Mounting and adjusting tool applicable to fork plunger type steering engine and use method thereof

A technology of installation adjustment and adjustment work, which is applied in the direction of hand-held tools, manufacturing tools, workpiece clamping devices, etc., can solve the problems of difficulty in ensuring the accuracy and reliability of equipment installation, no mention of technical design, and low accuracy. Achieve the effect of ensuring the accuracy and reliability of equipment installation, strong adjustability and multi-directional, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

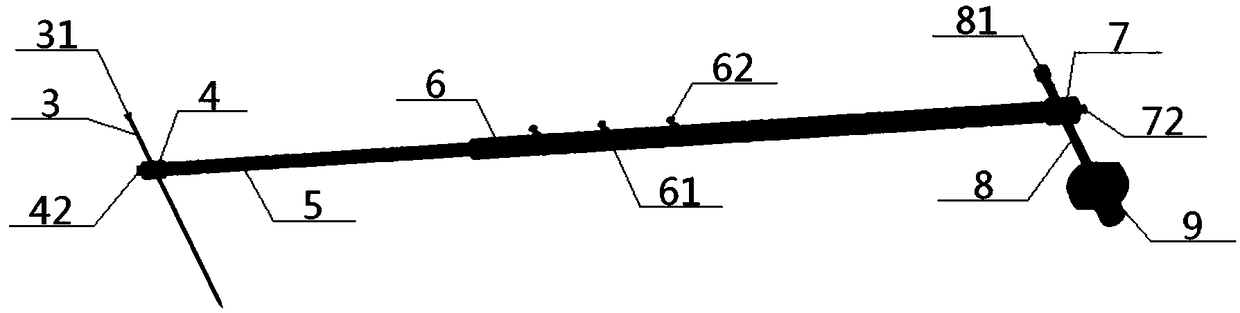

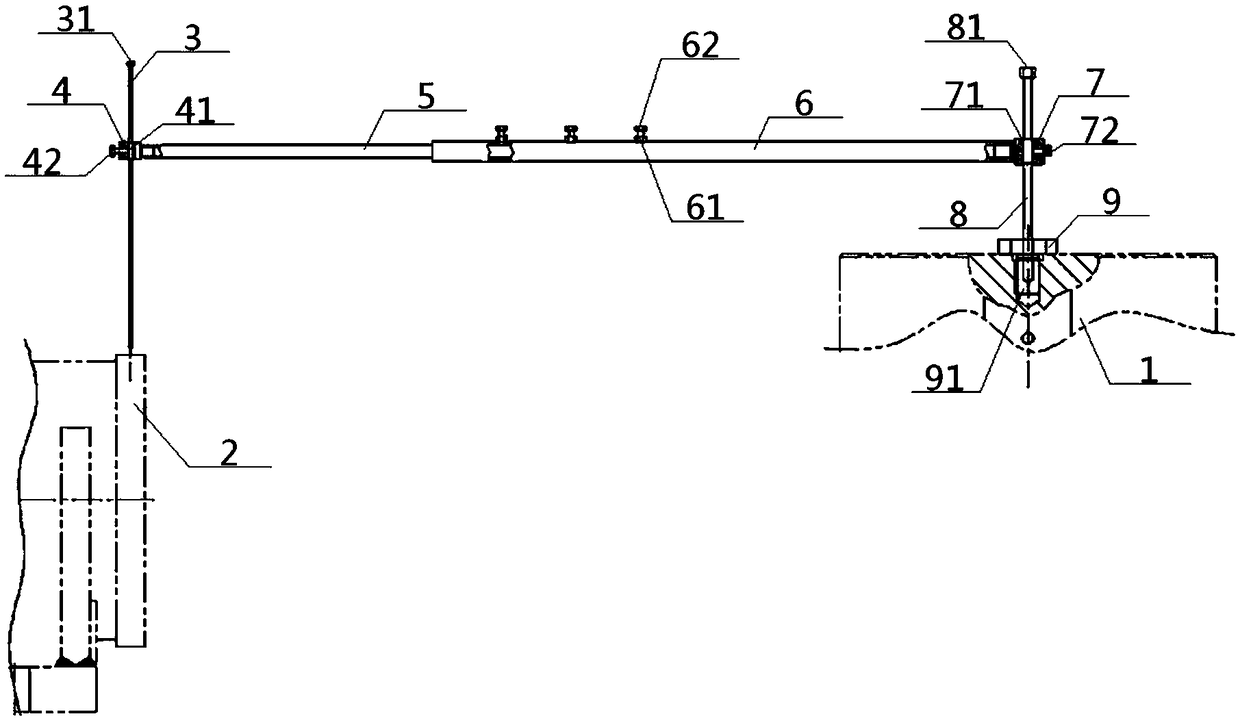

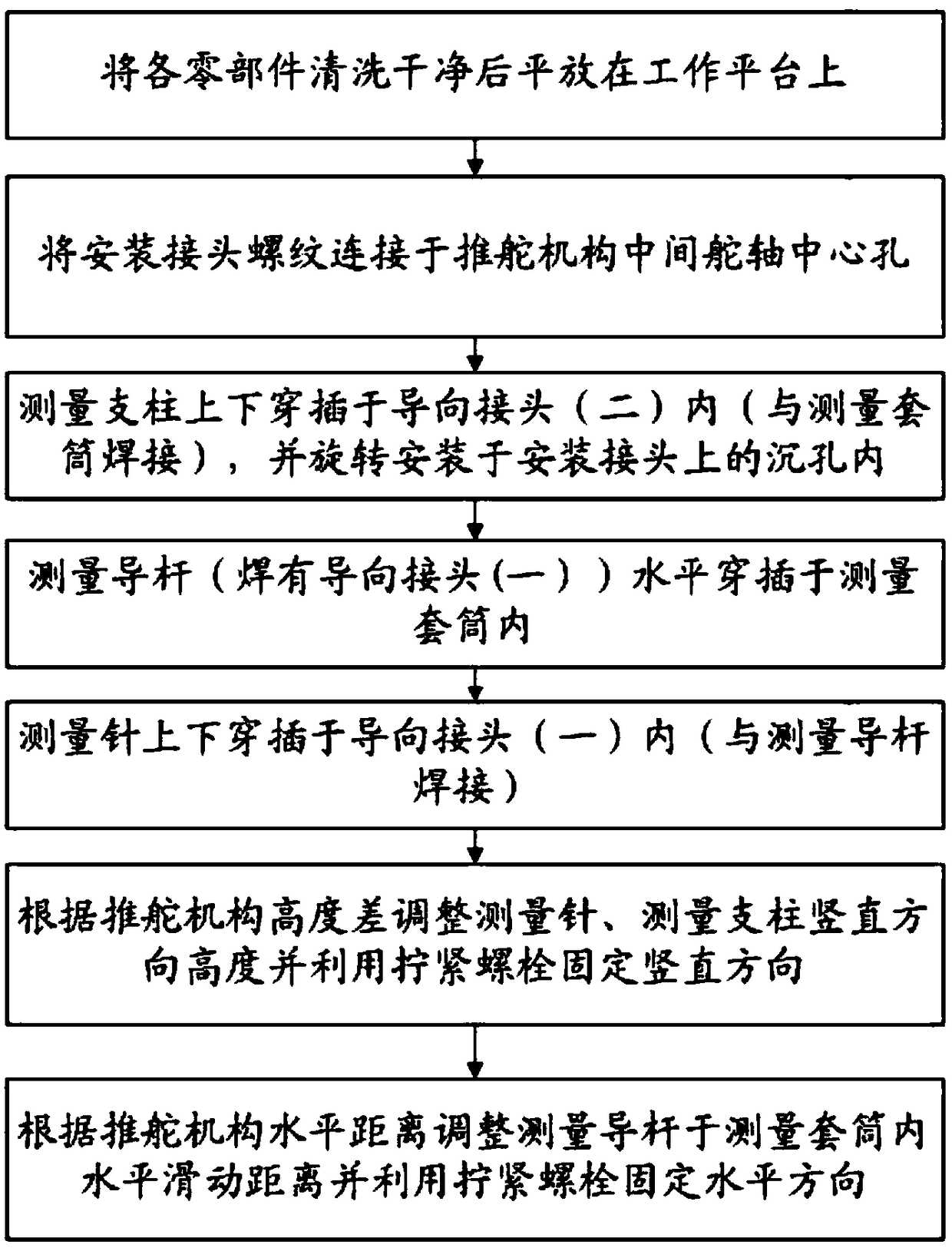

[0056] see Figure 1 to Figure 5 , a kind of installation and adjustment tooling suitable for a fork plunger type steering gear; the installation and adjustment tooling includes a measuring needle 3, a guide joint 1 4, a measuring guide rod 5, a measuring sleeve 6, a guide joint 2 7, a measuring pillar 8 and The joint 9 is installed, and the inside of the guide joint 4 is provided with a needle cavity 41 for the measuring needle 3 to pass through. The right end of the guide joint 4 is connected with the left end of the measurement guide rod 5, and the right end of the measurement guide rod 5 extends To the inside of the measuring sleeve 6, the part of the measuring guide rod 5 located in the measuring sleeve 6 is slidably fitted with the inner cavity of the measuring sleeve 6, the right end of the measuring sleeve 6 is connected with the left end of the guide joint 2 7, and the guide The inside of the joint 2 7 is provided with a column cavity 71 for the measuring pillar 8 to ...

Embodiment 2

[0066] Basic content is the same as embodiment 1, the difference is:

[0067] The fixing of the measuring needle 3 and the measuring pillar 8 refers to: the needle fixing bolt 42 is screwed inward along the through-needle cavity 41 to suppress the measuring needle 3 in the through-needle cavity 41 to realize the fixing of the measuring needle 3 The column fixing bolt 72 is screwed inward along the column cavity 71 to press the measuring pillar 8 in the column cavity 71 to fix the measuring column 8 . The fixing of the measuring guide rod 5 refers to: on the side wall of the measuring sleeve 6, the tightening bolt 62 is screwed inward along the tightening nut 61, so that the tightening bolt 62 presses the measuring guide rod in the measuring sleeve 6 5. Realize the fixing of the measuring guide rod 5 .

Embodiment 3

[0069] Basic content is the same as embodiment 1, the difference is:

[0070] After the measuring needle 3, the measuring pillar 8, and the measuring guide rod 5 are all fixed, the distance between the center 2 of an oil cylinder-like punching hole and the center of the rudder shaft 1 in the middle of the rudder mechanism can be measured, and then, the same method is used to measure Get the distance between the center 2 of the punching hole of the remaining three oil cylinder samples and the center of the rudder shaft 1 of the rudder mechanism, then compare the measured four actual distance values with the theoretical values, and then adjust the on-site installation in real time according to the comparison results, so as to Ensure that the installation accuracy of the rudder mechanism meets the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com