Speed increase gear drive mechanism of speed increase device of circulation type forward and backward turning and variable speed vacuum compressor

A vacuum compressor and speed-increasing gear technology, applied in the field of vacuum compressors, can solve the problems that the jaw clutch is easy to disengage the transmission device, restrict the efficiency of the vacuum compressor's vacuuming and compression functions, and achieve compact structure, The effect of reasonable design and high speed-up transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

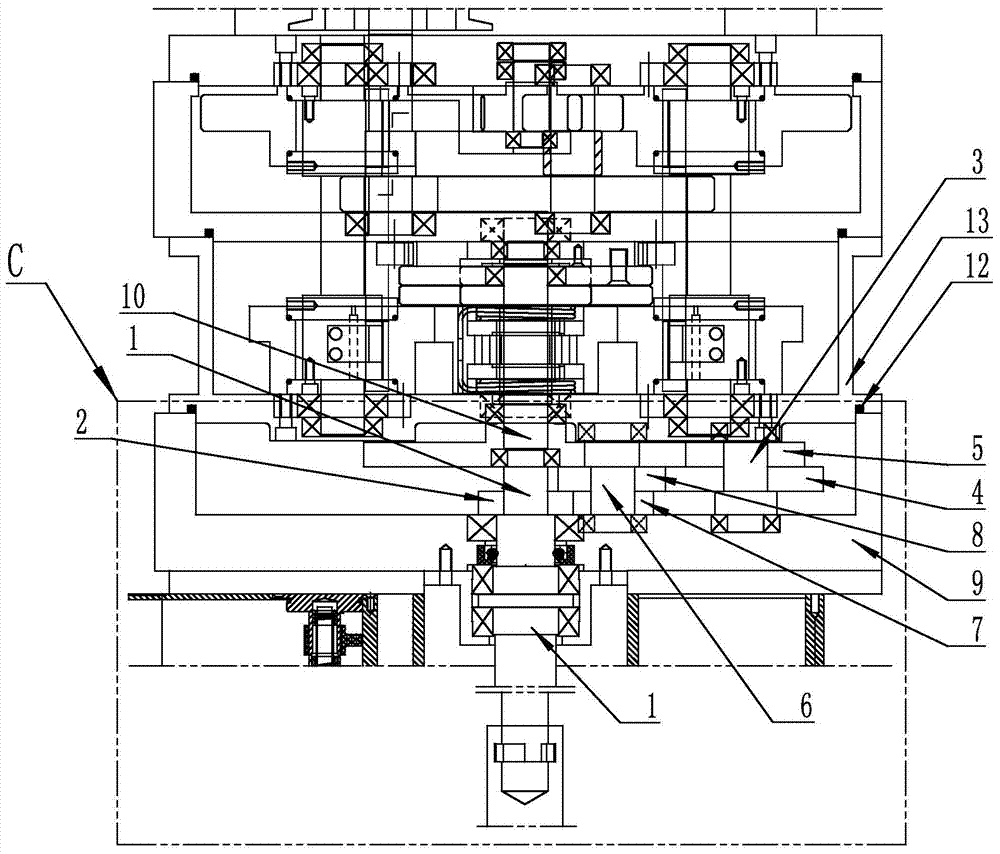

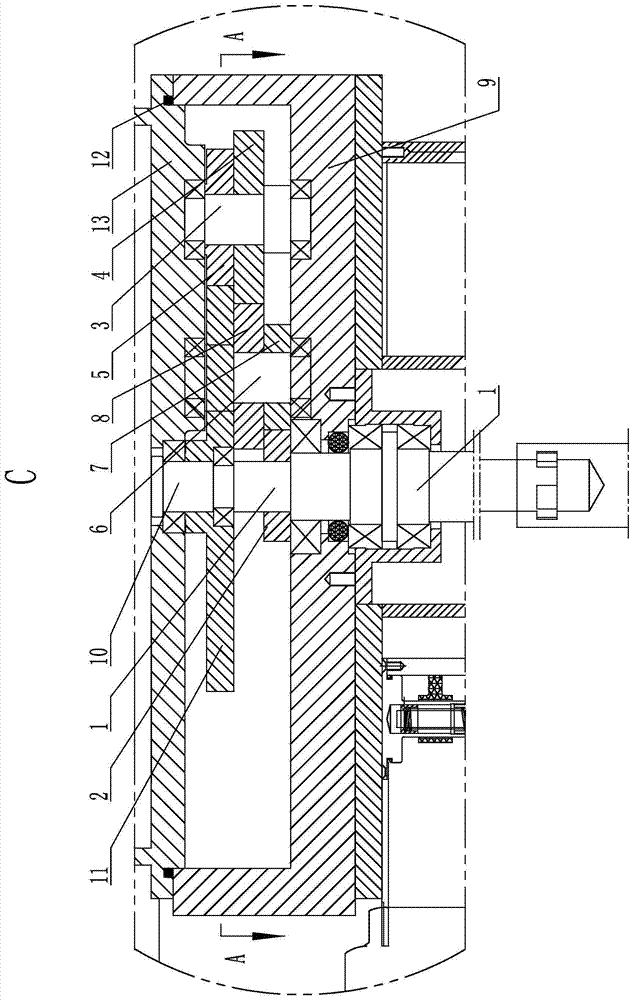

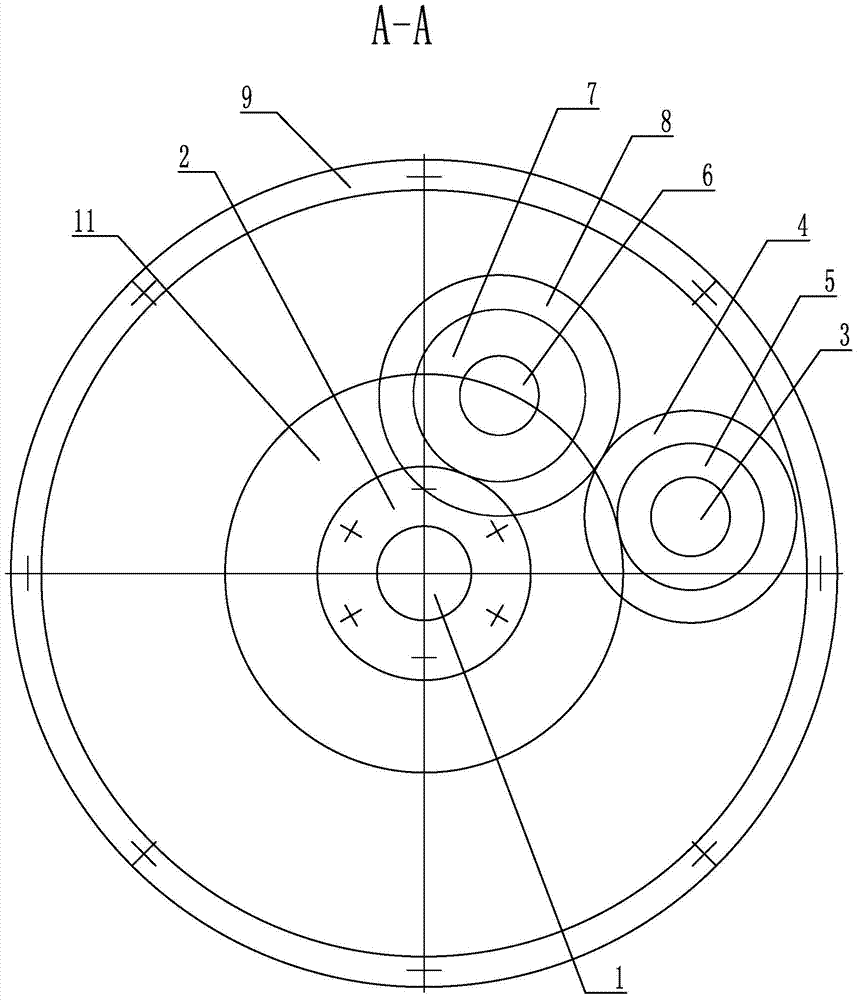

[0015] figure 1 , 2 Shown in , 3 is the specific embodiment of the present invention, and it is the speed-increasing gear transmission mechanism of the speed-increasing device of the vacuum compressor of circulating forward and reverse variable-speed, including output shaft 1, output gear 2, change-to-change main shaft 10, change-to-change Gear 11, speed-up box 9 and change direction box are characterized in that: on the output gear 2 of output shaft 1, speed-up gear transmission mechanism is installed, and described speed-up gear transmission mechanism consists of first transition gear shaft 3, first transition gear 4. The second transition gear 5, the second transition gear shaft 6, the third transition gear 7 and the D transition gear 8 are composed, the bottom end of the first transition gear shaft 3 is supported in the bottom surface of the speed-up box 9 by bearings, and the first transition gear The top of shaft 3 is supported in the boss on the top of speed-up box 9 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com