Cathode arc target device and vacuum multi-arc ion plating machine

A multi-arc ion and vacuum coating technology, which is applied in ion implantation coating, vacuum evaporation coating, sputtering coating, etc., can solve the problems of production stability, product quality reliability, slow vacuuming efficiency, and short maintenance cycle. problems, to achieve the effect of solving vacuum leakage and frequent maintenance, easy guarantee of vacuum degree, and high vacuuming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

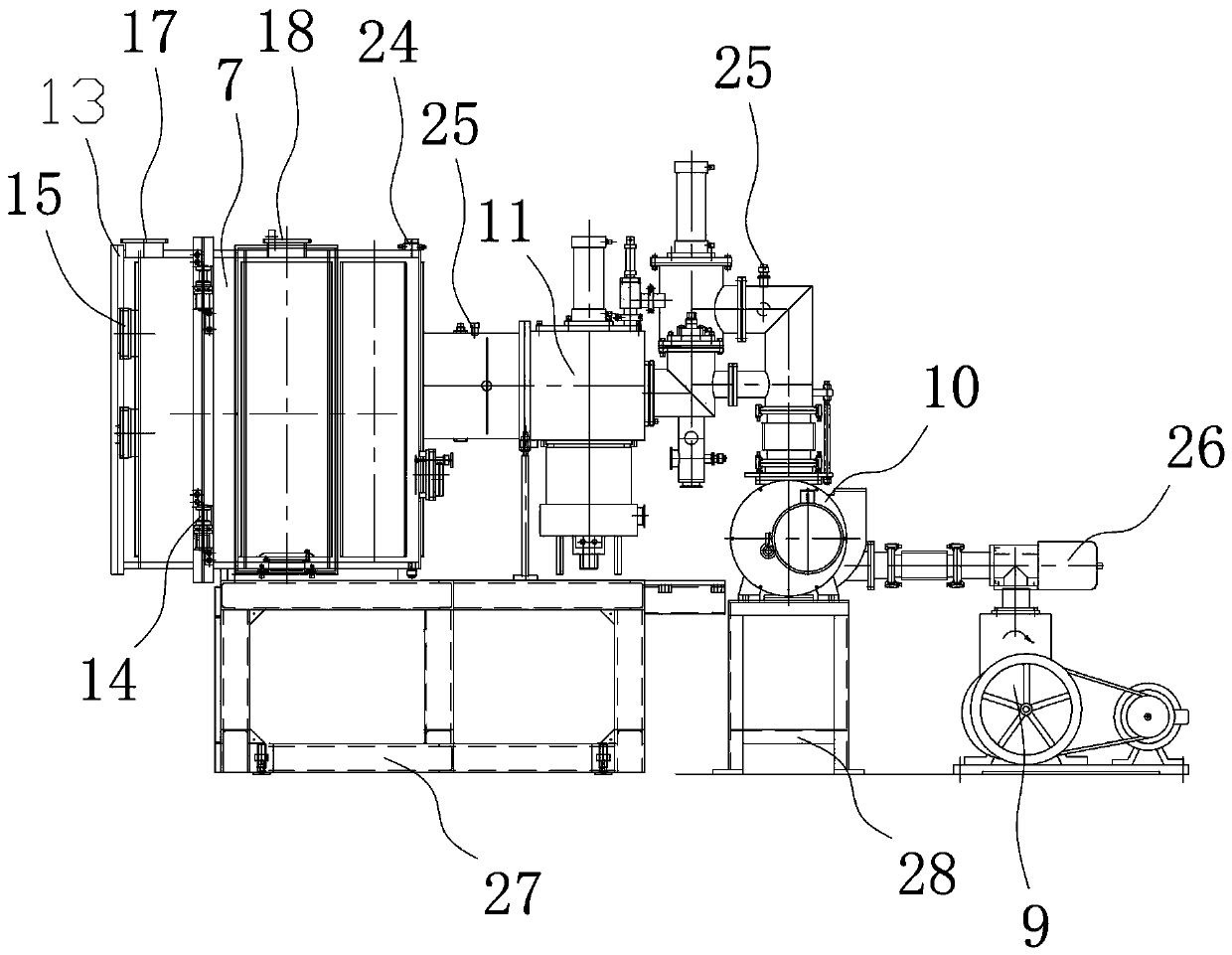

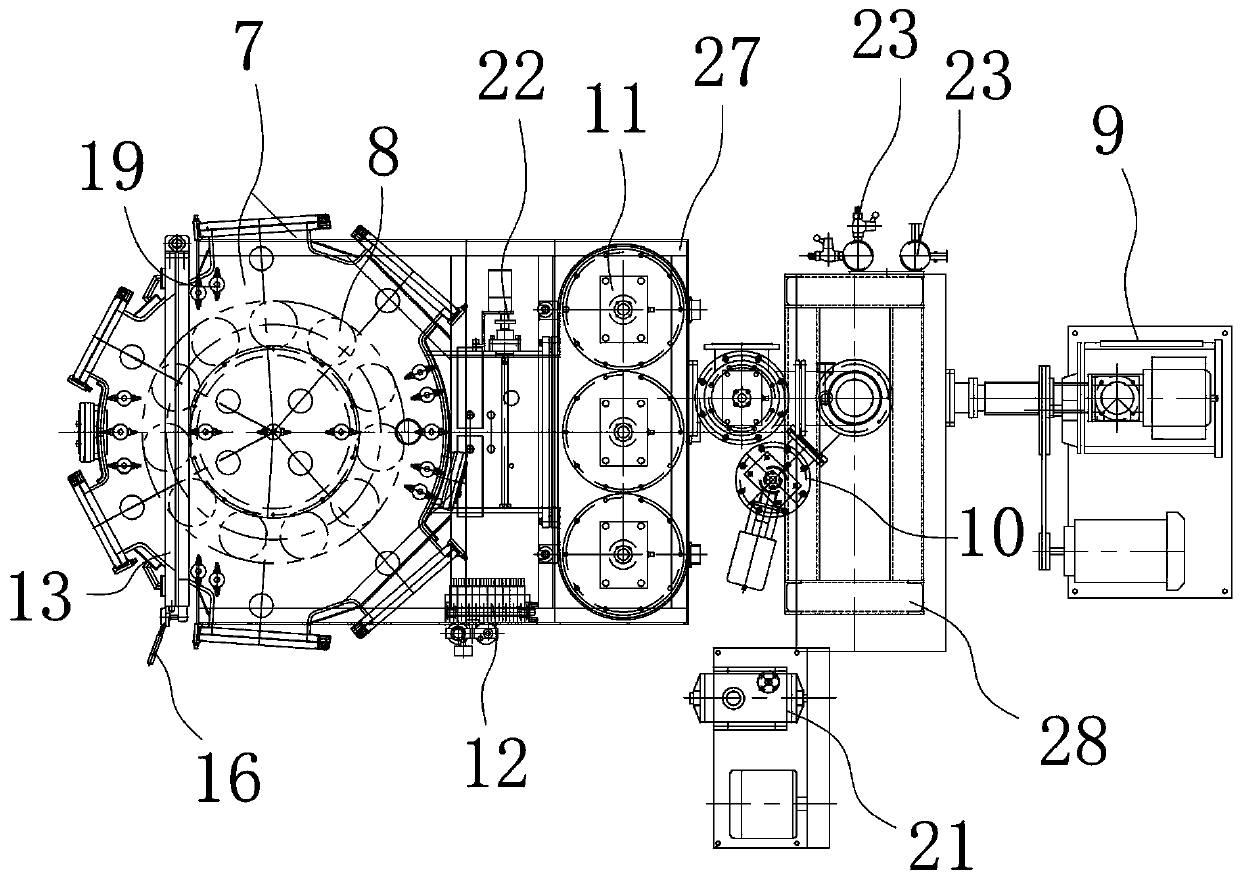

[0020] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

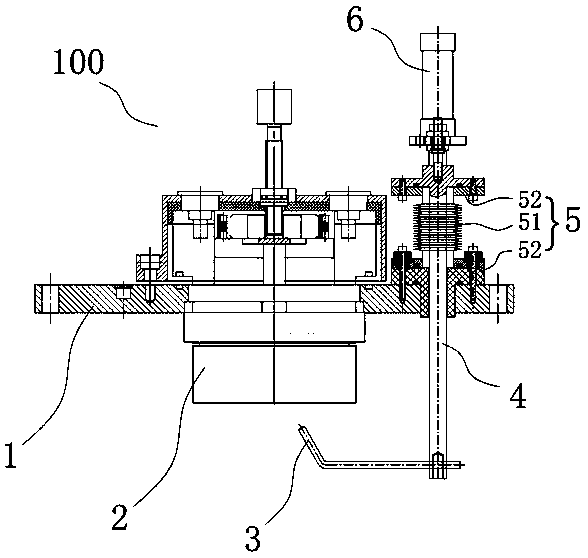

[0021] Such as figure 1 As shown, a cathode arc target device includes an arc target body 1, a target material 2, an arc ignition system 3, a sliding rod 4, a sliding sealing mechanism 5, and a sliding cylinder 6; the target material 2 is installed on the arc target body 1- side, the sliding rod 4 is slidably installed on one end of the arc target body 1, the sliding cylinder 6 is connected with the sliding rod 4, and drives the arc striking system 3 to approach or move away from the target 2 through the sliding rod 4; The sealing mechanism 5 is arranged outside the sliding rod 4, and is used for vacuum sealing the sliding rod 4; the sliding sealing mechanism 5 includes a bellows 51 and a bellows frame 52, and the bellows frame 52 is installed on the arc target body 1, the two ends of the bellows 51 are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com