Air suspension and vehicle

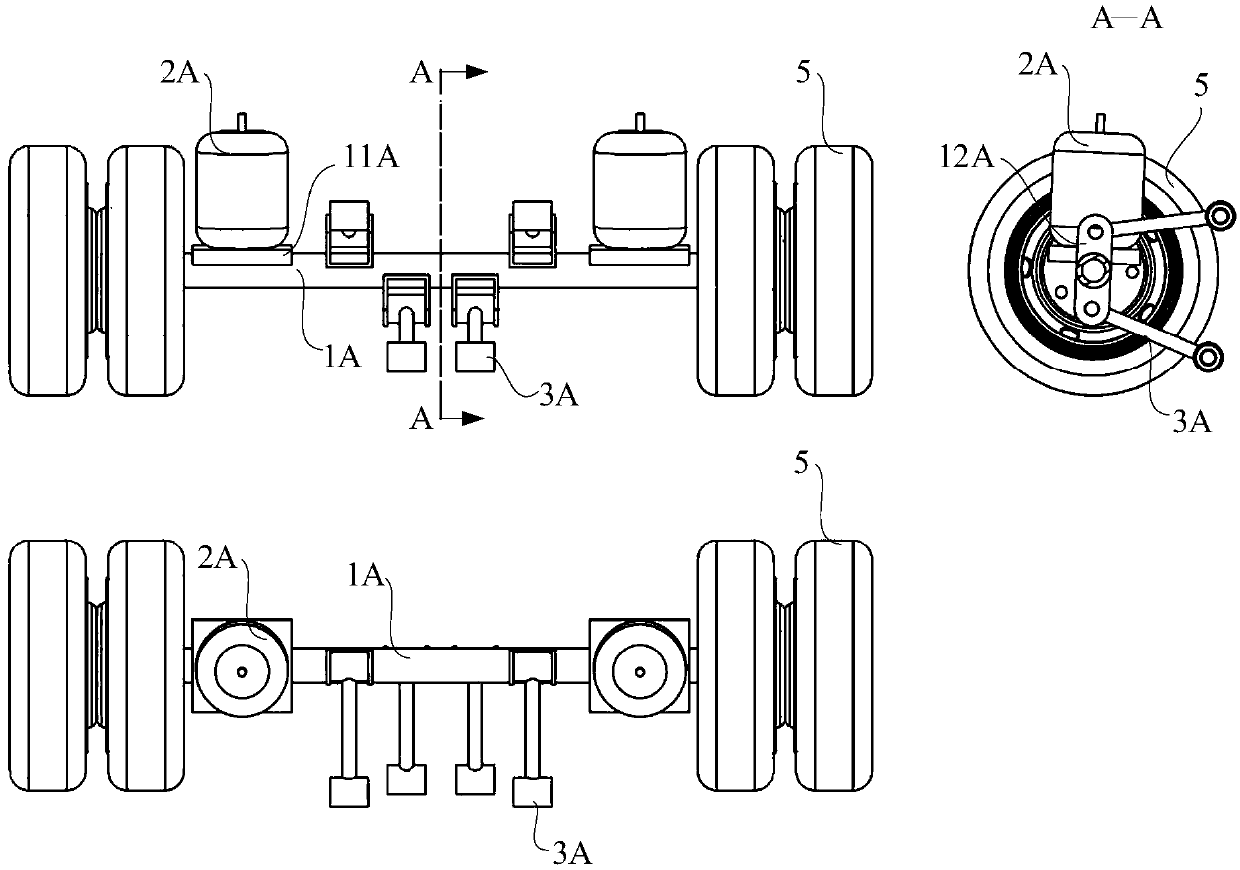

An air suspension, air spring technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problem of insufficient space, air suspension is difficult to balance ride comfort and roll stiffness and cost layout space, air spring 2A Problems such as increase in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

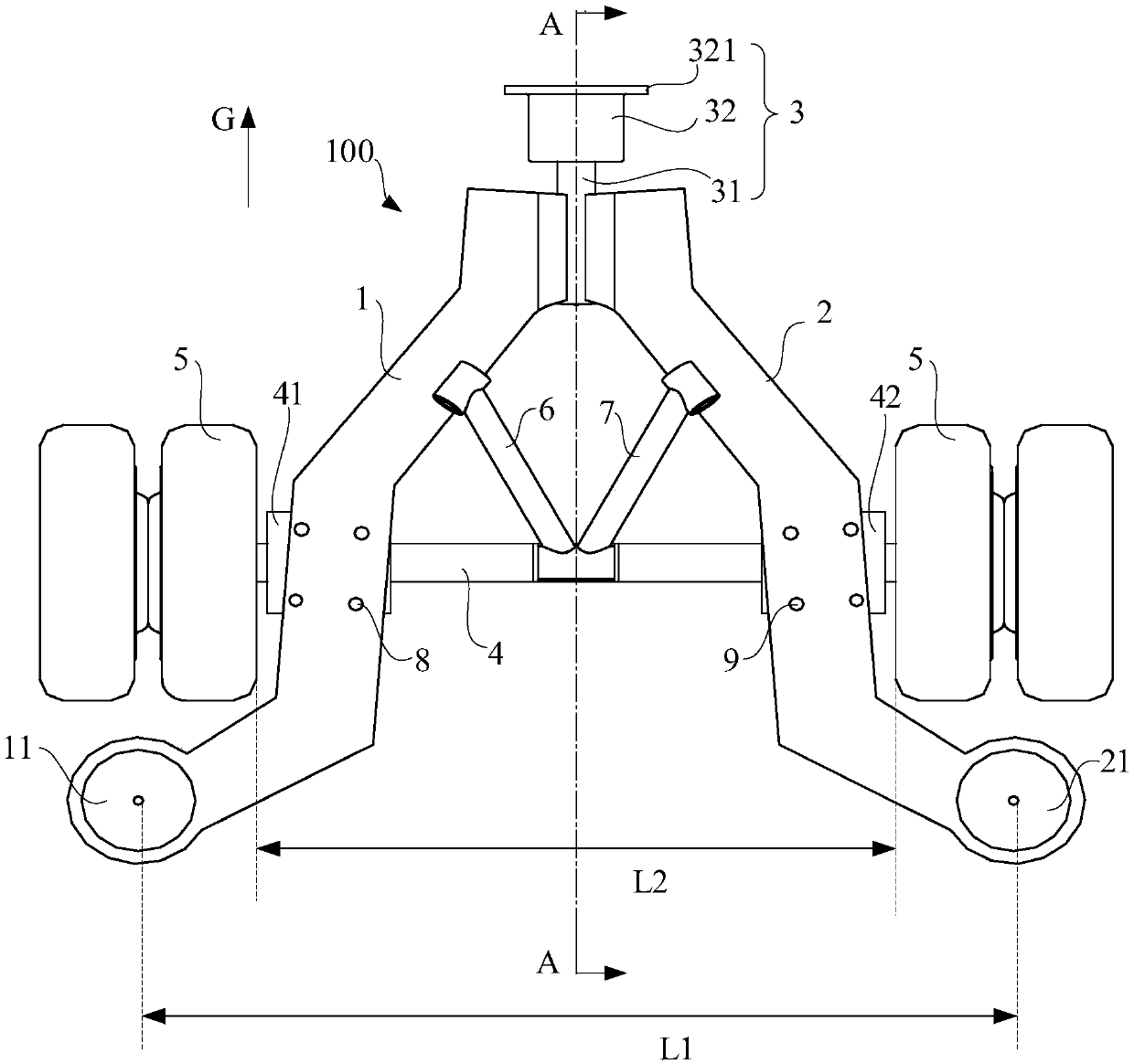

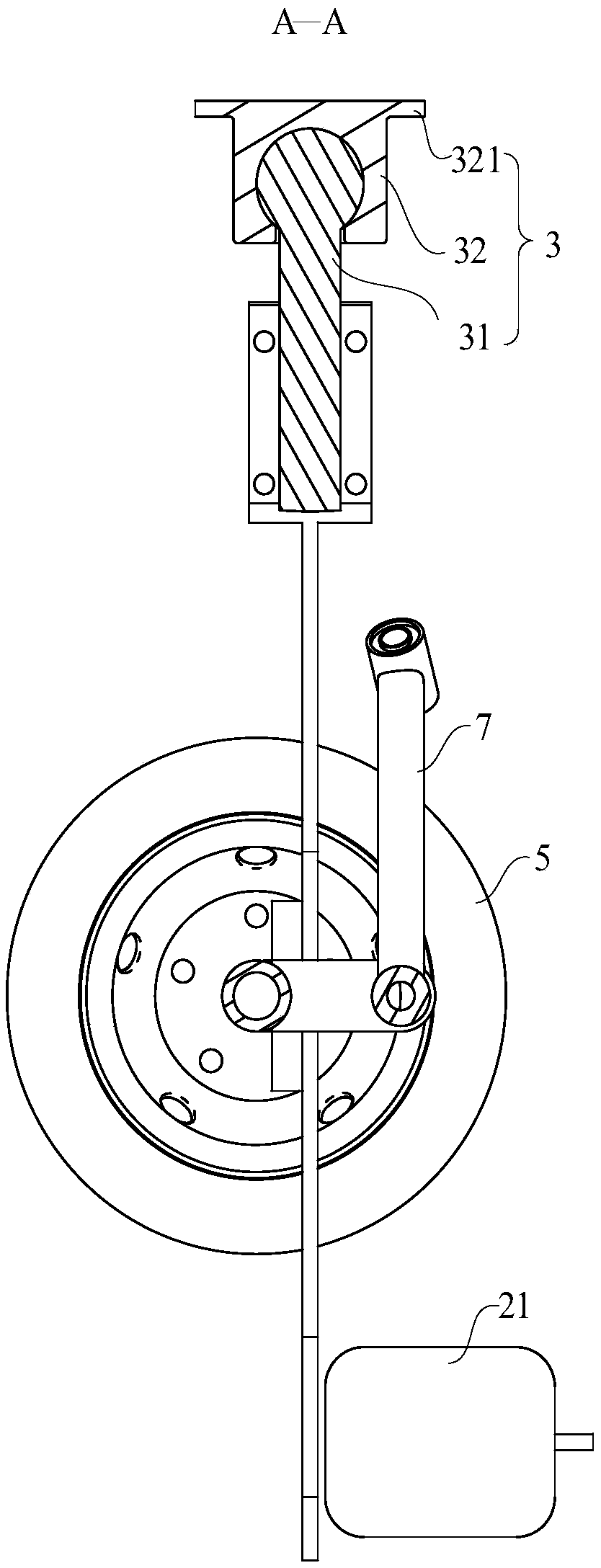

[0032] Please refer to Figure 2 to Figure 4, this embodiment provides an air suspension 100, which includes a first bracket 1 and a second bracket 2 whose middle sections are respectively fixedly connected to the axle 4. In this embodiment, the middle of the first bracket 1 Specifically, the segment can be fixedly connected to the first bracket arm support 41 welded on the vehicle axle 4 through the fixing bolt 8, and the middle section of the second bracket arm 2 can be fixedly connected to the bracket welded on the vehicle axle 4 through the fixing bolt 9. On the second support arm support 42. The first end of the first support arm 1 and the first end of the second support arm 2 are fixedly connected together, and the first end of the first support arm 1 and the first end of the second support arm 2 pass through a connecting assembly 3 together Connected to the vehicle body or frame, in this embodiment, the connection assembly 3 specifically includes a ball pin 31 that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com