Large torque reduction box for withdrawal and straightening machine

A high-torque, reducer technology, applied in the field of high-torque reducers for tension levelers, can solve the problems of small torque, unable to meet the requirements of continuous casting, unable to take into account the requirements of large speed ratio and large torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Further description will be made below in conjunction with drawings and embodiments.

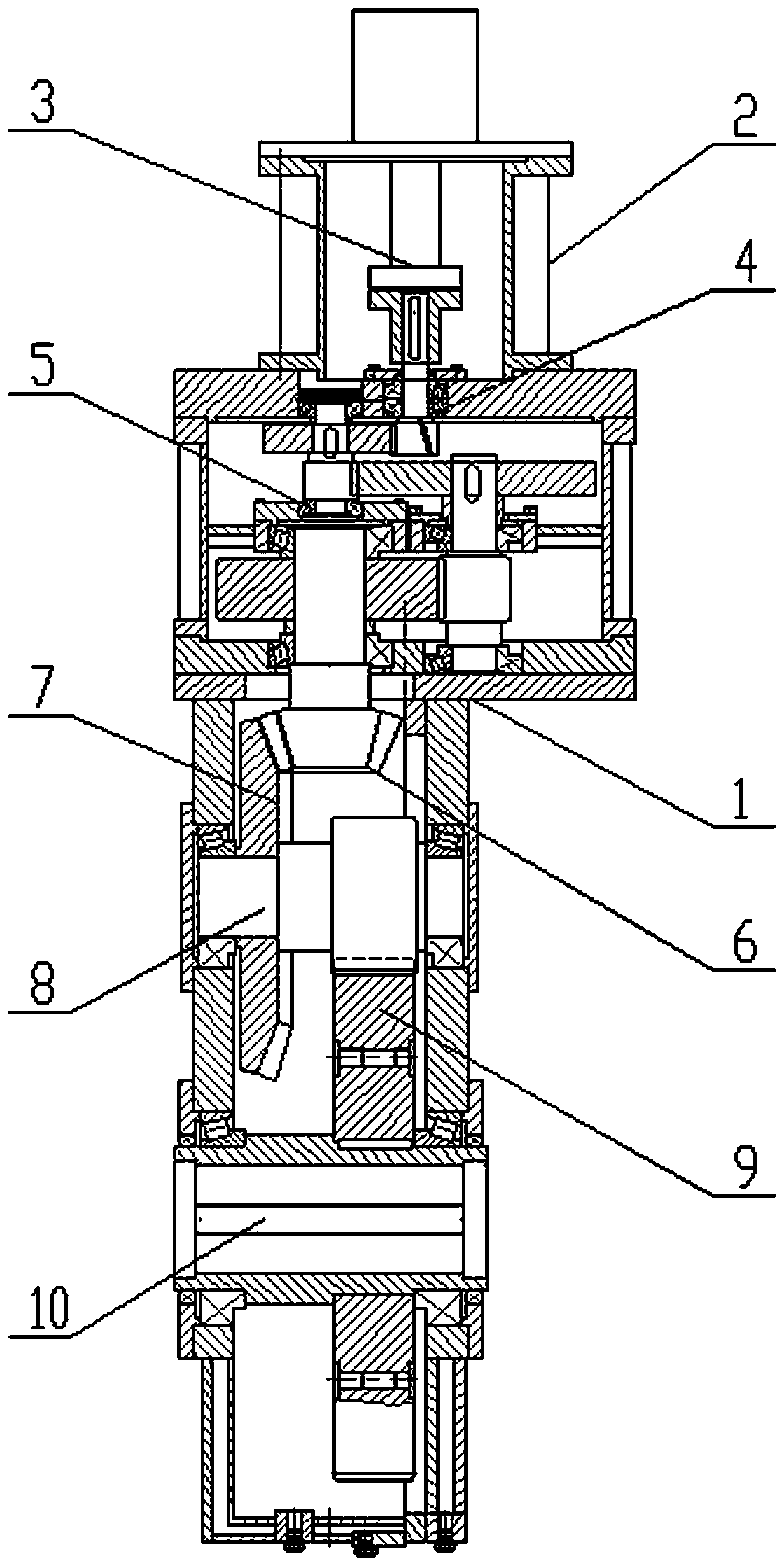

[0010] figure 1 Shown: a high-torque reducer for tension leveling machine includes box body 1, motor flange 2, coupling 3, input gear shaft 4, two-stage cylindrical gear transmission group 5, small bevel gear 6, final stage large cone Gear 7, final stage gear shaft 8, output bull gear 9, output hollow shaft 10. The two-stage cylindrical gear transmission group, the final bevel gear, the final gear shaft, the output large gear and the output hollow shaft are arranged in the box body 1, the motor flange 2 is arranged on one side of the box body, and the input gear shaft is installed in the motor flange. Extending into the box, the input gear shaft 4 outside the box is connected to the coupling 3, the input gear shaft 4 in the box is connected to the two-stage cylindrical gear transmission group 5 through transmission, and the second stage of the two-stage cylindrical gear transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com