A rotary drum flying shear

A flying shear and drum-type technology, which is applied in the field of steel rolling production, can solve the problems of enlarging the gap between cutting blades, complicated oil circuit, continuous cutting, etc., and achieve the effect of ensuring gapless connection, ensuring shearing effect, and stabilizing the overlapping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

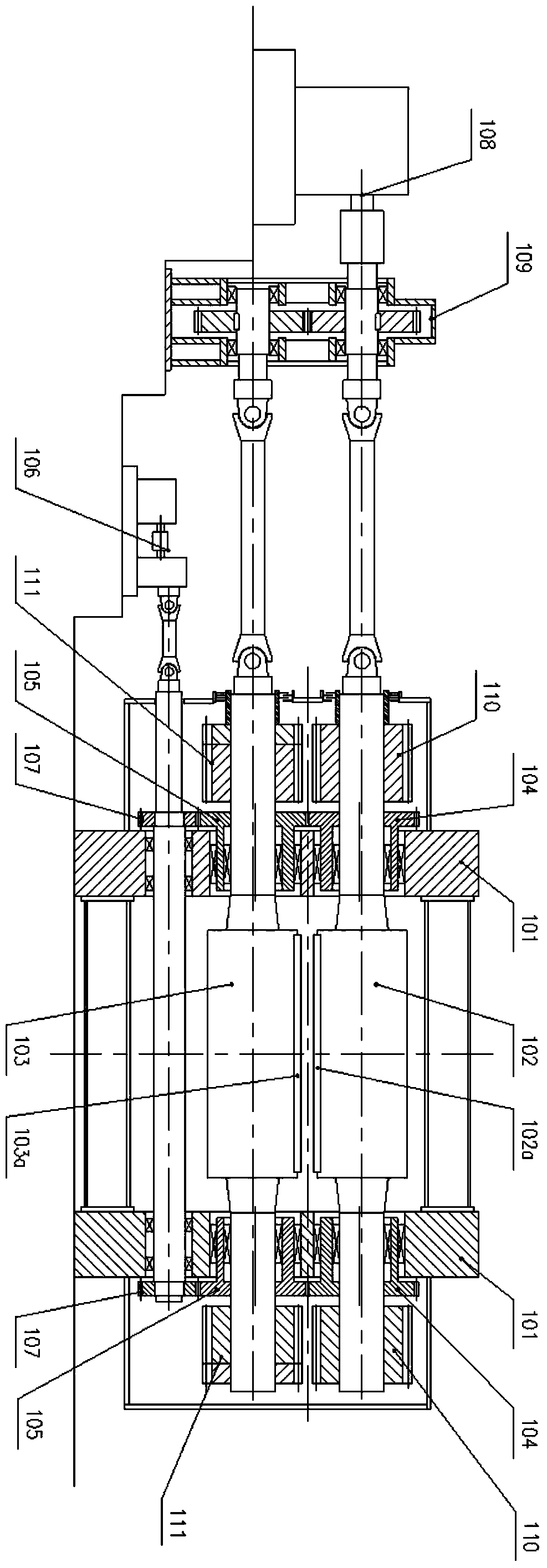

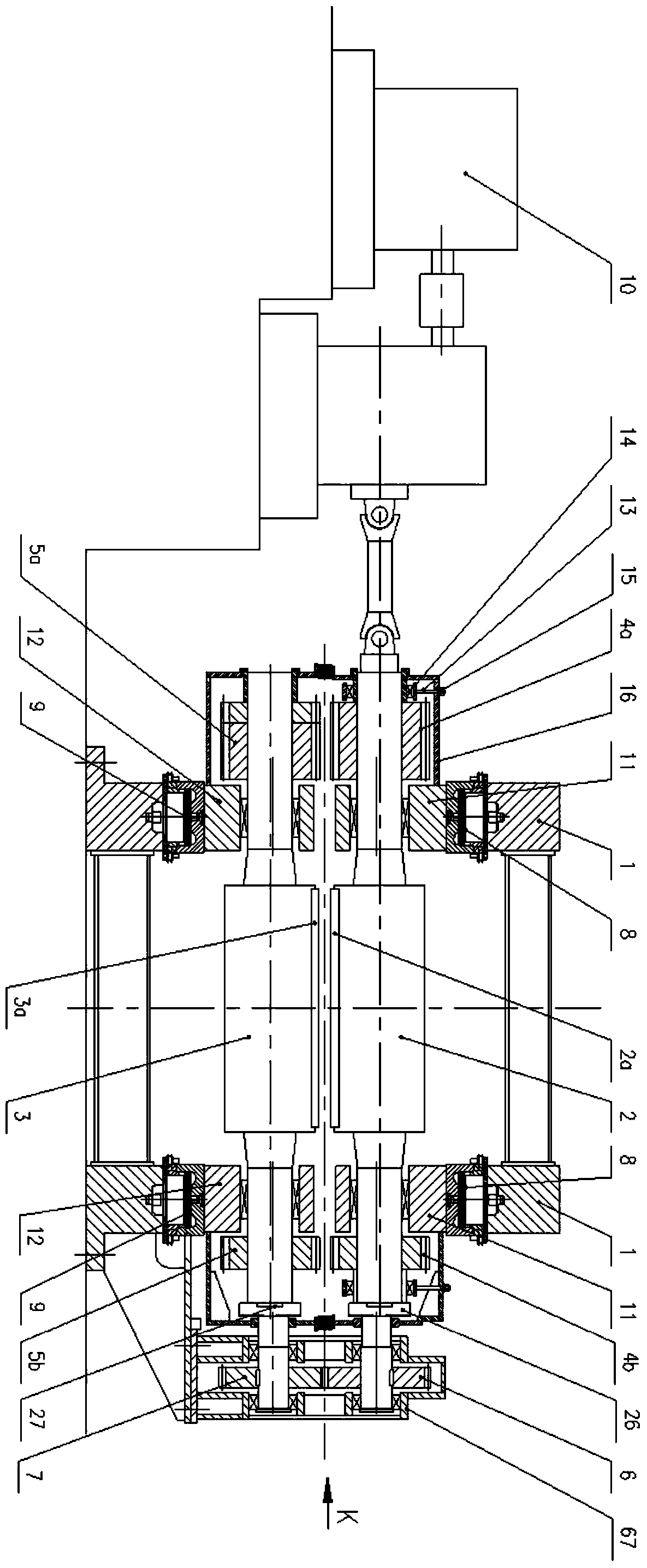

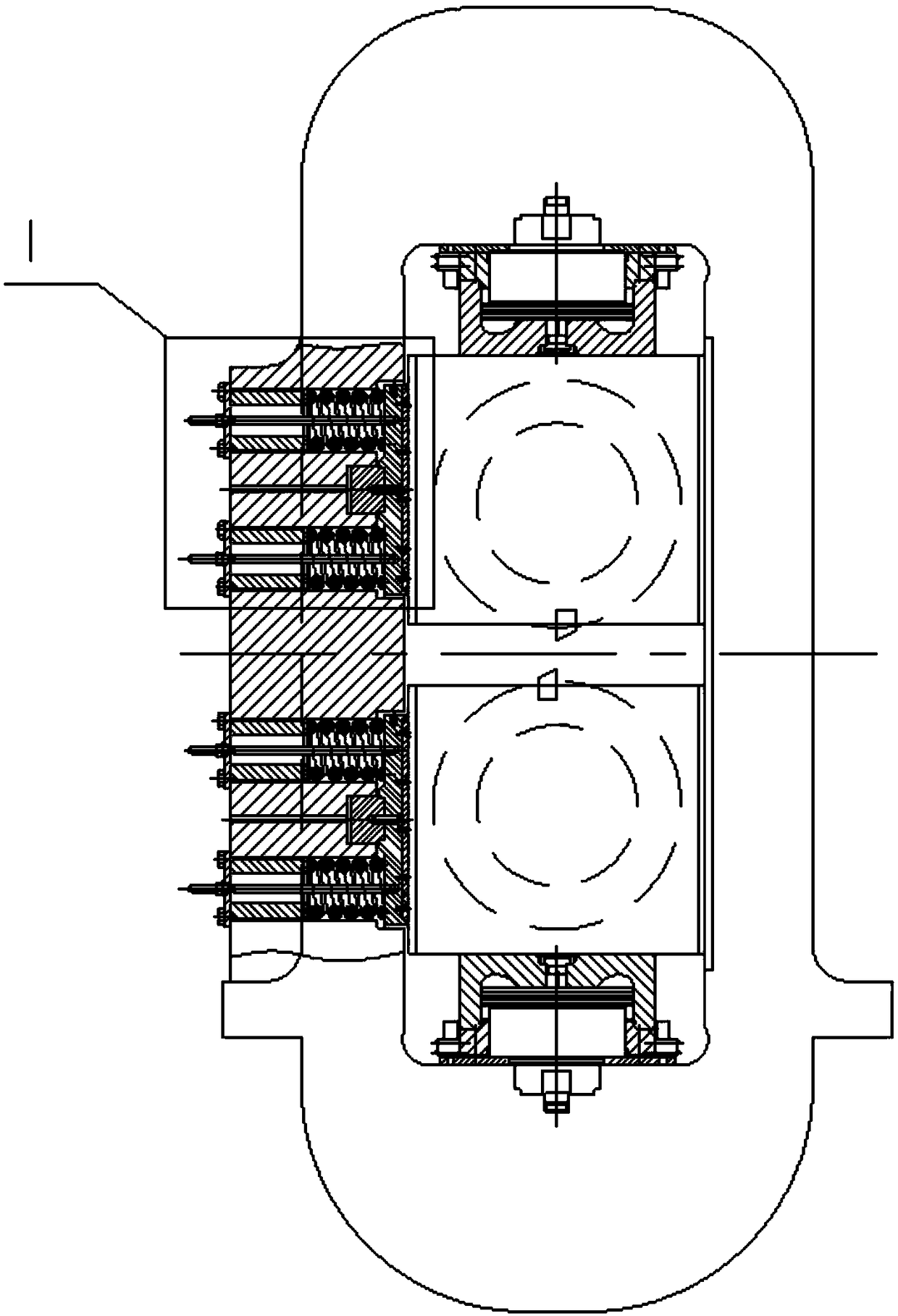

[0048] Such as figure 2 As shown, the present invention provides a drum-type flying shear, including a frame 1, a driving device 10, an upper drum assembly, and a lower drum assembly, and the upper drum assembly includes an upper bearing seat 11 and an upper bearing The upper drum 2 in the seat 11, the lower drum assembly includes the lower bearing seat 12 and the lower drum 3 installed in the lower bearing seat 12, the rotating outer circles of the upper drum 2 and the lower drum 3 are respectively installed with upper Cutting edge 2a and lower cutting edge 3a. The upper drum assembly and the lower drum assembly are installed in the frame 1, and the driving device 10 provides power for the upper drum assembly and the lower drum assembly. The frame 1 is equipped with an up and down push mechanism, and the up and down push mechanism is assembled with the upper drum. It is connected with the lower drum assembly, and can drive the upper drum assembly and the lower drum assembly...

Embodiment 2

[0060] Such as Image 6 As shown, in this example, except that the distribution gear box 109 is moved to the transmission side, and the power of the driving device 10 is simultaneously transmitted to the upper drum 2 and the lower drum 3 through the distribution gear box 109, the structure is the same as that of the first embodiment. In this case, when the upper drum 2 and the lower drum 3 need to be replaced, the upper drum 2, the lower drum 3 and other parts can be dragged out of the line without dismantling the distribution gear box 109 for convenience. Blade replacement, blade clearance adjustment and equipment maintenance.

[0061] As mentioned above the present invention has the following advantages:

[0062] 1. Using hydraulic pressure as the driving force for reducing the center distance between the upper drum and the lower drum, and canceling the eccentric sleeve, it is convenient to control the relative movement of the upper drum and the lower drum, and at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com