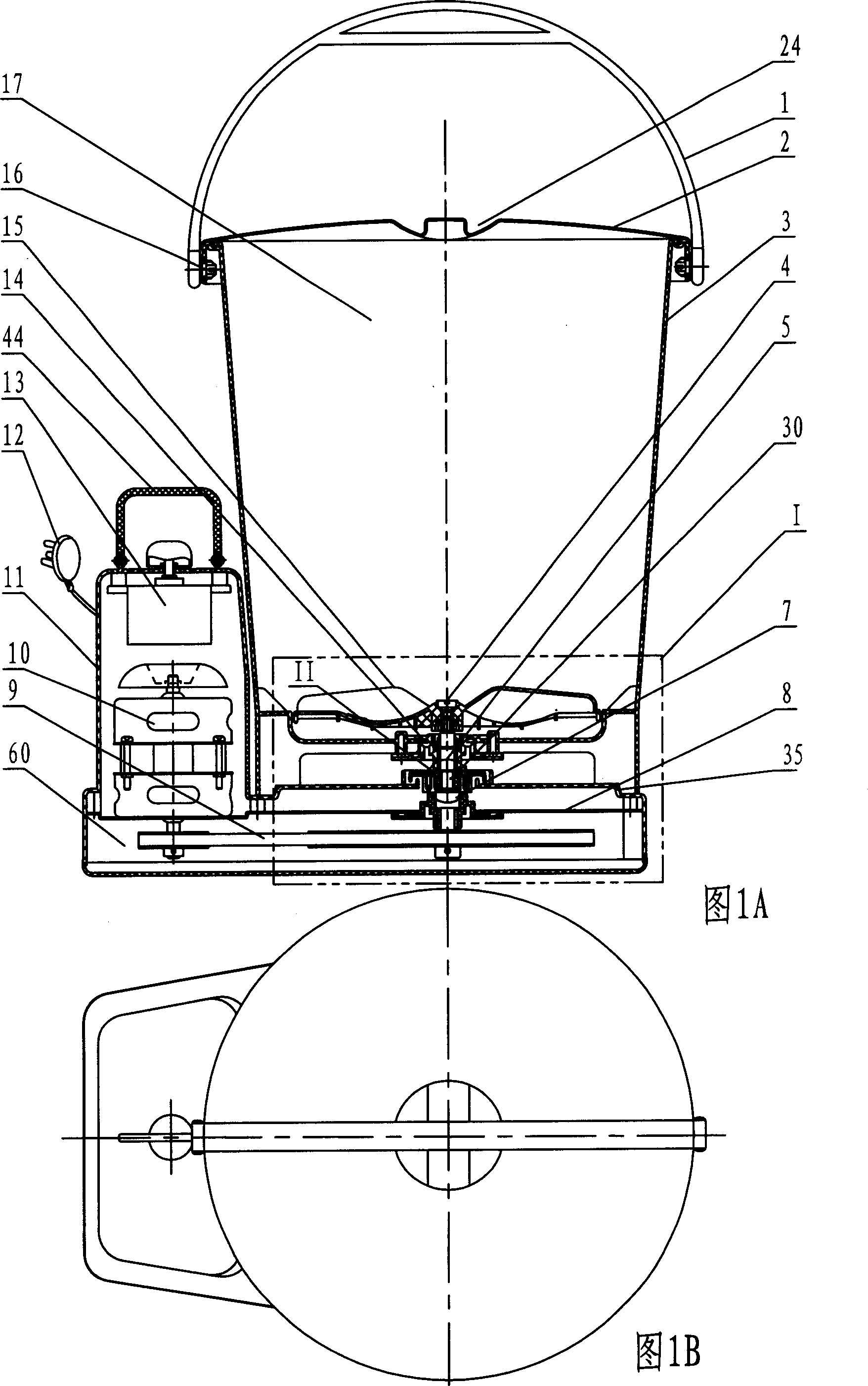

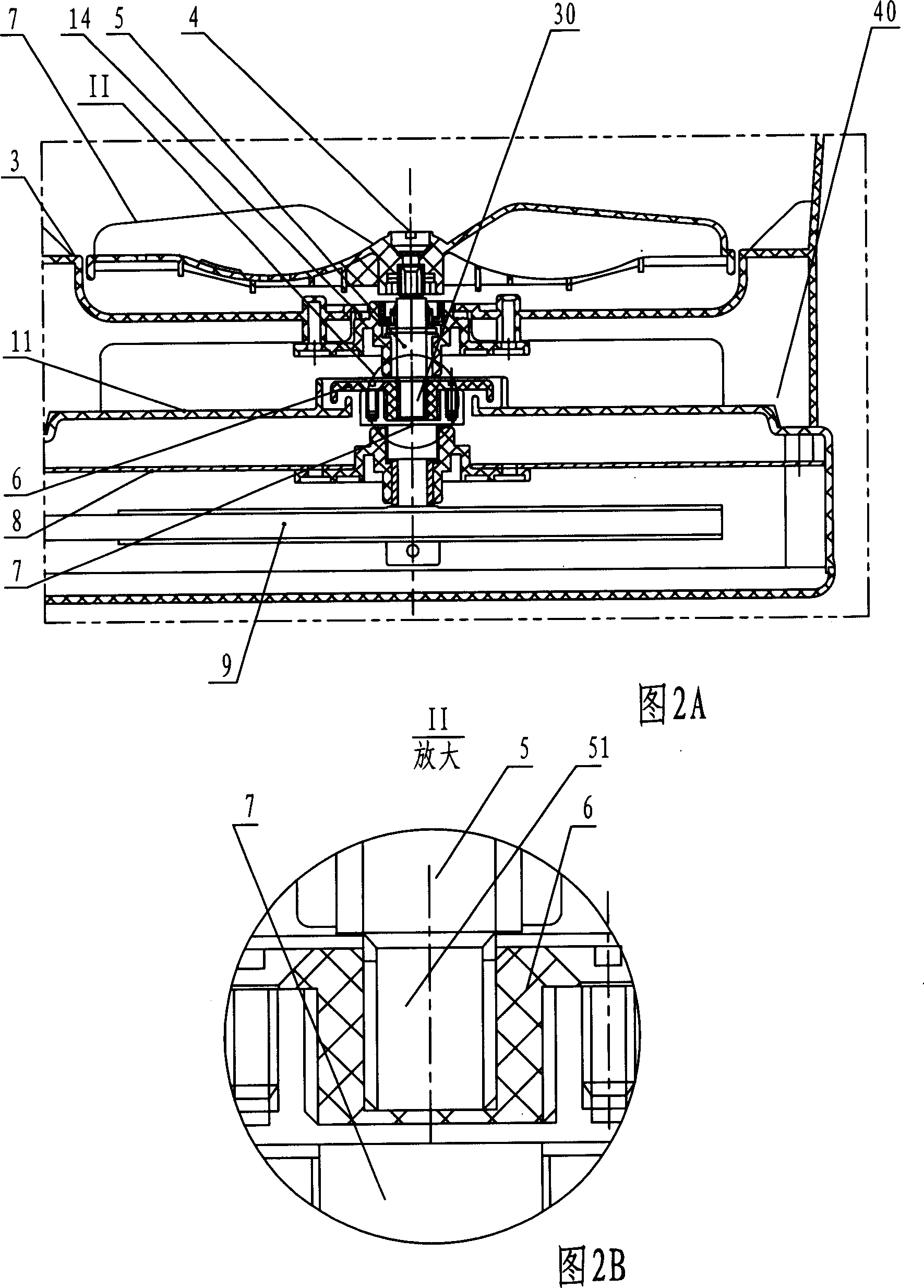

Portable split washing machine

A washing machine and portable technology, applied in the field of washing machines, can solve the problems of unfavorable deceleration devices, increased costs, and unstable work of the laundry bucket at the work center of gravity, so as to achieve the effects of reducing costs, stabilizing work, and avoiding electrical device failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

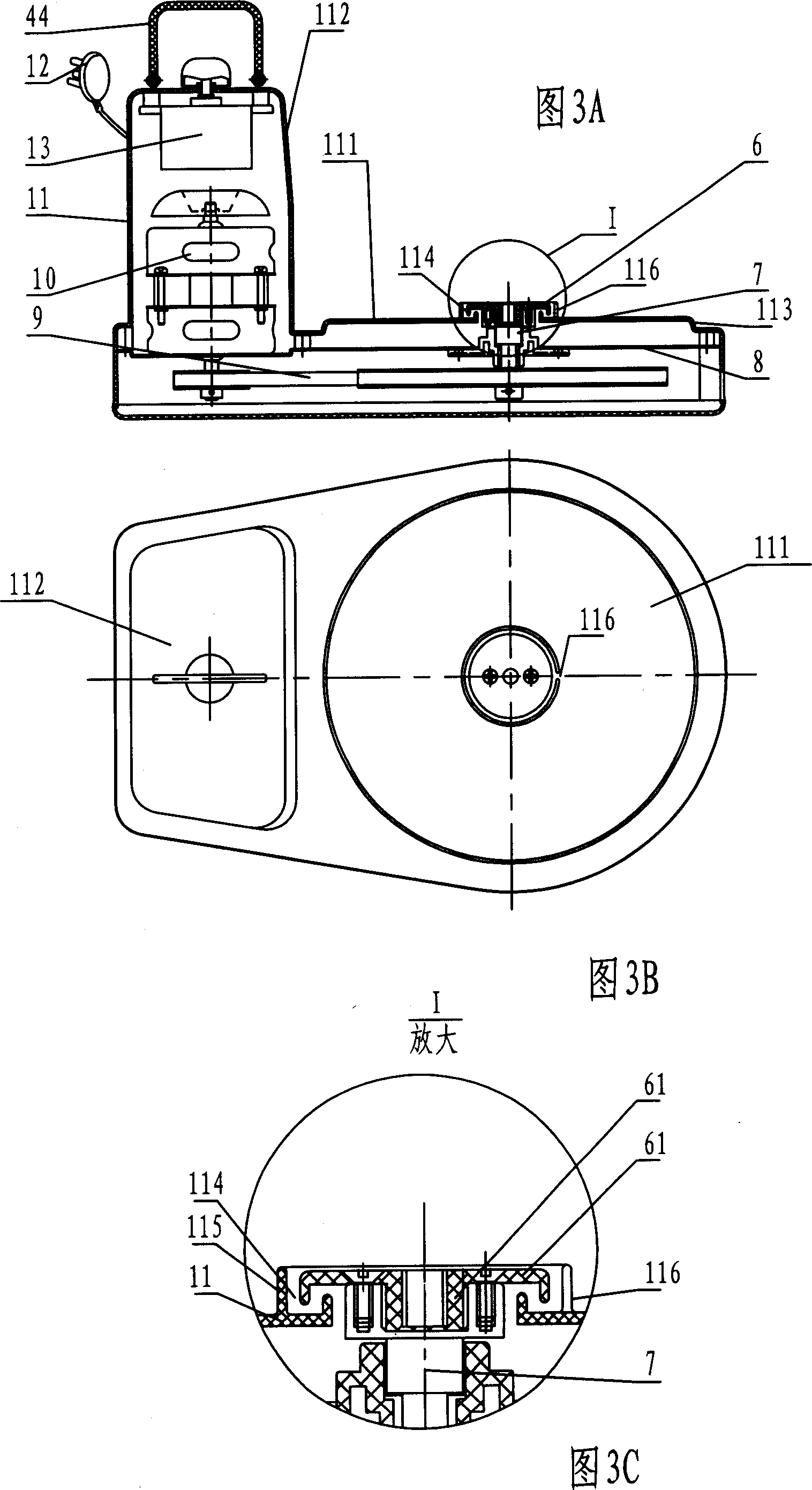

[0051] Referring to Figures 5A-5D, the difference between the second embodiment and the first embodiment is:

[0052] The side wall of the washing bucket 3 has a water level scale 36 that can see the internal water level from the outside. The water level scale 36 can be a transparent plastic strip that is mounted on the side wall, and the plastic strip is provided with a protruding water level scale line for use. Observe the internal water level from time to time; you can also use a translucent laundry bucket directly, with a raised water level scale line on the inner wall of the bucket;

[0053] The inner wall of the washing bucket 3 has longitudinal protruding ribs 32, which can strengthen the scrubbing of the clothes during washing;

[0054] The center of the bung 2 is inlaid with a plate 19 made of circular transparent plastic, which acts as a window, so that the internal washing situation can be observed during use;

[0055] Figures 5A-5D show another sealed waterproof s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com