Pitch positioning tool for multi-hole workpiece

A technology for positioning tooling and workpieces, applied in the field of hole spacing positioning tooling, can solve the problems of troublesome porous workpieces, easy to move porous workpieces, affecting processing accuracy, etc., and achieve reliable processing accuracy, improve center distance, and improve clamping accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

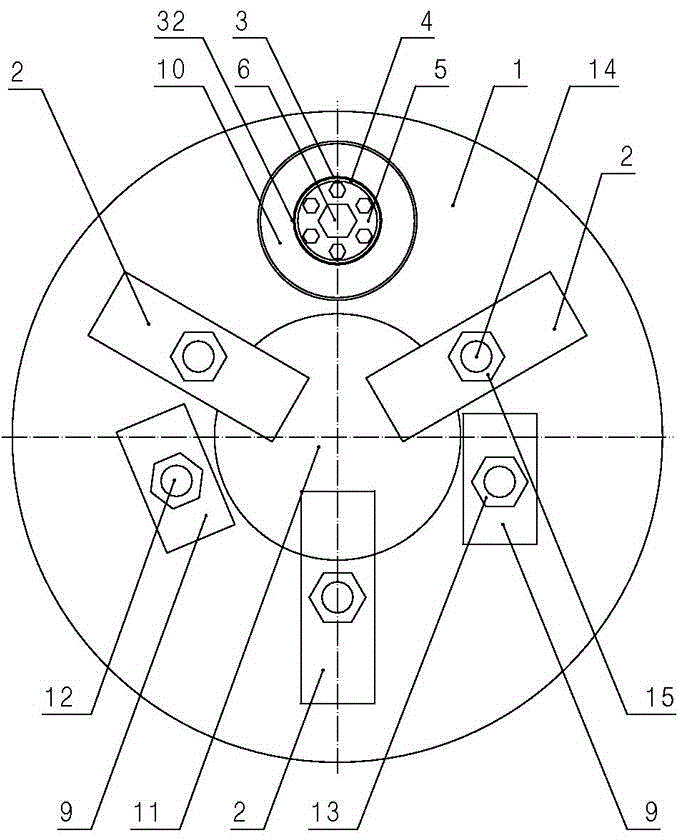

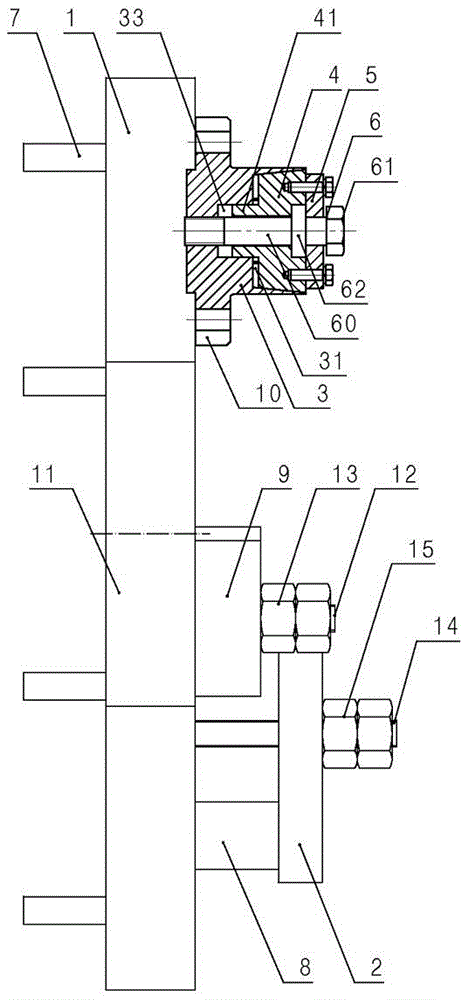

[0015] Below in conjunction with accompanying drawing, describe the specific embodiment of the present invention in detail:

[0016] Such as figure 1 and figure 2 As shown, a hole distance positioning tool for a porous workpiece includes: a base 1, a positioning column 3 and a push screw 6, and the push screw 6 includes: a rod body 60, a rod cap 61 is arranged on one end of the rod body 60, and a rod cap 61 is also arranged on the rod body 60 A locking boss 62 is provided, an annular groove is formed between the locking boss 62 and the rod cap 61, and the bottom wall of the annular groove may not be provided with threads; the base 1 is provided with a central hole 11, and the positioning The column 3 is provided with a mounting boss 10, and the mounting boss 10 is provided with at least one pair of mounting holes, and the base 1 is provided with mounting threaded holes corresponding to the mounting holes on the mounting boss 10, and the positioning column 3 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com