Big gear box body combination for rotary tiller

A gearbox body and rotary tiller technology, which is applied in the fields of tillage equipment, agricultural machinery and implements, etc. It can solve the problems of large rearward movement of the center of gravity of the equipment, poor strength of the bridge transmission box, and laborious operation, so as to achieve a suitable center of gravity, The effect of saving labor and increasing the center distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

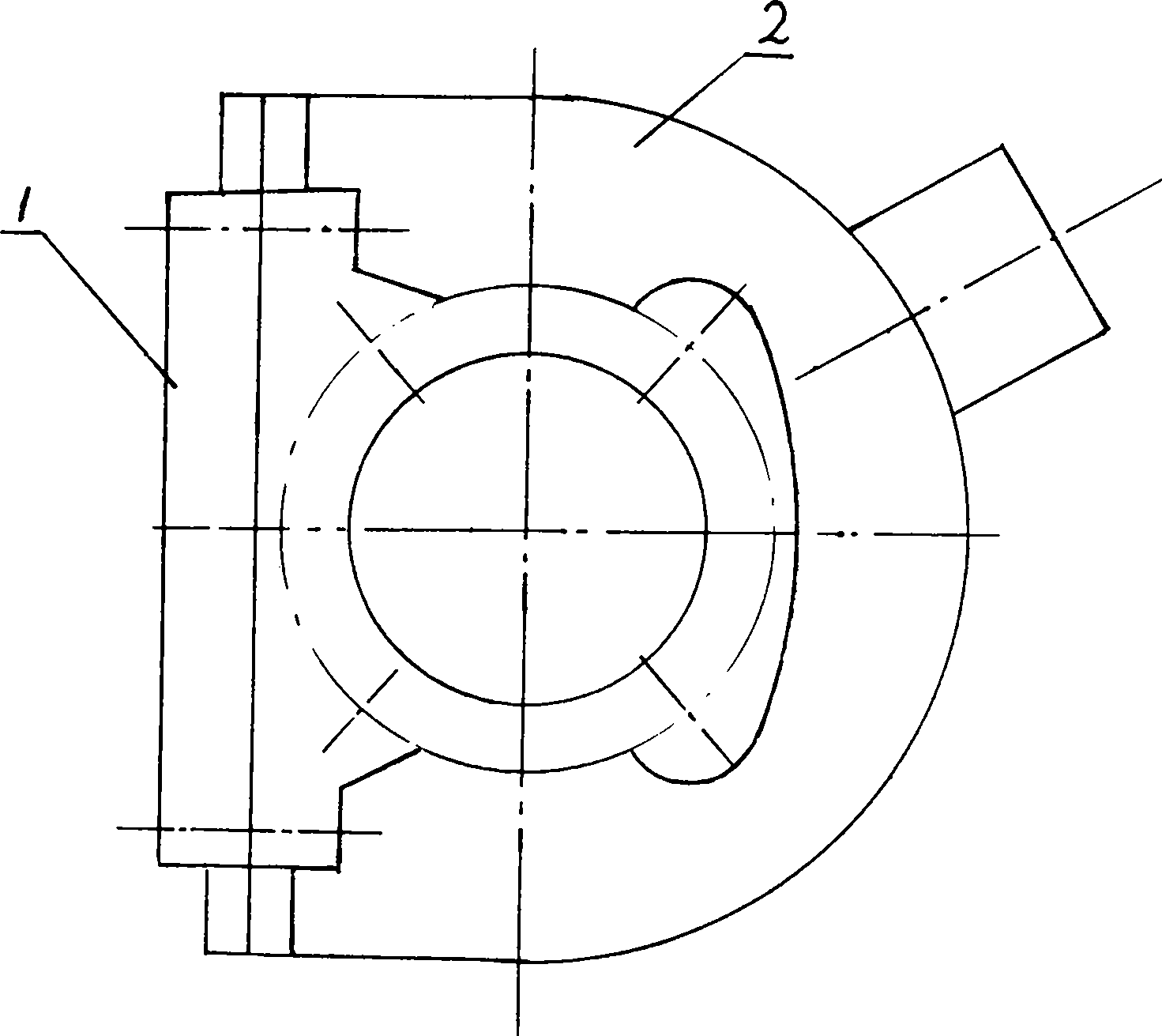

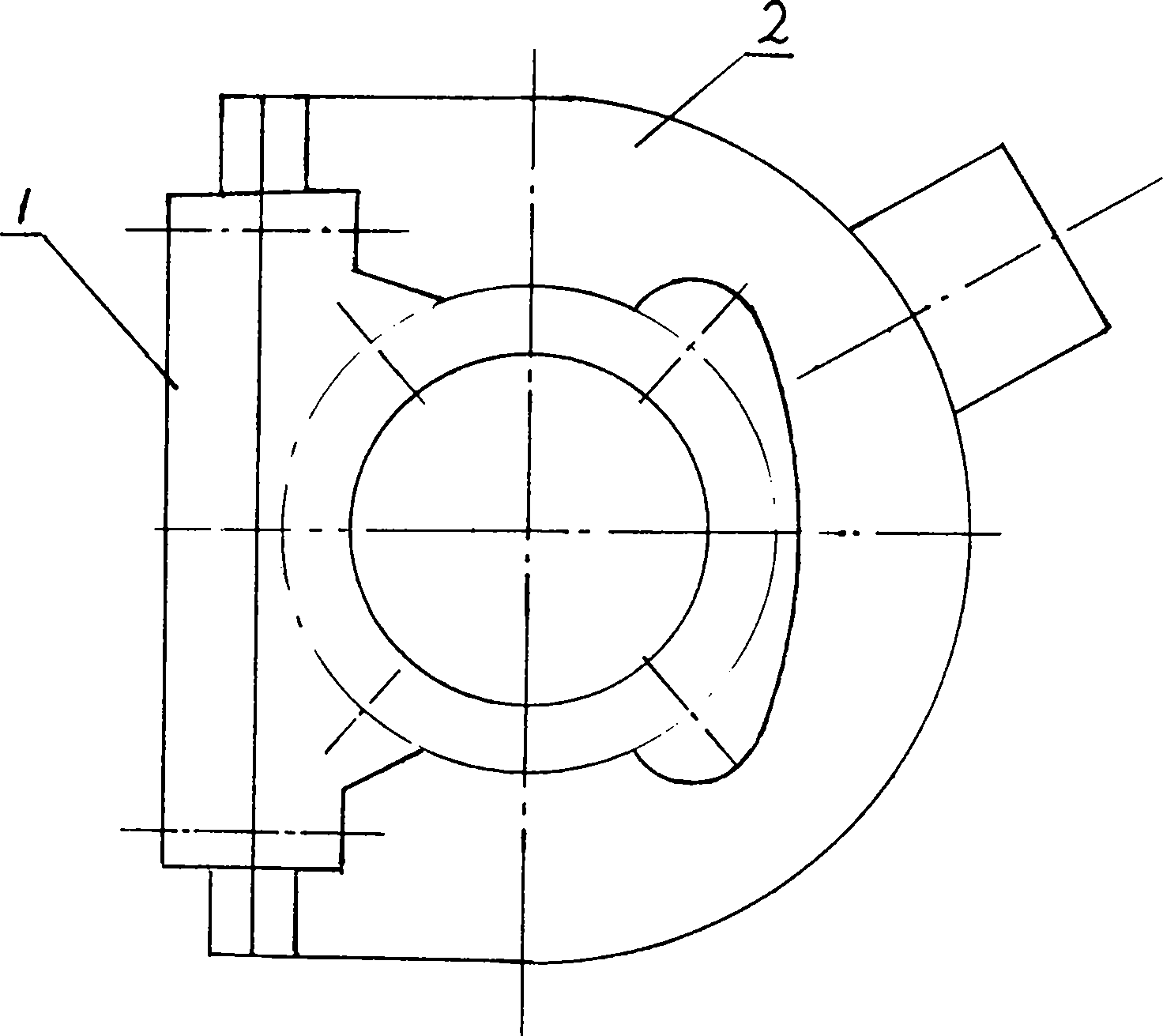

[0009] like figure 1 The large gearbox body combination of a rotary tiller shown is composed of a box body 2 and a backing plate 1, and the center distance between the rotary tiller and the driving wheel of the walking tractor is increased by increasing the coulter transmission gear to realize Large-scale anti-skid wheels for paddy fields can be installed. Due to the increase in gears, the box body 2 also needs to be enlarged. However, the hooking position of the chassis of the walking tractor cannot meet the requirements for the large gearbox body 2. Set the backing plate 1 between the joint surfaces, set the mating surface of the backing plate 1 and the box body 2 according to the specification requirements of the box body 2, and set the backing plate 1 and the chassis joint surface according to the specification requirements of the chassis joint surface, so that through the pad The combination of the plate 1 and the box body 2 realizes that the large gearbox body can be art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com