A spring tooth picker without retainer and a baler

A picker and spring tooth technology, applied in agricultural machinery and implements, loaders, agricultural gas emission reduction, etc., can solve the problems of long straw clogging and low picking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

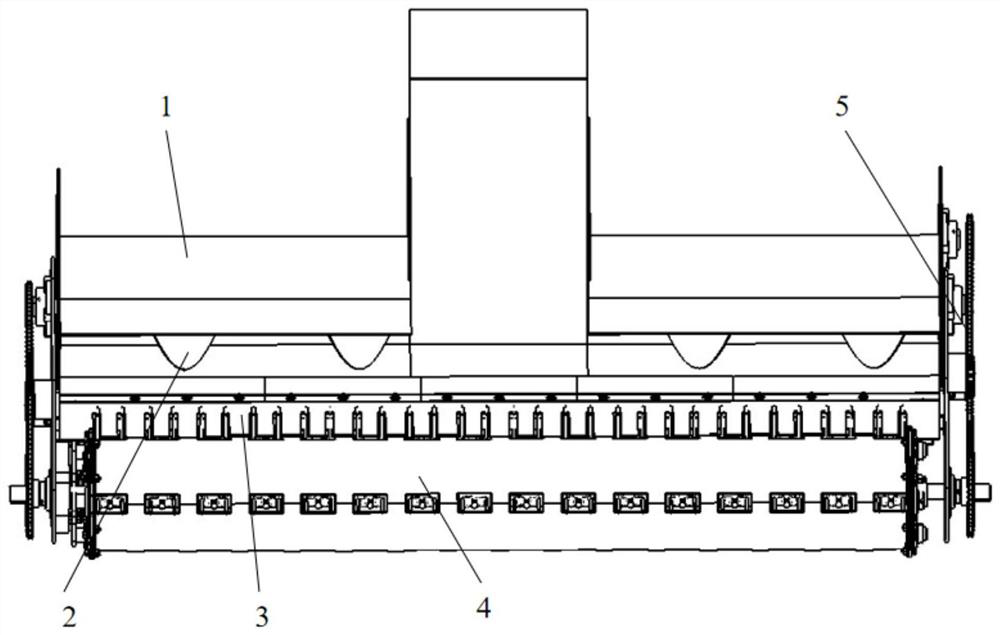

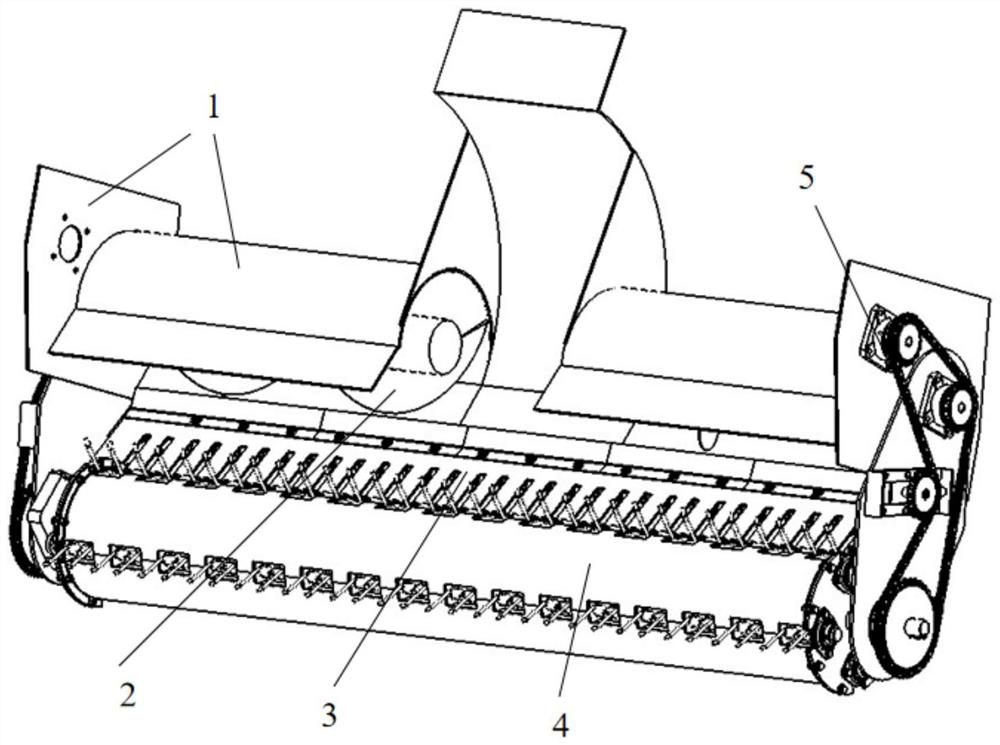

[0044] Combined attached Figure 1 and 2 As shown, a preferred embodiment of the ringless bullet tooth picker involved in the present invention, the ringless bullet picker, comprising a main frame 1, a pick-up device assembly 4, a transition device 3, a conveyor churning 2 and a transmission system 5; the pick-up device assembly 4 is connected to the main frame 1 by a bearing housing, located at the front of the system; the transition device 3 is welded at both ends of the main frame 1, located behind the pick-up device assembly 4; the conveyor churning dragon 2 is symmetrically distributed on both sides, and the two ends are connected to the main frame 1 through the bearing housing, Located behind the transition device 3; the drivetrain 5 is connected to the conveyor churning device 2, the pick-up device assembly 4.

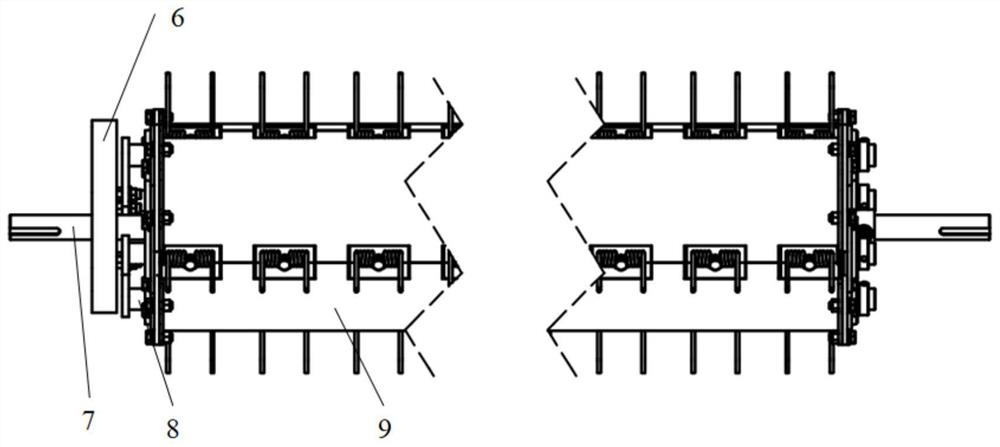

[0045] According to this embodiment, preferably, in combination with attached Figure 3 and attached Figure 4As shown, the pick-up device assembly 4 comprises a cam c...

Embodiment 2

[0053] A baler, comprising a guardless bullet picker as described in Example 1. Thus having all the beneficial effects described in Example 1, I will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com