Double-screw compressor for high pressure system

A high-pressure system and twin-screw technology, applied in the field of compressors, can solve problems such as increased manufacturing and use costs, increased use pressure, etc., and achieve the effects of reduced load, reduced vibration, and meeting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

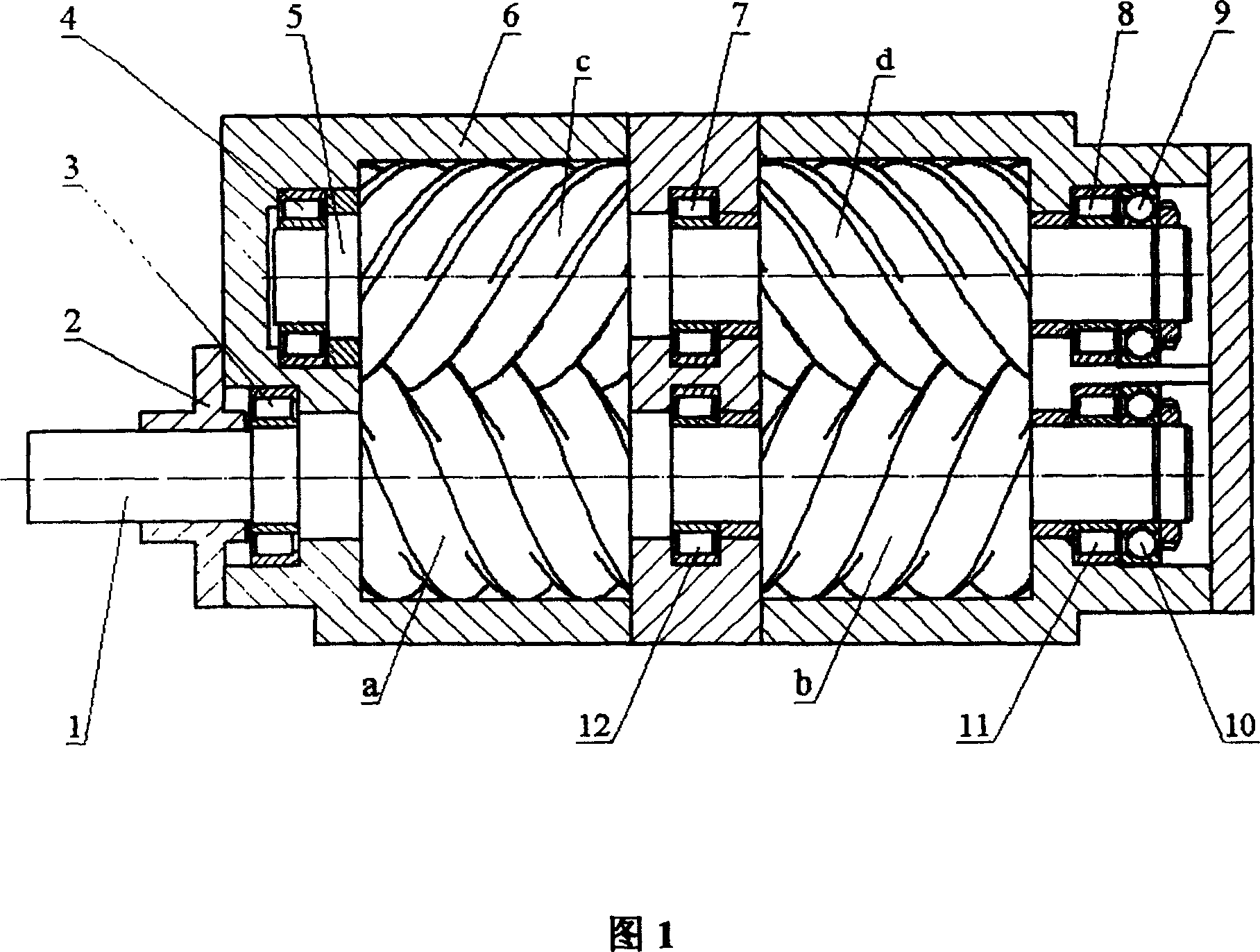

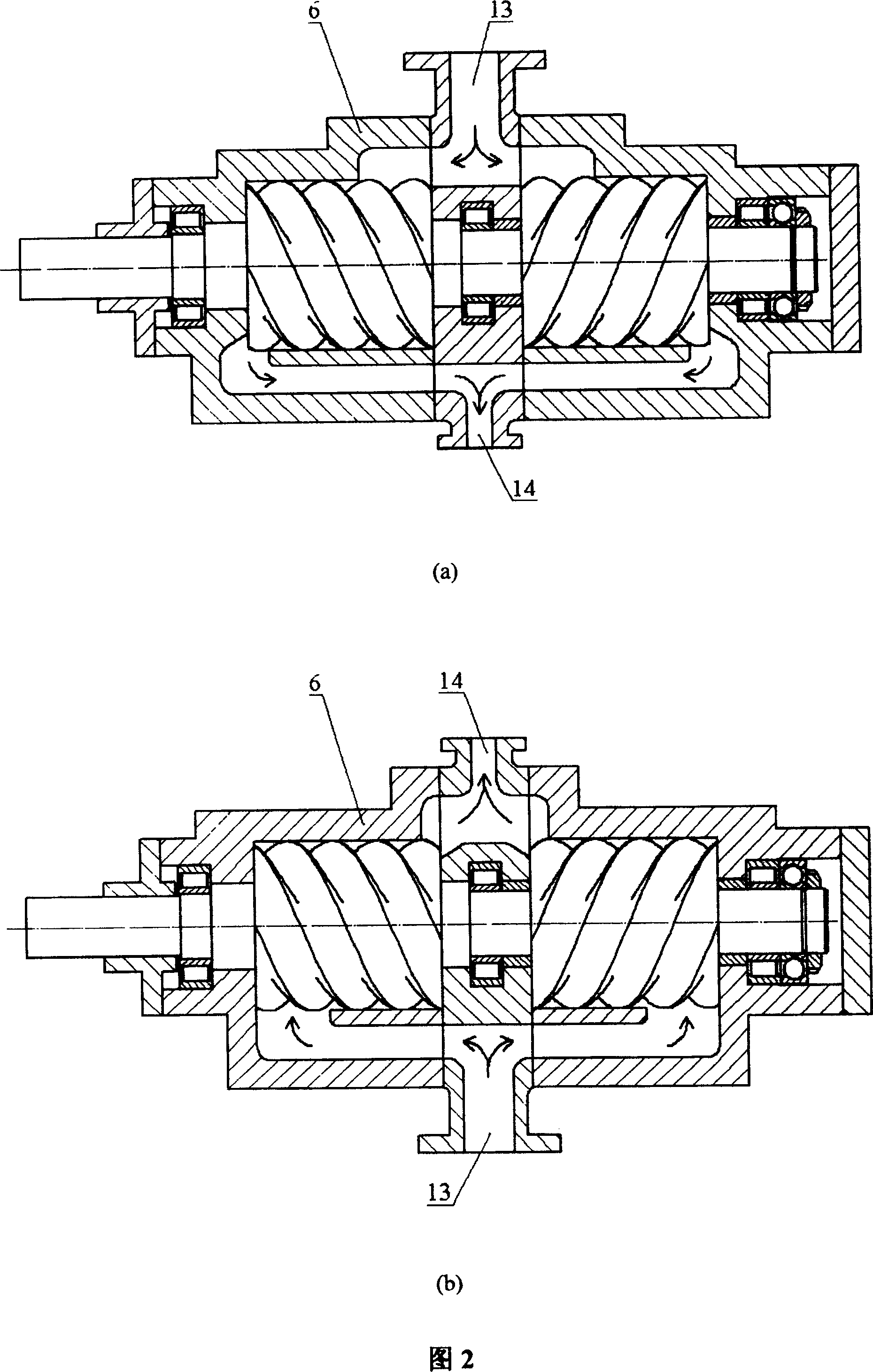

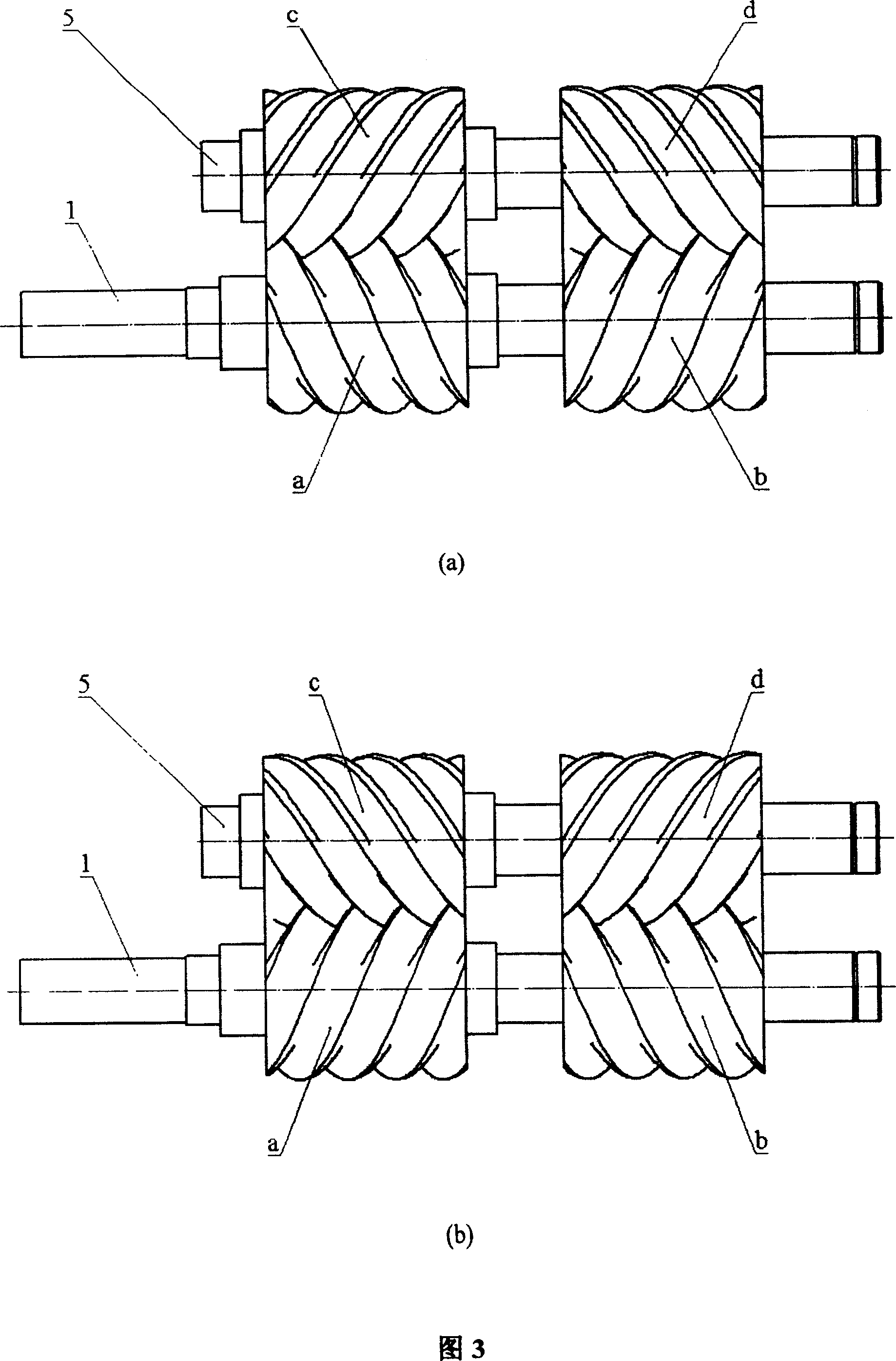

[0028] Referring to Fig. 1 and Fig. 3, the present invention includes a pair of intermeshing male rotor 1 and female rotor 5. There are two helical parts a and b with opposite directions on the male rotor 1, and there are two corresponding helical parts a and b on the female rotor 2. To the opposite helical parts c and d. Three sets of bearings are respectively arranged on the male rotor 1 and the female rotor 5, the radial force bearing 3, the radial force bearing 12, and the radial force bearing 11 at the two ends and the middle of the male rotor 1, and the radial force bearings at both ends and the middle of the female rotor 5. Radial force bearing 4, radial force bearing 7, radial force bearing 8, axial force bearing 9, axial force bearing 10;

[0029] The axial force bearing 9 and the axial force bearing 10 can be arranged at the end of the rotor, or at the middle section of the rotor.

[0030] The casing 6 with several components together with the male rotor 1 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com