Method for adjusting engagement gap between balance shaft driven gear and crankshaft driving gear of engine

A gap adjustment method and driven gear technology, which is applied to belts/chains/gears, mechanical equipment, transmission parts, etc., can solve the problems of poor assembly effect and low assembly efficiency, reduce adjustment time and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] The method for adjusting the tooth side clearance of the meshing gear of the engine balance shaft according to the present invention comprises the following steps:

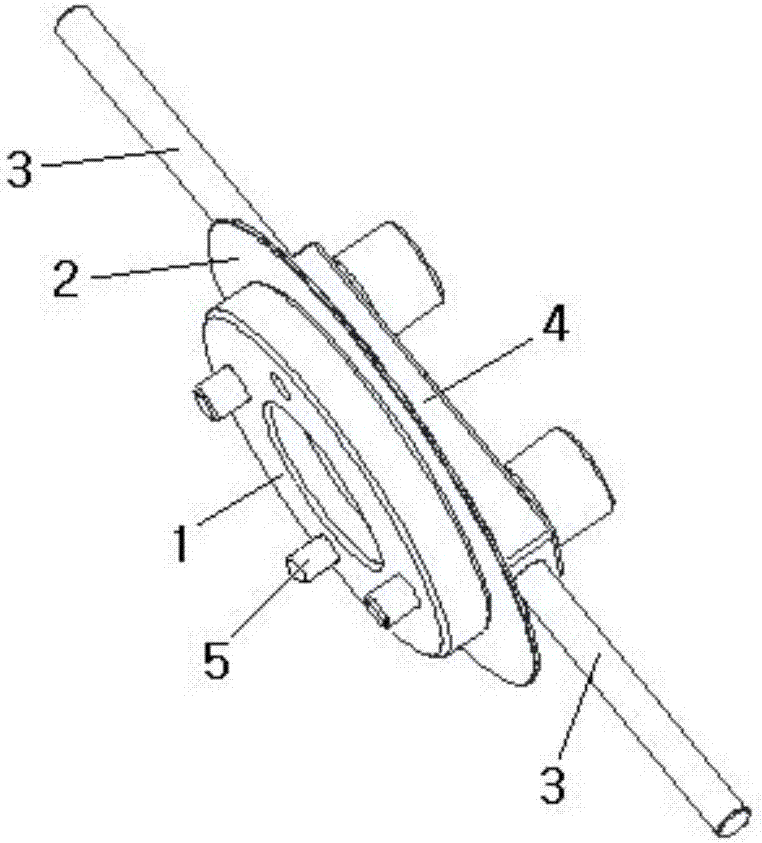

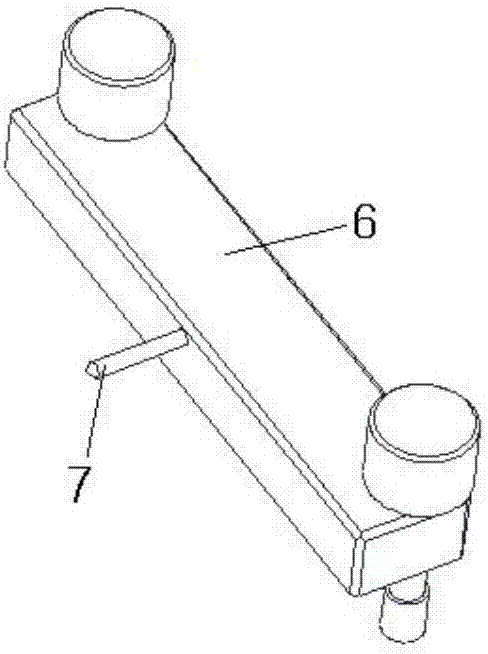

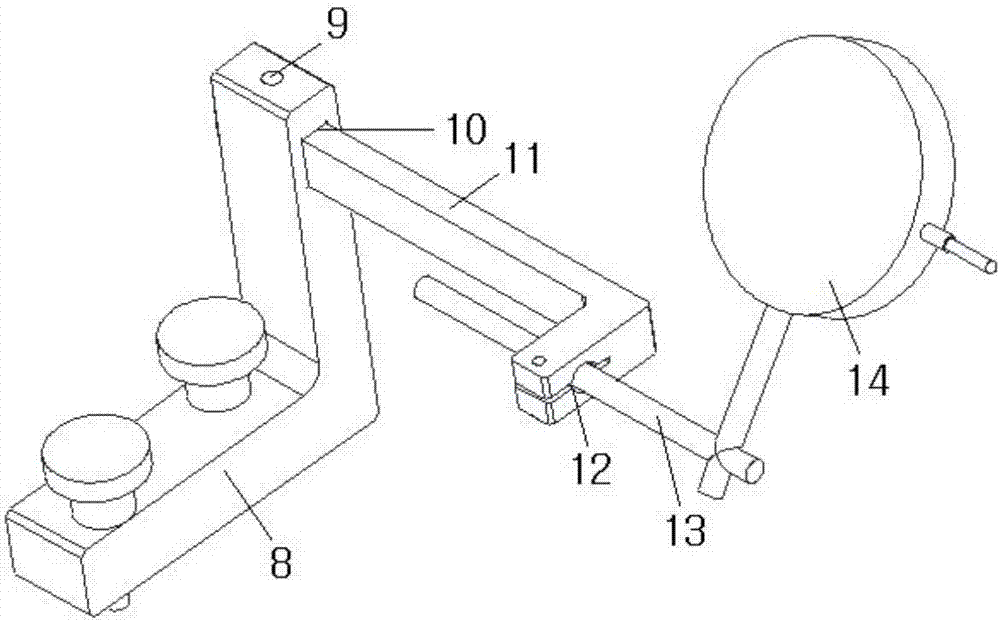

[0031] Step 1, preparing a crankshaft rotation device, a crankshaft rotation angle control device, a balance shaft gap measurement device and a balance shaft timing positioning device. The crankshaft rotating device such as figure 1 As shown, it includes a fixed plate 1 and a scale plate 2 stacked together, a positioning pin 5 is arranged on the inner side of the fixed plate 1, and an angle scale line is marked on the outer edge of the scale plate 2 . The crankshaft rotation angle control device such as figure 2 As shown, the pointer 7 and the pointer holder 6 are included, and the pointer 7 is horizontally fixed on the pointer holder 6 . The balance shaft gap measuring device is as image 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com