Track self-walking, tank overturning and tank colliding deslagging method

A self-propelled and track-based technology, which is applied in the field of slag dumping, tank turning, and track self-propelled in one, can solve the problems of high labor intensity, harsh working environment, and high labor costs, and achieve increased operational stability and automation. High-level, high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

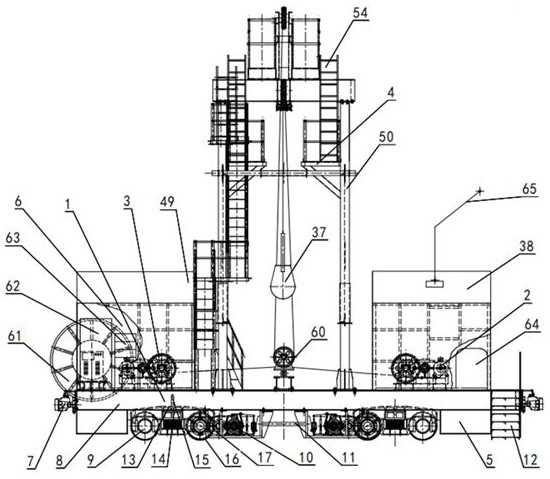

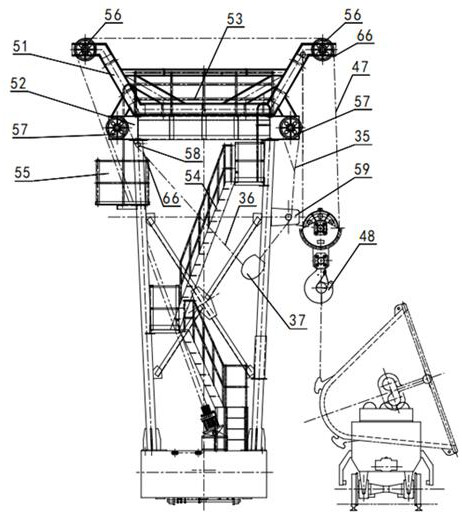

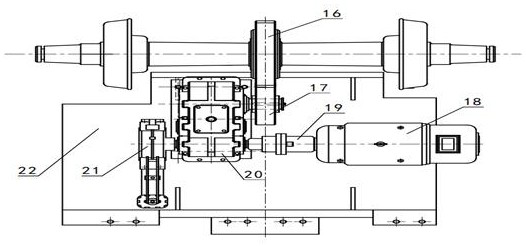

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0037] The method of turning over tanks, bumping tanks and dumping slag by track self-propelling includes the following steps:

[0038] S1. The slag tank truck drives into the unloading area;

[0039] S2. The lifting hook is hooked with the lifting lug of the slag tank; the lifting hook is lifted to carry out the tank turning operation;

[0040] S3. The slag tank is turned over by lifting the hook, and the turning angle is 101° for slag dumping and unloading;

[0041] S4. The steel slag in the slag tank is dumped clean, and the hook is lowered to reverse the slag tank and return to its original position, and start to dump the next slag tank.

[0042] The track self-propelled tank dumping method also includes the following steps:

[0043] S5. Observe that the steel slag in the slag tank is not clean in step S4, lift the pendulum to a height a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com