Heavy type 12-gear high torque transmission assembly

A transmission and high-torque technology, applied in the field of heavy-duty 12-speed high-torque transmission assembly, can solve problems such as engine matching in the torque range, improve the bearing capacity of the auxiliary box, improve the service life and reliability of the whole box, and achieve a clear gear position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

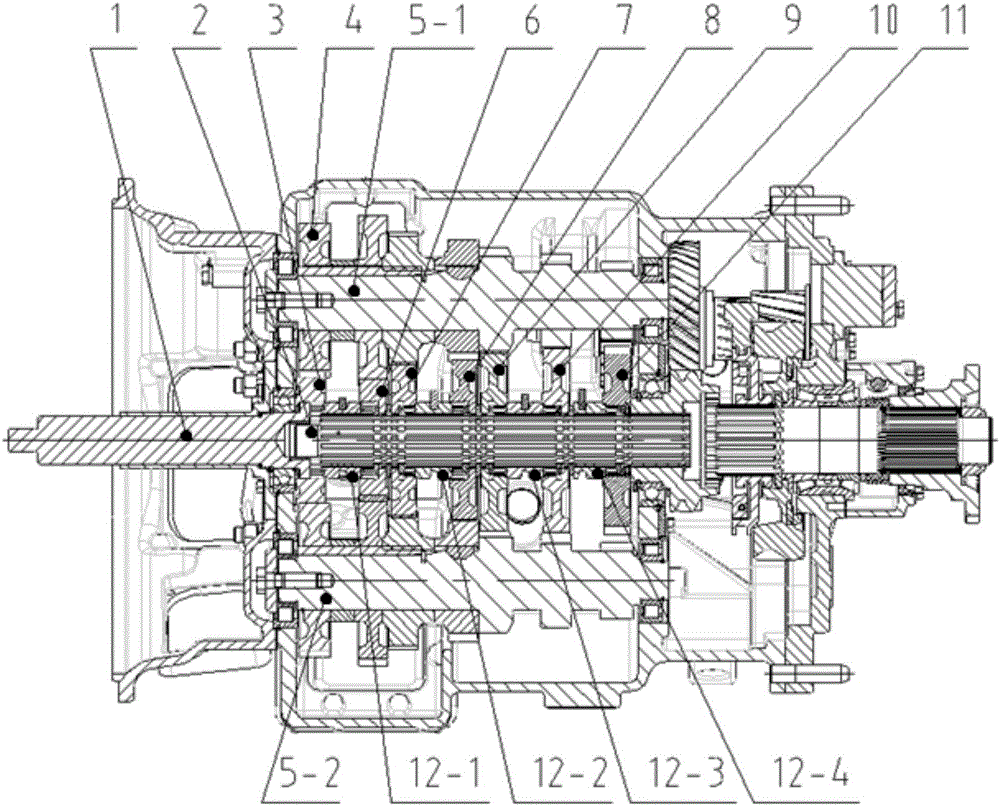

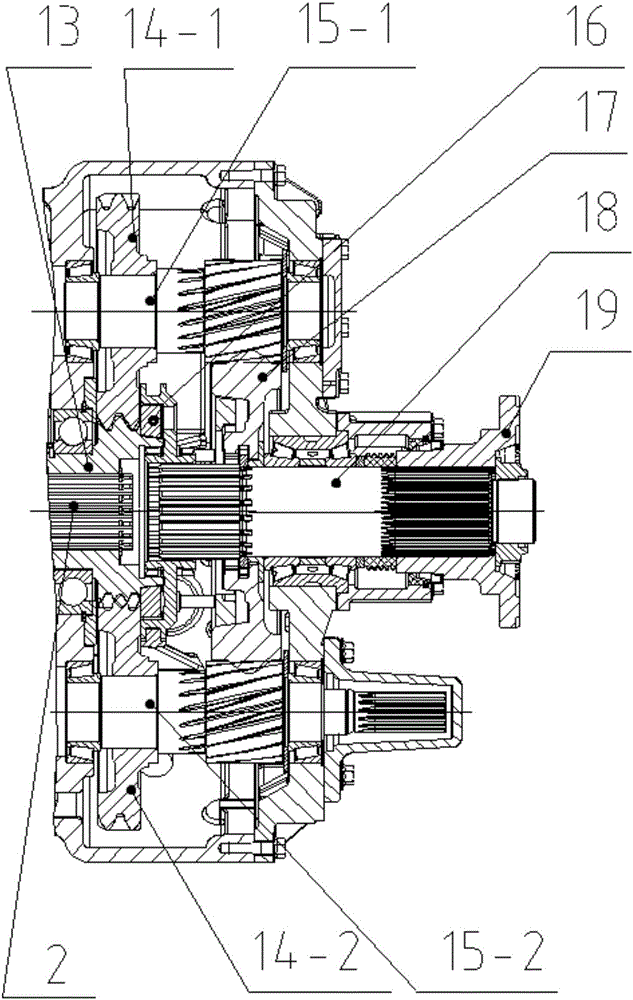

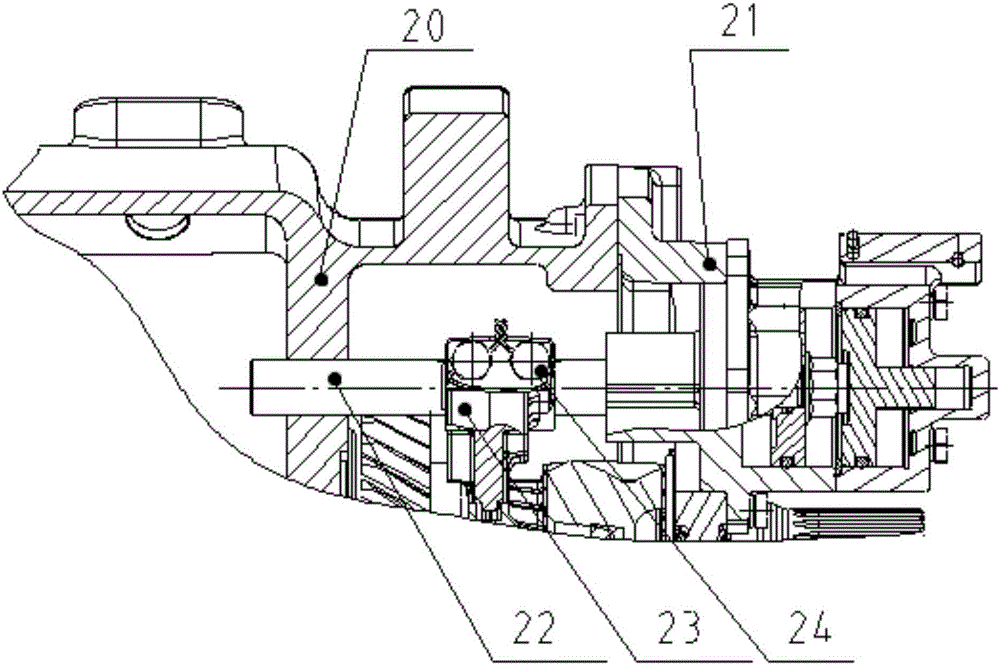

[0024] The purpose of the present invention is to provide a heavy-duty 12-speed high-torque transmission assembly. The technical solution of the present invention adopts a double countershaft structure with the lower left and upper right obliquely, and the main shaft and main shaft gear of the main and auxiliary cases float. The bearing capacity of the transmission is improved by increasing the center distance of the auxiliary case and configuring reasonable shaft tooth parameters. The transmission assembly of the present invention has reasonable gear positions, suitable speed ratio and large first gear speed ratio, and is a 12-speed high-torque transmission assembly with double countershafts with higher reliability, durability and fuel economy. In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0025] Such as figure 1 and figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com