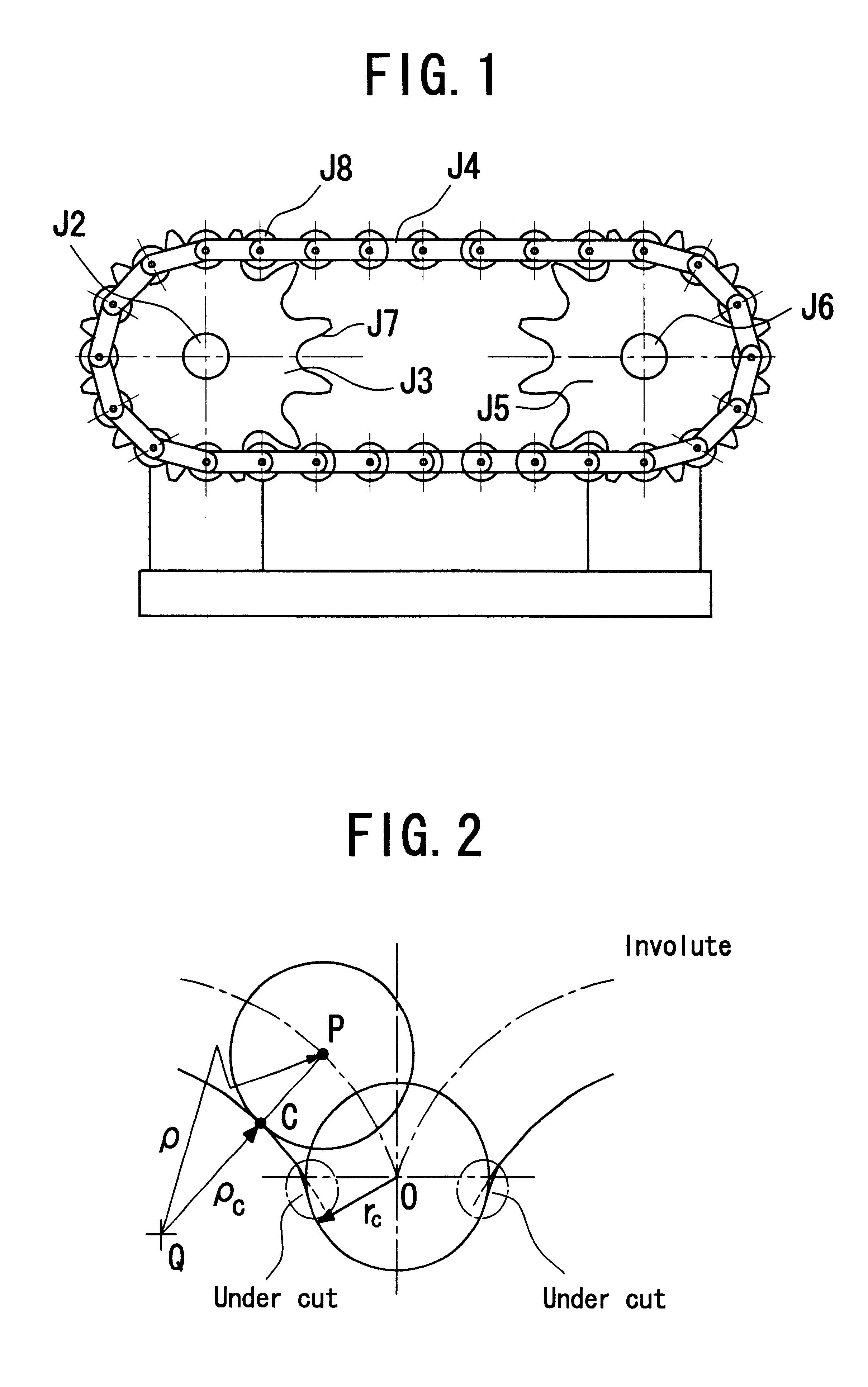

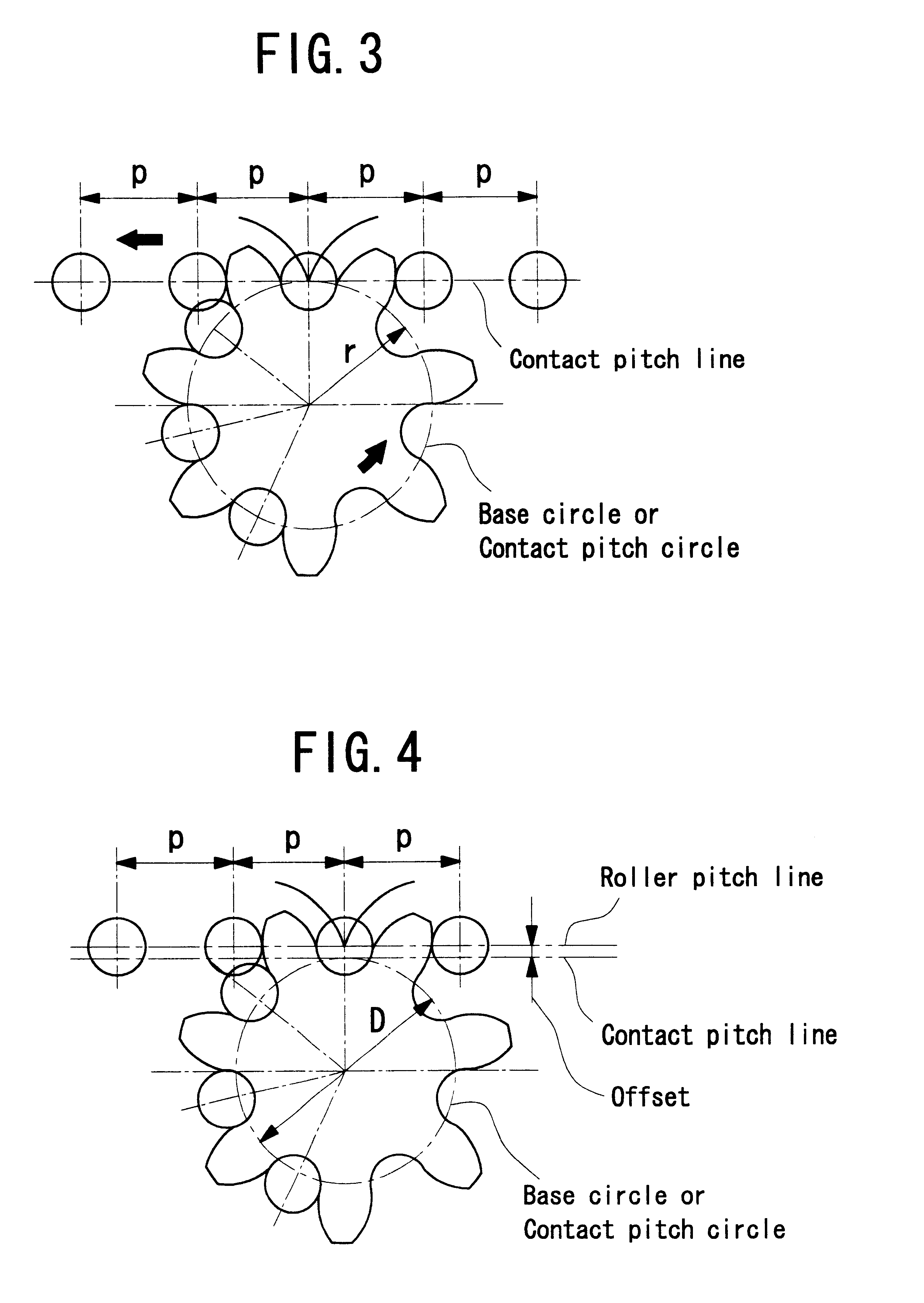

An improved chain drive mechanism having a closed loop of roller chain passing round the opposite sprocket wheels. The profile of each tooth formed on the circumference of the sprocket wheel is in conformity with the envelope curve traced by a roller when the roller moves with its center following an involute-trochoid curve. The involute-trochoid curve is determined by offsetting the roller pitch line a certain distance apart outside the contact pitch line, and by rotating the contact pitch line on the base circle of the sprocket wheel to allow a point on the roller pitch line to trace a curve. The certain distance is so determined that the roller pitch may be equal to the incremental arc length, which is determined by dividing the circumference of the base circle by the number of teeth.

Owner:SANKYO OILLESS IND

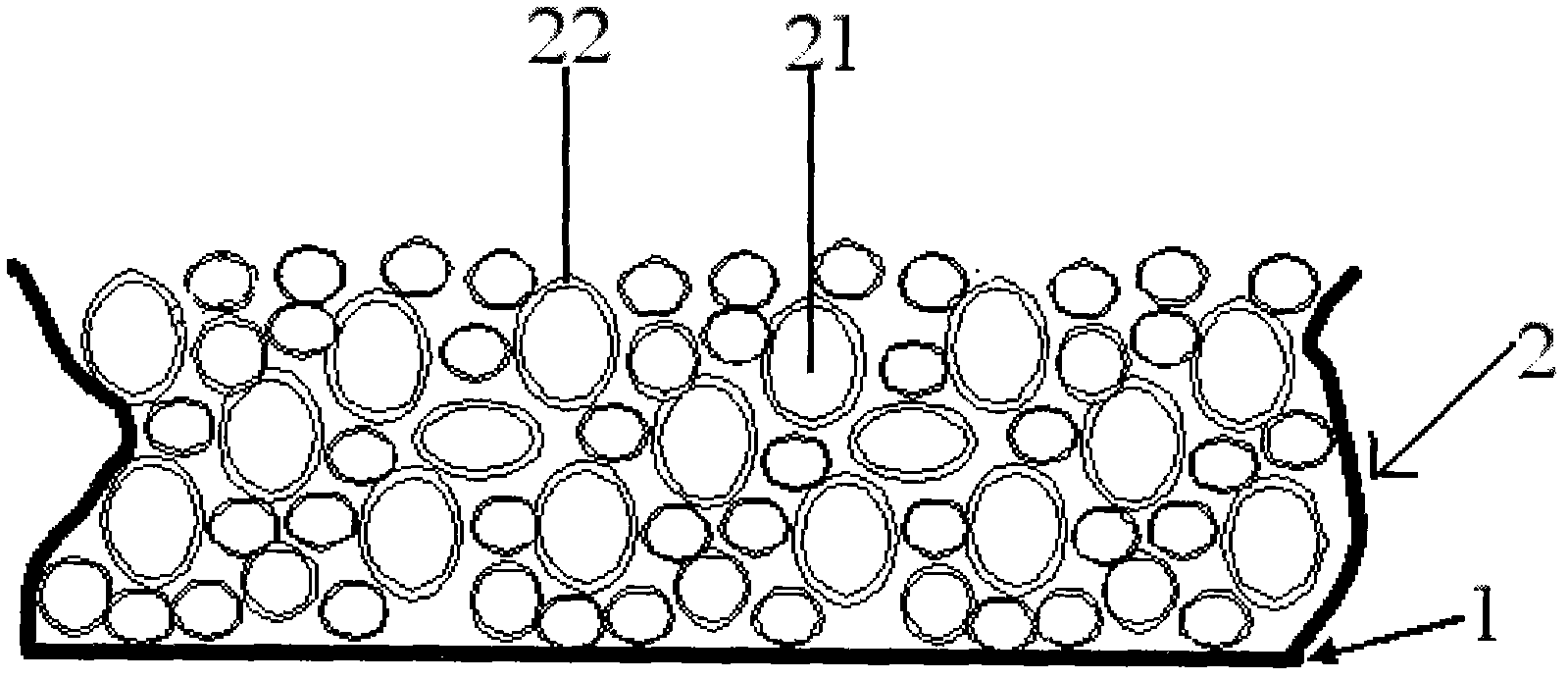

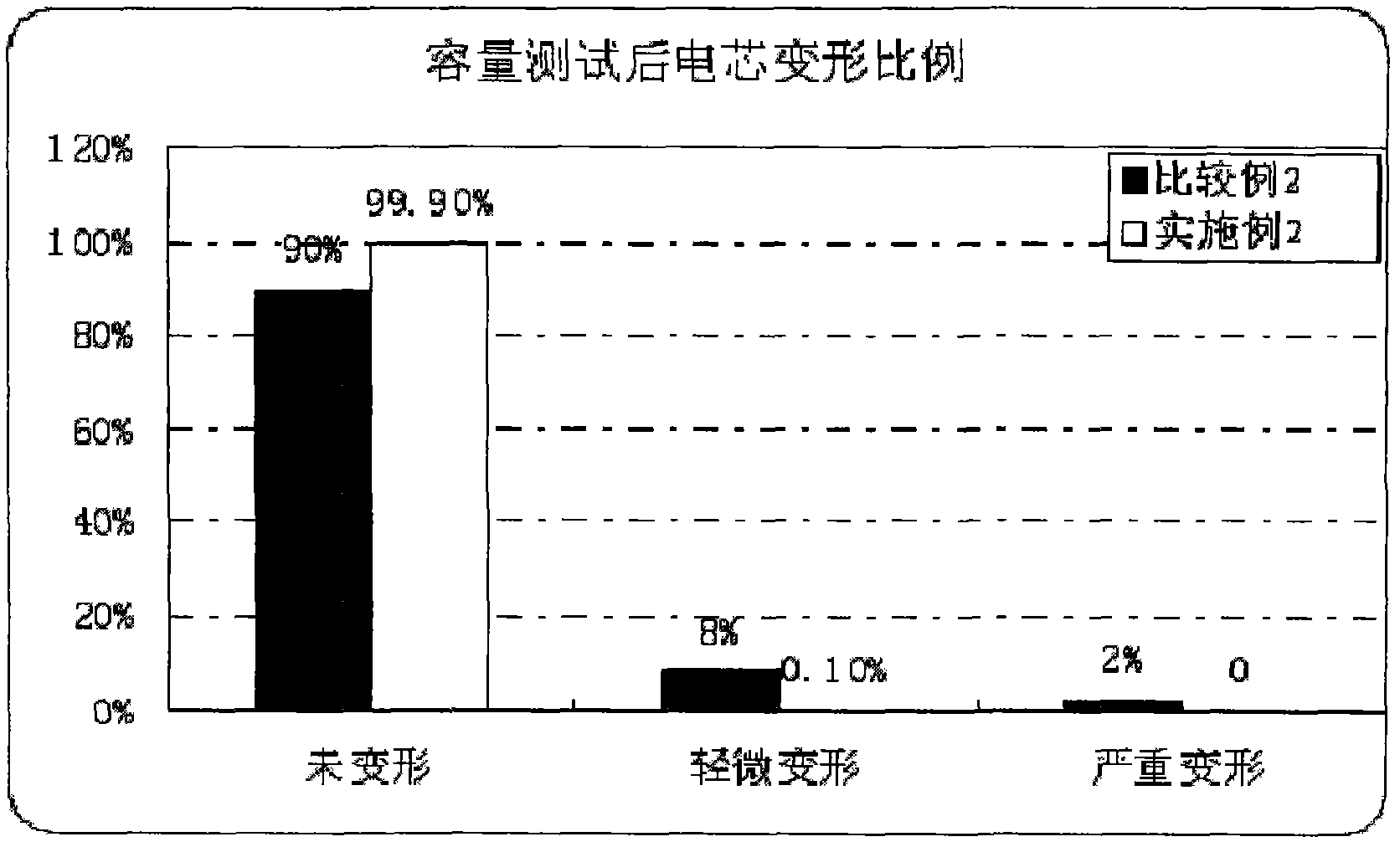

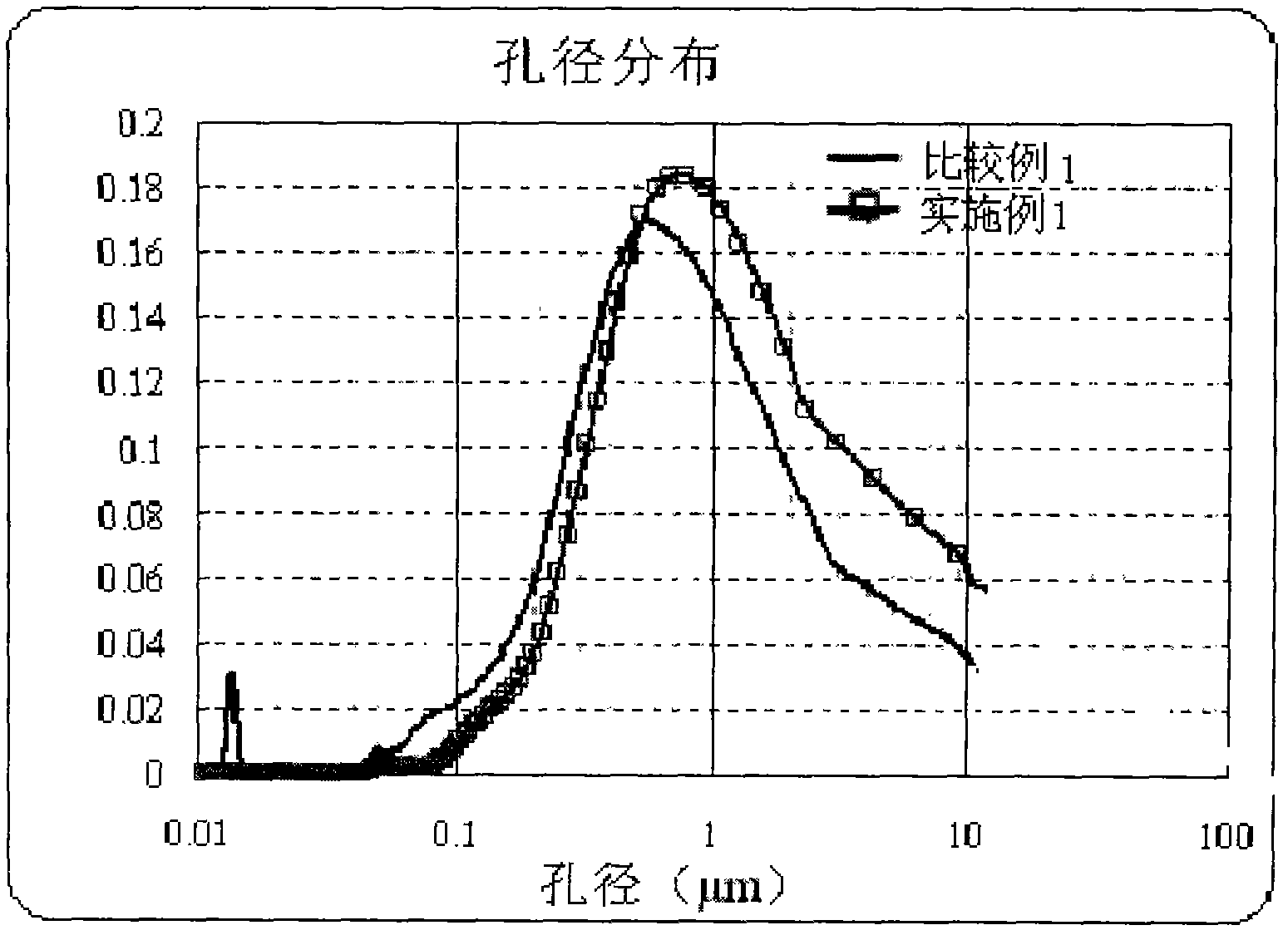

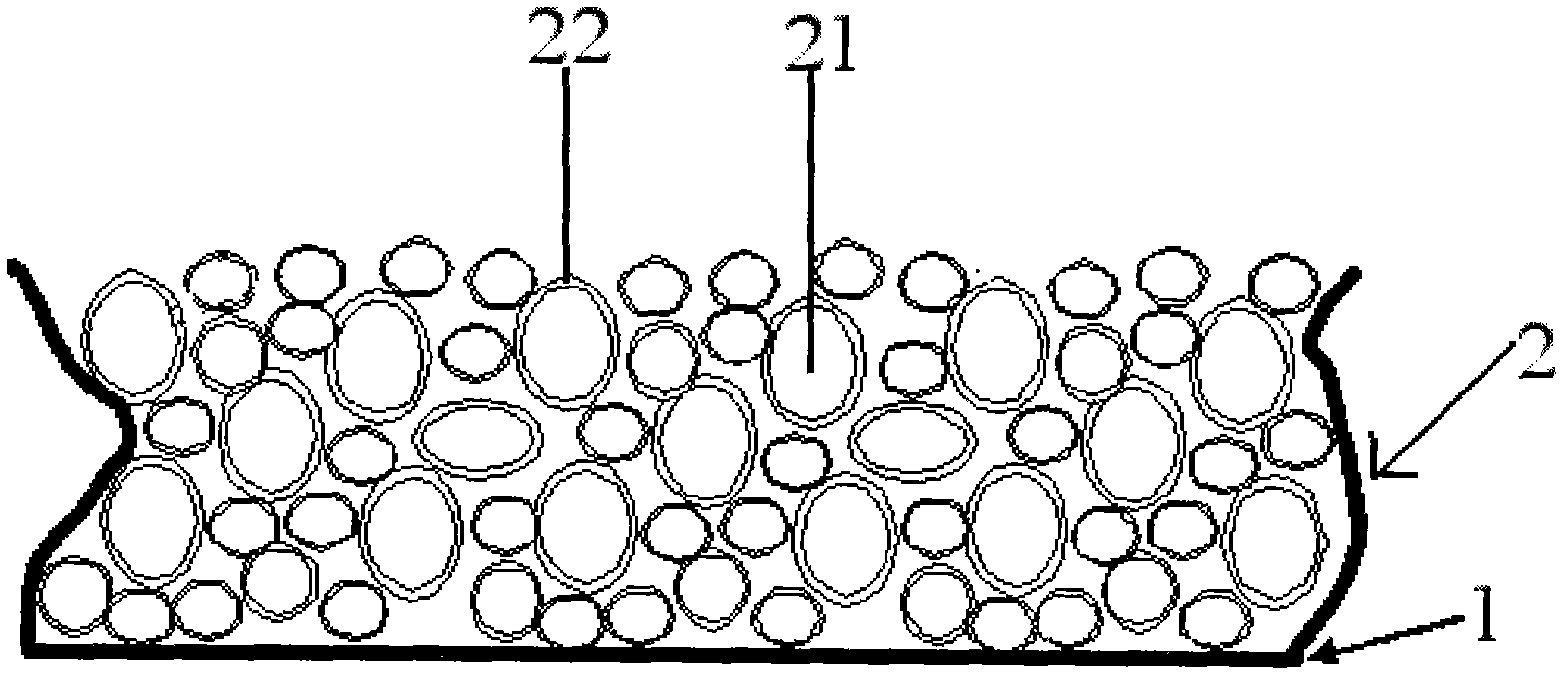

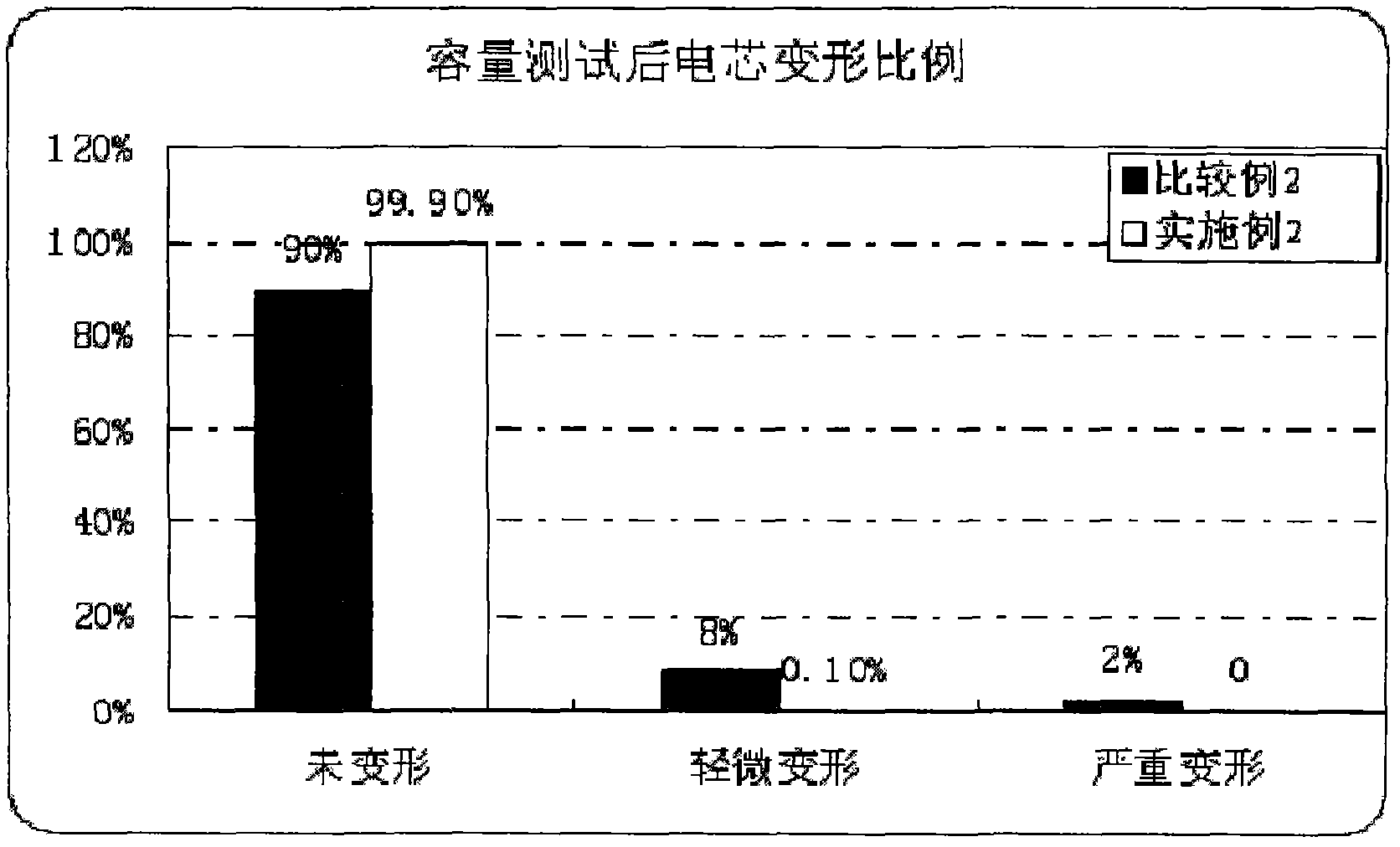

Lithium ion battery and anode and preparation method thereof

ActiveCN102623745AEliminate deformationAdvantages of preparation methodSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries and particularly relates to an anode of a lithium ion battery. The anode of the lithium ion battery comprises an anode current collector and an anode film coated on the anode current collector, and the anode film comprises anode active material, adhesive and conductive additive. The surface of the anode active material is coated with ethylene carbonate (EC), and the weight ratio of the EC and the anode active material is (0.1-30):(99.9-70). Compared with the prior art, the EC coated on the surface of the anode active material is dissolved in electrolyte after liquid injection, the space occupied by the EC in the film can be released, so that a certain space is reserved for expansion of particles of the anode active material during charging and circulating, and the problem of deformation of flexibly-packaged cell due to expansion of the active material is eliminated. Further, the invention further discloses a method for preparing the lithium ion battery, namely the lithium ion battery comprising the anode.

Owner:NINGDE AMPEREX TECH +1

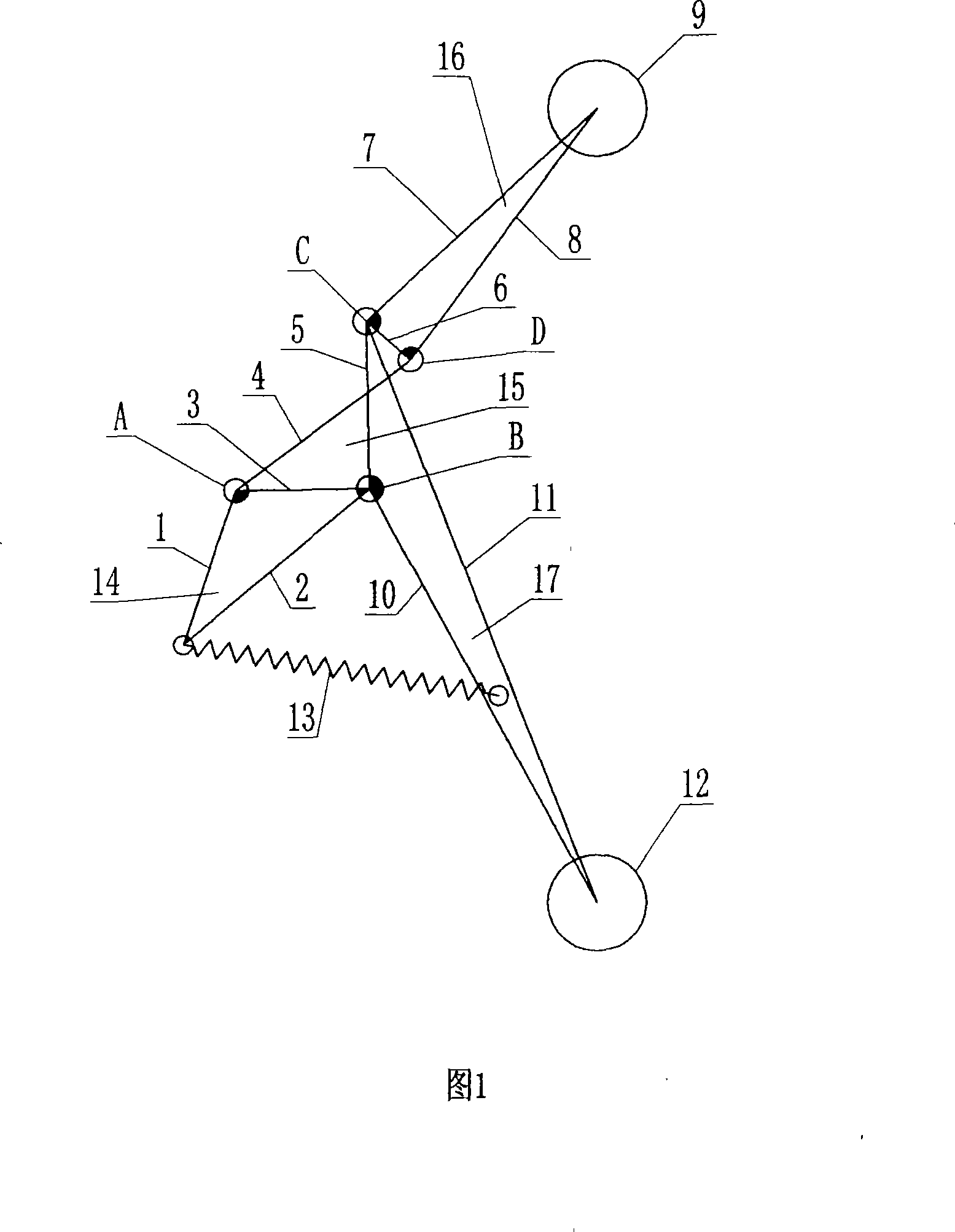

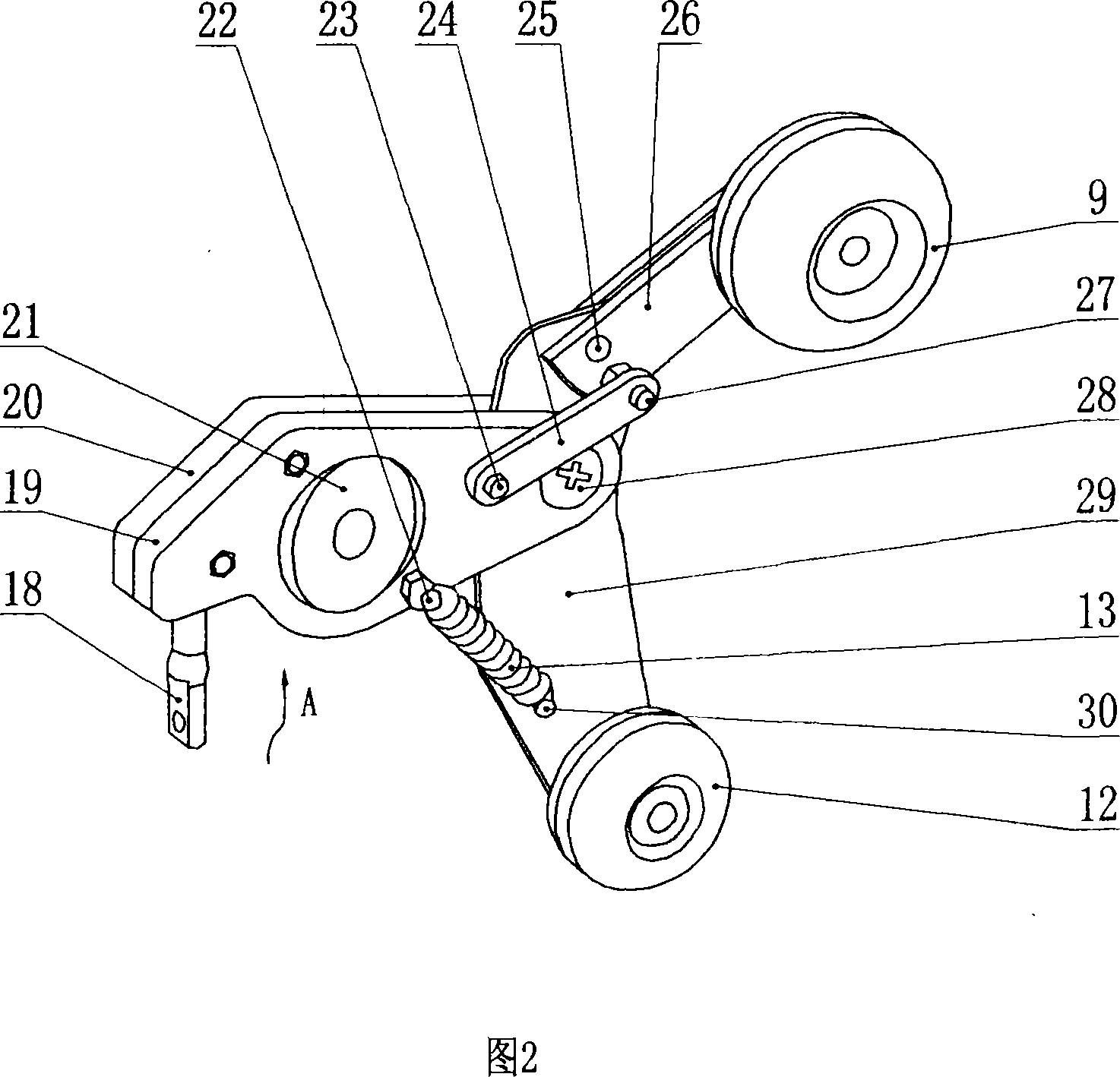

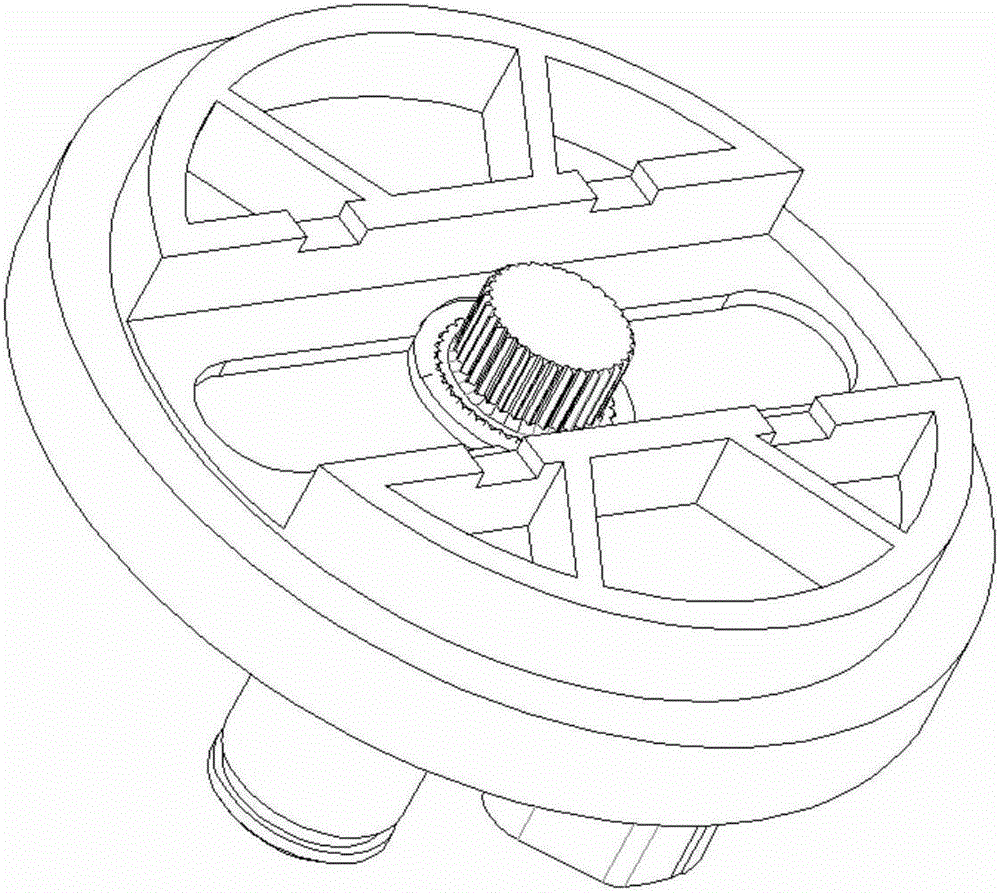

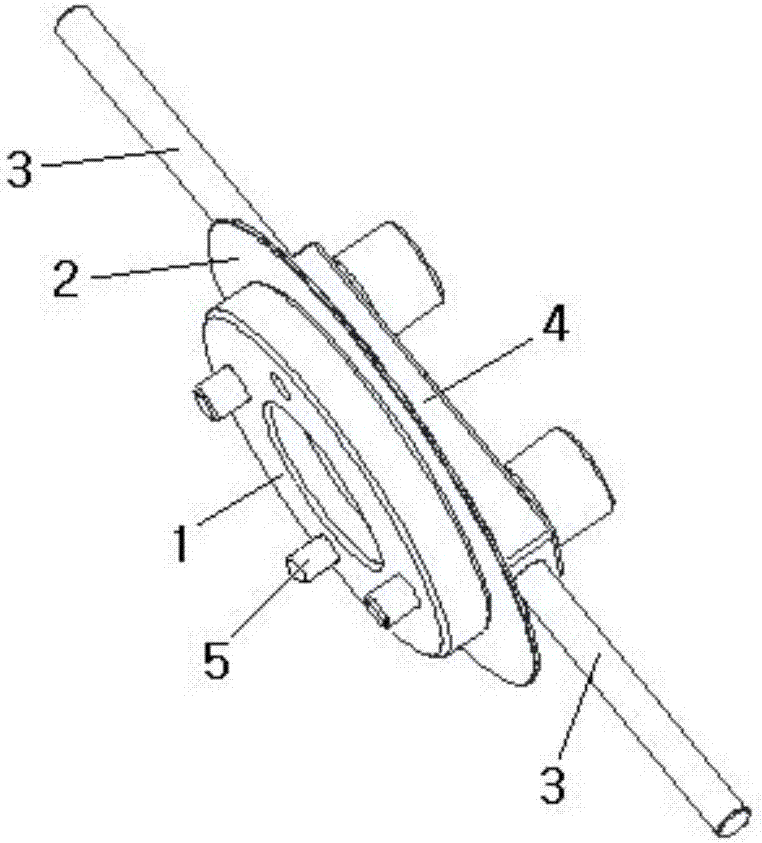

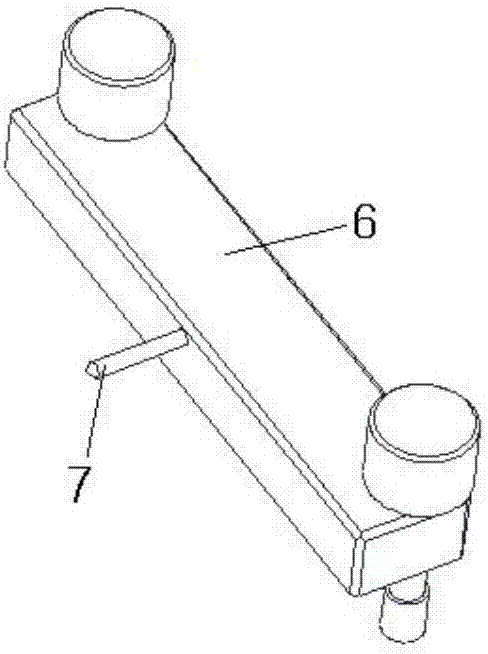

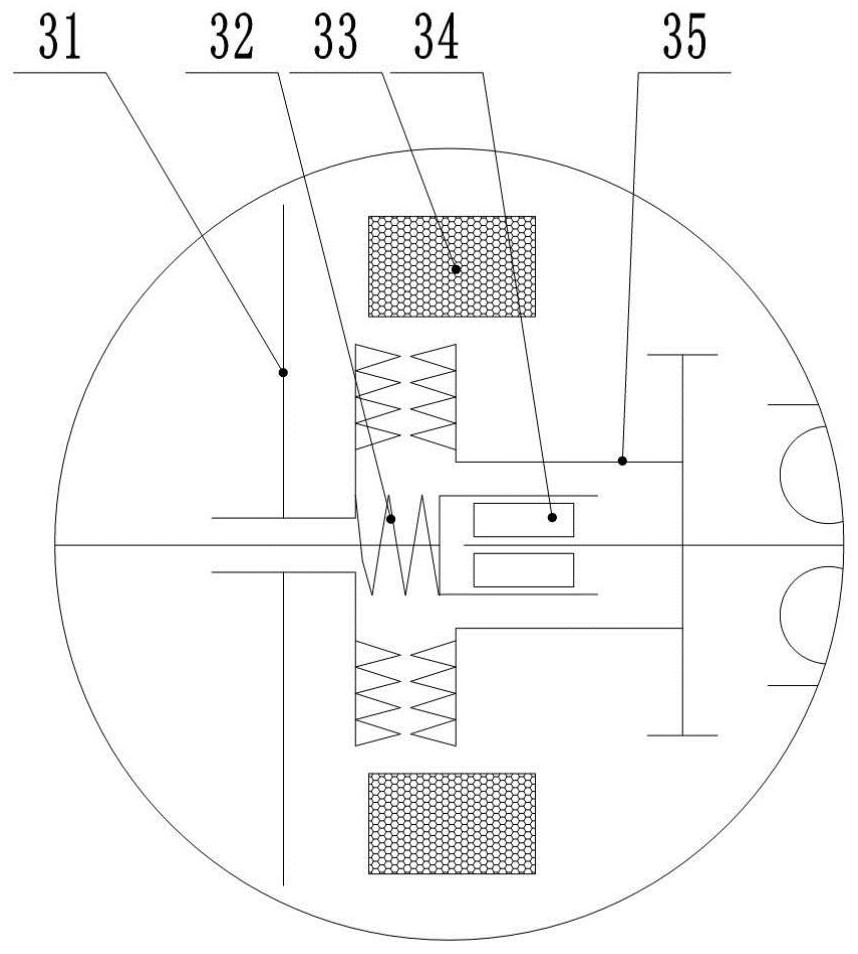

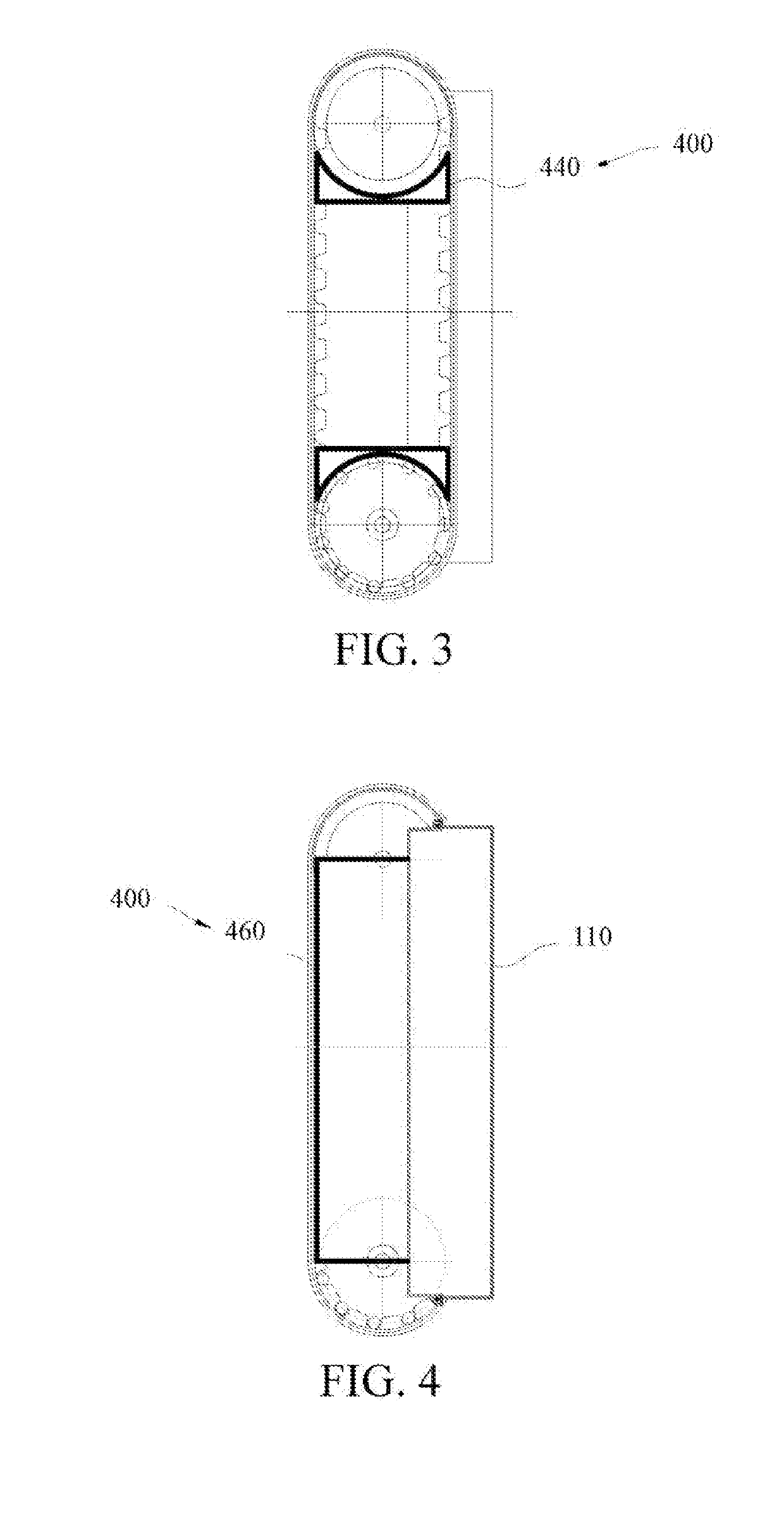

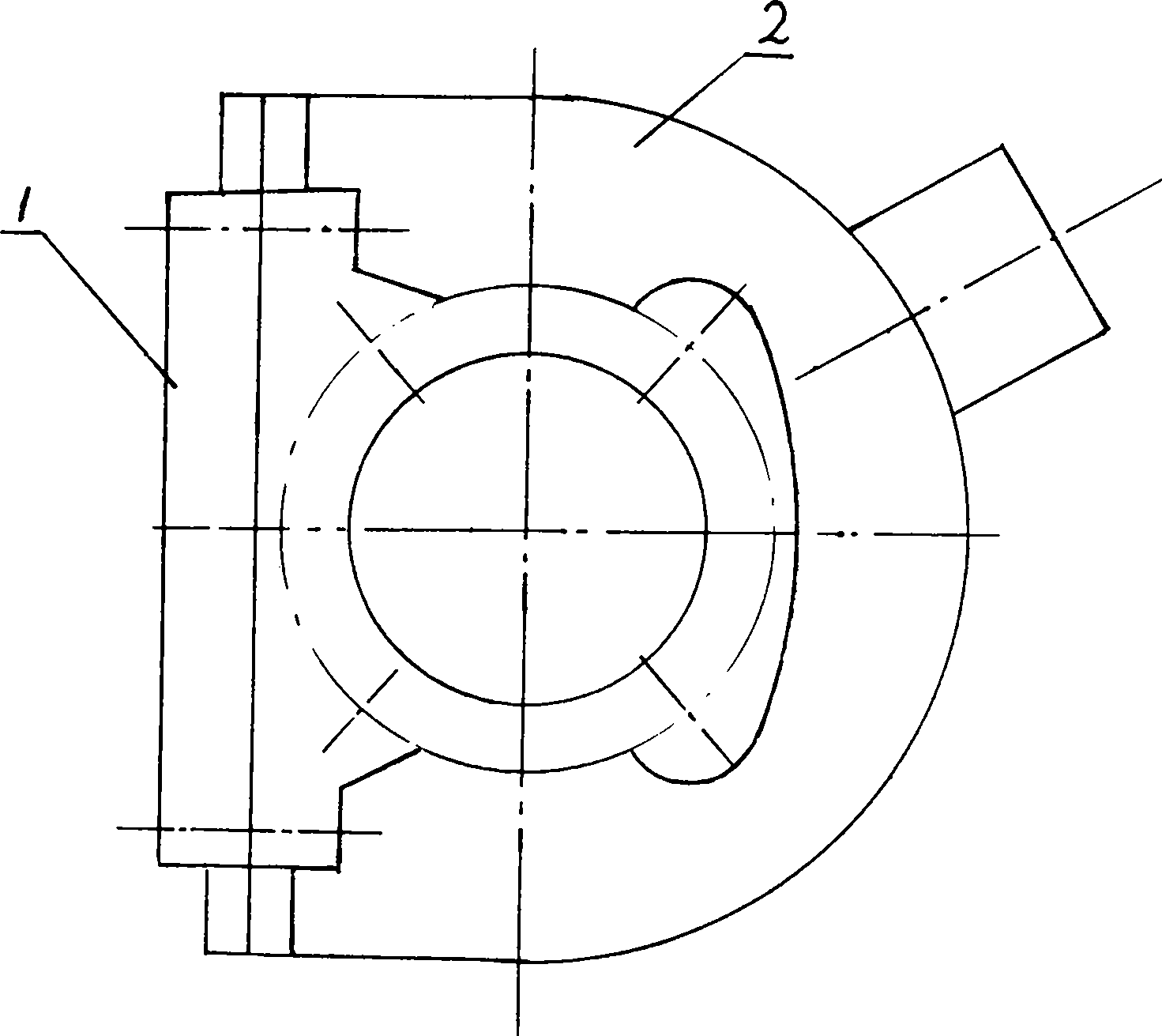

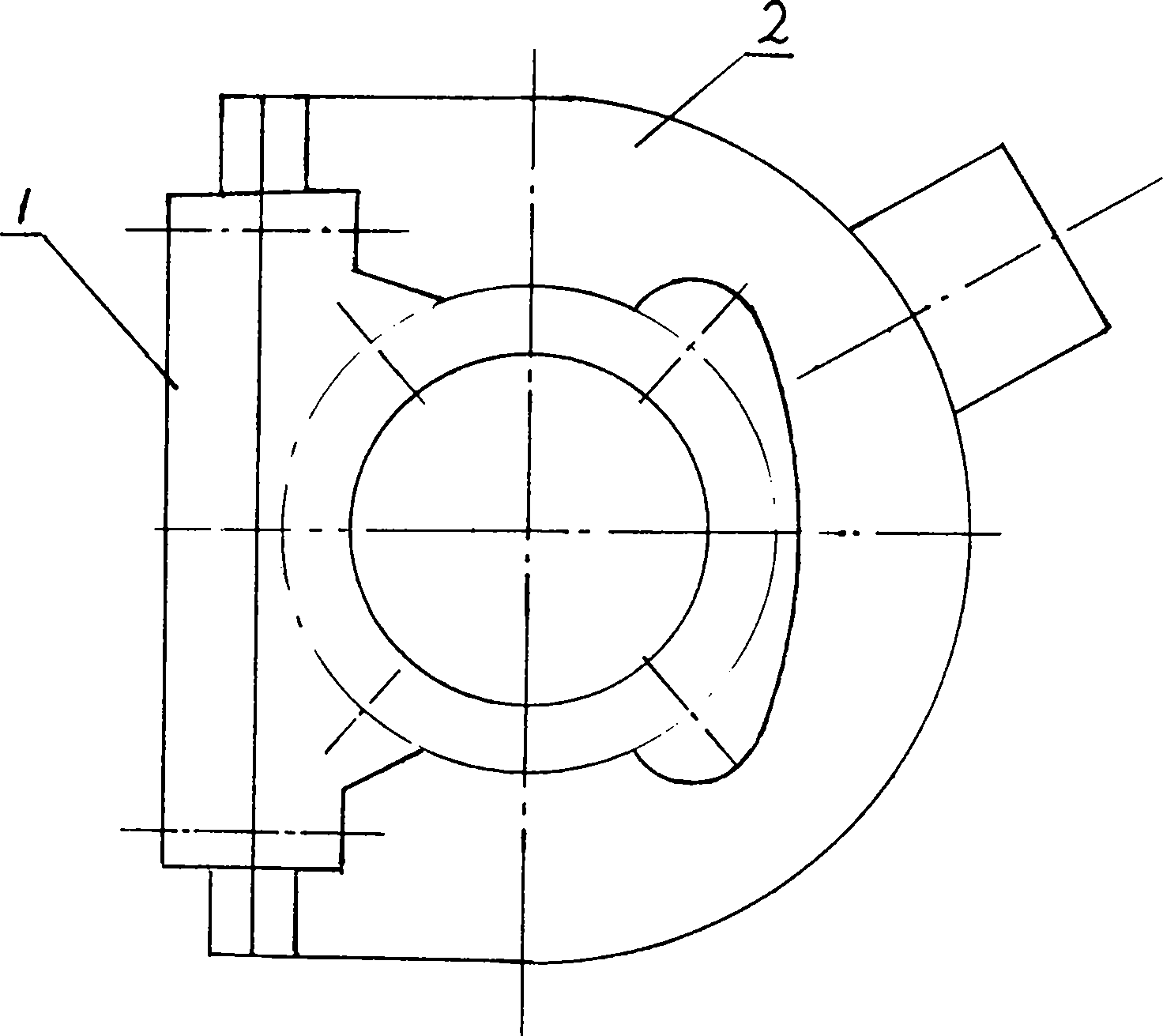

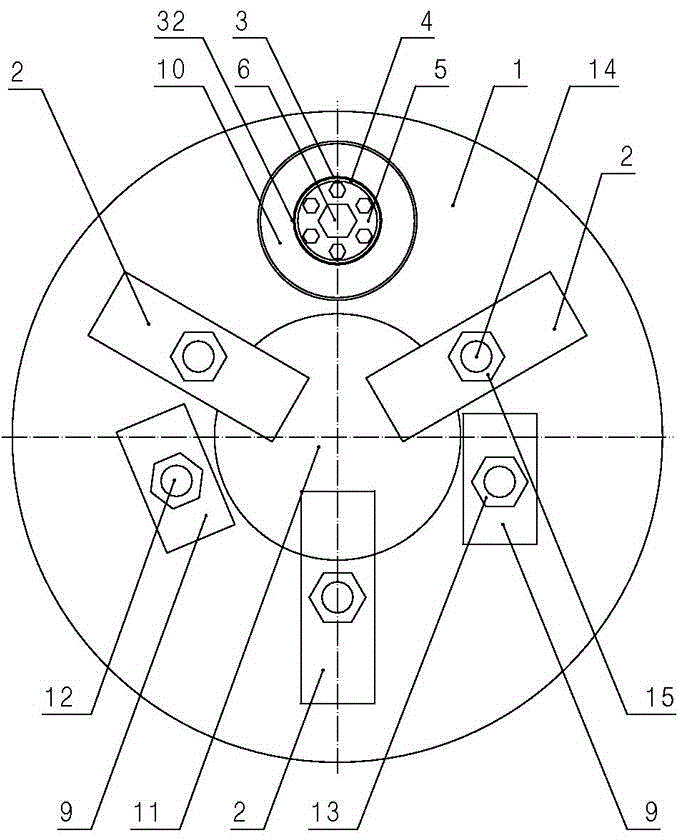

Massage chair shoulder back kneading mechanism

ActiveCN101234066AIncrease the center distanceAvoid harsh massage effectsRoller massageSuction-kneading massageHuman bodyMassage

The invention discloses a shoulder and back kneading mechanism used in massage chairs, which comprises kneading arms and massaging wheels. The invention is characterized in that the shoulder and back kneading mechanism is also provided with an upper swing arm, a lower swing arm, a swing arm connecting rod and springs. The kneading arm comprises an inner kneading arm and an outer kneading arm which are integrated into a whole through screws; the upper swing arm is movably connected with the lower swing arm; the upper swing arm and the lower swing arm are connected with the kneading arm through crank screws; the swing arm connecting rod is connected with the kneading arm; the springs are respectively connected with the kneading arm and the lower swing arm; the kneading arm, the swing arm connecting rod, the upper swing arm and the lower swing arm form into a linkage mechanism. The depth and distance in vertical direction of the upper massage wheel and the lower massage wheel of the invention can be adapted freely according to the back curve of human body. The massage depth is uniform, therefore, the massage wheels more perfectly simulate massage effects of a real person and cause people feel more comfortable; the springs has buffer effects to massage strength and massage wheel speed, thus making the massage operation be more gentle. Besides, the massage effects are especially suitable for middle-aged and elder people.

Owner:IREST HEALTH TECH CO LTD

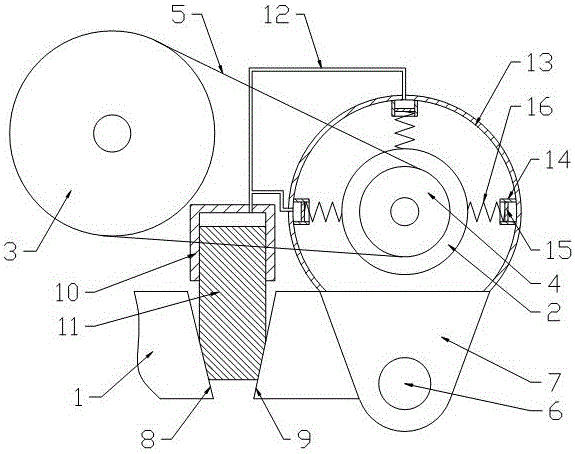

Mass transfer head and method for an electronic element

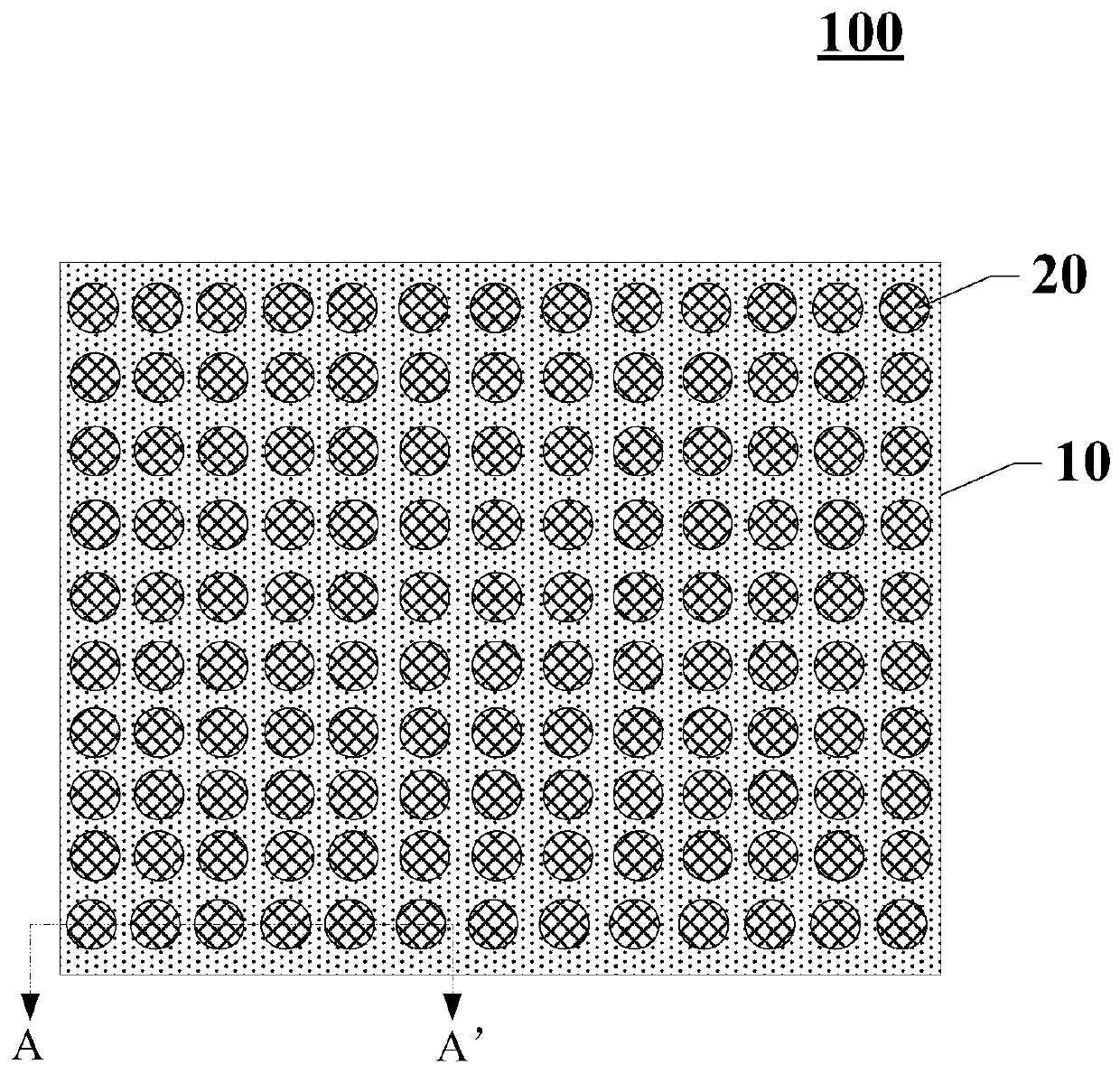

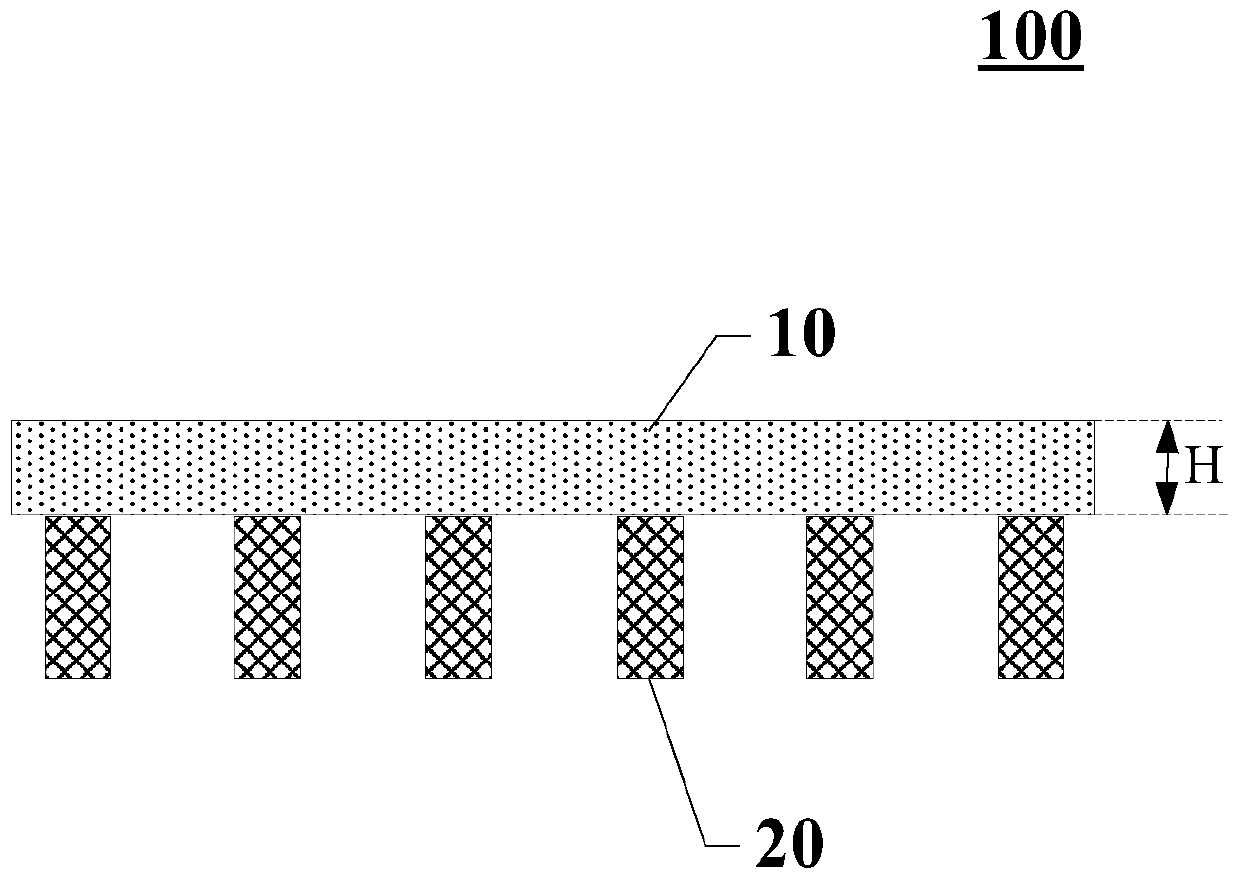

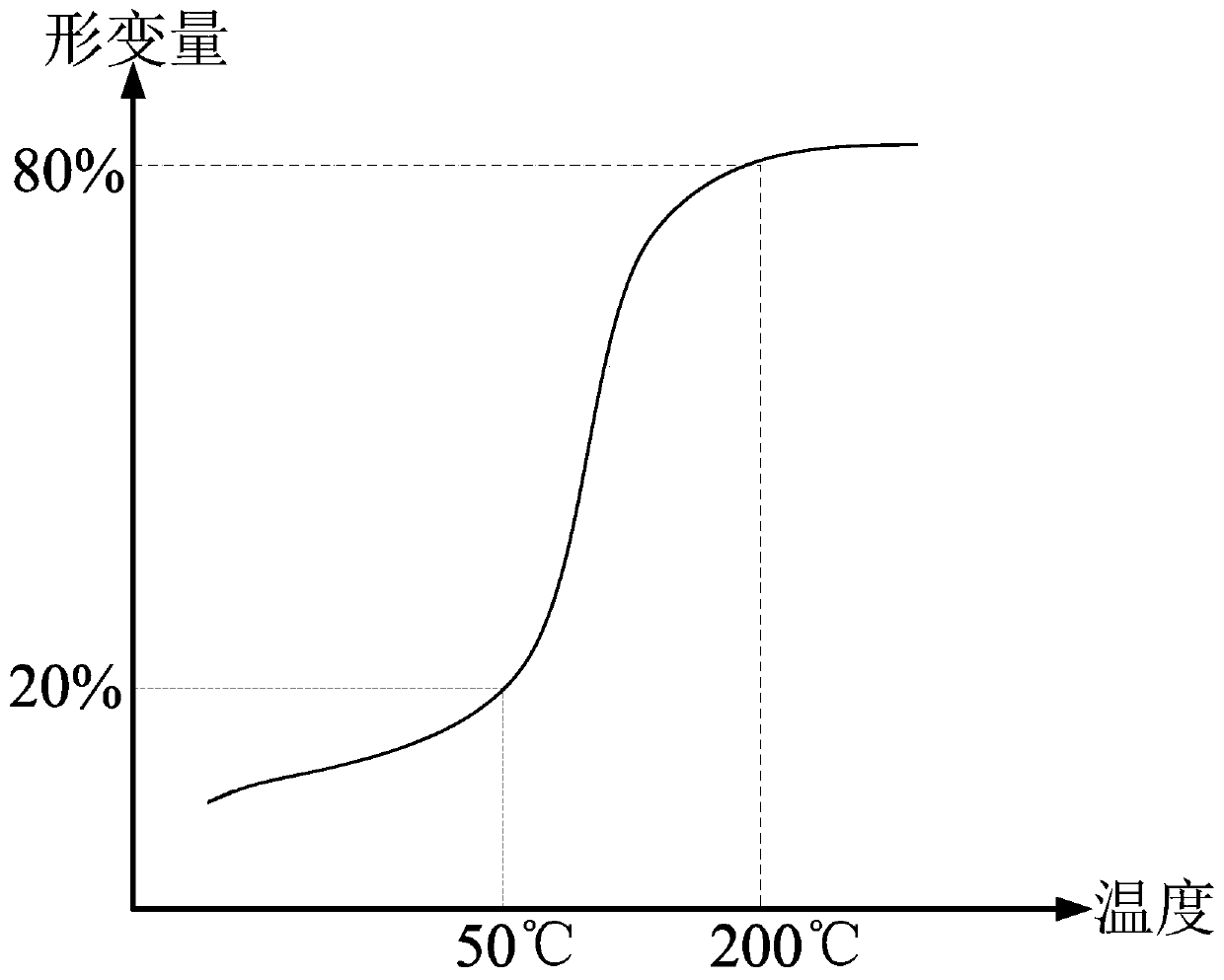

InactiveCN110289240AIncrease the center distanceReduce the center distanceSemiconductor/solid-state device manufacturingSemiconductor devicesAlloy substrateMass transfer

The invention discloses a mass transfer head and method for an electronic element, and relates to the technical field of electronic element production. The transfer head comprises a memory alloy substrate and a plurality of electronic element pick-up heads fixed on the first surface of the memory alloy substrate. At the same temperature, the center distances between any two adjacent electronic element pick-up heads are equal; the memory alloy substrate deforms along with the change of temperature; when the temperature rises, the memory alloy substrate stretches, and the center distance between any two adjacent electronic element pick-up heads is increased; when the temperature decreases, the memory alloy substrate is shrunk, and the center distance between any two adjacent electronic element pick-up heads is reduced. The distance between the electronic element pick-up heads fixed on the memory alloy substrate can be adjusted by the adjustment of the temperature. The mass transfer head is flexibly suitable for different Micro-LED pitches and pixel pitches, thereby avoiding the consumption of the Micro-LED resources.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

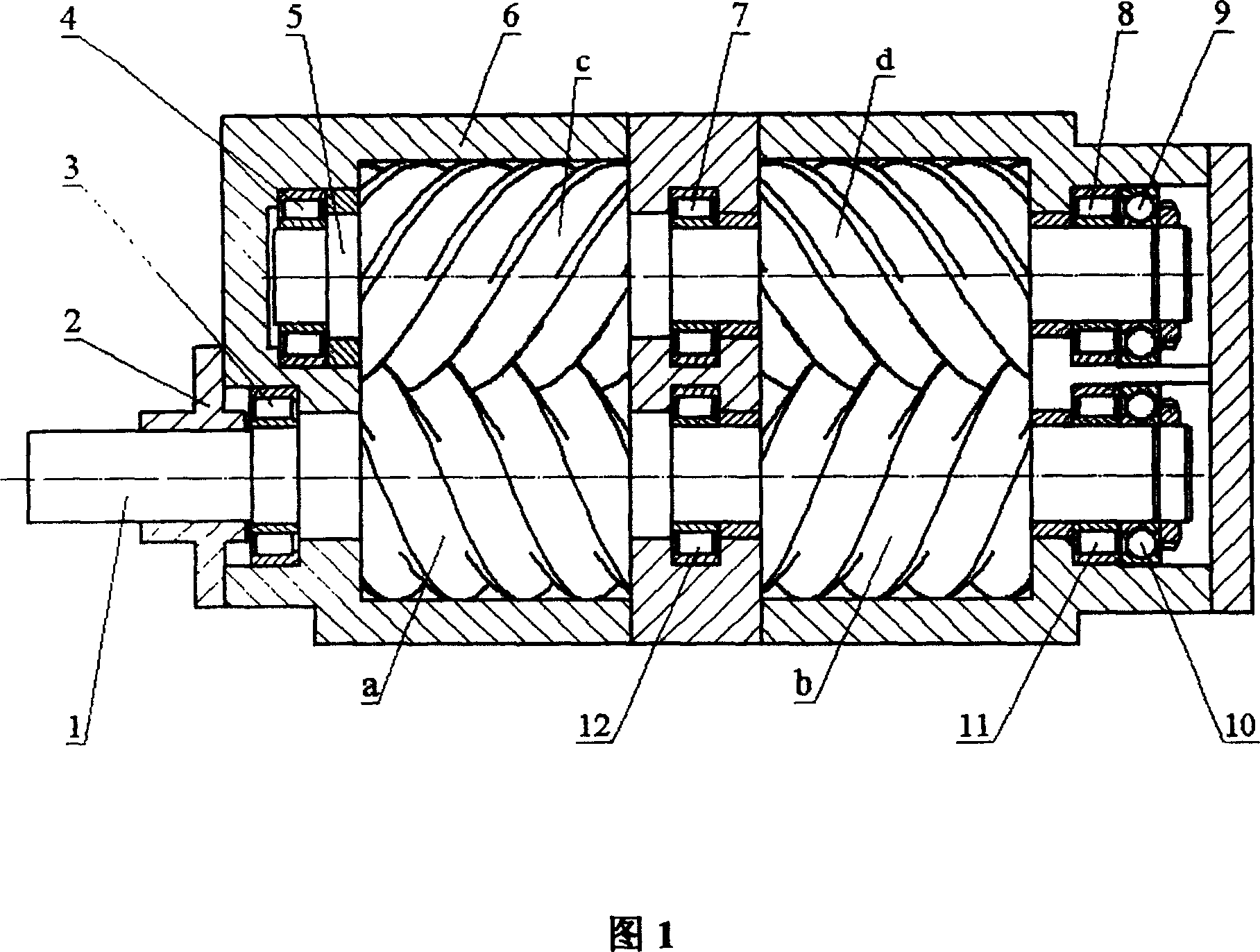

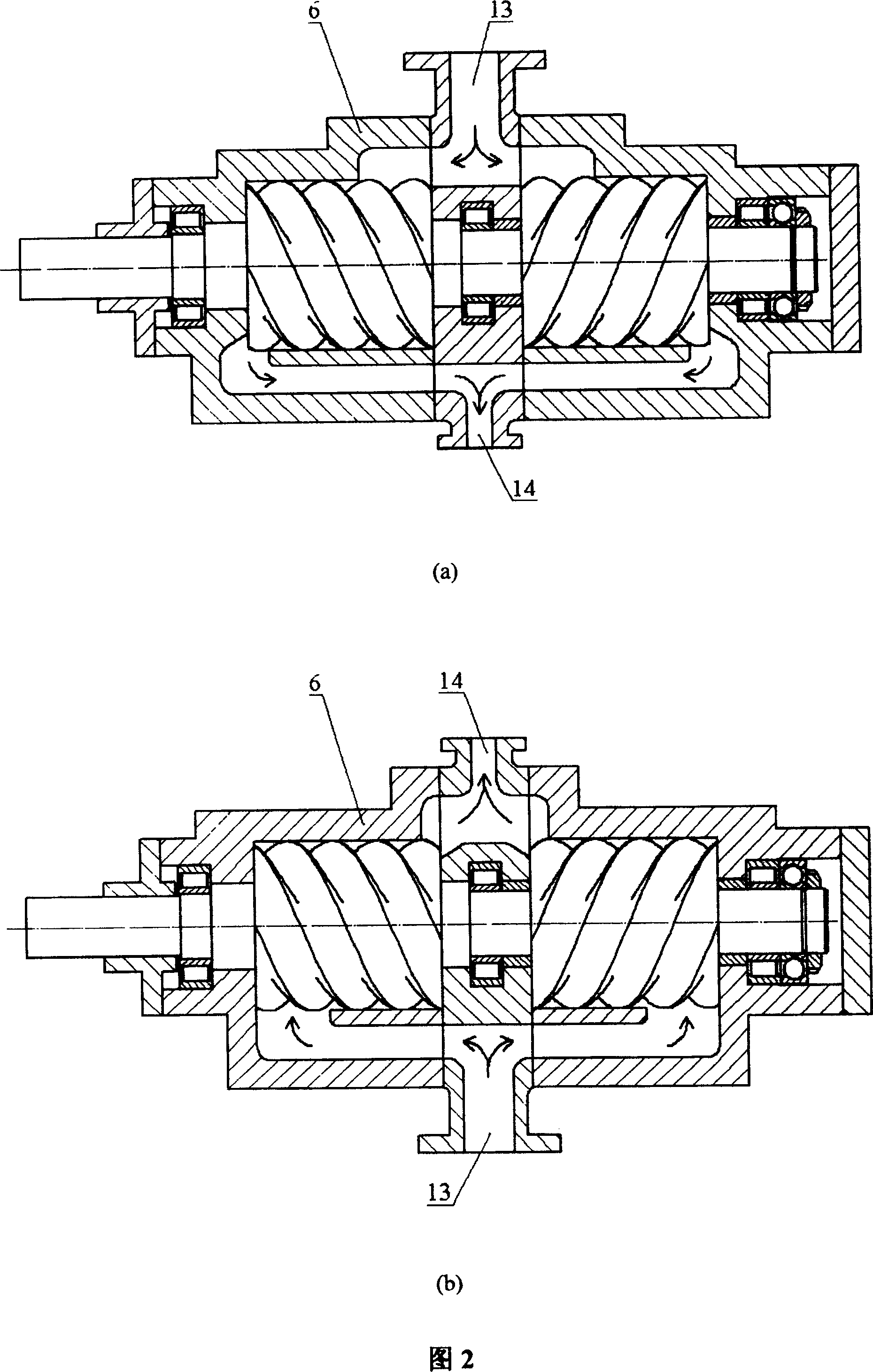

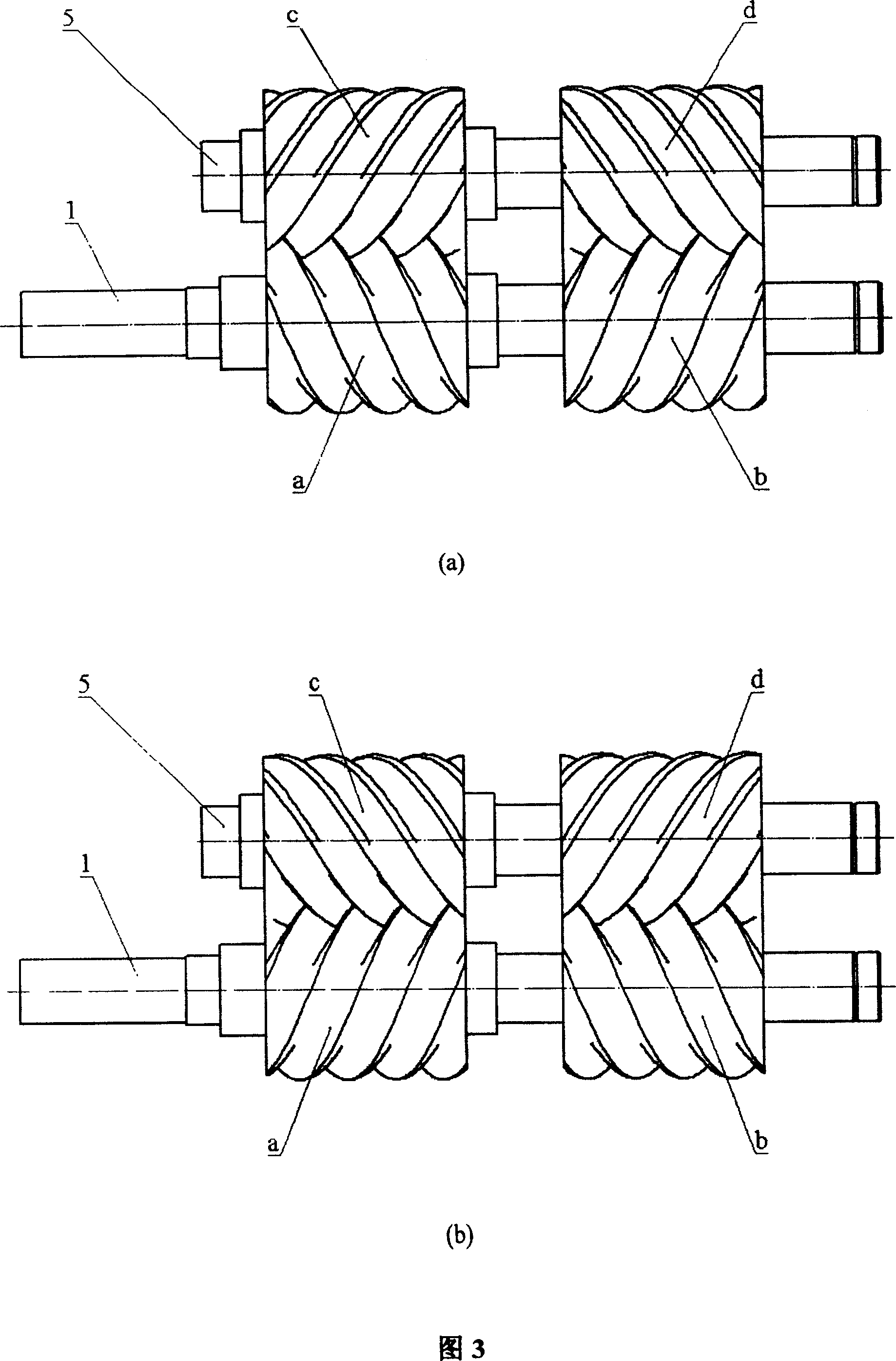

Worm and helical gear transmission pair based on variable pressure angle and application of worm and helical gear transmission pair

PendingCN105179601AImprove machining accuracyReduce noisePortable liftingToothed gearingsGear transmissionEngineering

The invention discloses a worm and helical gear transmission pair based on a variable pressure angle and application of the worm and helical gear transmission pair. The worm and helical gear transmission pair is reliable in transmission, durable and easy to manufacture. In order to achieve the purposes, the worm and helical gear transmission pair based on the variable pressure angle comprises a worm and a helical gear which are engaged with each other, wherein the transverse module (Mt2) of the helical gear is equal to the shaft surface module (Ma1) of the worm; the tooth profile angle alpha n2 of the end face reference circle of the helical gear is larger than the tooth profile angle alpha n1 of the shaft surface reference circle of the worm; the swing angle beta 2 of the reference circle of the helical gear is equal to the lead angle lambda 1 of the shaft surface reference circle of the worm; the difference between the tooth profile angle alpha n2 of the end face reference circle of the helical gear and the tooth profile angle alpha n1 of the shaft surface reference circle of the worm is smaller than 10 degrees.

Owner:SHENZHEN POWER MOTOR IND

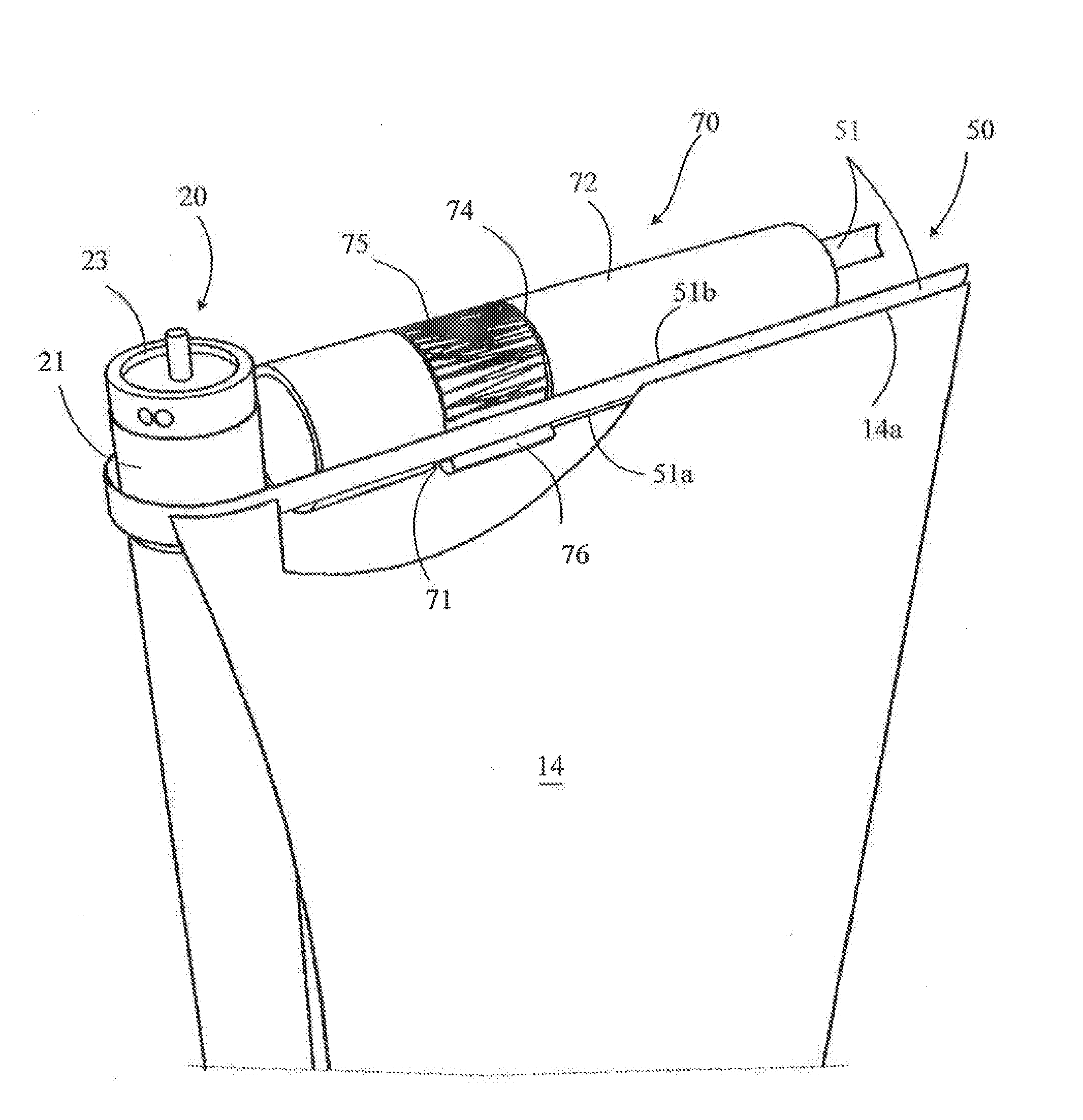

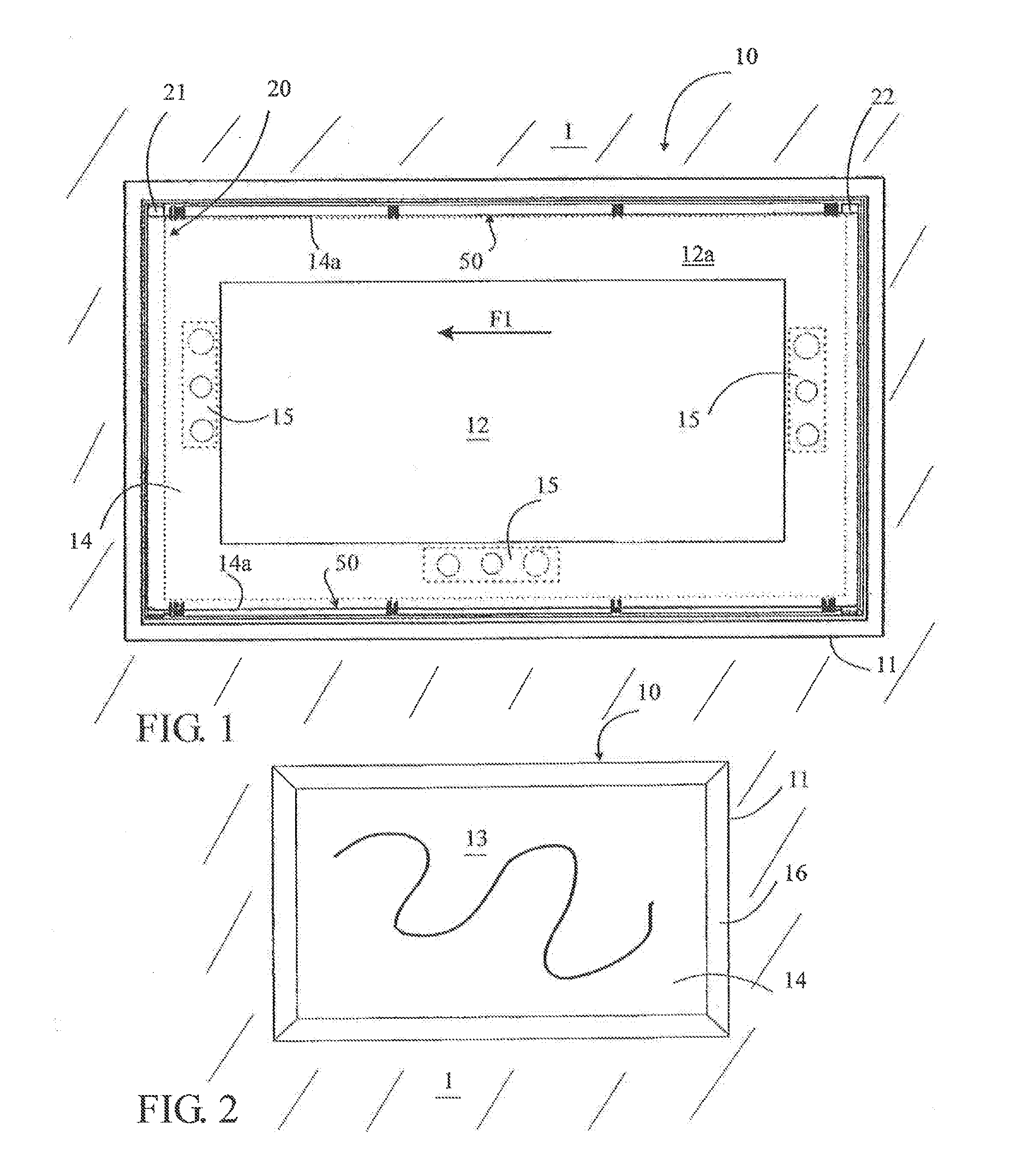

Retractable projection screen

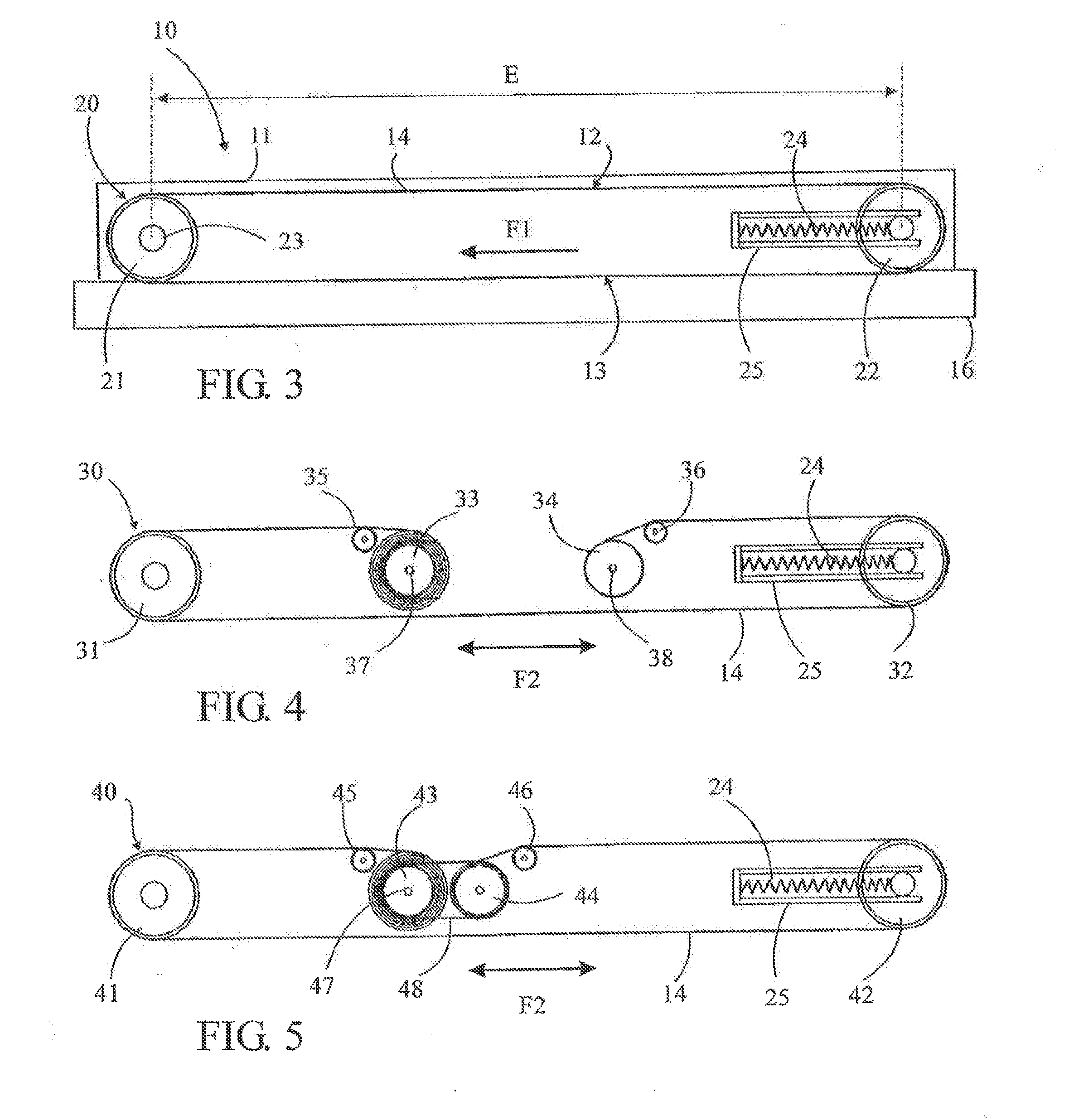

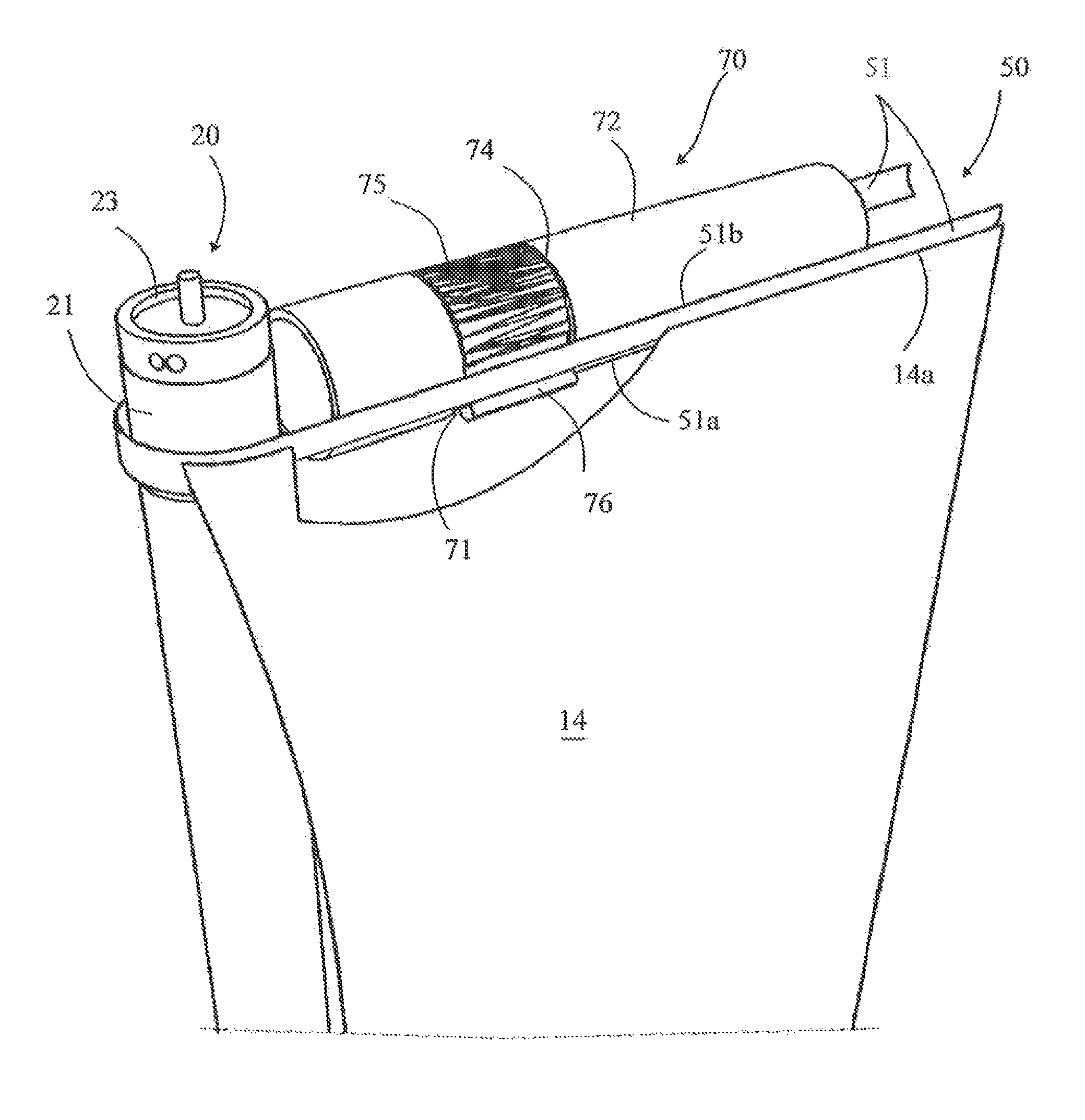

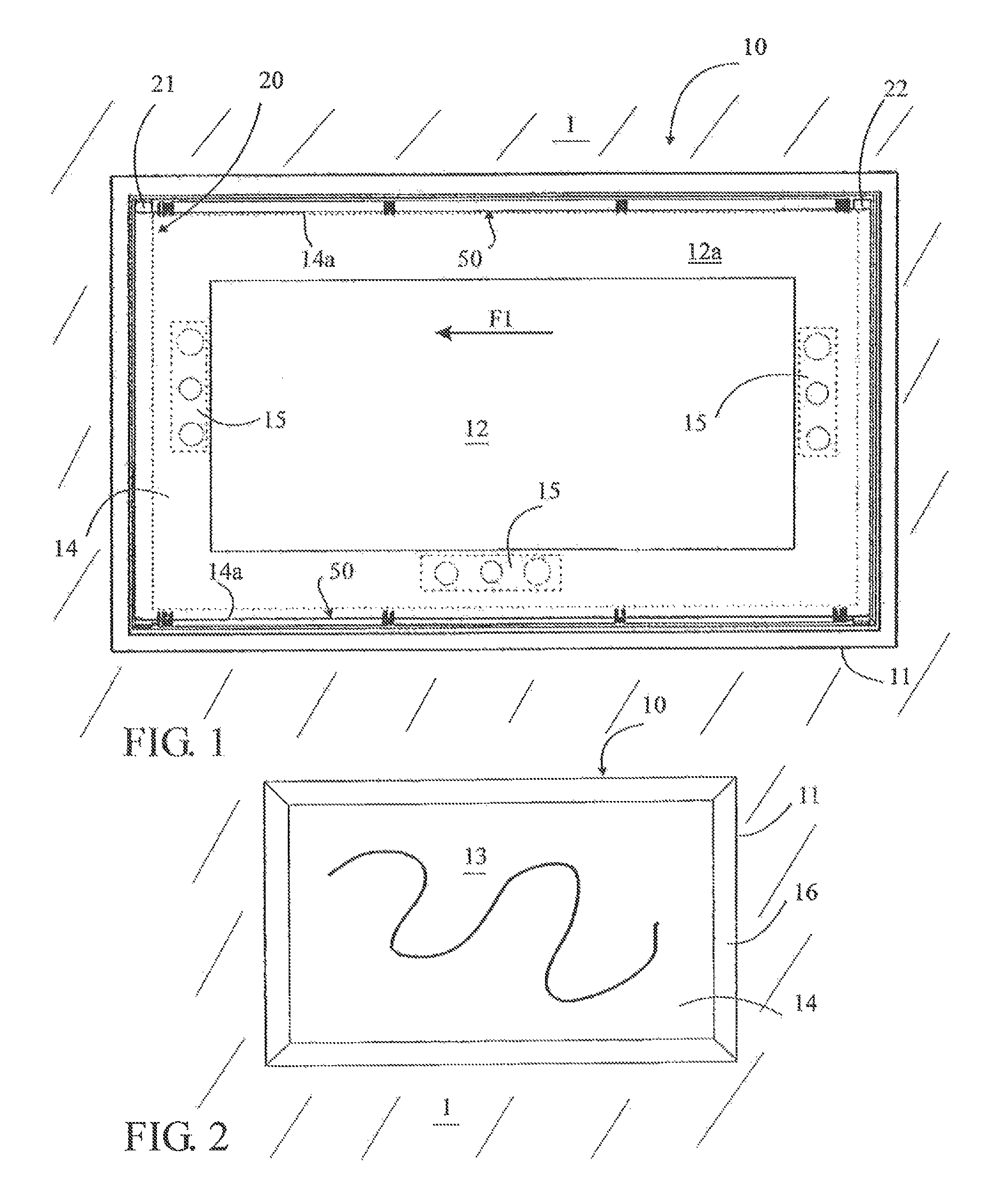

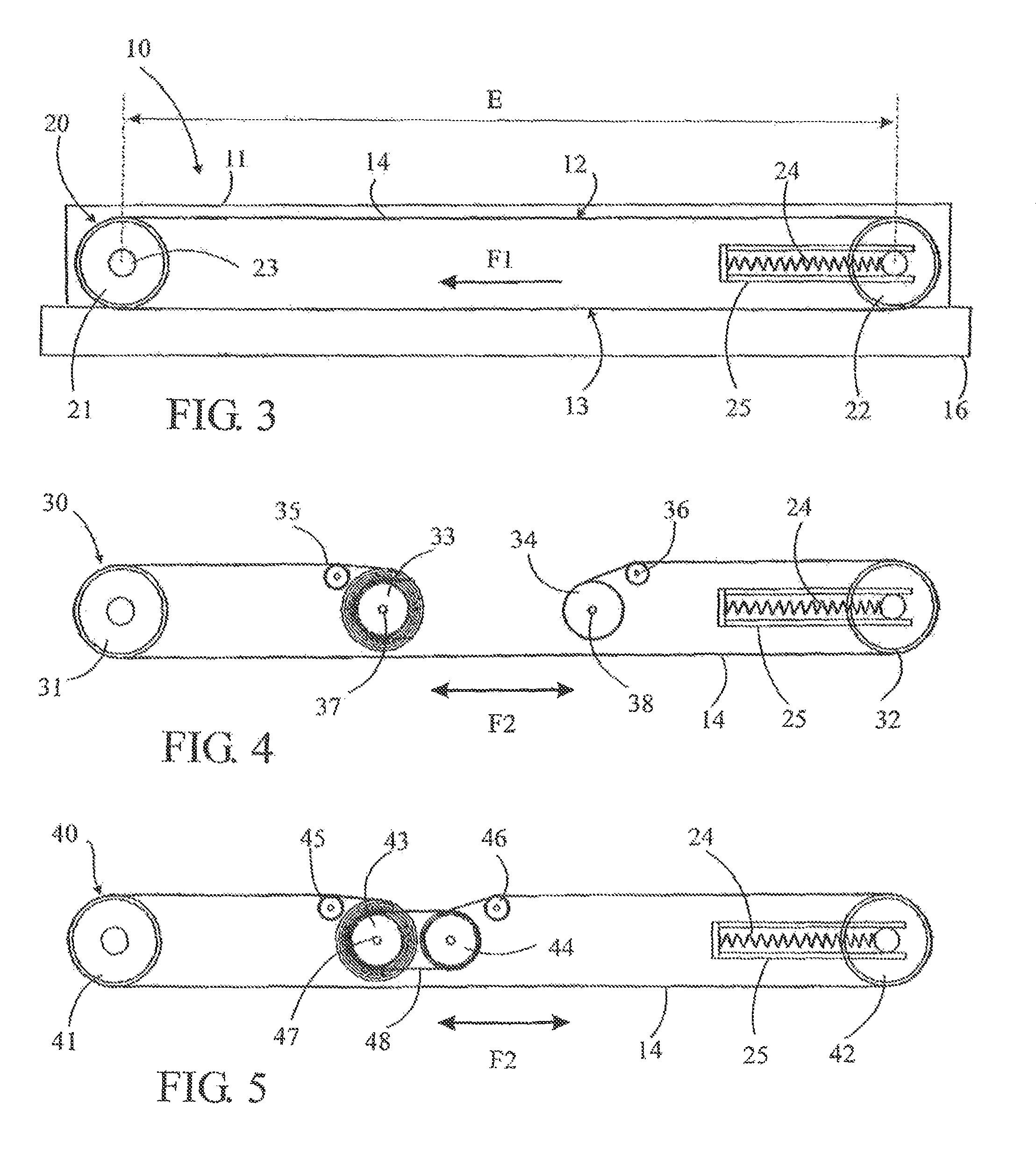

InactiveUS20150109665A1Simple and reliable and cost-effectiveReduce depthProjectorsEngineeringSheet material

A screen device (10) having a casing (10), a projection screen (12) and a setting (13) associated with displacement mechanism (20) for modifying the visible content of the casing. The projection screen (12) and the setting (13) are combined on a unitary support sheet (14) and the displacement mechanism (20) comprise two parallel winding rollers (21, 22) about which the support sheet (14) is wound, and one of the rollers is a driven roller. Stiffening mechanism (50) is associated with the two free edges (14a) of the support sheet (14) for stiffening the free edges in the winding direction of the and to confer a perfect flatness to the sheet over its entire surface area. A guide mechanism (60) is associated with the stiffening mechanism (50) for the free edges (14a) of the support sheet (14).

Owner:VASSARDS JEAN MARC

Retractable projection screen

InactiveUS9329468B2Simple and reliable and cost-effectiveReduce depthProjectorsProjection screenEngineering

A screen device (10) having a casing (10), a projection screen (12) and a setting (13) associated with displacement mechanism (20) for modifying the visible content of the casing. The projection screen (12) and the setting (13) are combined on a unitary support sheet (14) and the displacement mechanism (20) comprise two parallel winding rollers (21, 22) about which the support sheet (14) is wound, and one of the rollers is a driven roller. Stiffening mechanism (50) is associated with the two free edges (14a) of the support sheet (14) for stiffening the free edges in the winding direction of the and to confer a perfect flatness to the sheet over its entire surface area. A guide mechanism (60) is associated with the stiffening mechanism (50) for the free edges (14a) of the support sheet (14).

Owner:VASSARDS JEAN MARC

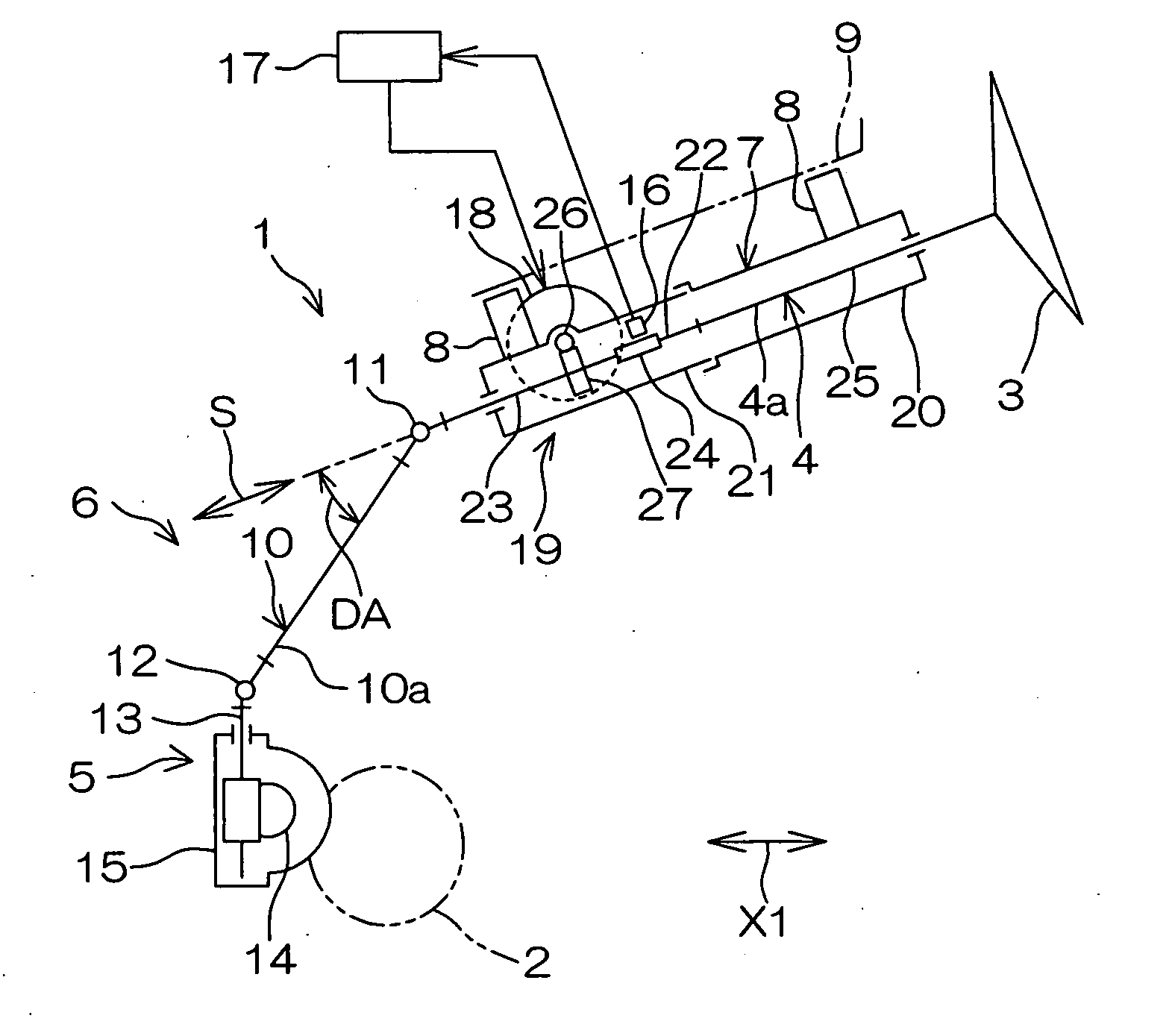

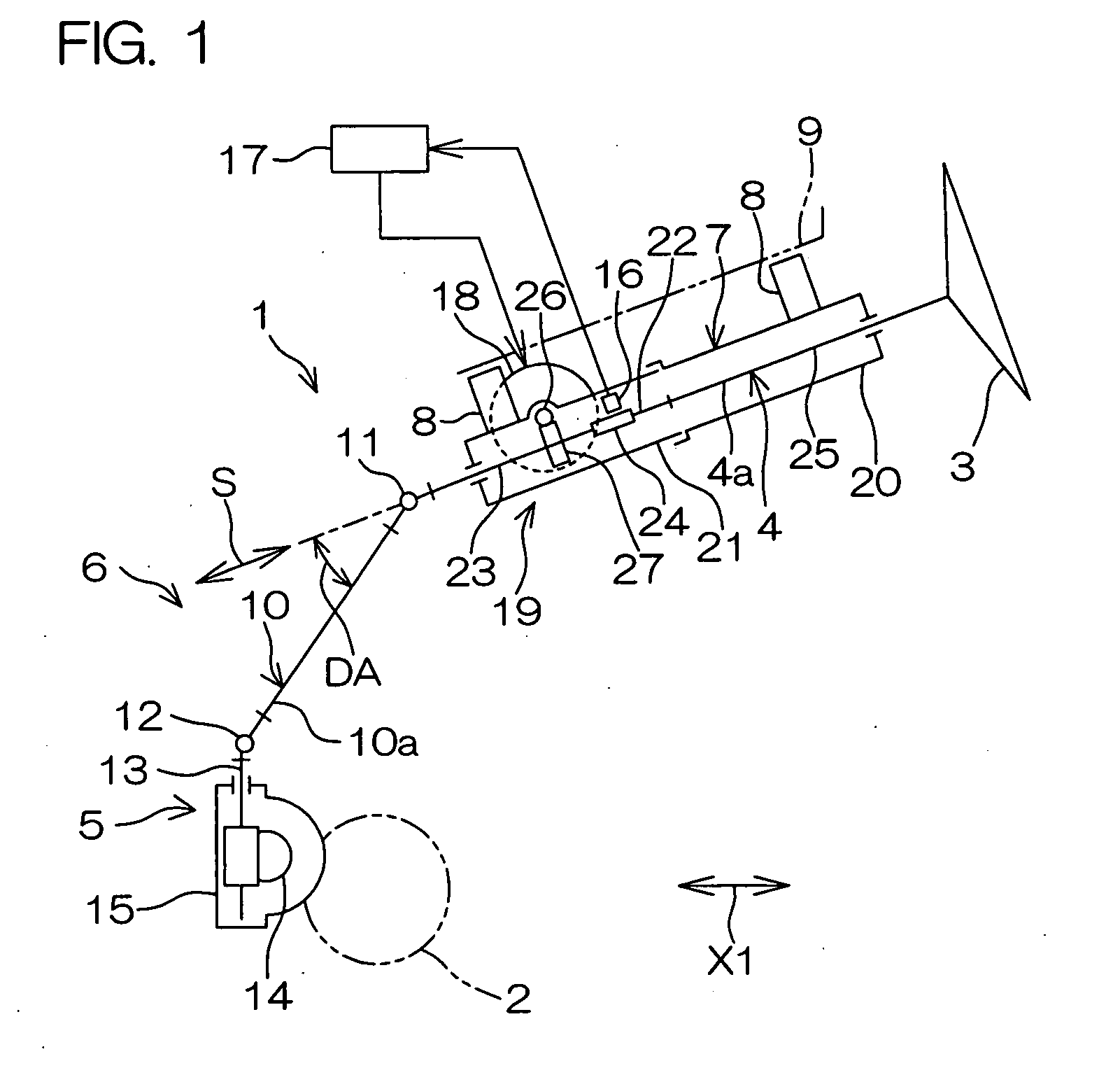

Electric power steering apparatus

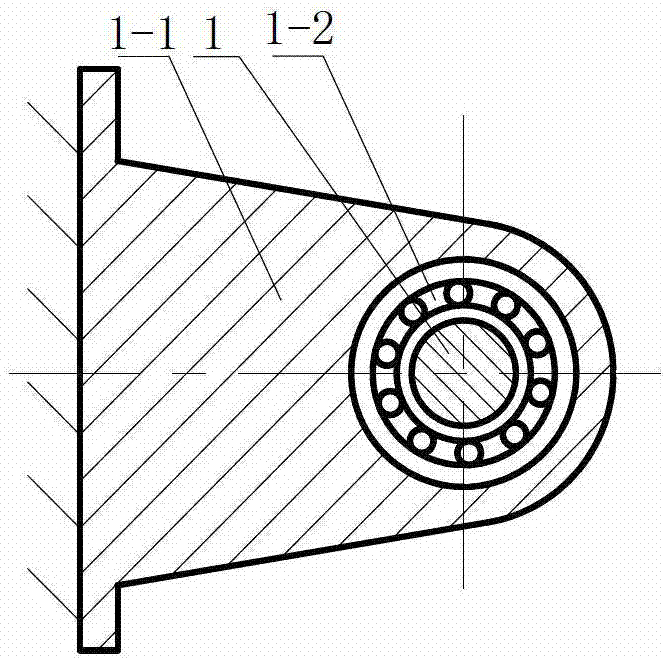

InactiveUS20080035416A1Avoid positioningFavorable steering feelingToothed gearingsElectrical steeringElectric power steeringGear drive

An electric power steering apparatus comprises a driving gear driven by an electric motor for steering assist and a driven gear meshed with the driving gear. A steering shaft is rotated along with the driven gear. The steering shaft is rotatably supported by a first bearing and a second bearing. An urging member is arranged in a recess provided in a housing. The urging member urges at least one of the first bearing and the second bearing in a direction in which a center-to-center distance between the driving gear and the driven gear increases.

Owner:JTEKT CORP

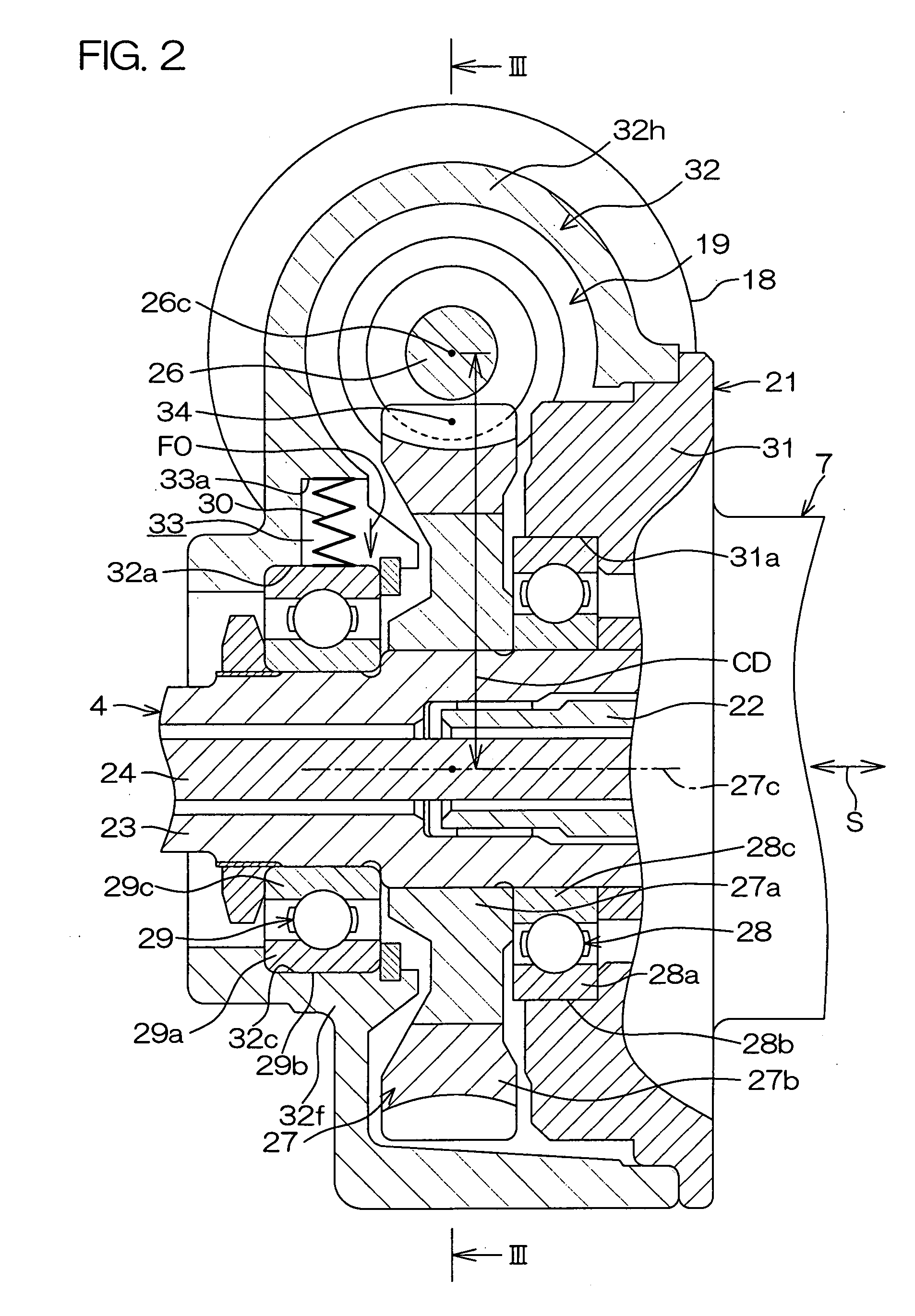

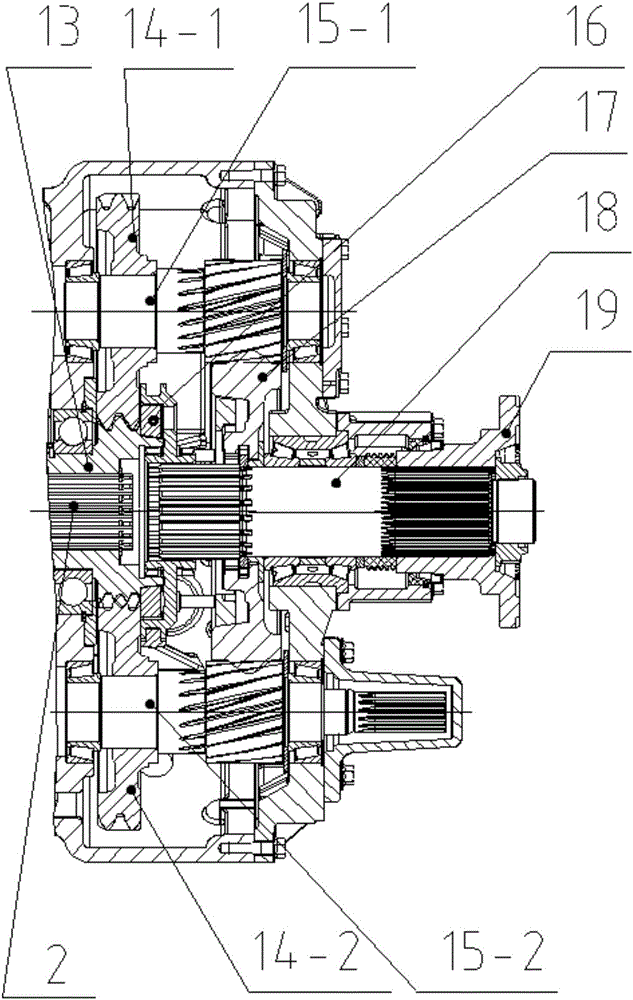

Heavy type 12-gear high torque transmission assembly

InactiveCN106015470AIncrease the center distanceImprove carrying capacityToothed gearingsGear lubrication/coolingLine shaftGear wheel

The invention provides a heavy-duty 12-speed high-torque transmission assembly, which is composed of a main box and an auxiliary box installed front and rear. The main shaft and the main shaft gear float radially. The 6 manual gears in the main box are set on the main shaft and connected with the shift fork to realize the gear switching, and the 2 pneumatic gears in the auxiliary box are set on the main shaft and connected with the The synchronizer connected with the shift fork realizes gear position switching, and the input and output gear pairs in the auxiliary box are both helical gears. The invention has reasonable gear positions, suitable speed ratio and large first gear speed ratio, and is a 12-speed high-torque transmission assembly with double countershafts with higher reliability, durability and fuel economy.

Owner:CHINA FIRST AUTOMOBILE

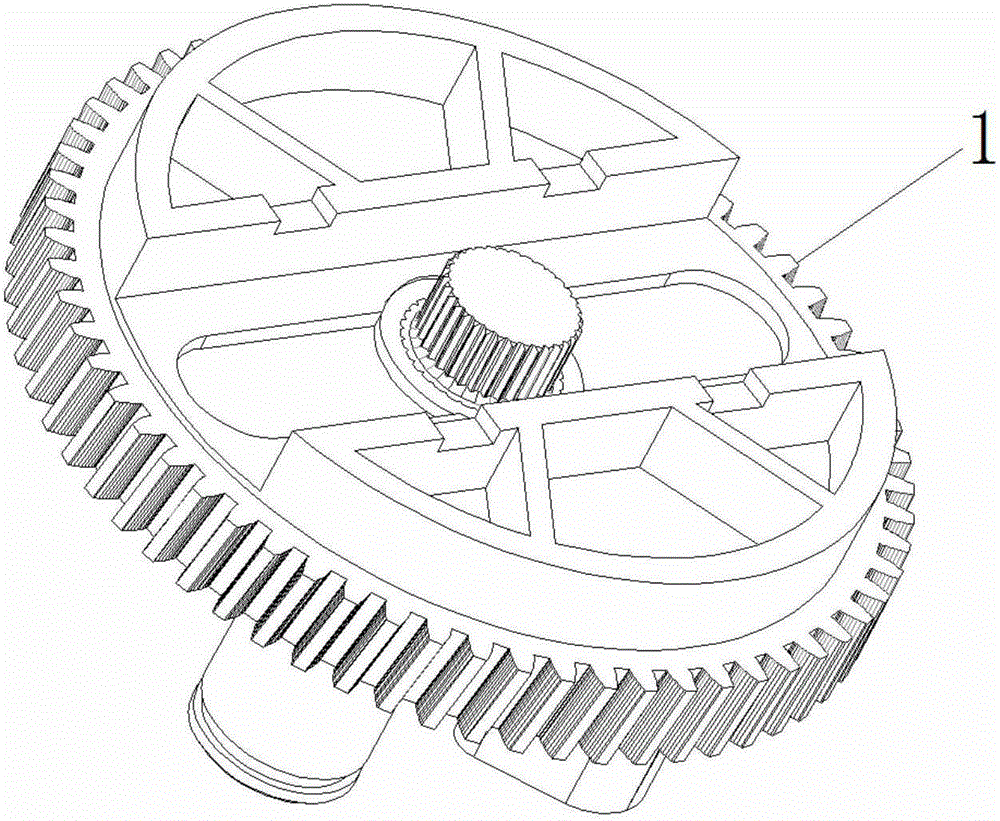

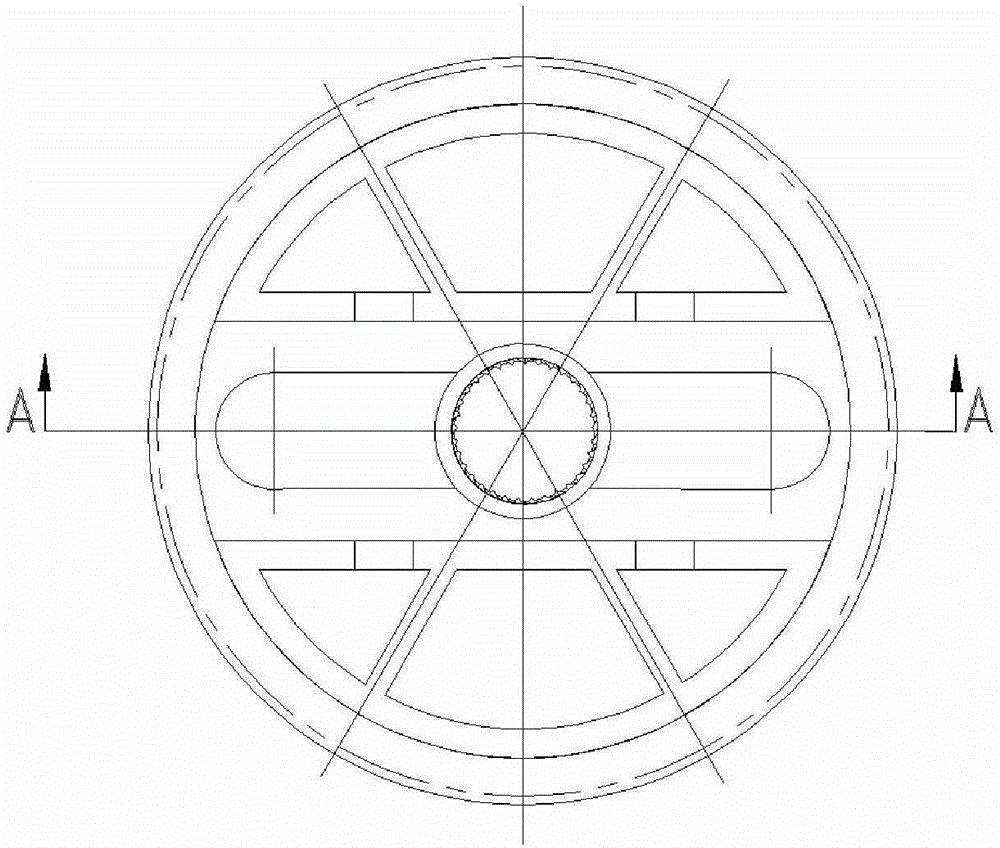

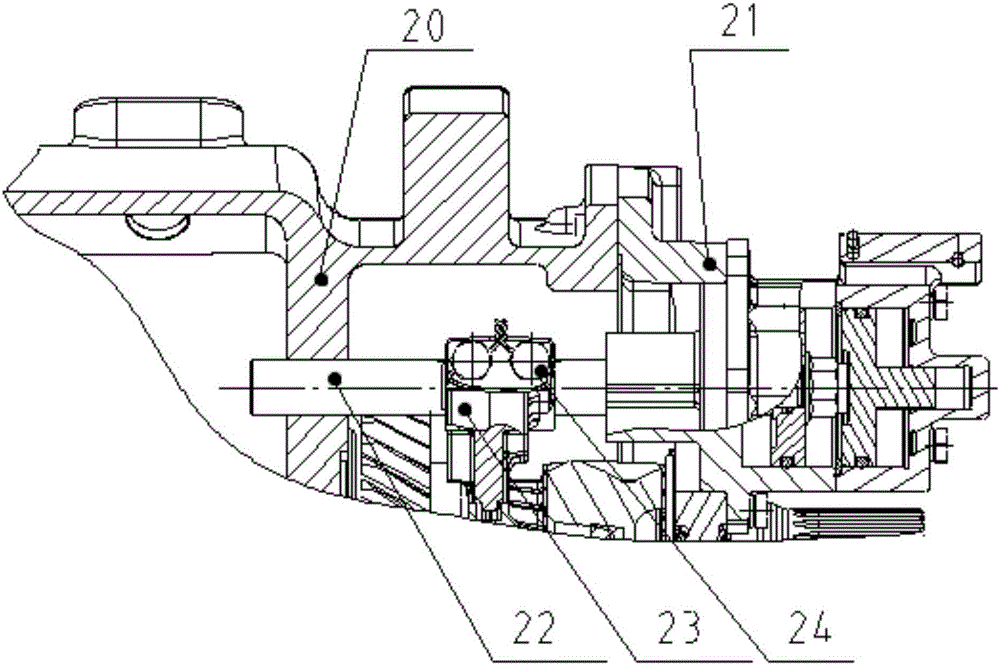

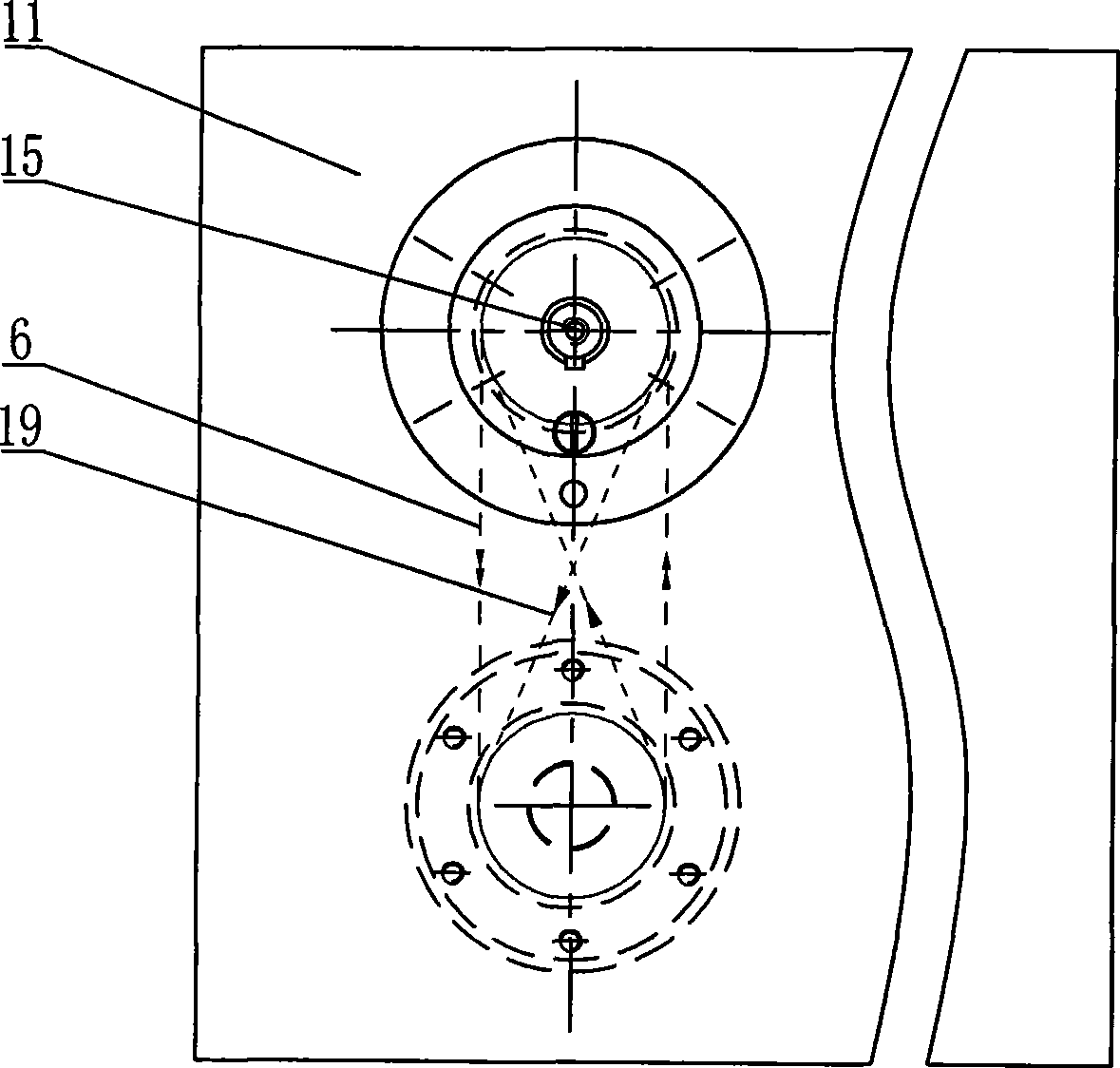

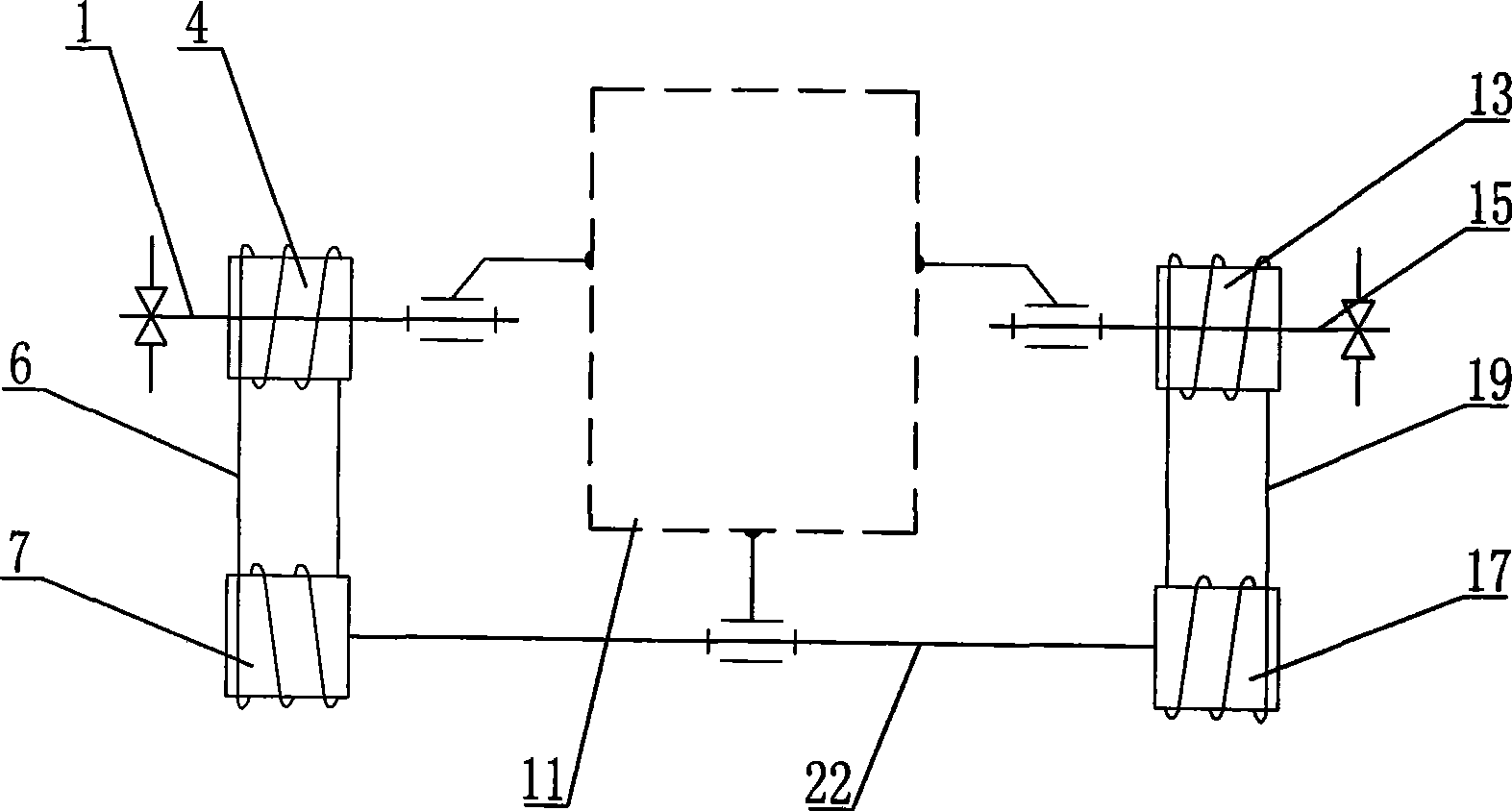

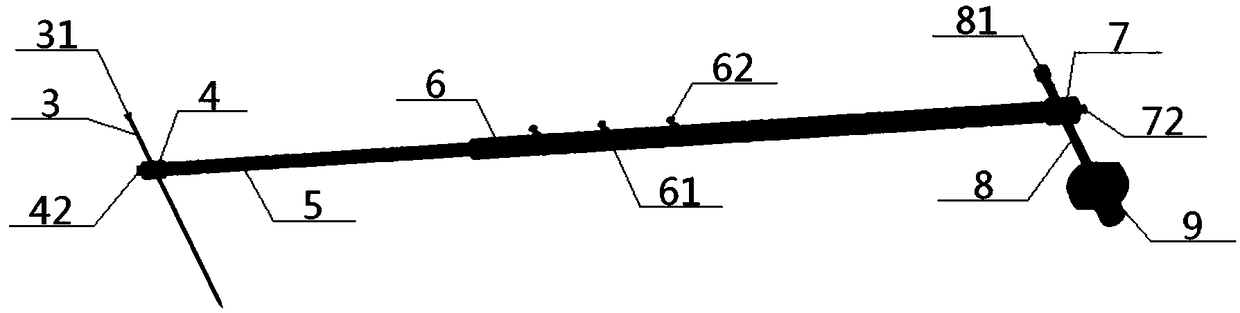

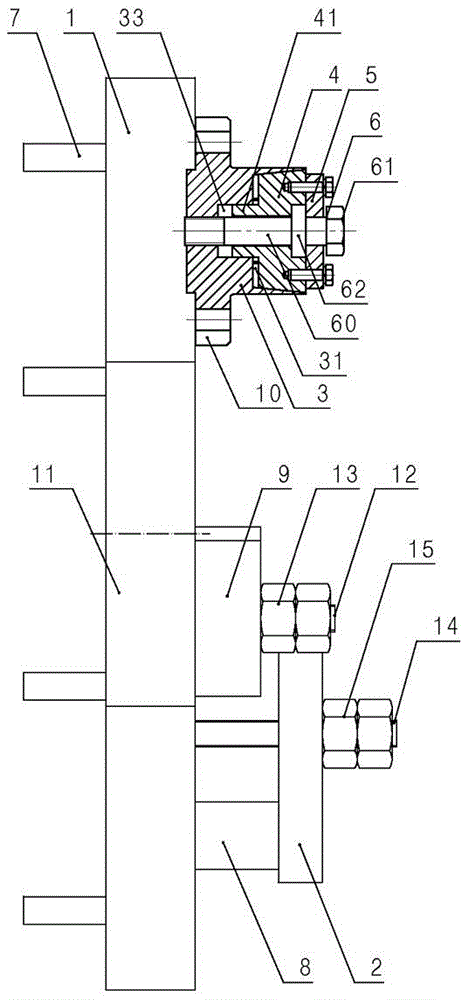

Cable type differential for detection vehicle

InactiveCN101363529ALight in massStructural symmetryDifferential gearingsVehiclesEngineeringWire rope

A rope differential used for a probe vehicle relates to a differential used for a probe vehicle, and solves the problem that the existing gear differential used for a probe vehicle adopts a bevel wheel for transmission, which has high processing cost and large mass owing, and a differential shell is arranged in a load platform, which occupies the inside storage space of the load platform and emits little effective load. The invention is composed of a co-rotating transmission unit, a reverse transmission unit and a hollow shaft (22); the co-rotating transmission unit and the reverse transmission unit are arranged at the two ends of the hollow shaft respectively; a co-rotating driven wire wheel (7) is arranged under a co-rotating driving wire wheel (4) which is connected with the co-rotating driven wire wheel (4) by a co-rotating wire rope (6); a reverse driven wire wheel (17) is arranged under a reverse driving wire wheel (13) which is connected with a reverse driven wire wheel (17) by a reverse wire rope (19). The differential has the advantages of reducing the space occupying of the load platform, being easy to arranged, having little mass and wider application scope.

Owner:HARBIN INST OF TECH

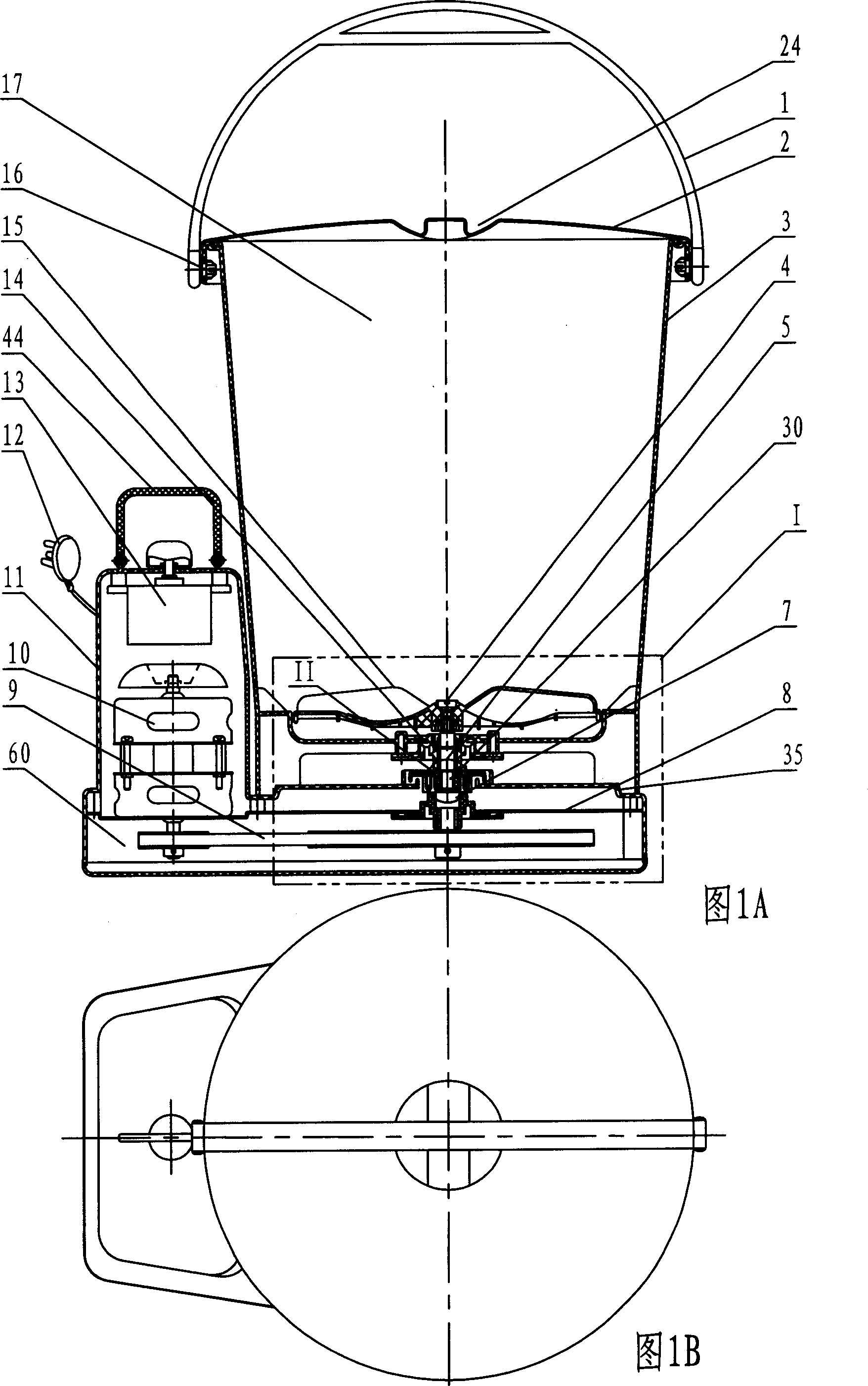

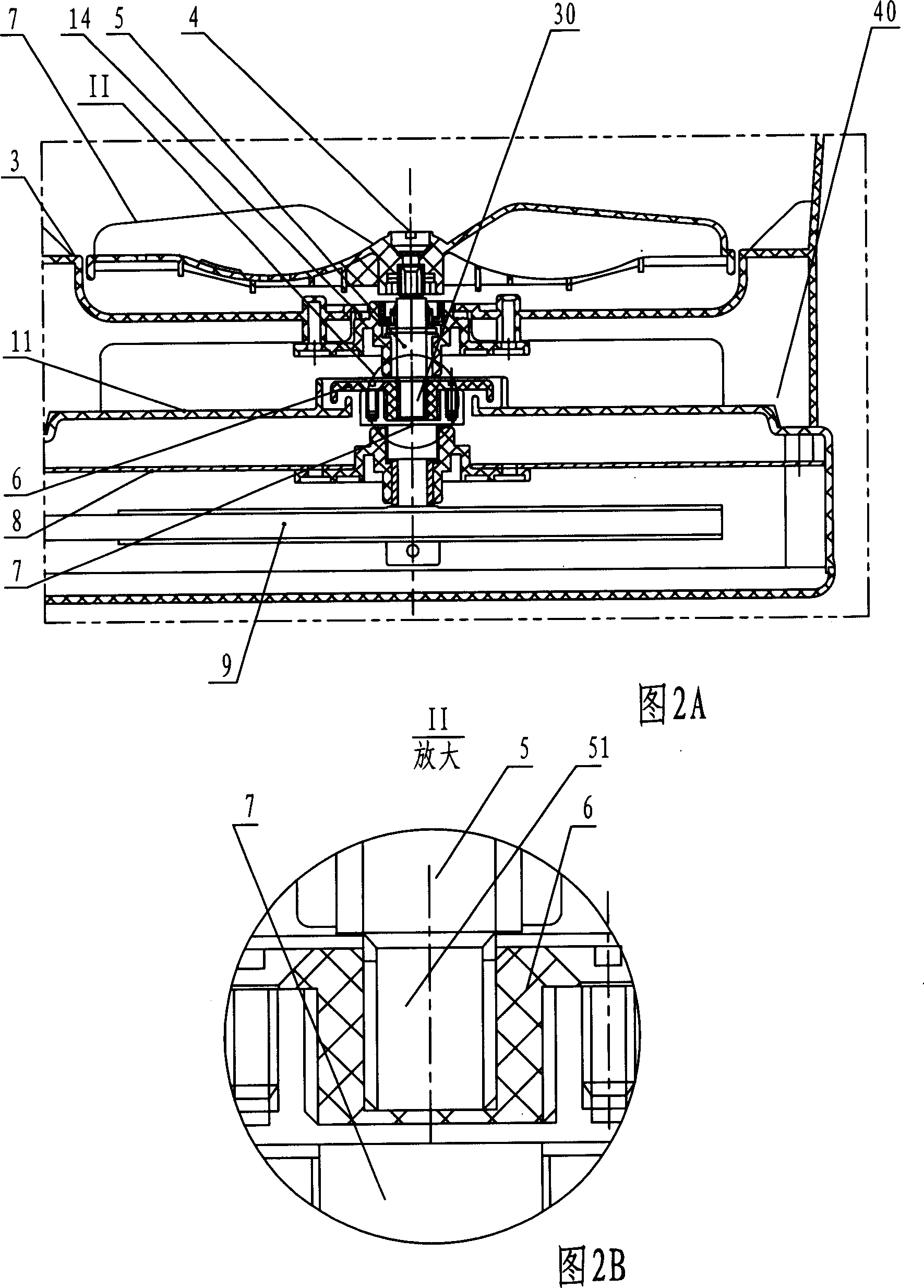

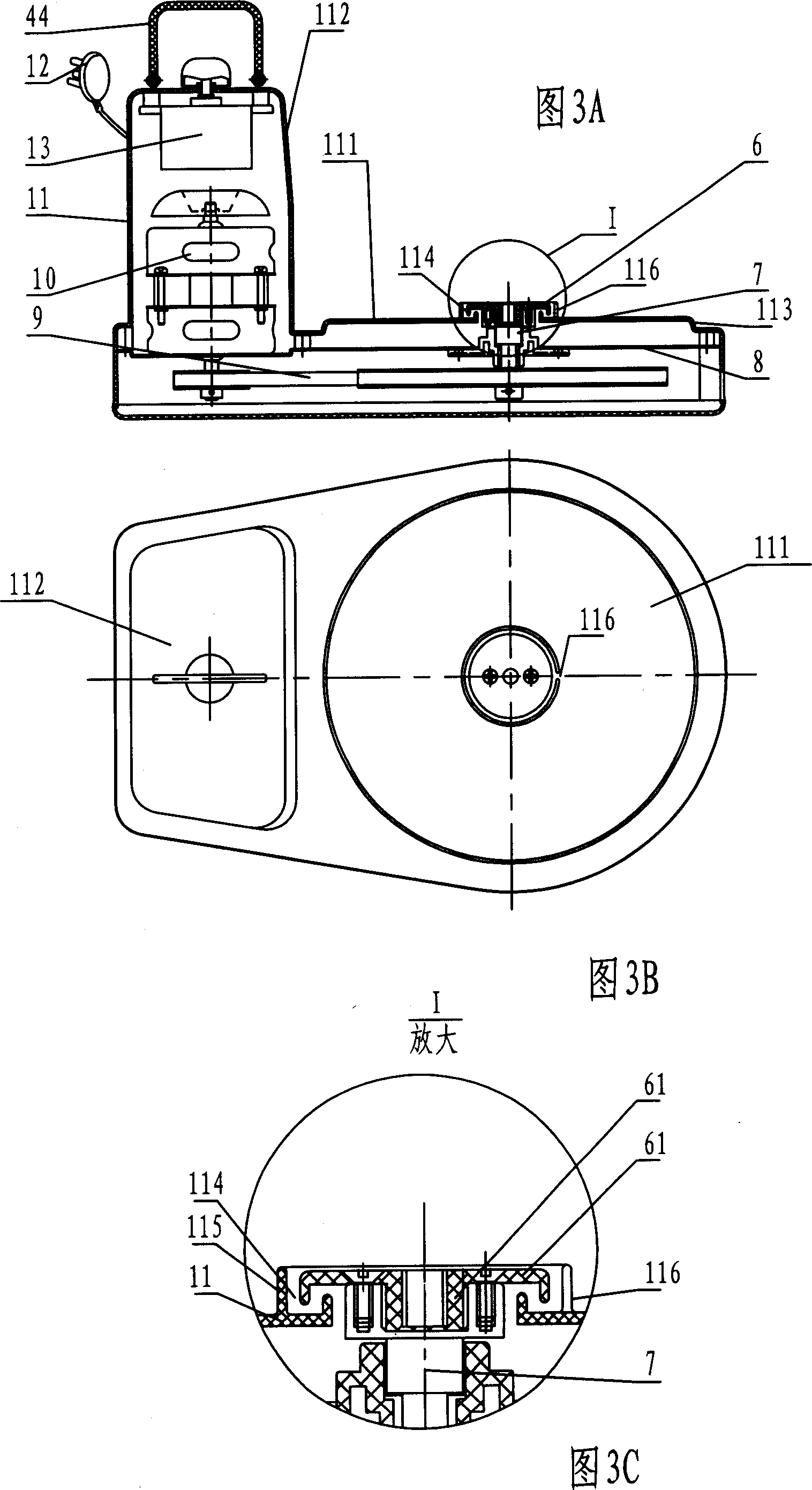

Portable split washing machine

InactiveCN1448573ALower the center of gravityStable jobOther washing machinesWashing machine with receptaclesCouplingMotor controller

The portable separated washing machine consists of two parts including separable washing barrel assembly and driver assembly. The washing barrel assembly includes washing barrel and stirring wheel installed on the rotating shaft in the bottom; and the driver assembly includes motor, transmission mechanism connected to the motor, motor controller and casing for holding the said parts. The casingis one L-shaped one comprising one horizontal casing and one vertical electric element casing with communicated inner cavities. The output shaft of the motor is set downwards inside the electric element casing, and the output shaft of the transmission mechanism is connected to the shaft of the stirring wheel via a detachable transmission coupling mechanism. The present invention has lower working gravity center, high stability and safety and low cost, and is favorable to setting belt transmission unit with great transmission ratio and preventing leakage.

Owner:JINLING ELECTRICAL CO LTD

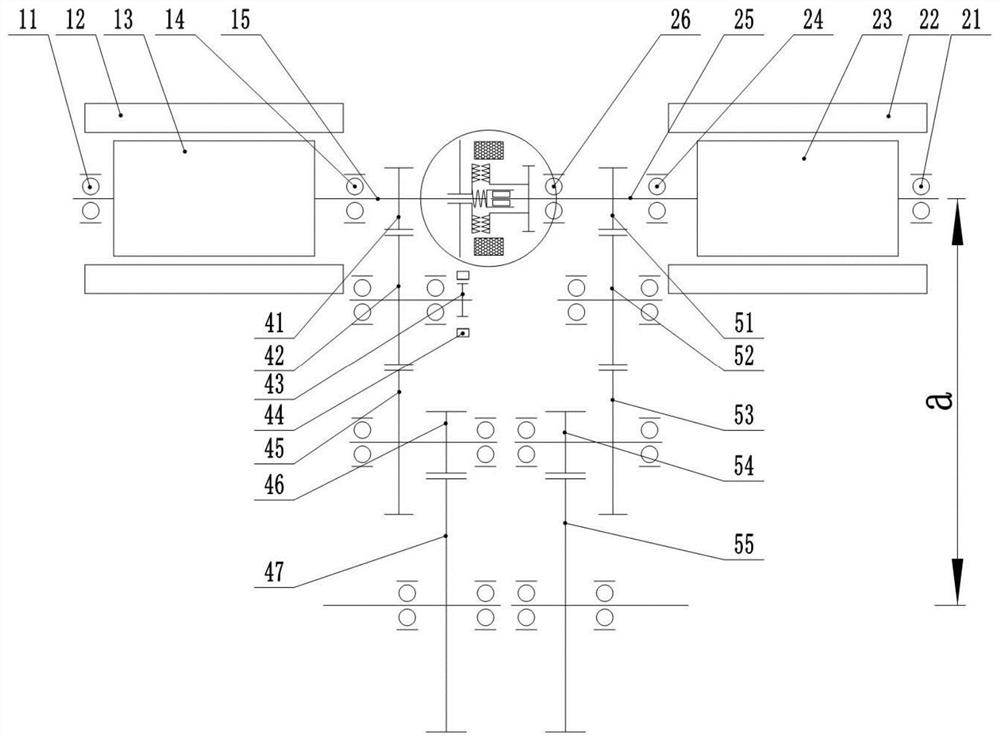

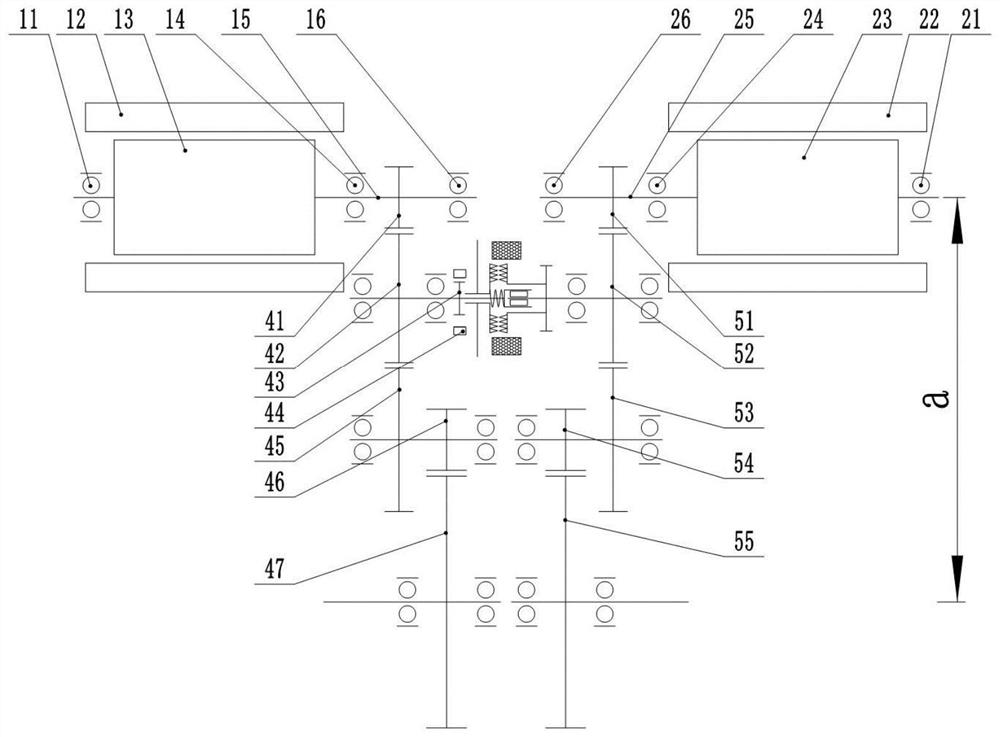

Method for adjusting engagement gap between balance shaft driven gear and crankshaft driving gear of engine

The invention discloses a method for adjusting an engagement gap between a balance shaft driven gear and a crankshaft driving gear of an engine. A technology gasket is mounted between the joint positions of a balance shaft fixing cover and an engine box body in a cushioned mode; a fixing disc of a crankshaft rotating device is mounted and fixed to the end portion of a crankshaft; a joint head of a balance shaft timing positioning device is mounted on the end portion of a second balance shaft in a sleeving mode; a supporting base of a balance shaft gap measuring device is fixed to the top face of an engine box body; the crankshaft is rotated, and the difference valve of the maximum value and the minimum value displayed on a dial indicator is read and recorded; the difference value between the real central distance and the non-backlash central distance of a driving gear and a second driven gear is calculated according to the engagement equation of a parallel cylinder gear; the thickness of a needed gasket which is mounted between the balance shaft fixing cover and the engine box body in a cushioned mode is determined; and finally the technology gasket is replaced by the gasket with the calculated thickness. The method can rapidly and accurately adjust the backlash value at the engagement position of the driven gear on the balance shaft and the driving gear on the crankshaft.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

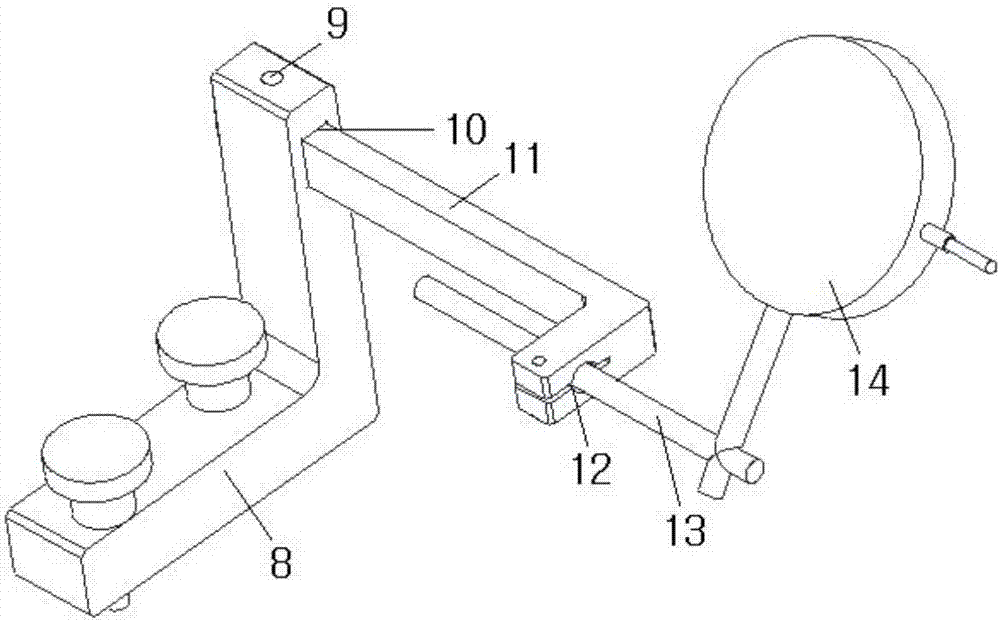

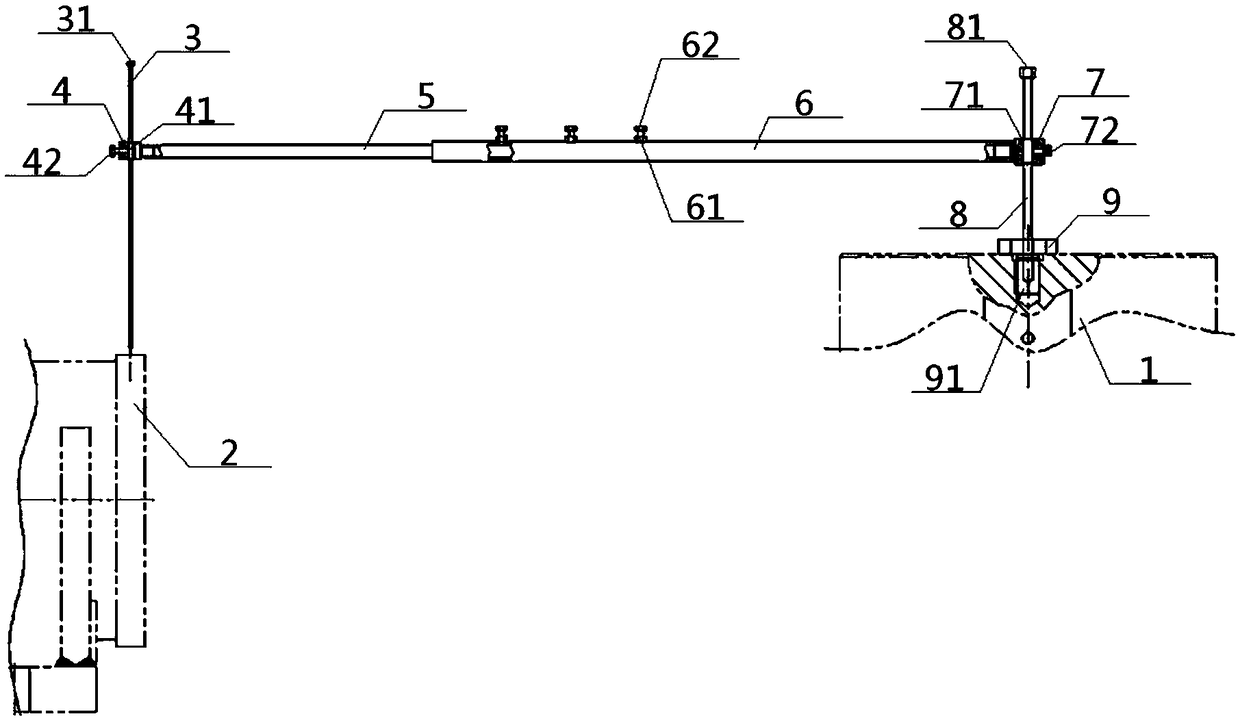

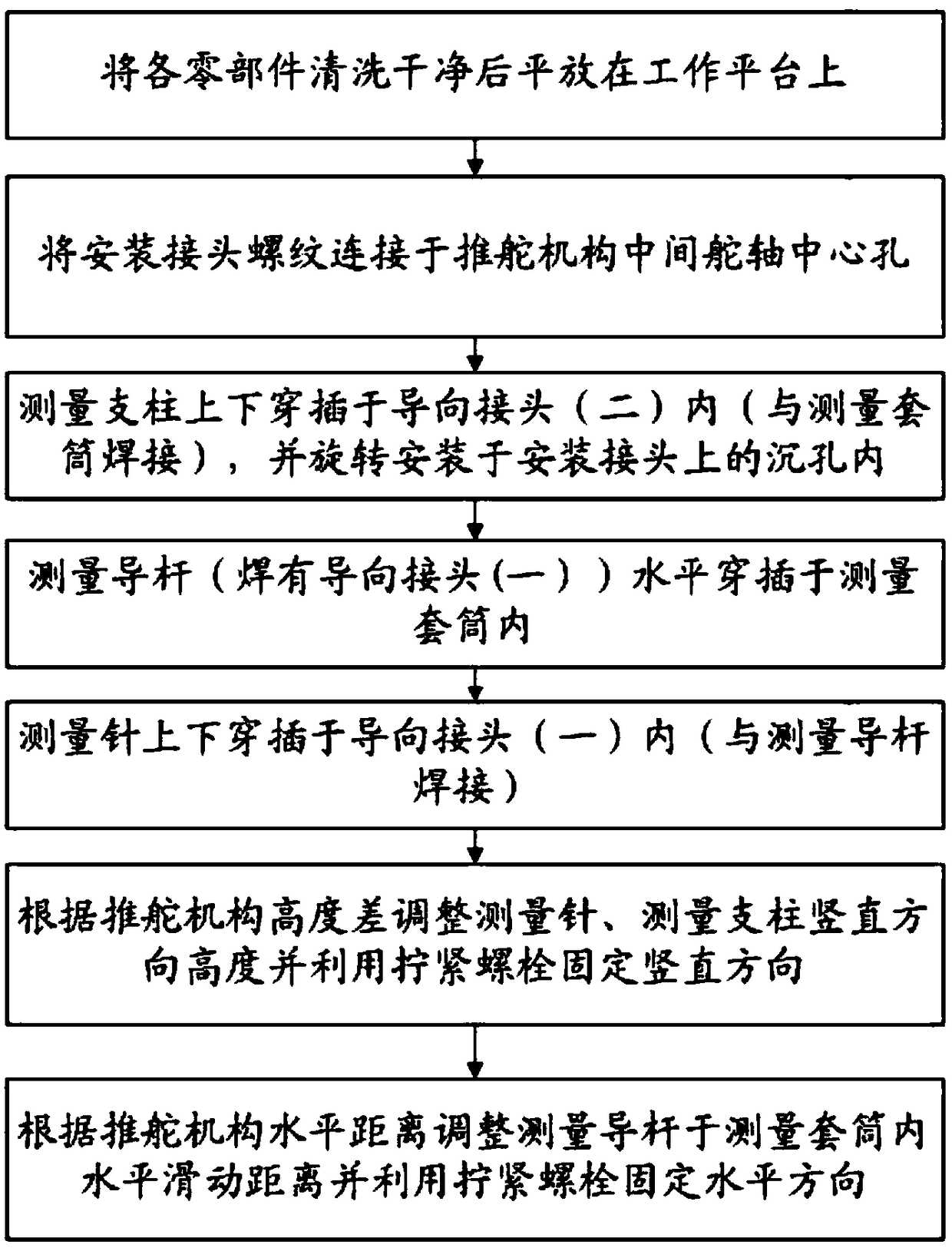

Mounting and adjusting tool applicable to fork plunger type steering engine and use method thereof

InactiveCN108942727AHigh precisionImprove adjustabilityWork holdersMetal-working hand toolsPunchingRudder

The invention discloses a mounting and adjusting tool applicable to a fork plunger type steering engine. The mounting and adjusting tool comprises a measuring pin, a guide sub I, a measuring guide rod, a measuring sleeve, a guide sub II, a measuring strut and a mounting joint; the measuring pin slides up and down along the interior of the guide sub I; the guide sub I is connected with the left endof the measuring guide rod; the right end of the measuring guide rod extends into the measuring sleeve for sliding fit; the measuring sleeve is connected with the guide sub II; and the bottom end ofthe measuring strut sliding up and down along the interior of the guide sub II is vertically connected with the mounting joint. During application, the heights of two different points are adjusted with the measuring pin and the measuring strut, and the distance between the two different points are adjusted by relative sliding of the measuring guide rod and the measuring sleeve, so that the actualdistance between a middle rudder shaft an oil cylinder is measured, and site installation is adjusted in real time according to an actual distance value and a theoretical value. The precision of the distance between the circle center of a punching point eye of the oil cylinder and the center of the middle rudder shaft of a rudder pushing mechanism can be improved, and equipment installation veracity and reliability can be guaranteed.

Owner:WUHAN MARINE MACHINERY PLANT

Dual-motor driving system assembly and vehicle

PendingCN112721620AIncrease the center distanceMeet the needs of large center distanceControl devicesElectric propulsion mountingGear wheelElectric machinery

The invention discloses a dual-motor driving system assembly and a vehicle. The dual-motor driving system assembly comprises a first motor and a second motor which are coaxially arranged, a first gear transmission, a second gear transmission and a plurality of idle wheel pairs, the first gear transmission is driven by the first motor, the second gear transmission is driven by the second motor, and the idler wheel pairs are arranged in the first gear transmission and the second gear transmission respectively and used for increasing the distance between an output shaft of the first motor and a tail end shaft of the first gear transmission. According to the scheme, due to the fact that the idle wheels are additionally arranged, the center distance between the input shaft and the output shaft in the assembly can be adjusted more flexibly by adjusting the size of the idle wheels, large-center-distance design is achieved, structural space brought by the large center distance is fully utilized for installing other components, and adjustment can be conducted according to space arrangement requirements and performance requirements of different clients.

Owner:JING JIN ELECTRIC TECH CO LTD

Automatic tensioning device for electric generator

The invention relates to the field of tensioning devices, and discloses an automatic tensioning device for an electric generator. The automatic tensioning device comprises an engine, the electric generator, a driving wheel, a driven wheel and a belt. The engine is provided with a first side wall and a regulating device. A rotating base is provided with a second side wall. The first side wall and the second side wall form a V-shaped groove. The regulating device comprises a piston cylinder and a piston. The piston is connected into the piston cylinder in a sliding mode. The piston is conical and abuts against the first side wall and the second side wall. A fixing ring coaxial with the electric generator is arranged on the periphery of the electric generator. A plurality of inflators are fixed to the inner wall of the fixing ring. Air plugs are connected into the corresponding inflators in a sliding mode, and compressed springs are arranged between the air plugs and the outer wall of the electric generator. All the inflators communicate with the piston cylinder through an air pipe. The automatic tensioning device for the electric generator is provided, and accordingly the electric generator belt can be tensioned automatically.

Owner:安徽能联科技有限公司

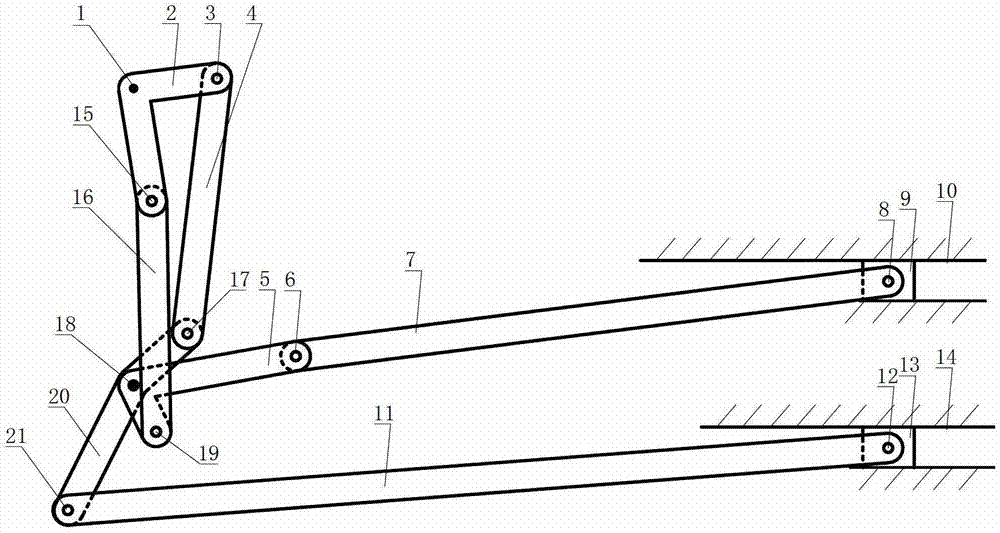

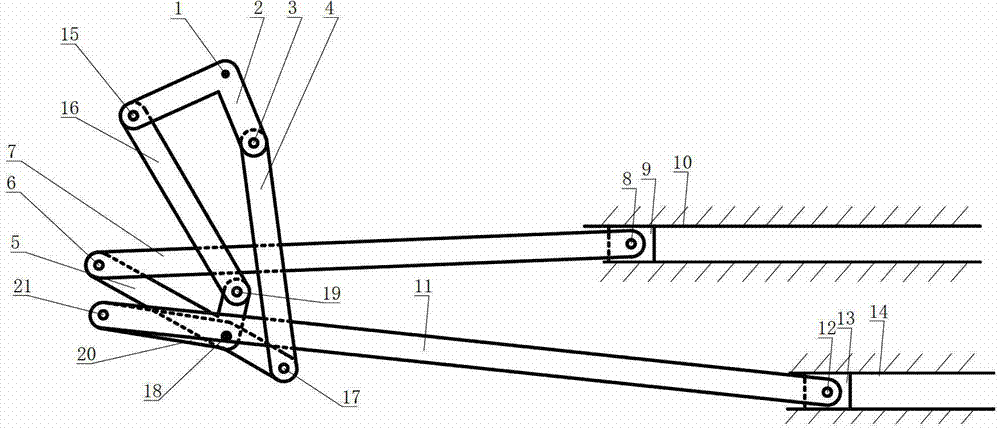

Double glide transmission mechanism

ActiveCN102881477ACompact structureReduce frictionContact driving mechanismsHigh-tension/heavy-dress switchesTime segmentEngineering

The invention provides a double glide transmission mechanism, which comprises a first glide transmission branch mechanism and a second glide transmission branch mechanism, wherein the first glide transmission branch mechanism and the second glide transmission branch mechanism comprise two slideways, two slide blocks, three connecting levers and four connecting rods; a few connecting levers and connecting rods are adopted, so that the double glide transmission mechanism is simple in structure and convenient to manufacture and mount and transmits large kinetic energy, and the double slide of the two slide blocks can be realized through one input; the three connecting levers employ two support shafts, and the structure is compact; small angles are formed between the connecting rods and the slideways, so that the friction between the slide blocks and the slideways is reduced and the slide blocks slide smoothly; and in a time interval in the moving process of the two slide blocks, one slide block decelerates, the other slide blocks accelerates, the decelerating impulse of the decelerating slide block helps accelerate the accelerating slide block, and drive energy is saved.

Owner:CHINA XD ELECTRIC CO LTD +1

Large torque reduction box for withdrawal and straightening machine

The invention relates to a large torque reduction box for a withdrawal and straightening machine. One or more stages of cylinder gear transmission sets, a tail stage taper gear, a tail stage gear shaft, an output large gear and an output hollow shaft are arranged in a box, a motor flange is arranged on one side of the box, an input gear shaft extends into the box from the motor flange, the part, outside the box, of the input gear shaft is connected with a coupler, a tooth part of the part, inside the box, of the input gear shaft is in transmission connection with the one or more stages of cylinder gear transmission sets, a cylinder gear shaft of the last stage of cylinder gear transmission set in the one or more stages of cylinder gear transmission sets is provided with a small taper gear,the small taper gear is meshed with a tail stage large taper gear connected to the tail stage gear shaft in a sleeving manner, and the tooth part of the tail stage taper gear is meshed with an outputlarge gear connected to the output hollow shaft in a sleeving manner. The large torque reduction box is simple in structure and capable of effectively giving consideration to the high speed ratio andthe large torque.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

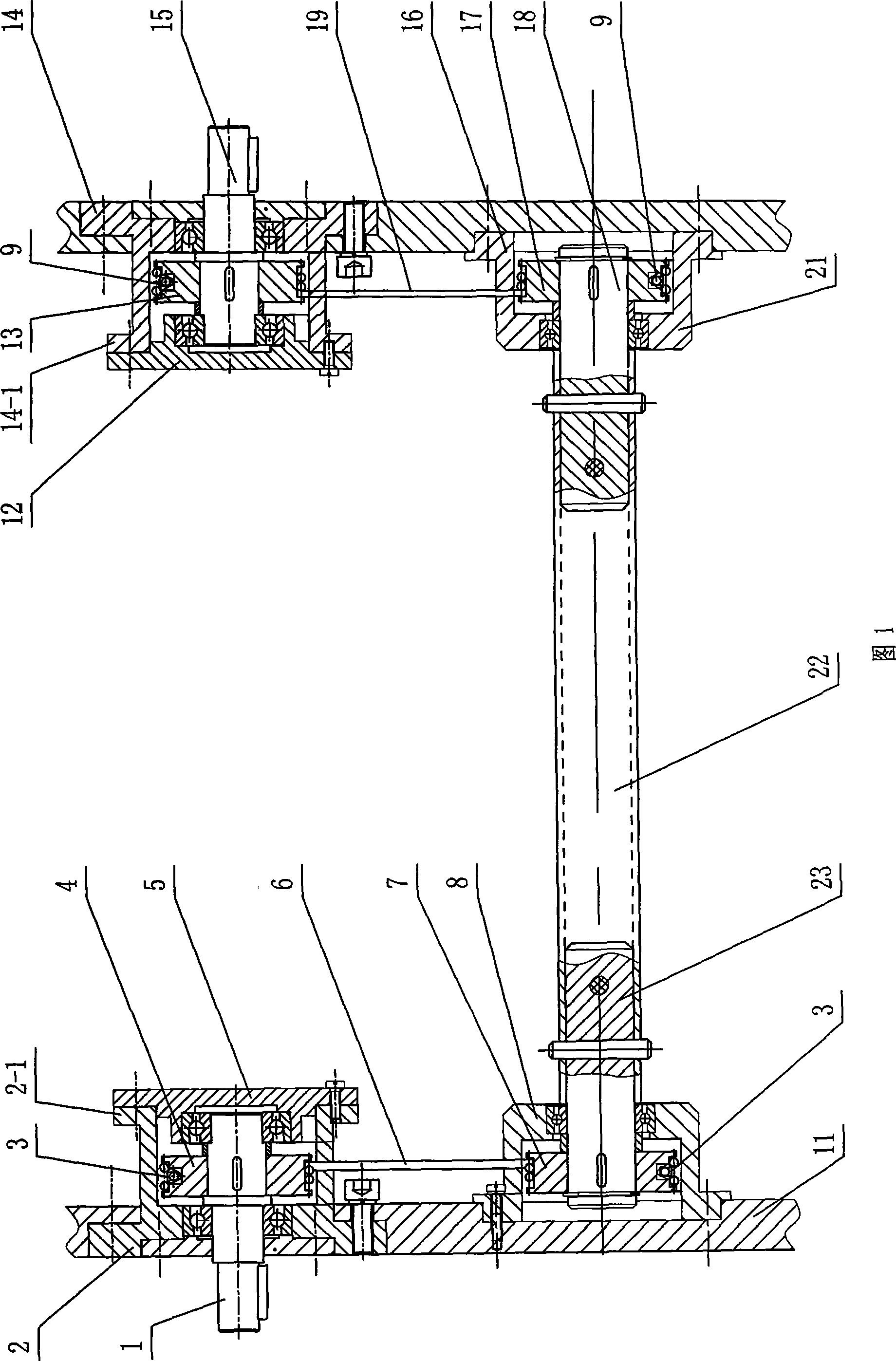

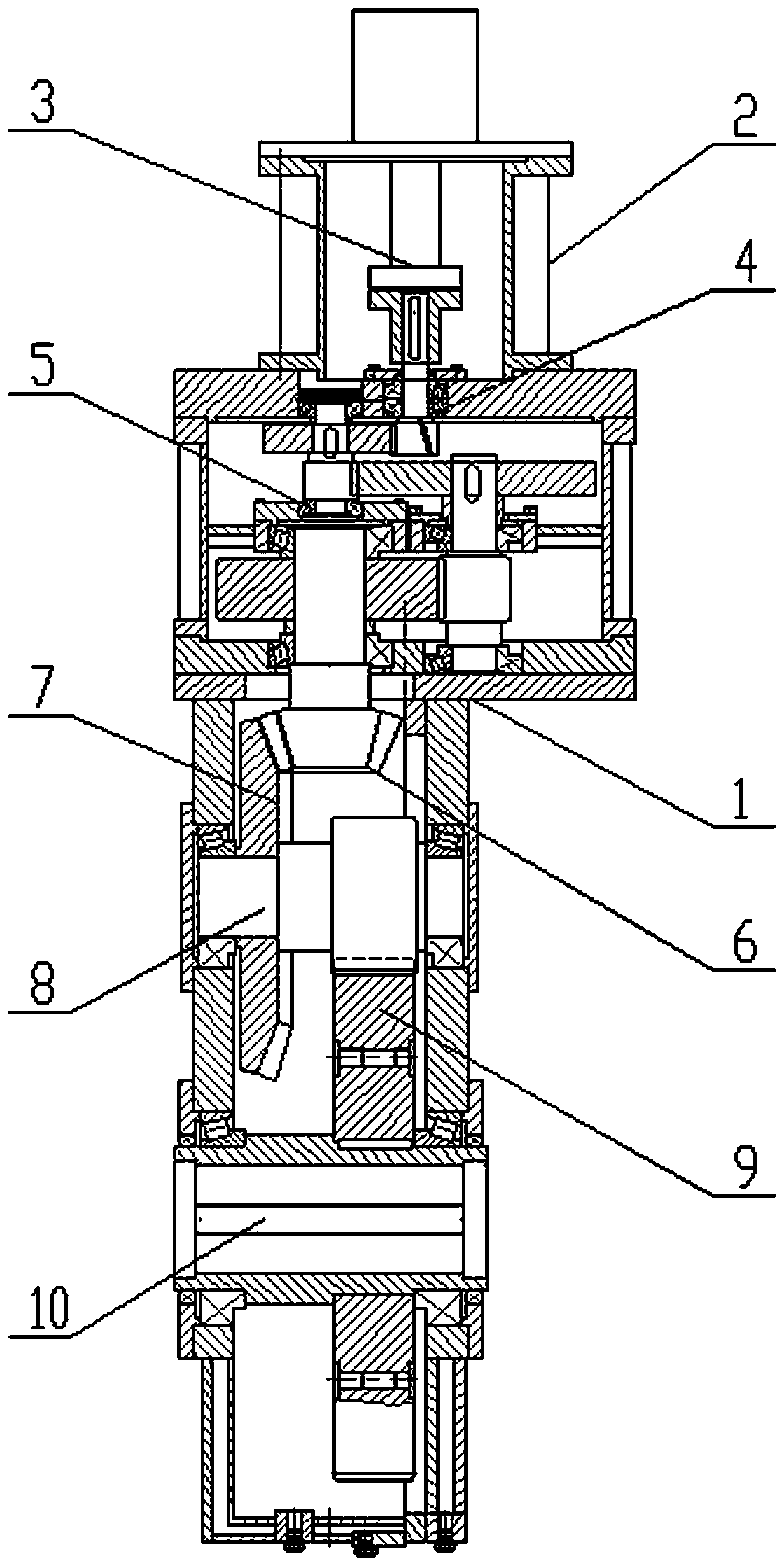

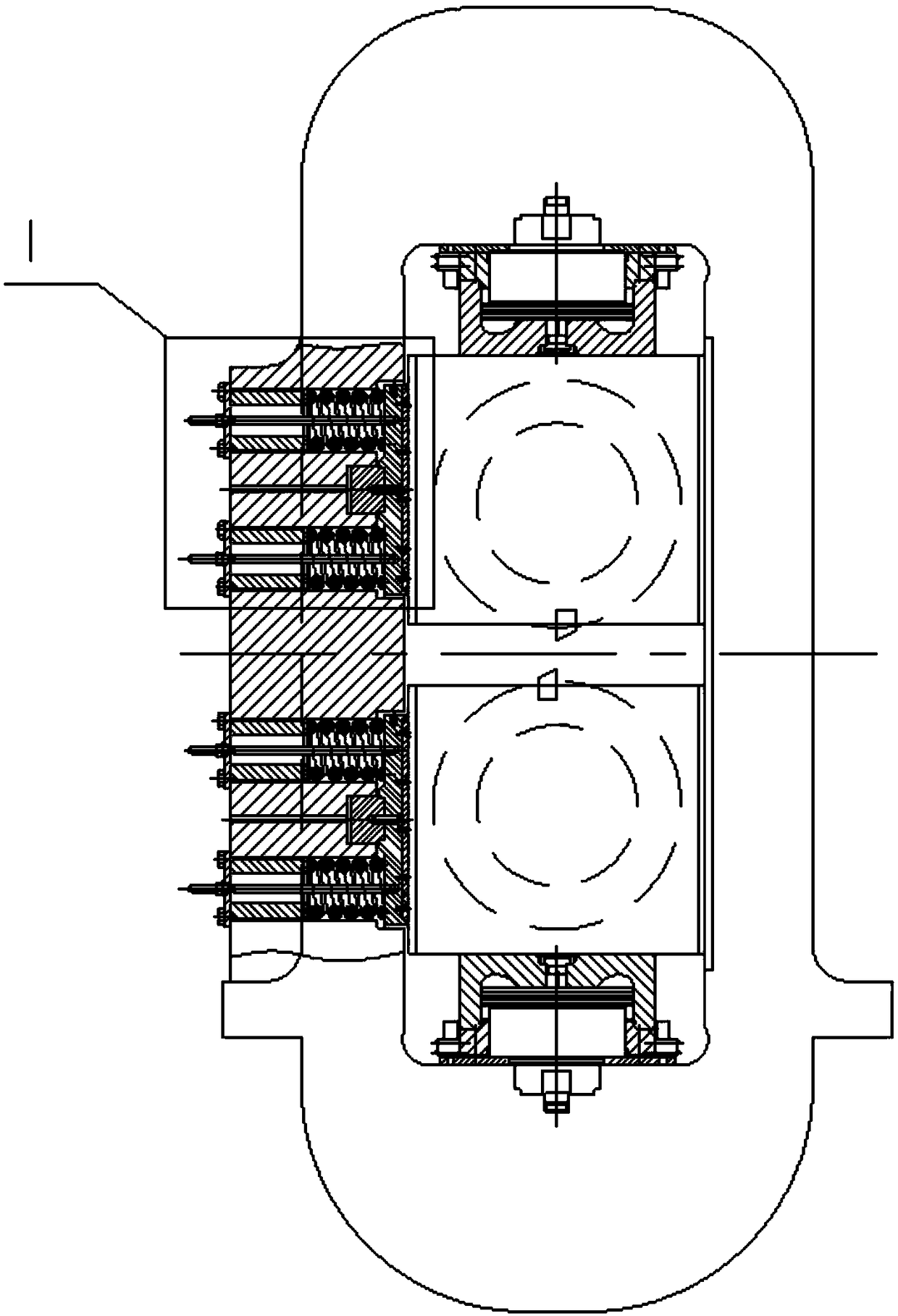

Double-screw compressor for high pressure system

InactiveCN100340769CIncrease the center distanceIncrease stiffnessRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

The invention discloses a double screw rod compressor for a high pressure system, comprising a working cavity composed of positive rotor and negative rotor, mutually engaging, and casing; the casing is provided with air intake and air outlet, the extension shaft of the positive rotor is provided with shaft seal, and air inlet and outlet channels are arranged in the casing; each of the negative and positive rotors has bearings which bear axial and radial forces and are distributed on two ends and in the middle; each of the negative and positive rotors are provided with two spiral sections whose tooth shape and size are the same as those of two spiral sections of a rotor, where the teeth correspond one to one and their spiral directions are opposite; the ratio of length to diameter of the spiral section is 1:1-1:1.2, the positive rotor has five or six teeth and the negative has seven or eight teeth, and the diameter of root circle of the negative rotor is not less than that of the positive rotor. Its exhaust pressure can be up to 15MPa, able to be widely applied to high pressure systems of critical CO2 refrigeration, process compression, oil gas mixed transport, etc.

Owner:SUZHOU HALDANE NEW ENERGY

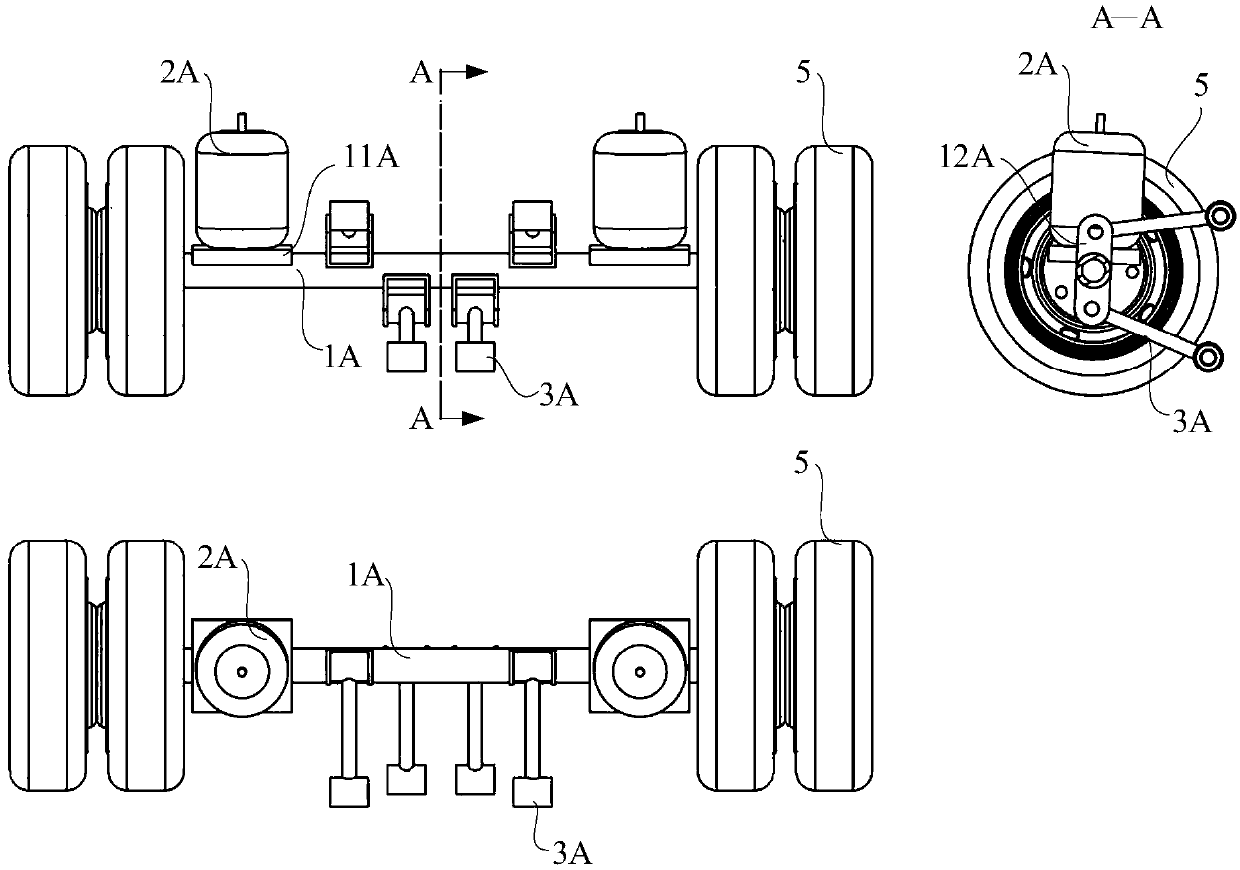

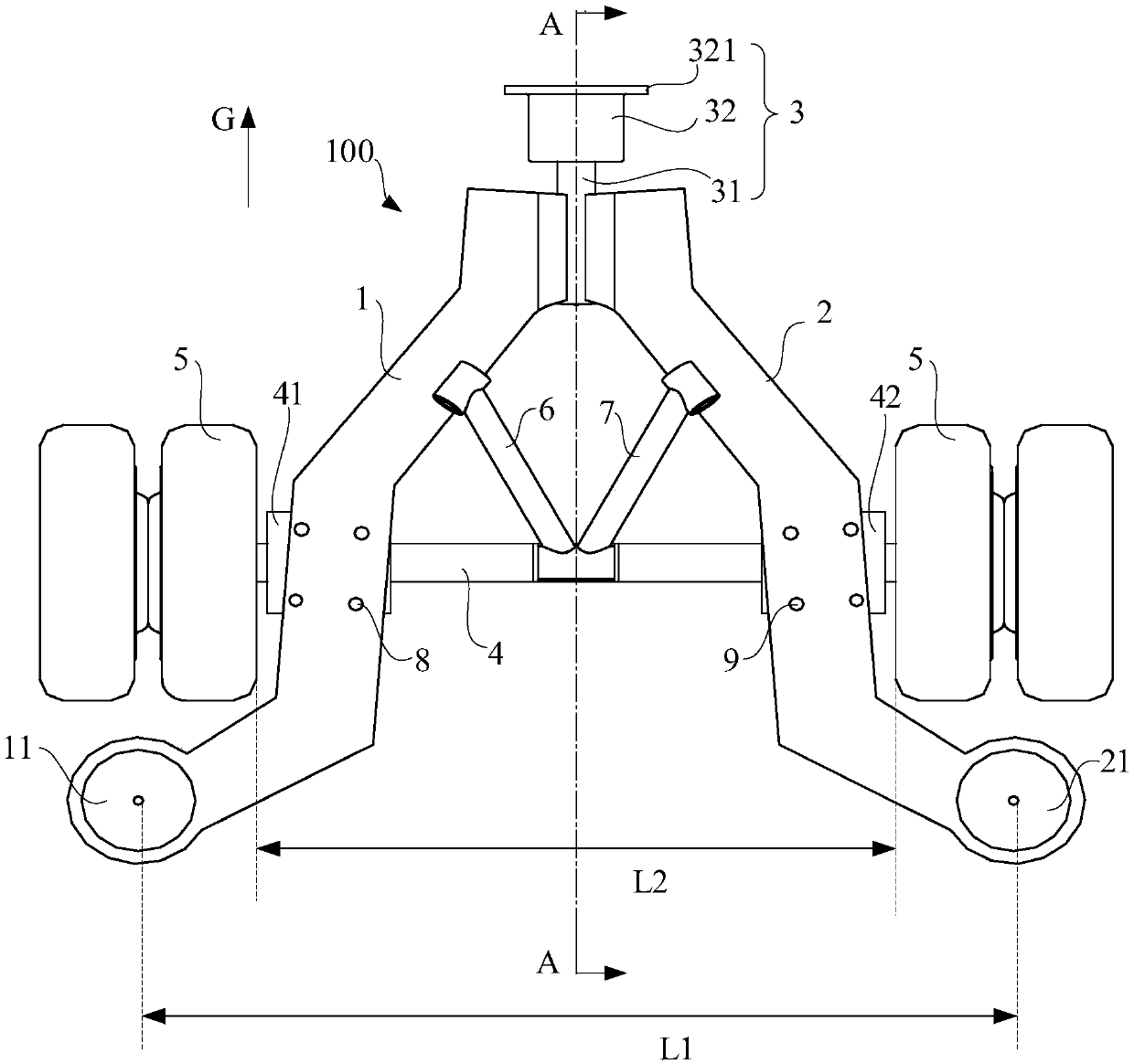

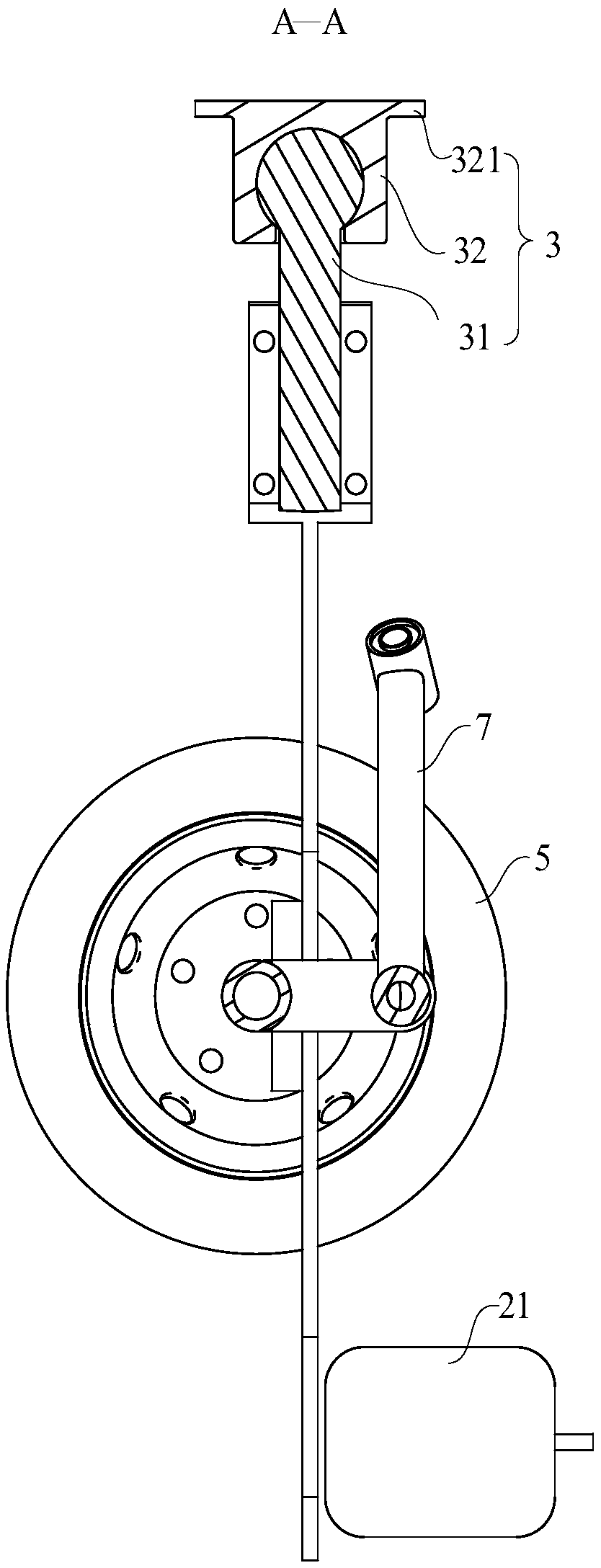

Air suspension and vehicle

PendingCN109515093AIncrease the center distanceImprove roll stiffnessResilient suspensionsVehicle frameAir spring

The invention discloses an air suspension and a vehicle. The air suspension comprises an intermediate section, a first supporting arm and a second supporting arm fixed on and connected to an axle respectively; the first end of the first supporting arm is fixedly connected with the first end of the second supporting arm, the first ends of the first supporting arm and the second supporting arm are connected to a vehicle body or a vehicle frame through a connecting assembly jointly, the second ends of the first supporting arm and the second supporting arm extend to both ends of the axle respectively, and the distance between the second ends of the first supporting arm and the second supporting arm is greater than the distance between two tires connected to both ends of the axle; and the second ends of the first supporting arm and the second supporting arm are connected to the vehicle body or the vehicle frame through a first air spring and a second air spring respectively, and the first supporting arm and the second supporting arm form a V-shaped structure jointly.

Owner:ZHEJIANG PANGOOD POWER TECH CO LTD

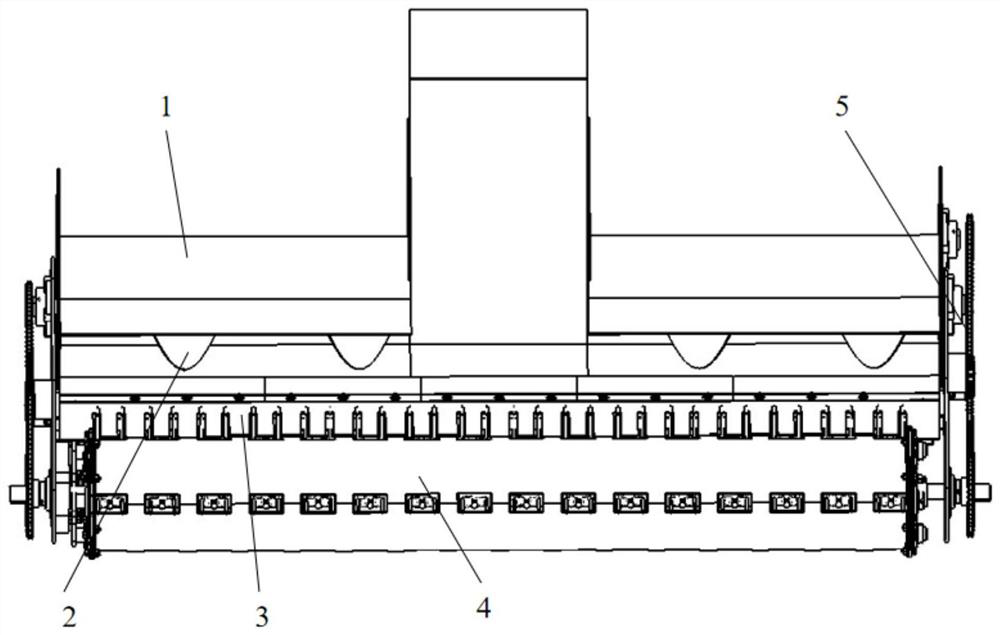

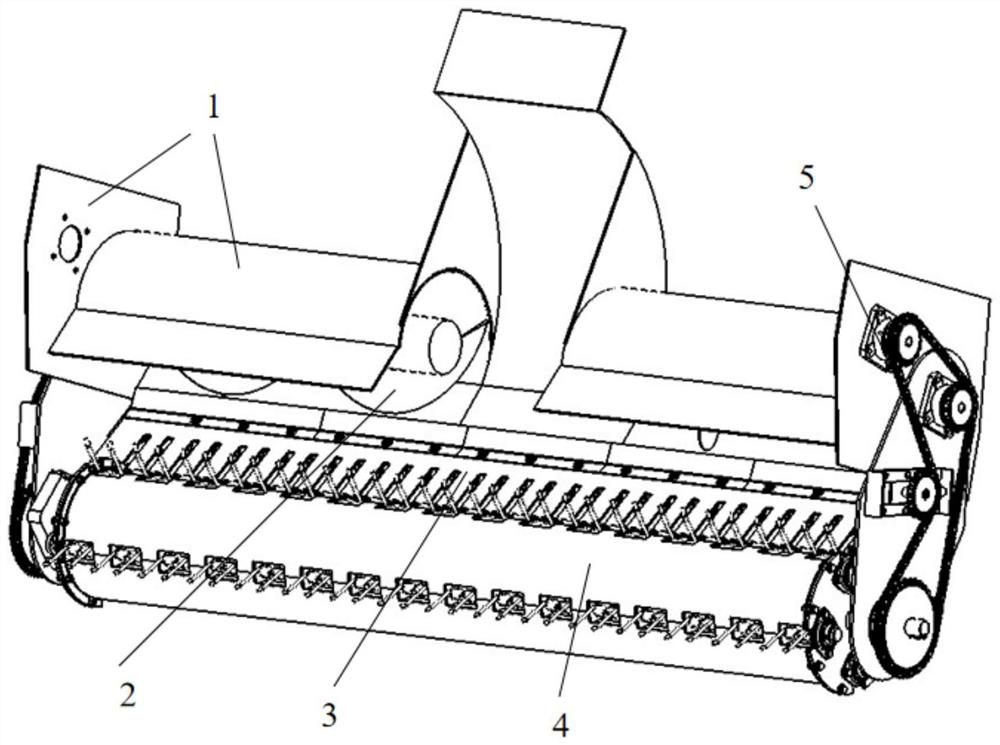

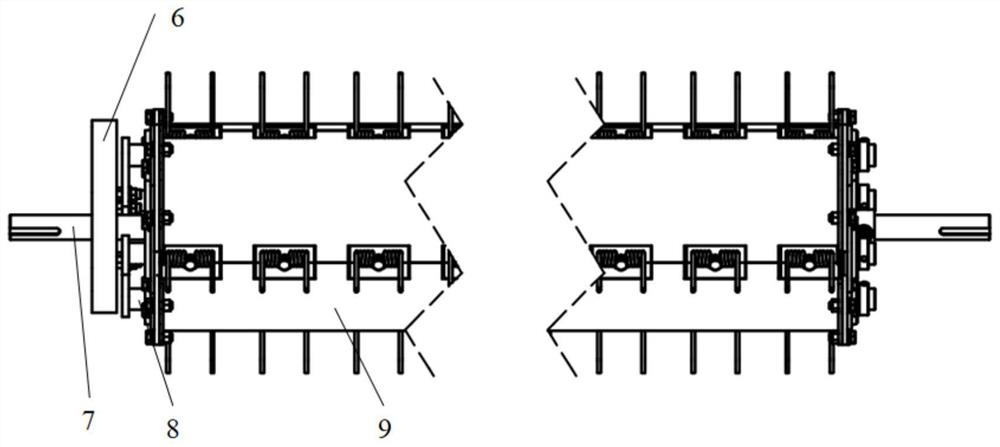

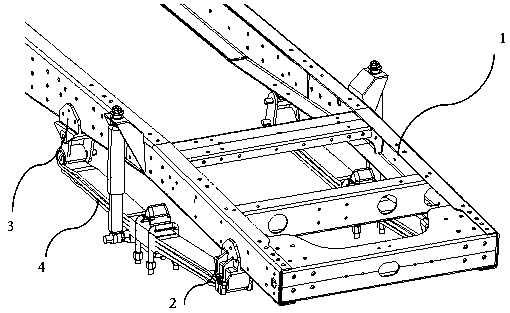

A spring tooth picker without retainer and a baler

ActiveCN112913479BIncrease speedExtend your lifeLoadersAgriculture gas emission reductionDrive shaftEngineering

The invention provides a spring tooth picker without retaining ring and a baler, including a main frame, a pick-up device assembly, a transition device, a conveying auger and a transmission system; both ends of the pick-up device assembly are connected with the main frame; The two ends of the conveying auger are connected with the main frame and located behind the transition device; the transmission system is respectively connected with the conveying auger and the pick-up device assembly; the pick-up device assembly Including cam slideway, transmission shaft assembly, multiple gear rod assembly and arc welded plate assembly; the cam slideway is connected with one side of the main frame; one end of the transmission shaft assembly is connected with the cam slideway through a bearing seat; the gear rod The assembly and the arc-shaped welded plate assembly are alternately distributed around the transmission shaft assembly, and both ends of the gear rod assembly and the arc-shaped welded plate assembly are connected to the transmission shaft assembly. The invention avoids the problem of blocking long straws in the gaps of the retaining ring, and improves the picking efficiency.

Owner:JIANGSU UNIV

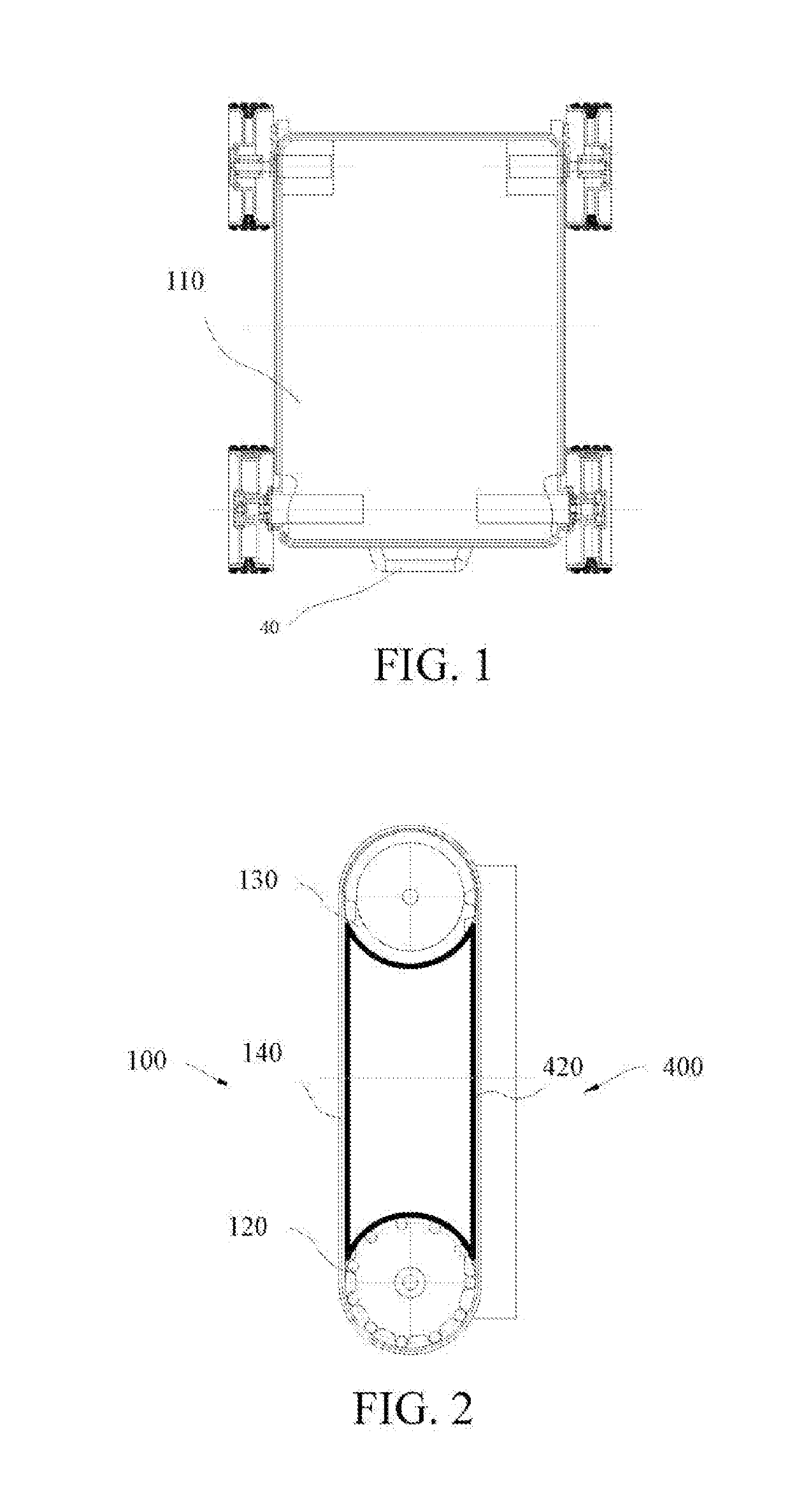

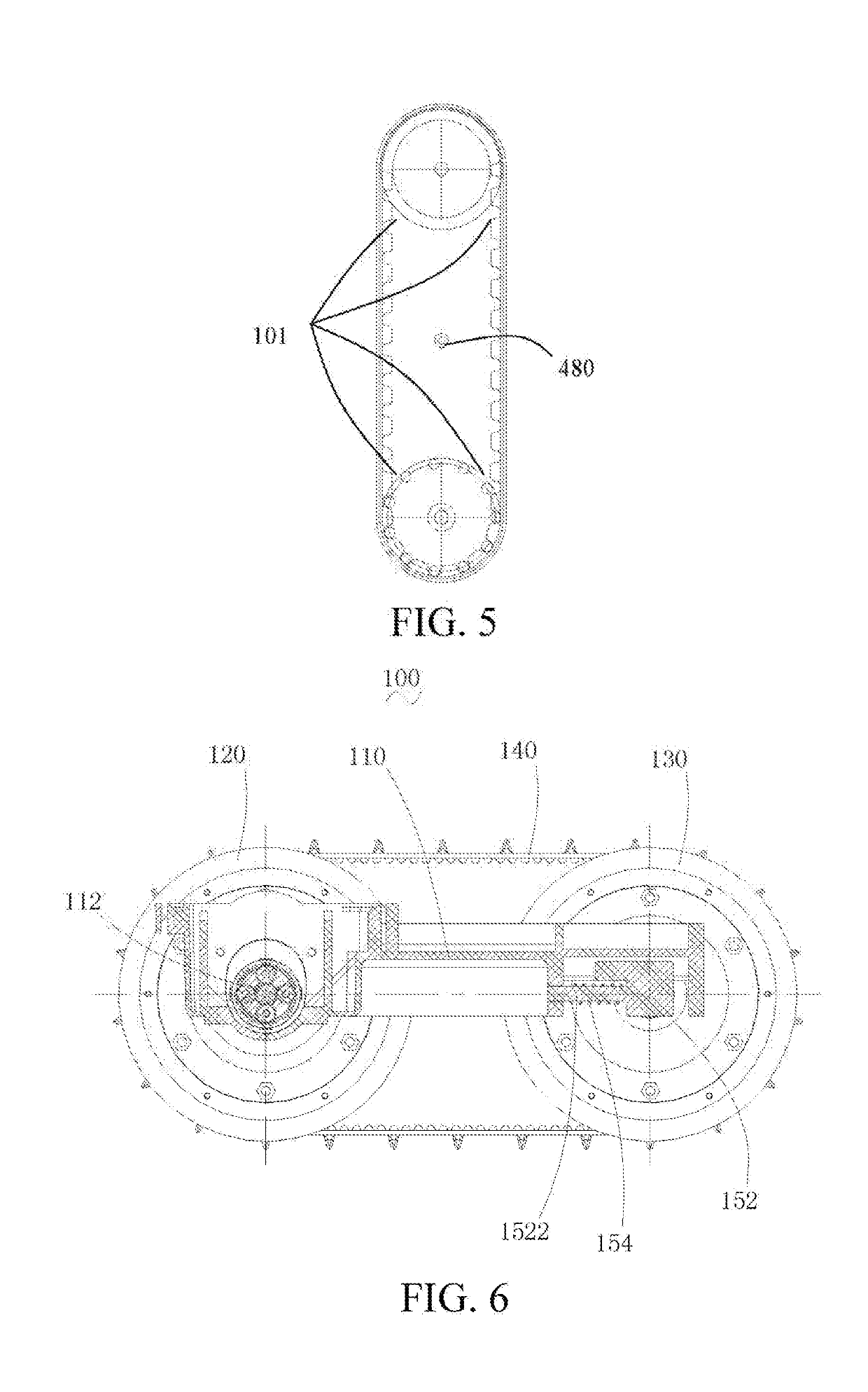

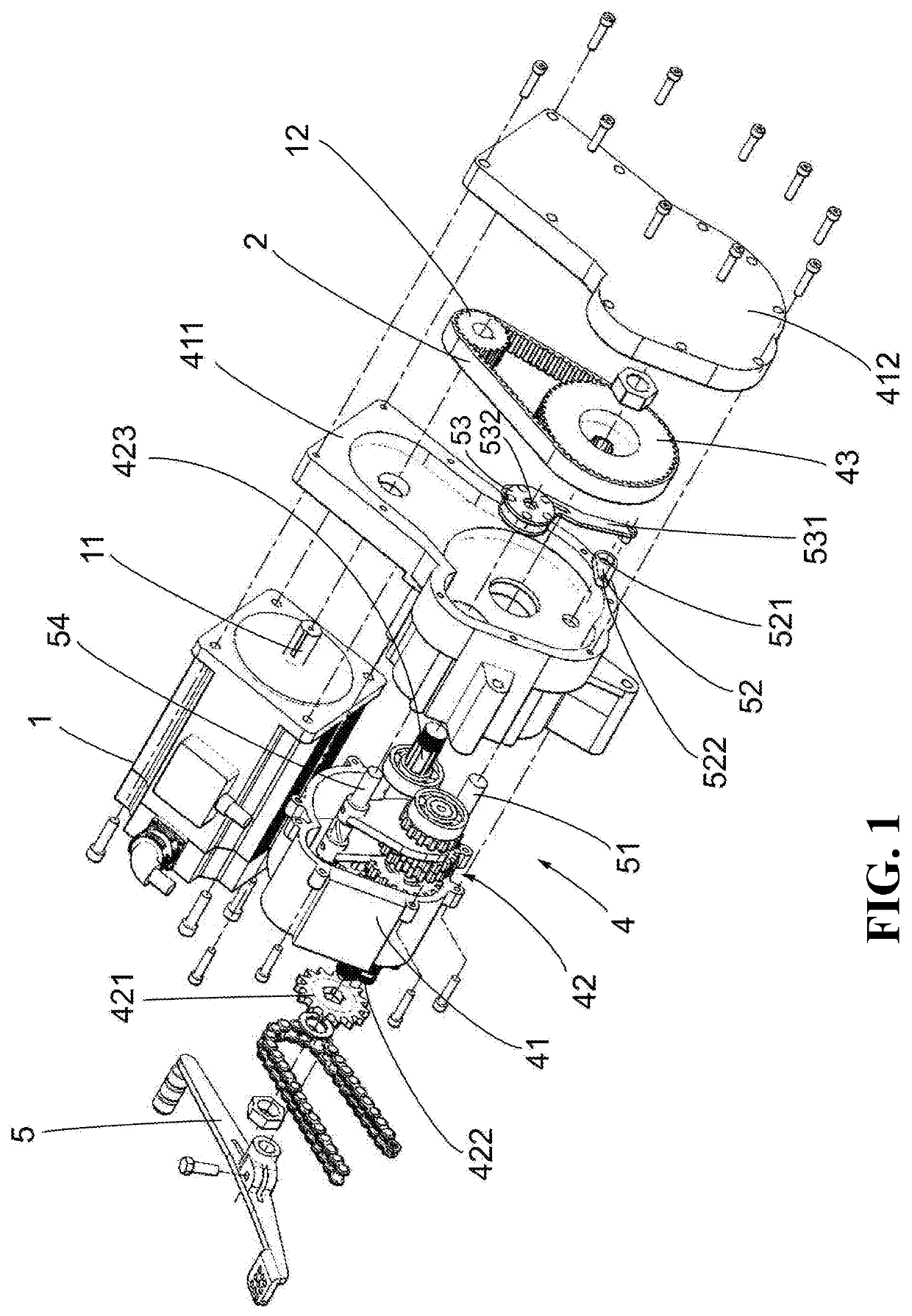

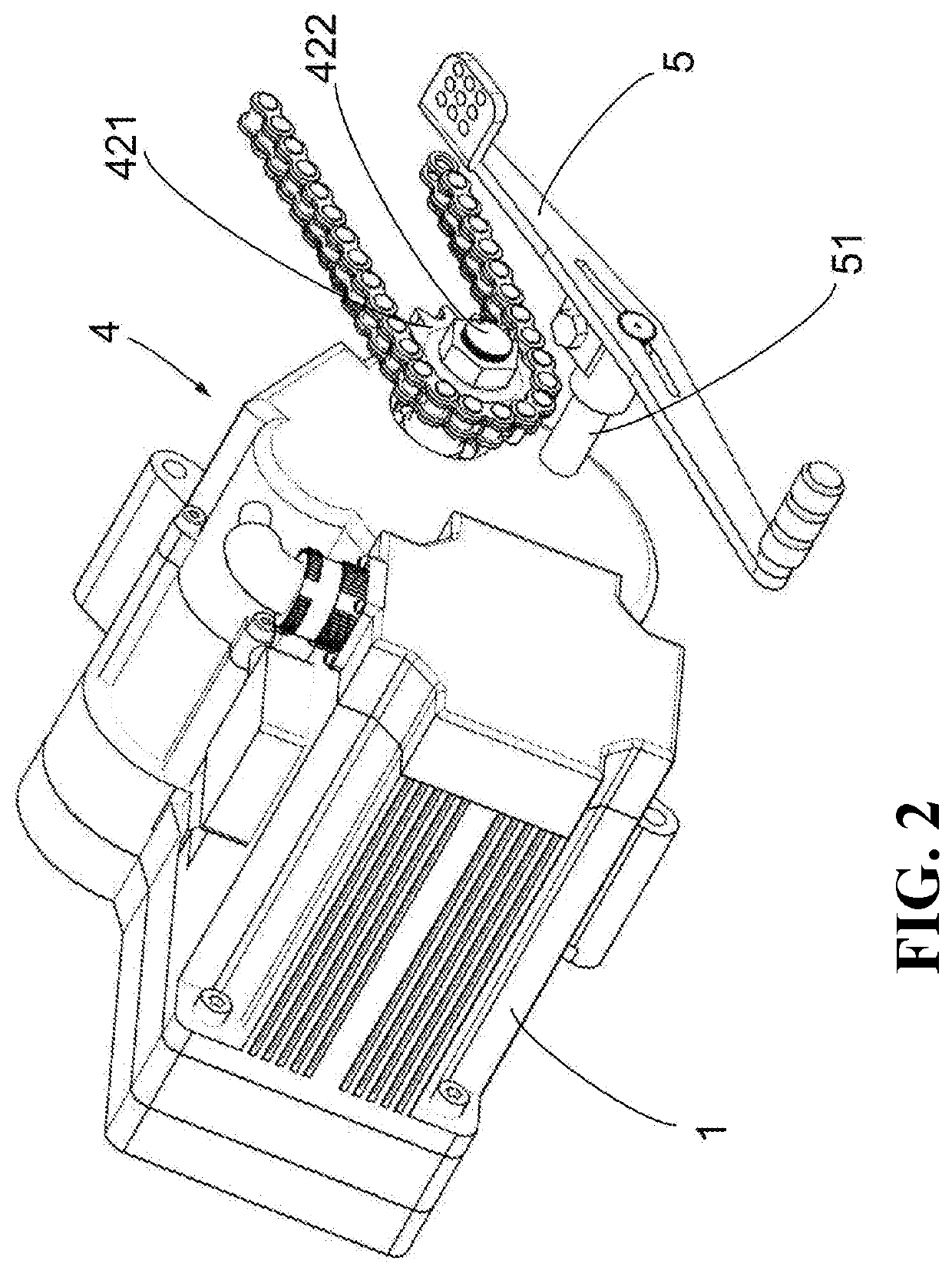

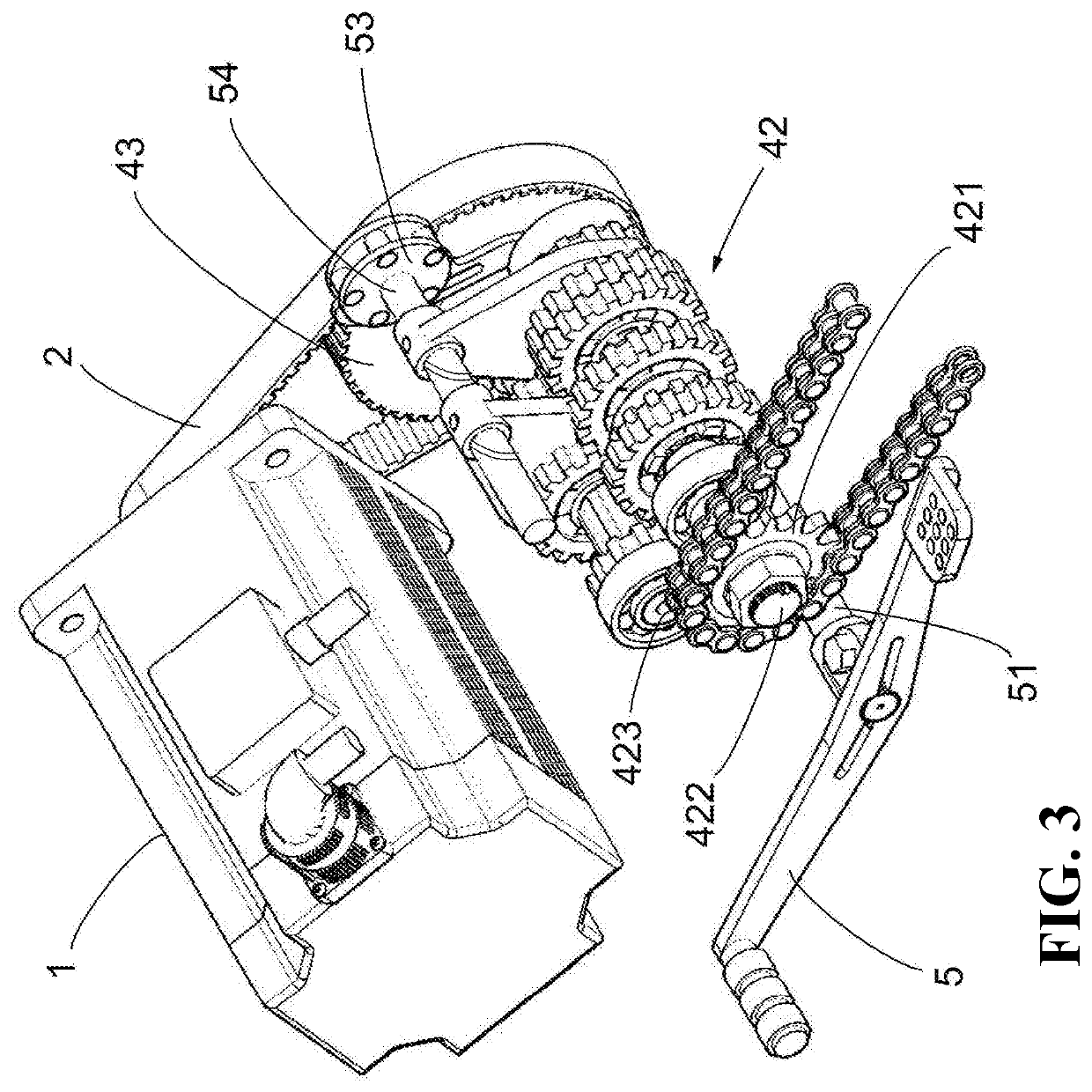

Autonomous Track-Type Moving Device

ActiveUS20190118877A1Easy to useIncrease the center distanceMowersEndless track vehiclesDrive wheelEngineering

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

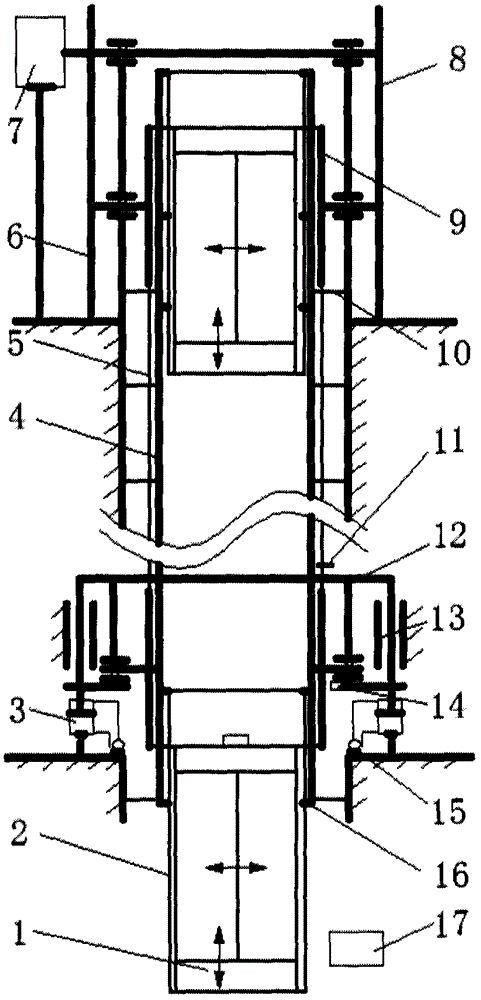

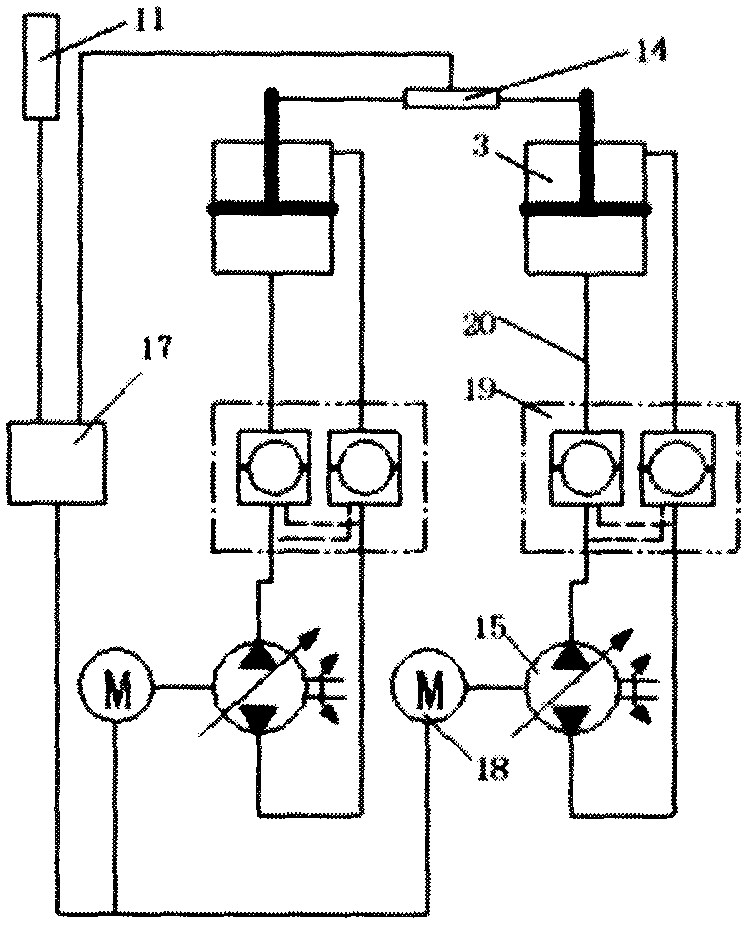

Power transmission method of high-efficiency energy-saving elevator

InactiveCN104876098AIncrease the center distanceMaintain level qualityBuilding liftsSprocketMechanical design

The invention relates to a power transmission method of a high-efficiency energy-saving elevator. According to a power transmission scheme, two large chain wheels on the upper portion of a roof bear the elevator, and also have a power driving function and a transmission guiding function; and two large chain wheels on the lower portion of a bottom have a chain wheel center distance adjusting function, bear part of the elevator and have a transmission guiding function. A function allocation scheme in the design can meet requirements of a mechanical design principle; two chain wheel seats on the lower portion of the bottom are modified into sliding seats capable of sliding vertically, and the heights of the sliding seats can be adjusted hydraulically; the sliding seats are connected to a piston rod of a single-piston cylinder below the sliding seats; and a base of the single-piston cylinder is connected to a horizontal seat surface in a hinged manner. By the seats, a center distance between the upper chain wheel and the lower chain can be adjusted in time according to tension detection of chain cables and horizontal height comparison detection of two ends of each seat, and power transmission of the high-efficiency energy-saving elevator is in an optimal mechanical state during working of the high-efficiency energy-saving elevator; and the elevator can work smoothly, stably and safely, and noises are small.

Owner:李先登

Electric motorcycle with improved motor efficiency

ActiveUS20210086858A1Simple structureStreamline structureWheel based transmissionGearboxesGear wheelEngineering

An electric motorcycle includes a transmission gear set mounted in a gearbox housing and having a power input shaft inserted through a middle block of the gearbox and a power input pulley mounted on the power input shaft, an electric motor mounted on one side of the middle block and having a motor pulley mounted on the motor shaft thereof, and a transmission belt coupled between the motor pulley and the power input pulley for enabling the electric motor to rotate the power input shaft of the transmission gear set through the transmission belt, a gear shift pedal and a gear shift axle for gear shifting, and a speed output chain gear mounted on an output shaft of the transmission gear set and driven by the output shaft to rotate the rear wheel of the electric motorcycle through a chain.

Owner:SU KUO HSIN +1

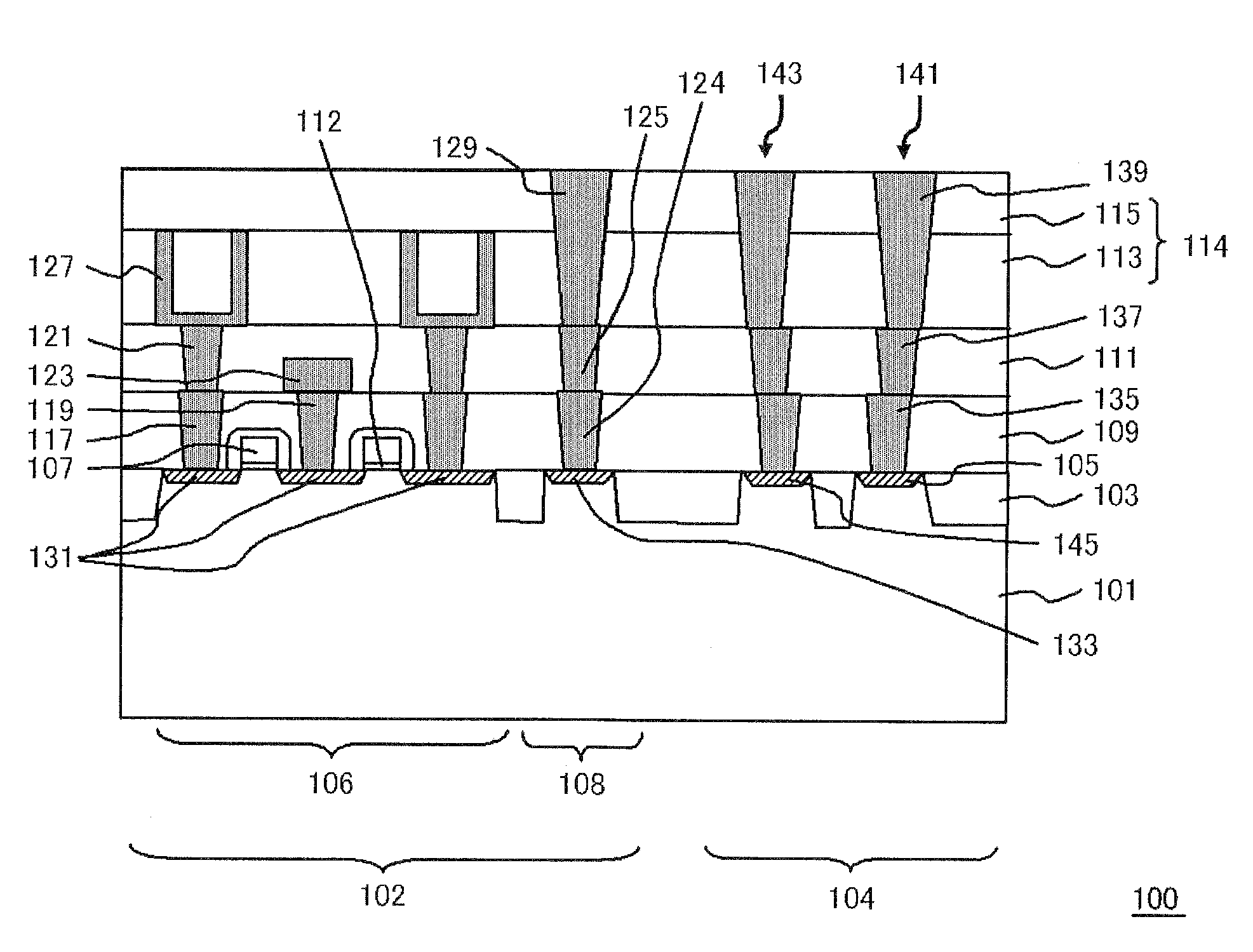

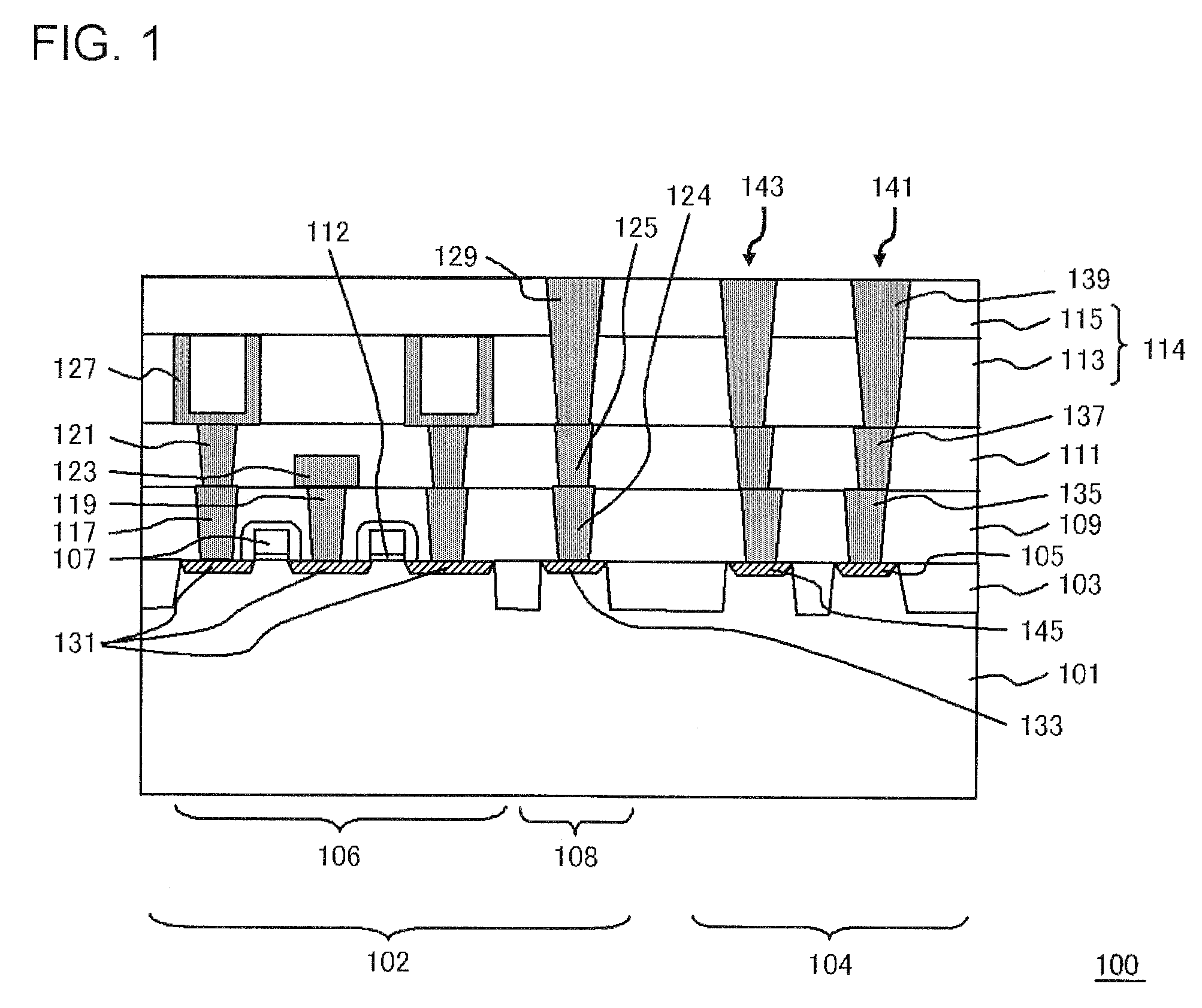

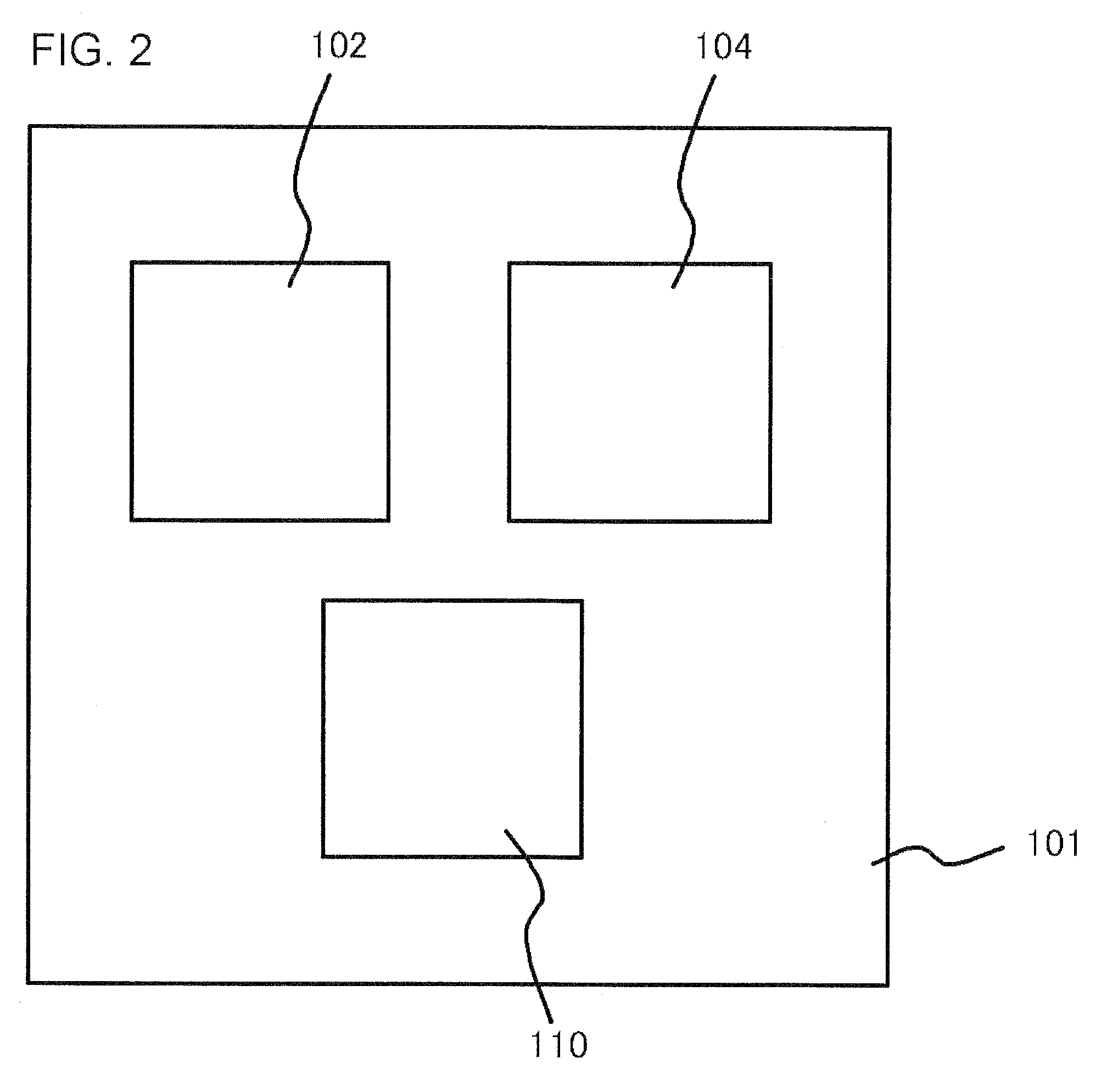

Semiconductor device

ActiveUS7936001B2Increase the center distanceInhibition is effectiveTransistorSemiconductor/solid-state device detailsPower semiconductor deviceSemiconductor

In a pair of adjacent stack contact and stack contact in the semiconductor device, the plugs and the plugs are disposed so that a center-to-center distance of the plugs extending through a second interlayer insulating film, which is thicker than the first interlayer insulating film, is larger than a center-to-center distance of the plugs extending through the first interlayer insulating film.

Owner:RENESAS ELECTRONICS CORP

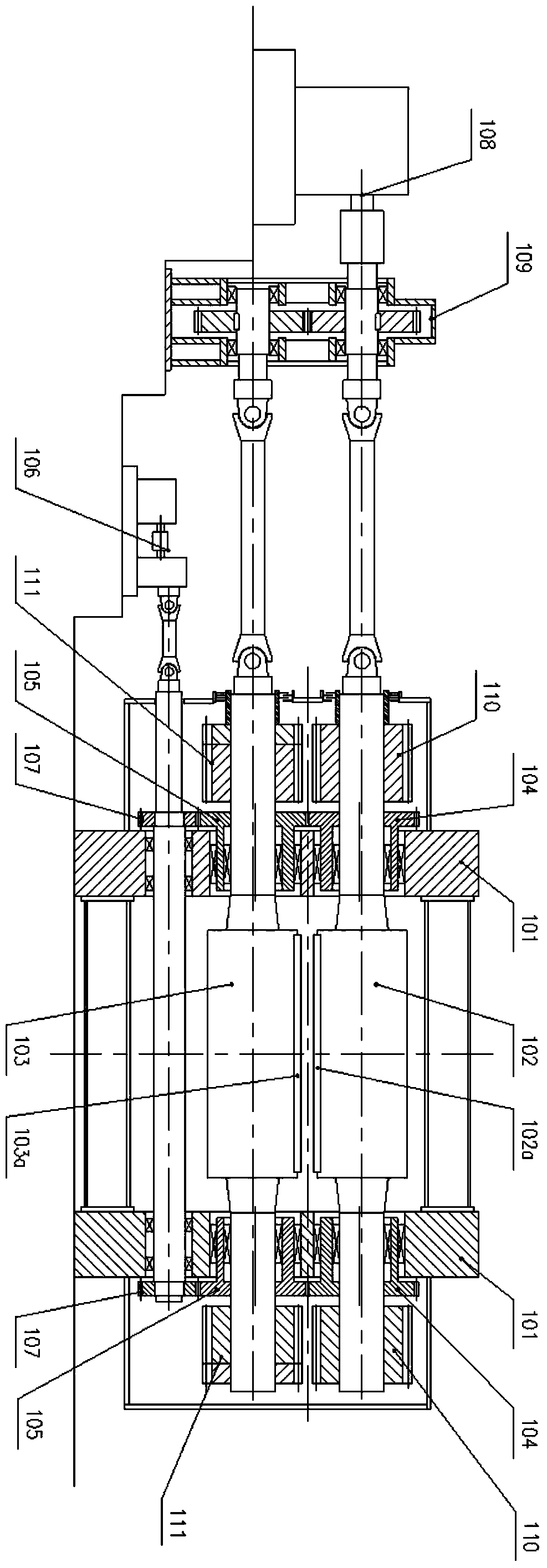

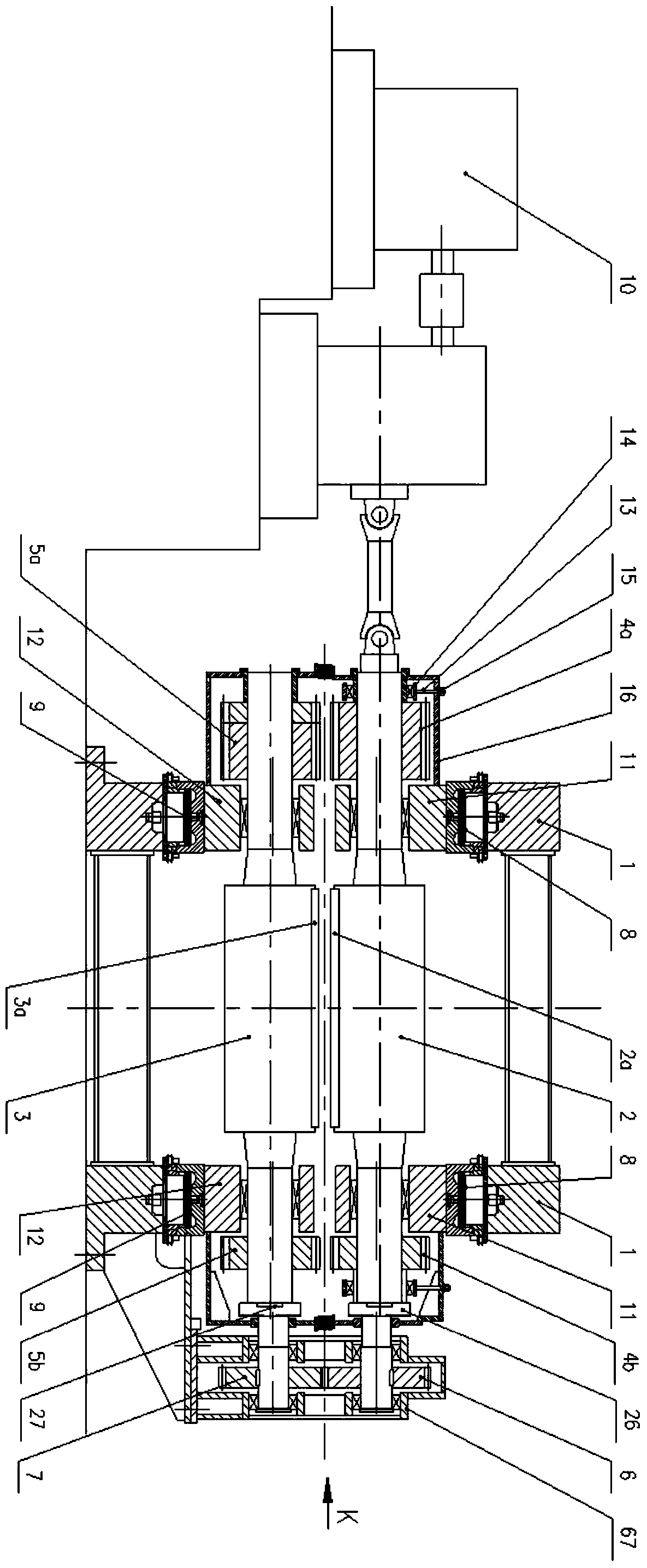

A rotary drum flying shear

ActiveCN105345129BEasy to control relative movementIncrease the center distanceStock shearing machinesShearing machine accessoriesHydraulic cylinderEngineering

The invention provides a drum-type flying shear comprising a rack, a driving device, an upper bearing block, an upper drum, a lower bearing block and a lower drum, wherein the upper drum and the lower drum are provided with shearing blades; the rack is provided with a vertical pushing mechanism; the vertical pushing mechanism comprises an upper hydraulic cylinder and a lower hydraulic cylinder which are arranged inside the rack; the upper hydraulic cylinder is connected with the upper bearing block and can drive the upper drum to move downwards; and the lower hydraulic cylinder is connected with the lower bearing block and can drive the lower drum to move upwards. According to the drum-type flying shear, hydraulic pressure is used as power for reducing the central distance between the upper drum and the lower drum, and an eccentric bushing is omitted, so that the problems that a shearing gap cannot be ensured and a non-shearing accident is easily generated are avoided. The upper drum is suspended by a set of upper drum balancing device and is enabled to be always pressed on the top of an inner hole of the upper bearing block, so that a gap from the upper drum to the rack is eliminated. The upper drum and the lower drum are pressed to the other side of the rack by a pressing device arranged on the rack, so that a stable shearing blade gap required during shearing is ensured.

Owner:CISDI ENG CO LTD

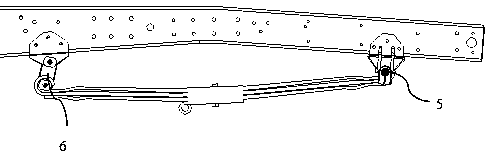

Offset connection fixing structure of center lines of plate springs and center lines of lower wing surfaces of longitudinal beams

InactiveCN110271374ASimple structureReasonable designLeaf springsResilient suspensionsMiddle lineBattery system

The invention discloses an offset connection fixing structure of center lines of plate springs and center lines of lower wing surfaces of longitudinal beams. The offset connection fixing structure is characterized in that the plate springs have the center lines in the longitudinal direction of a vehicle, and the plate springs are each roughly and equally divided into two parts by the center lines; and the lower wing surfaces of the longitudinal beams have the center lines in the longitudinal direction of the vehicle, and the lower wing surfaces of the longitudinal beams are each roughly and equally divided into two parts by the center lines; front lifting lugs and rear lifting lugs are partially connected in an overlapped mode on the horizontal plane, and the center lines of the plate springs and the center lines of the longitudinal beams are fixed together in an offset mode; and the front lifting lugs and the rear lifting lugs are in an h shape and in an L shape, so that the plate springs are partially covered under the lower wing surfaces of the longitudinal beams, and the front lifting lugs and the rear lifting lugs of the plate springs are fixed to the longitudinal beams of a chassis and are connected with plate spring elastic pieces. The offset connection fixing structure of the center lines of the plate springs and the center lines of the lower wing surfaces of the longitudinal beams has the advantages that the structure is simple, the design is reasonable, the center distance of the plate springs is increased by changing the form of the lifting lugs of the plate springs, the lifting lugs of the plate springs can adjust the size covered under the lower wing surfaces of the longitudinal beams according to the requirements of a whole vehicle, and thus the spacing of the plate springs can meet the clearance requirements of an arrangement scheme of a middle-mounted chassis in a standard battery system.

Owner:北京华田汽车科技有限公司

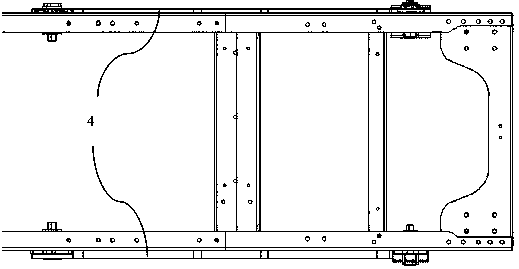

Big gear box body combination for rotary tiller

InactiveCN102396309AIncrease the center distanceModerate center of gravityTilling equipmentsGravity centerHooking

The invention discloses a big gear box body combination for a rotary tiller, which is formed by combining a box body with a base plate. The detachable base plate is arranged on the box body. The surface of the base plate, which is matched with the box body, is set according to specification requirements of the box body. The surface of the base plate, which is hooked with a manual chassis, is set according to specification requirements of the hooking surface of the chassis. The transmission requirements of matching hanging of the big gear box body and the walking tractor chassis are realized through the combination of the base plate and the box body. The gravity center of a unit is appropriate. Moreover, large-sized paddy-field anti-slip wheels can be used universally by wide rotary tillers. The big gear box body combination has a simple structure, easiness for processing and manufacturing, high strength and easiness for popularization. The big gear box body is changed on a common wide rotary tiller for realizing two purposes of usage on farmland and paddy field.

Owner:ZHENJIANG WANJIN AGRI MACHINERY

Pitch positioning tool for multi-hole workpiece

InactiveCN102990423BAvoid swimmingGuaranteed machining accuracyPositioning apparatusMetal-working holdersEngineeringMachining process

The invention discloses a pitch positioning tool for a multi-hole workpiece. According to the pitch positioning tool, the positioning is convenient and the multi-hole workpiece is difficult to move in the machining process. The pitch positioning tool comprises a base, wherein a central hole is formed in the base; a positioning column which is matched with a positioning hole serving as a datum point of the hole to be machined of the multi-hole workpiece is arranged on the base; the center distance from the positioning column to the central hole of the base is equal to the center distance from the positioning hole to the hole to be machined; and a pressing device and a positioning device matched with the multi-hole workpiece are arranged on the base. Due to the pitch positioning structure, the hole to be machined of the multi-hole workpiece can be conveniently aligned to the central hole on the base, and the multi-hole workpiece and the positioning column are fixed on the base through a locking device and a positioning device after alignment, so that the multi-hole workpiece can be effectively prevented from moving in the machining process; and therefore, the machining precision of the multi-hole workpiece is reliably guaranteed.

Owner:信阳豪隆实业有限公司

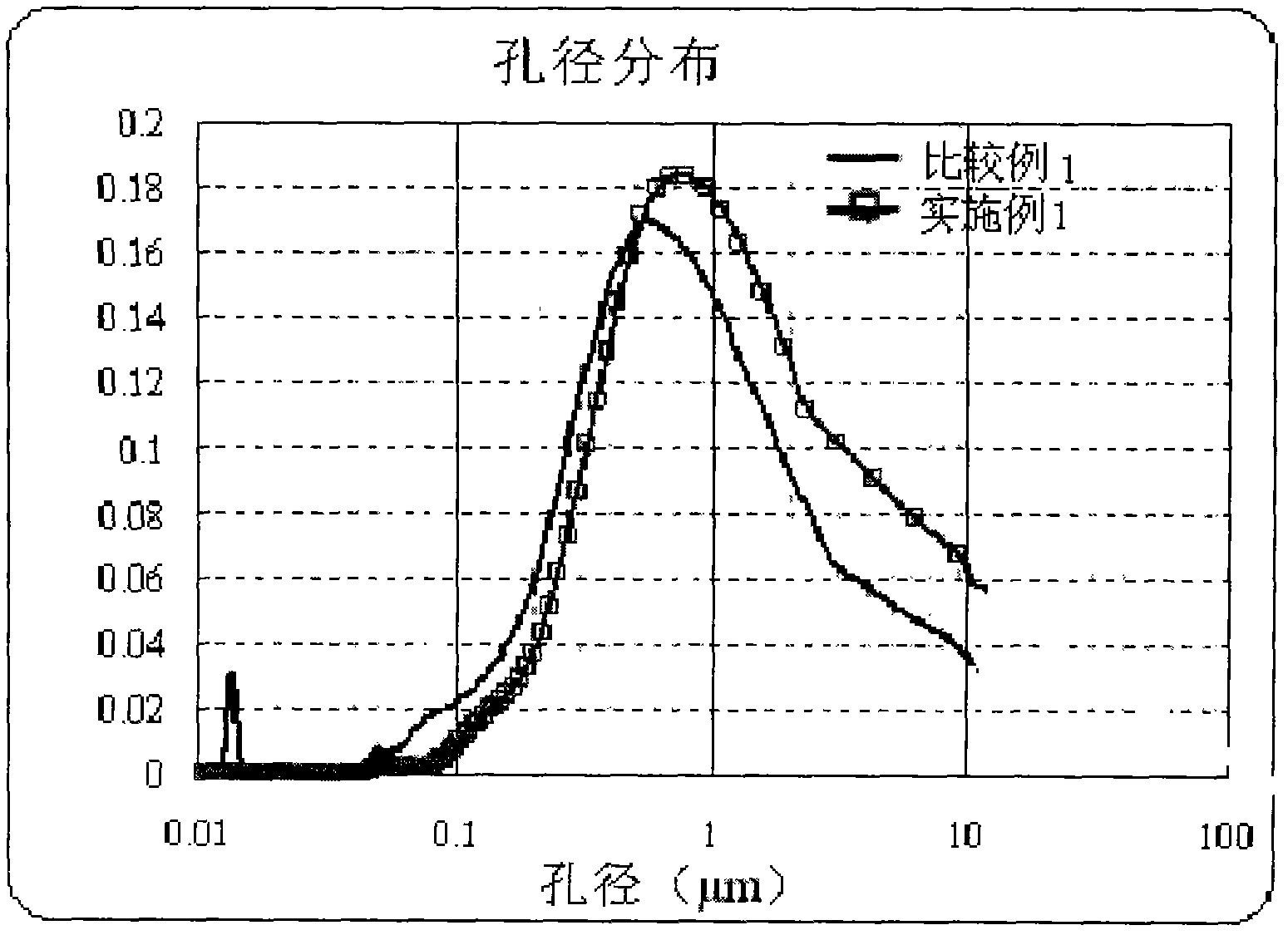

Lithium ion battery and anode and preparation method thereof

ActiveCN102623745BStress reliefIncrease the center distanceSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries and particularly relates to an anode of a lithium ion battery. The anode of the lithium ion battery comprises an anode current collector and an anode film coated on the anode current collector, and the anode film comprises anode active material, adhesive and conductive additive. The surface of the anode active material is coated with ethylene carbonate (EC), and the weight ratio of the EC and the anode active material is (0.1-30):(99.9-70). Compared with the prior art, the EC coated on the surface of the anode active material is dissolved in electrolyte after liquid injection, the space occupied by the EC in the film can be released, so that a certain space is reserved for expansion of particles of the anode active material during charging and circulating, and the problem of deformation of flexibly-packaged cell due to expansion of the active material is eliminated. Further, the invention further discloses a method for preparing the lithium ion battery, namely the lithium ion battery comprising the anode.

Owner:NINGDE AMPEREX TECH +1

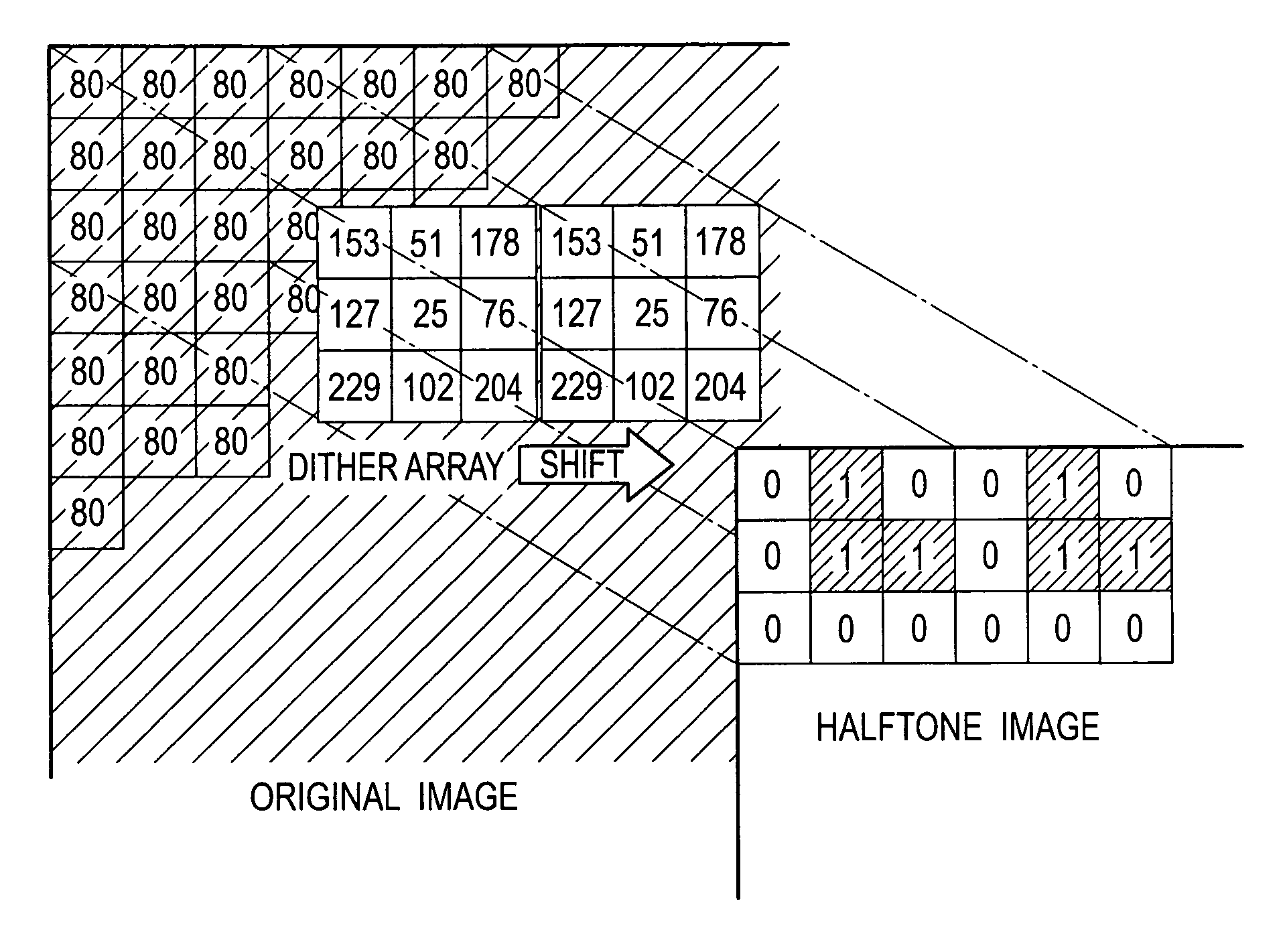

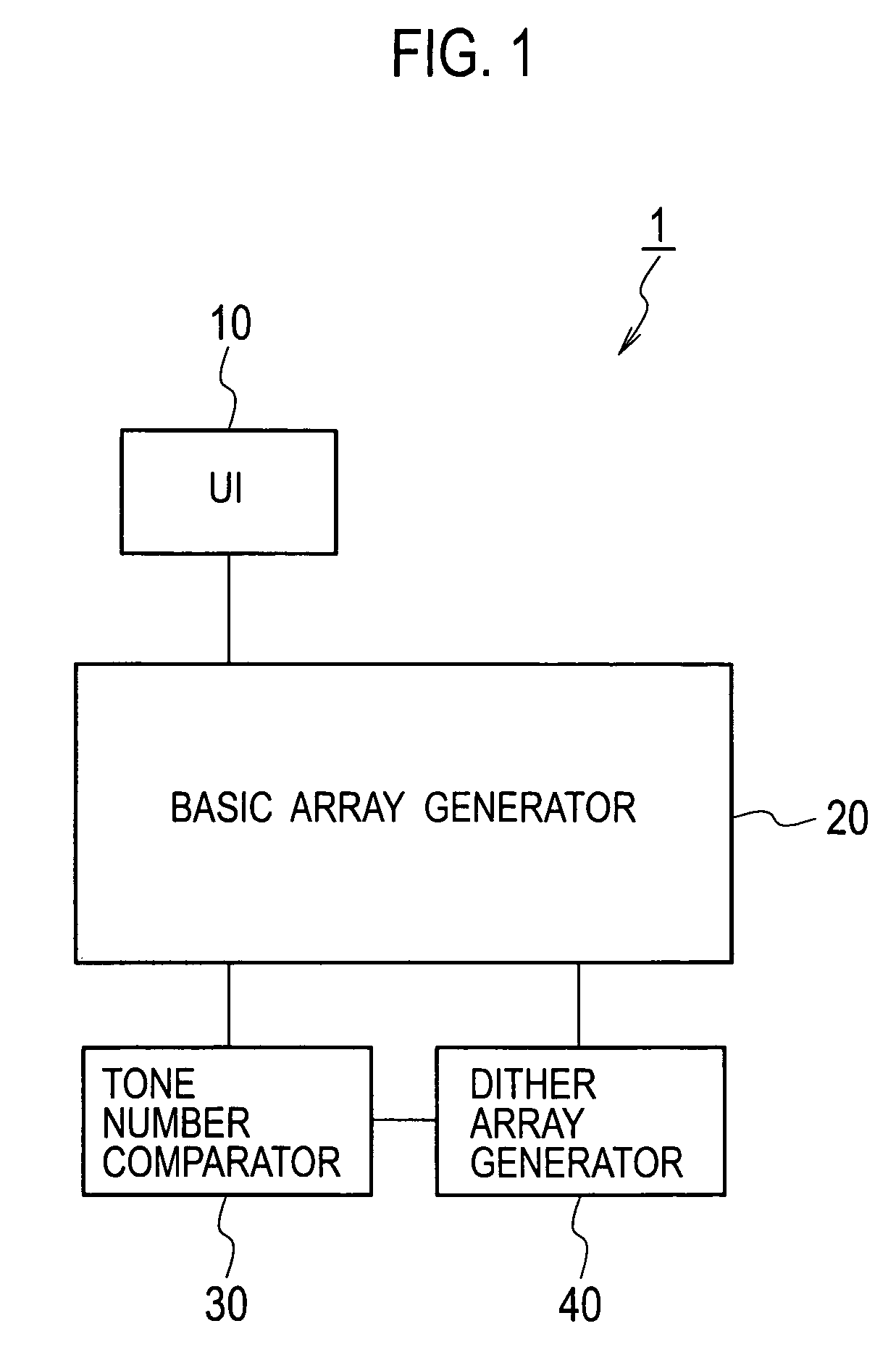

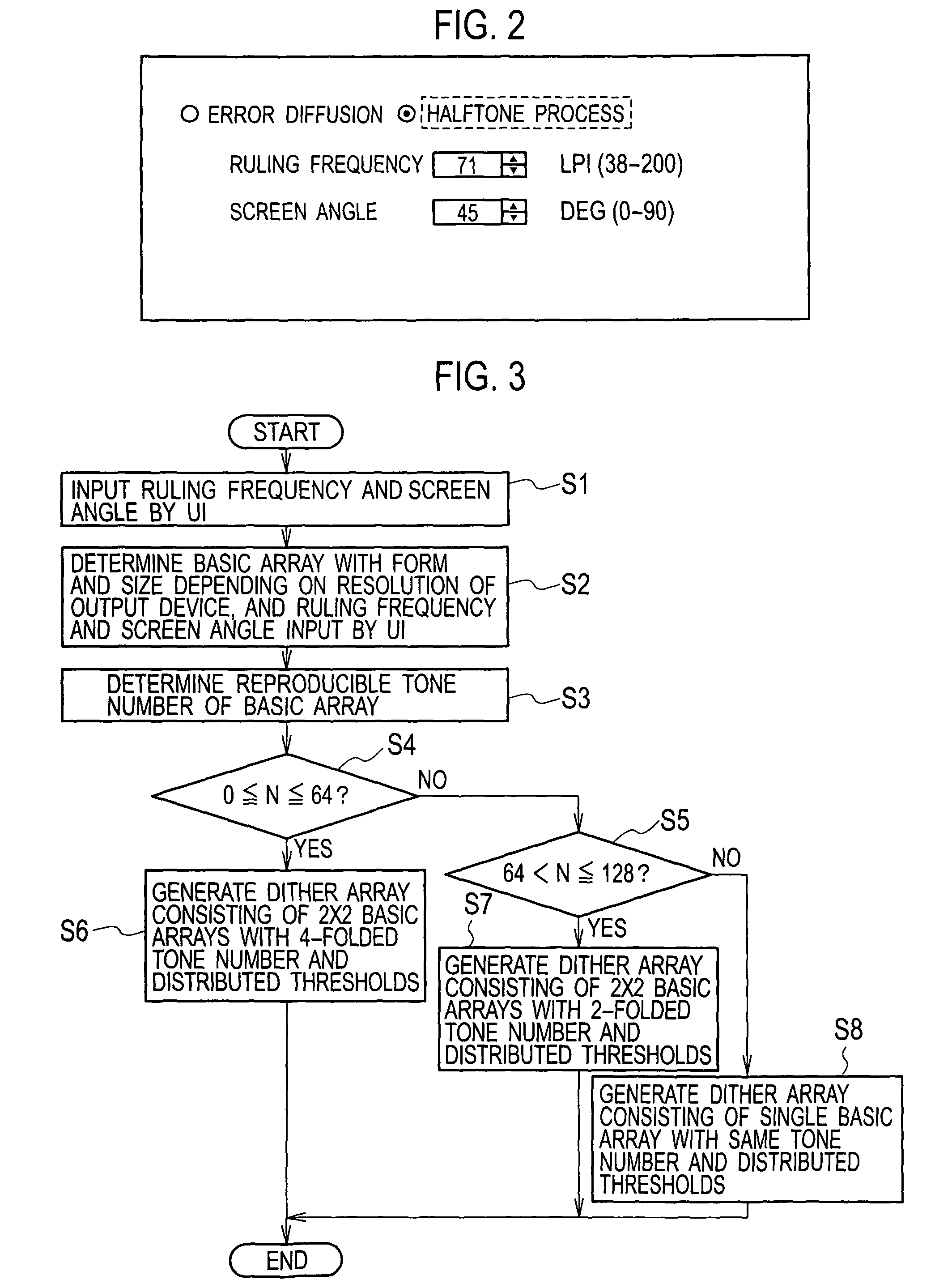

Image creating method and image creating system

ActiveUS8094968B2Reduce reproducibilityIncrease the center distanceDigitally marking record carriersDigital computer detailsHueDither

For a halftone representation of a grayscale data of an original image of P tones, an output resolution, a screen ruling frequency, and a screen angle are based to set a basic array of L×L pixels, where L is an integer greater than 1, and a number N of tones reproducible by the basic array is compared with P to generate a dither array using the basic array as its sub-array, such that numbers are assigned to pixels of sub-arrays by a prescribed rule, in order between the sub-arrays, starting from prescribed ones of centered and centermost pixels of the sub-arrays.

Owner:RISO KAGAKU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com