Cable type differential for detection vehicle

A technology for differentials and detection vehicles, applied in differential transmissions, motor vehicles, belts/chains/gears, etc., can solve the problems of small launch payload, occupy storage space, and high processing costs, and increase the launch payload. , Wide range of applications, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

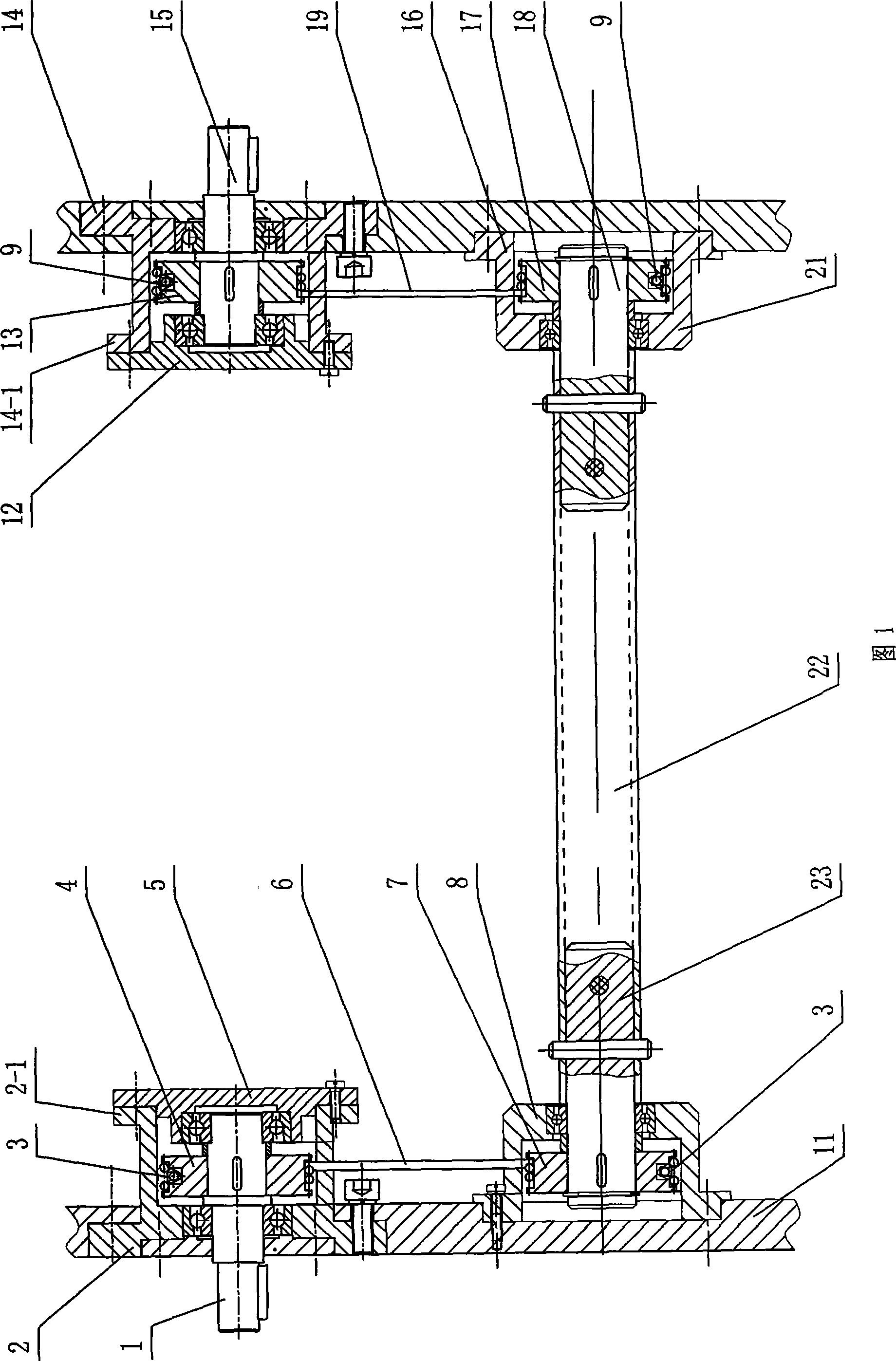

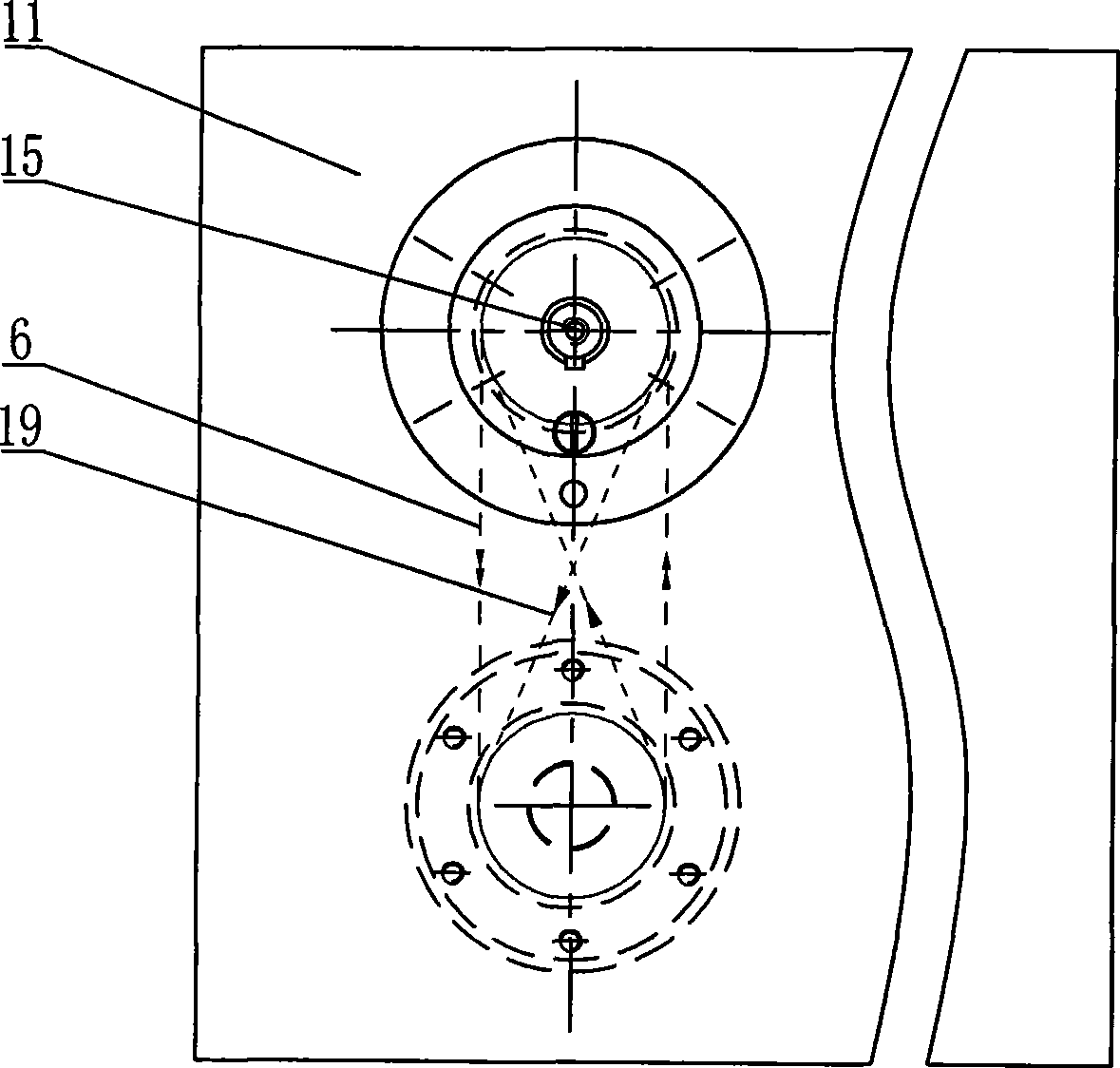

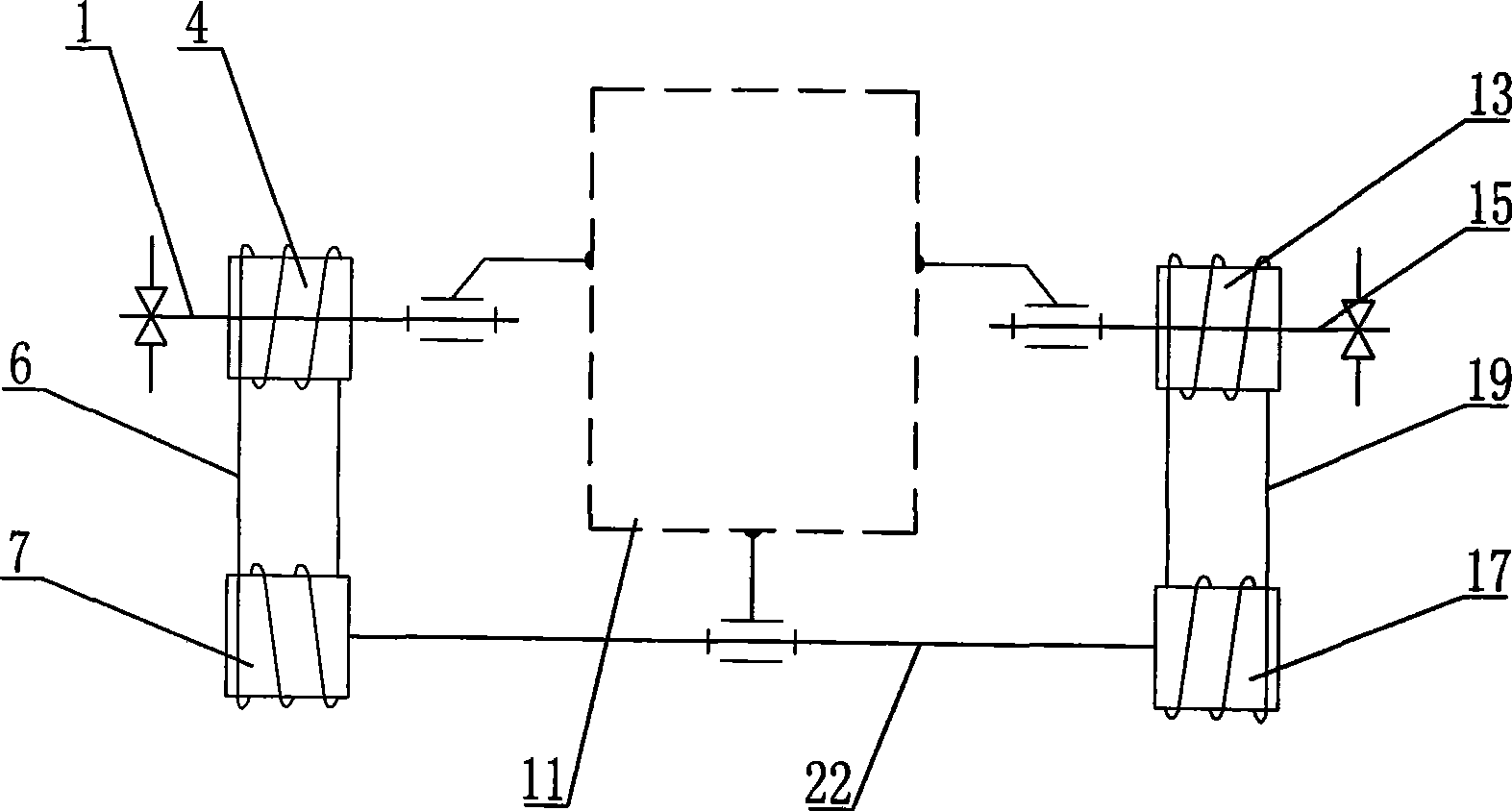

[0007] Specific implementation mode one: in conjunction with Fig. 1~ image 3 This embodiment is described. This embodiment is composed of a co-directional transmission unit, a reverse transmission unit, a hollow shaft 22 and a load platform 11. The co-directional transmission unit and the reverse transmission unit are installed at both ends of the hollow shaft 22 respectively. The same-direction transmission unit includes the same-direction driving wire pulley 4, the same-direction driven wire pulley 7, the first input shaft 1, the same-direction support sleeve 2, the same-direction steel wire rope 6, the same-direction end cover 5, and the same-direction bearing end cover 8 and the same direction connecting short shaft 23; the same direction support sleeve 2 is installed on the first input shaft 1, and the same direction end cover 5 is fixed on the small flange end surface 2-1 of the same direction support sleeve 2, And the first input shaft 1 is rollingly matched with the s...

specific Embodiment approach 2

[0008] Embodiment 2: This embodiment is described with reference to FIG. 1 . The axes of the first input shaft 1 and the second input shaft 15 in this embodiment are on the same straight line. Such setting ensures the symmetrical installation of the suspension on both sides and the better work of the rope differential. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment three: This embodiment is described in conjunction with Fig. 1. The co-directional transmission unit of this embodiment is also added with two co-directional steel wire briquetting blocks 3, and the two co-directional steel wire briquetting blocks 3 are installed on the co-directional driving steel wires respectively. Wheel 4 and the same direction driven wire wheel 7. Such setting is used to fix the wire rope to prevent the wire rope from falling off. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com