Control device for belt-type continuously variable transmission

A technology of continuously variable transmission and control device, which is applied in the direction of transmission, transmission control, components with teeth, etc., to achieve high power transmission efficiency, reduce thrust, and improve energy consumption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

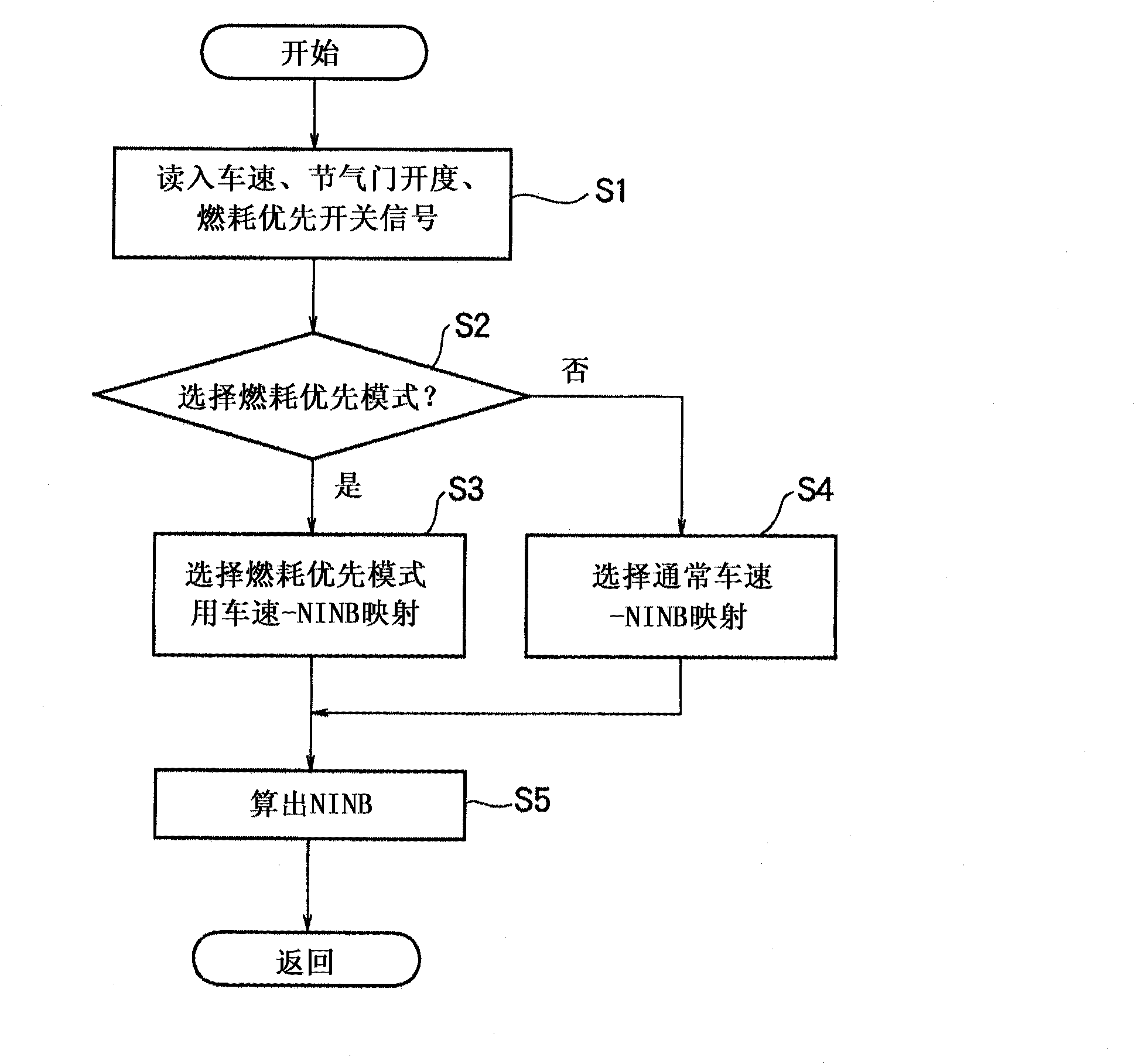

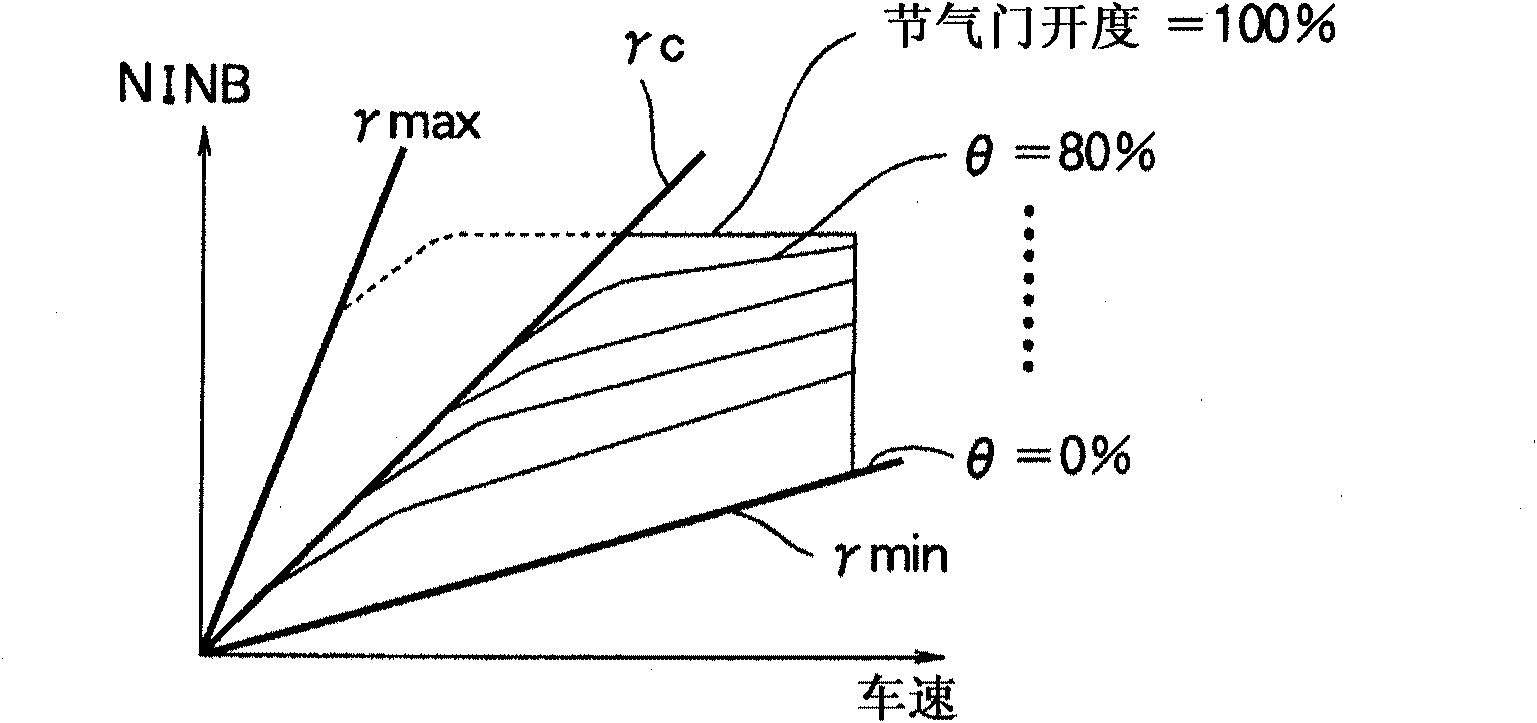

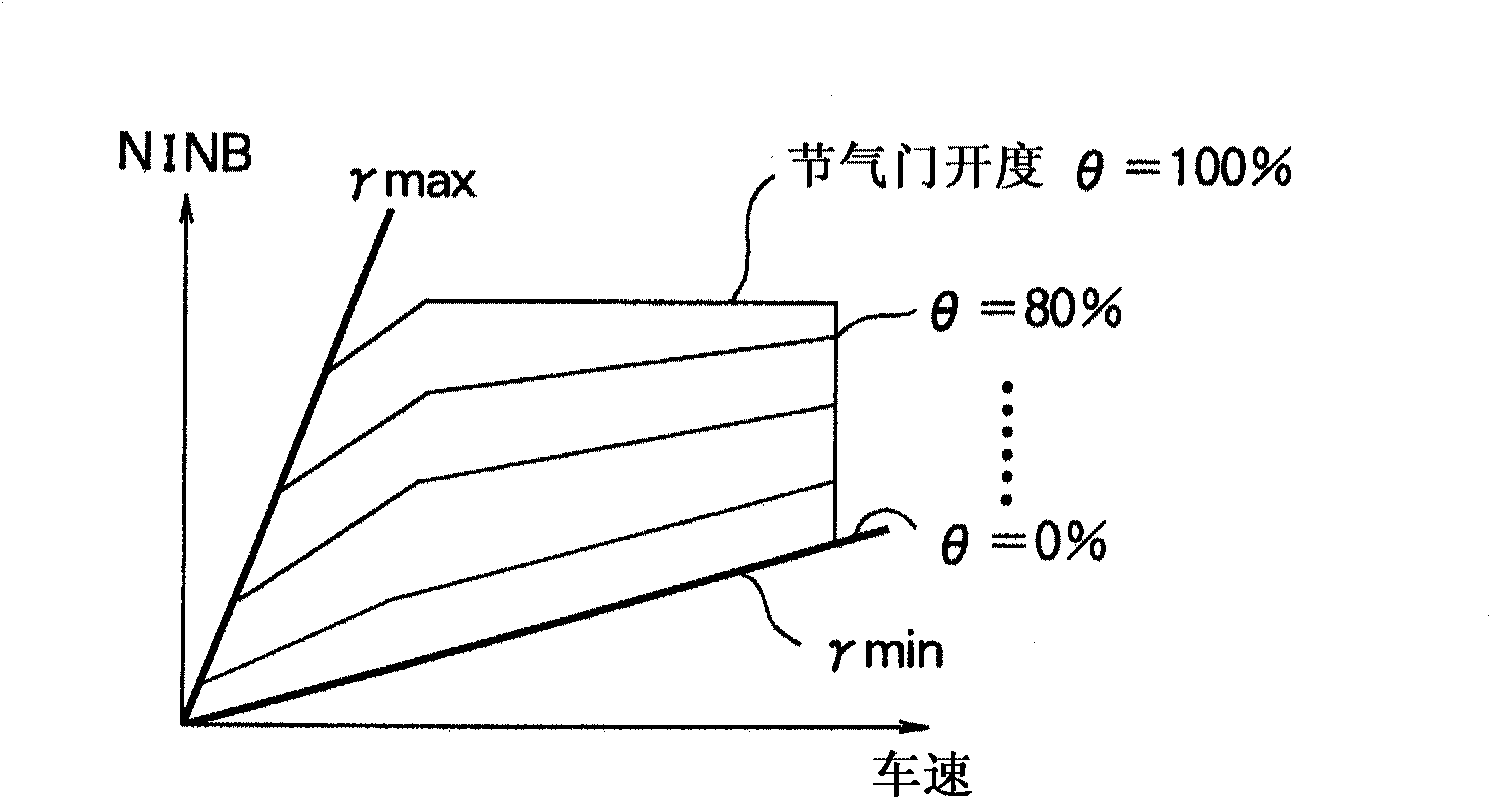

[0032] The present invention is a control device for a belt-type continuously variable transmission. The belt-type continuously variable transmission is configured such that a transmission belt is wound around a driving pulley and a driven pulley, and the winding radius is continuously changed to achieve a transmission ratio Variety. Such a control device includes a plurality of gear change control modes for changing the gear ratio, and is configured to control the change of the gear ratio in accordance with the selected gear change control mode. Therefore, the dynamic performance and acceleration characteristics of the vehicle differ depending on the selected shift control mode. That is, the selected shift control mode affects the energy consumption efficiency of the driving force source that generates torque for traveling.

[0033] First, the belt-type continuously variable transmission described above is described, which is configured to change the wrapping radius of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com