Driving mechanism of particle crusher

A transmission mechanism and shredder technology, applied in grain processing and other directions, can solve the problems of difficulty in ensuring the roller spacing, small range of gear pairs, and small adjustable range, so as to reduce the frequency of replacing rollers, achieve uniform synchronization and precise adjustment, and expand The effect of adjusting the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

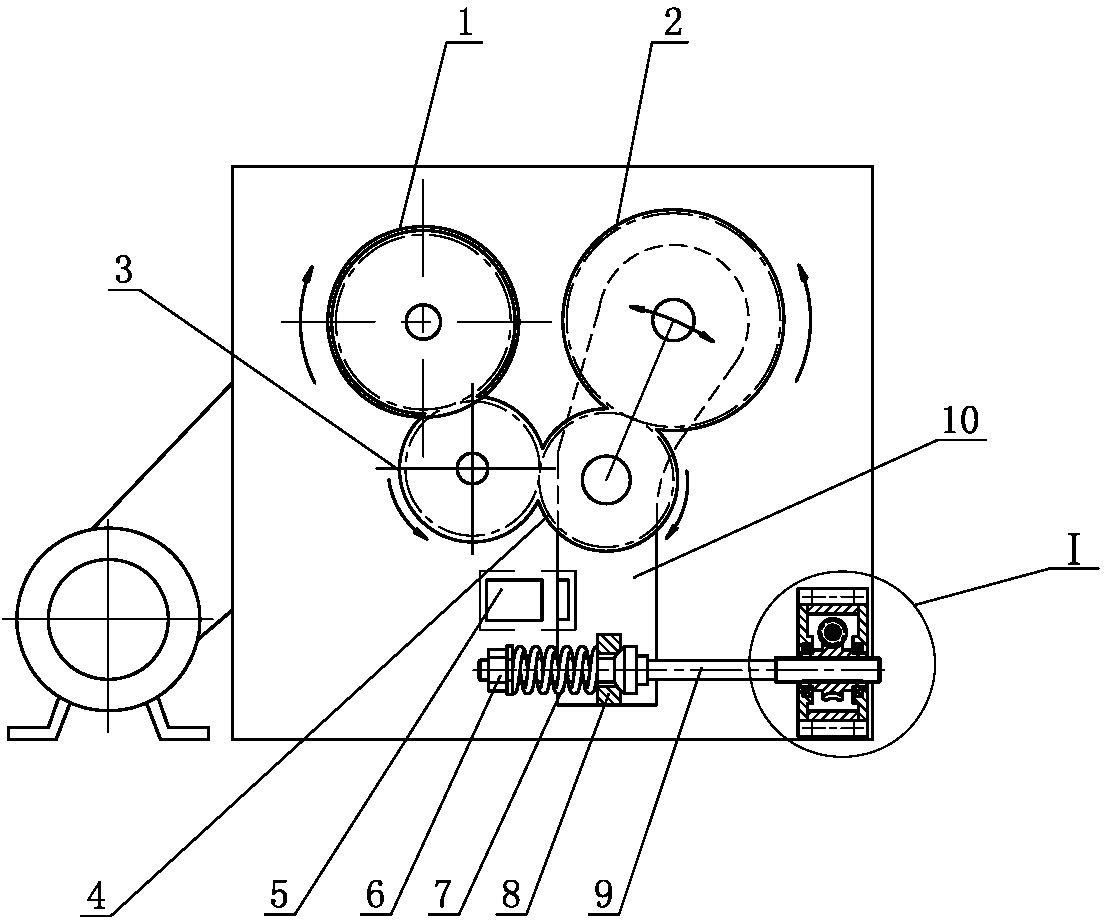

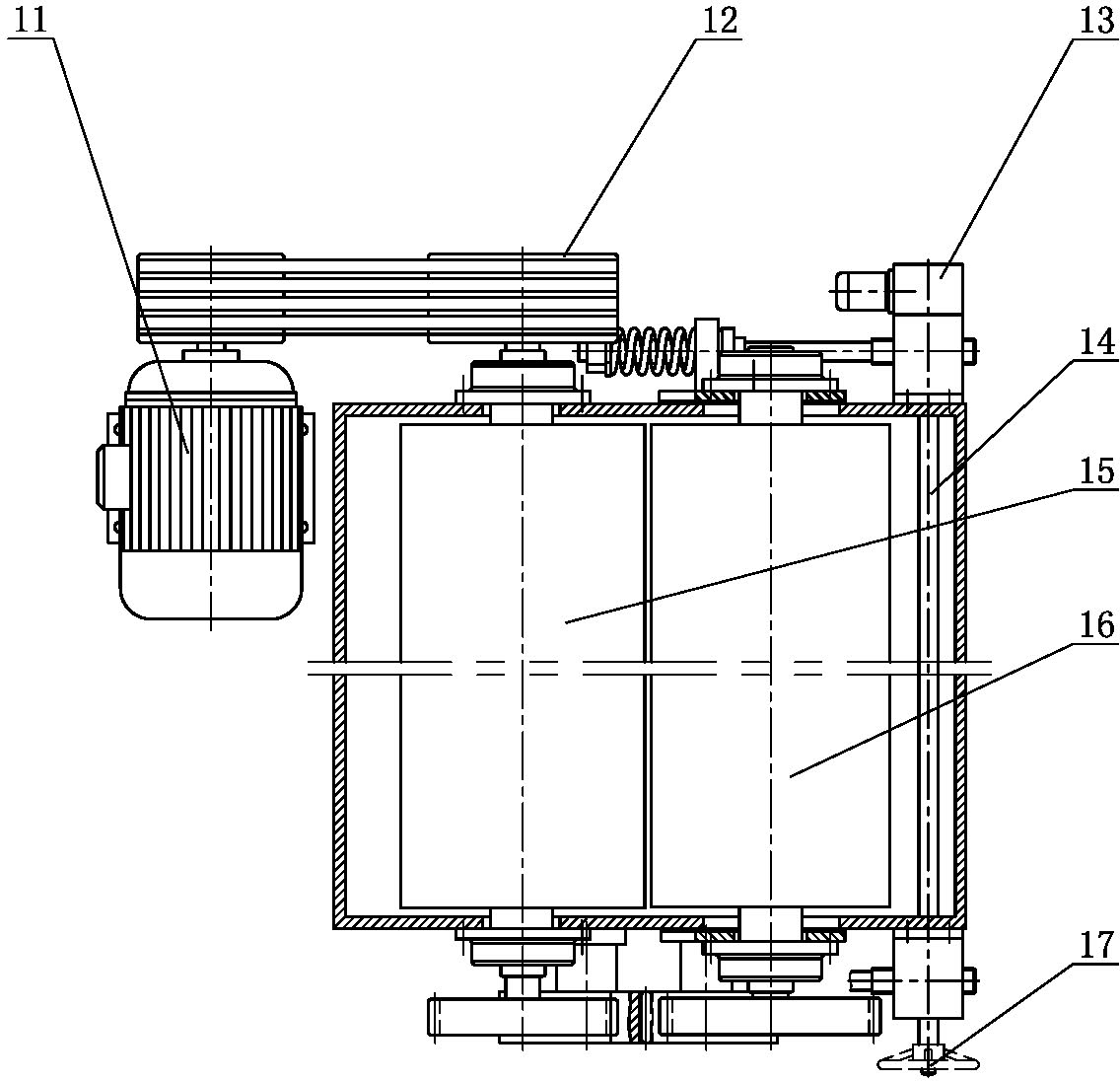

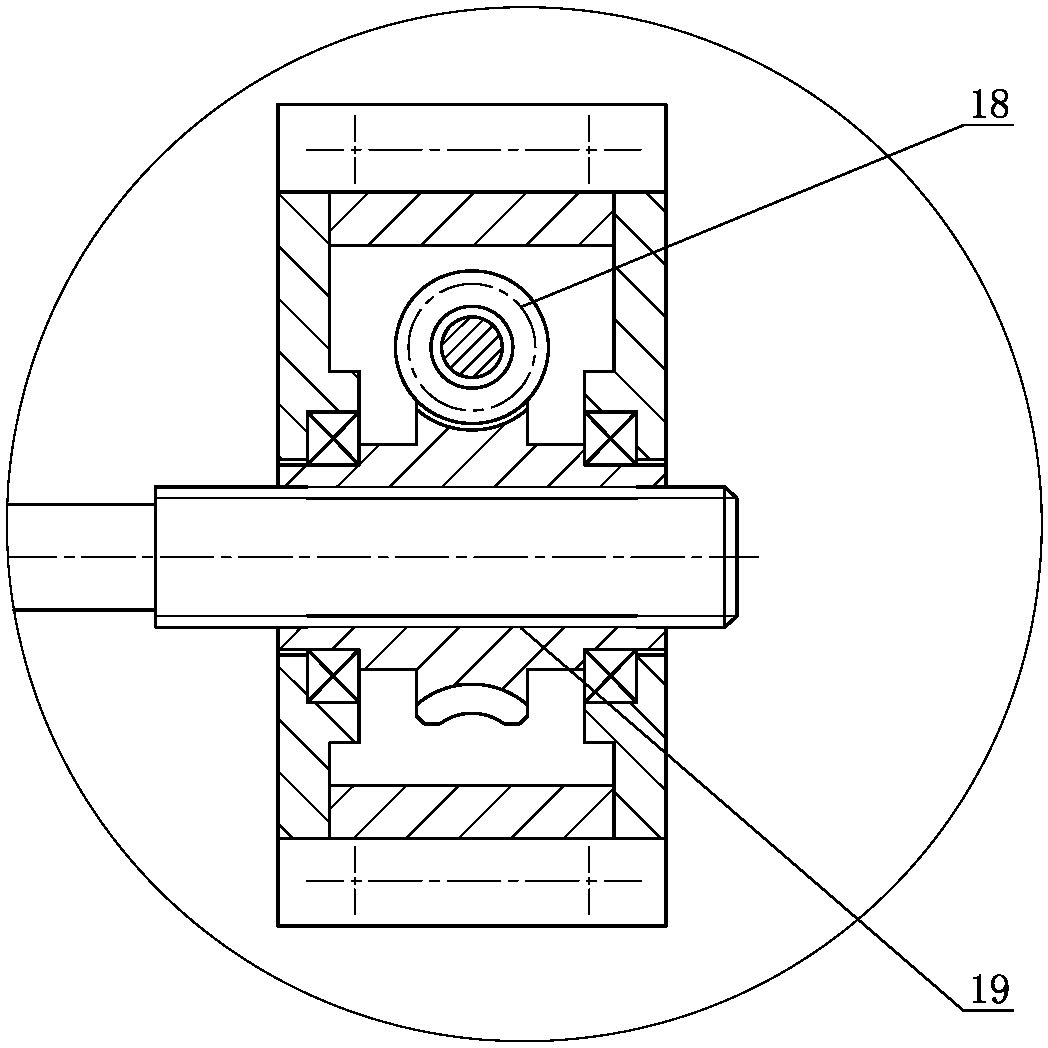

[0018] Such as figure 1 Shown in -3 is the granulator transmission mechanism of the present invention, comprising fast roller 15, slow roller 16, idler gear I3 and idler gear II4, and the shaft end of quick roller 15 one side is equipped with belt pulley 12, and by belt driving device and The motor 11 is connected, the driving gear 1 is installed on the other side of the fast roller 15, the slow roller driving gear 2 is installed on the same side of the slow roller 16, the idler gear I3 meshes with the driving gear 1 and the idler gear II respectively 4, and the idler gear I Gear Ⅱ4 meshes with the slow roller drive gear 2, and the shaft ends on both sides of the slow roller 16 are provided with a pair of support plates 10 for adjusting the distance between the fast roller 15 and the slow roller 16, and the slow roller 16 supports the support plates 10 installed on both sides Above, the two pairs of support plates 10 drive the slow roller 16 and the slow roller drive gear 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com