Lift-type soft light emitting diode (LED) display screen

A LED display and lifting technology, applied in the direction of instruments, identification devices, etc., can solve the problems of unwinding, unfavorable movement, and large volume of rectangular boxes, and achieve the effect of reducing weight and solving lighting problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

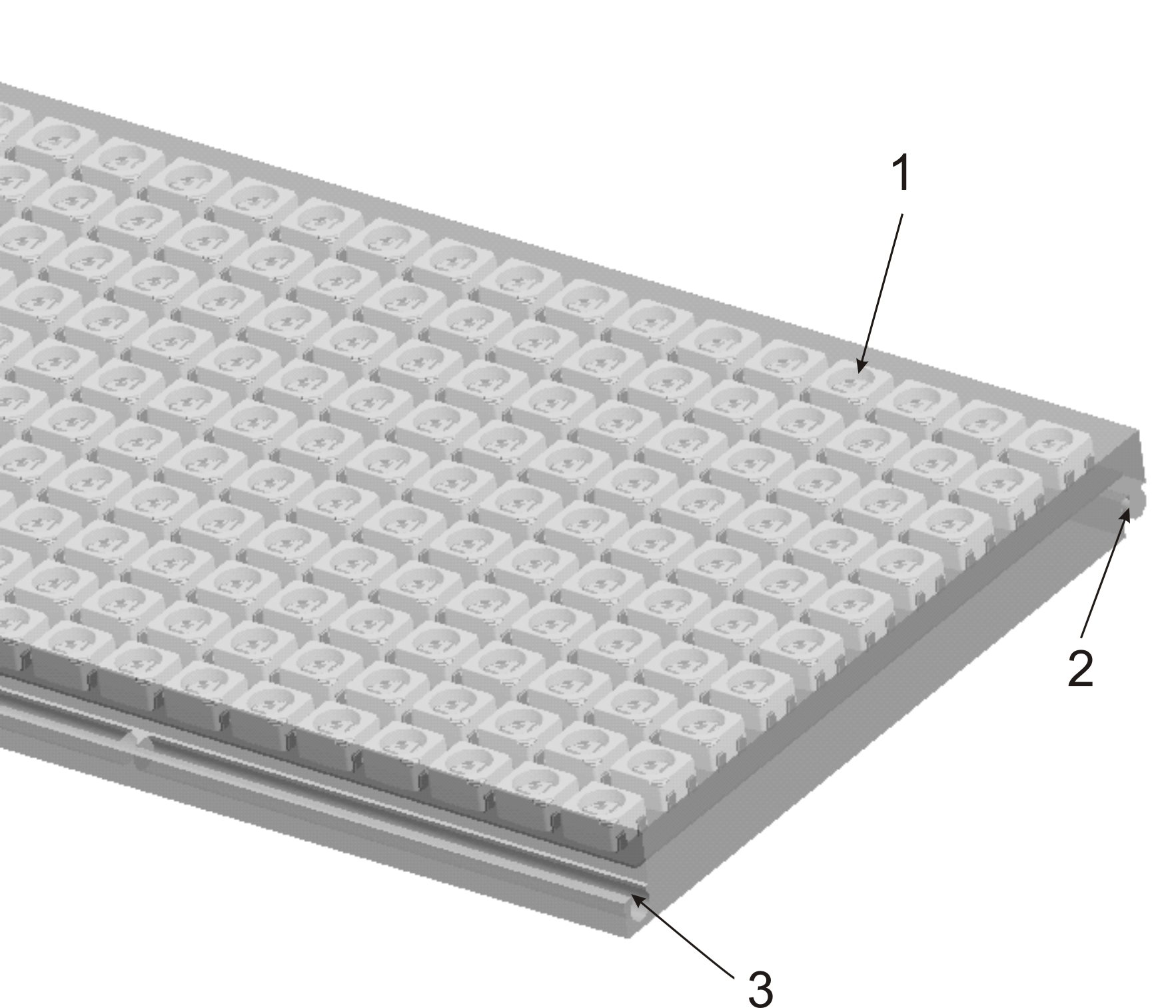

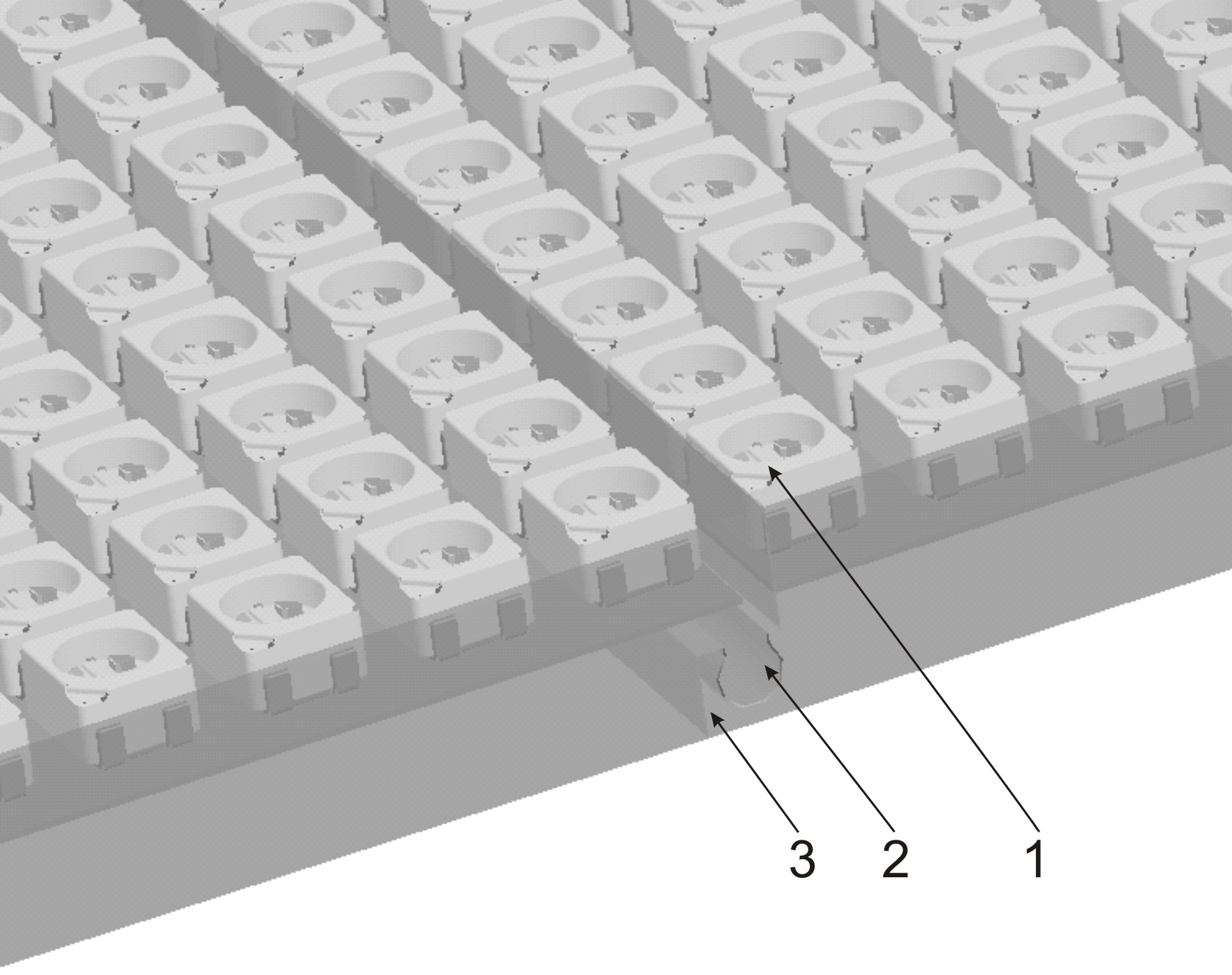

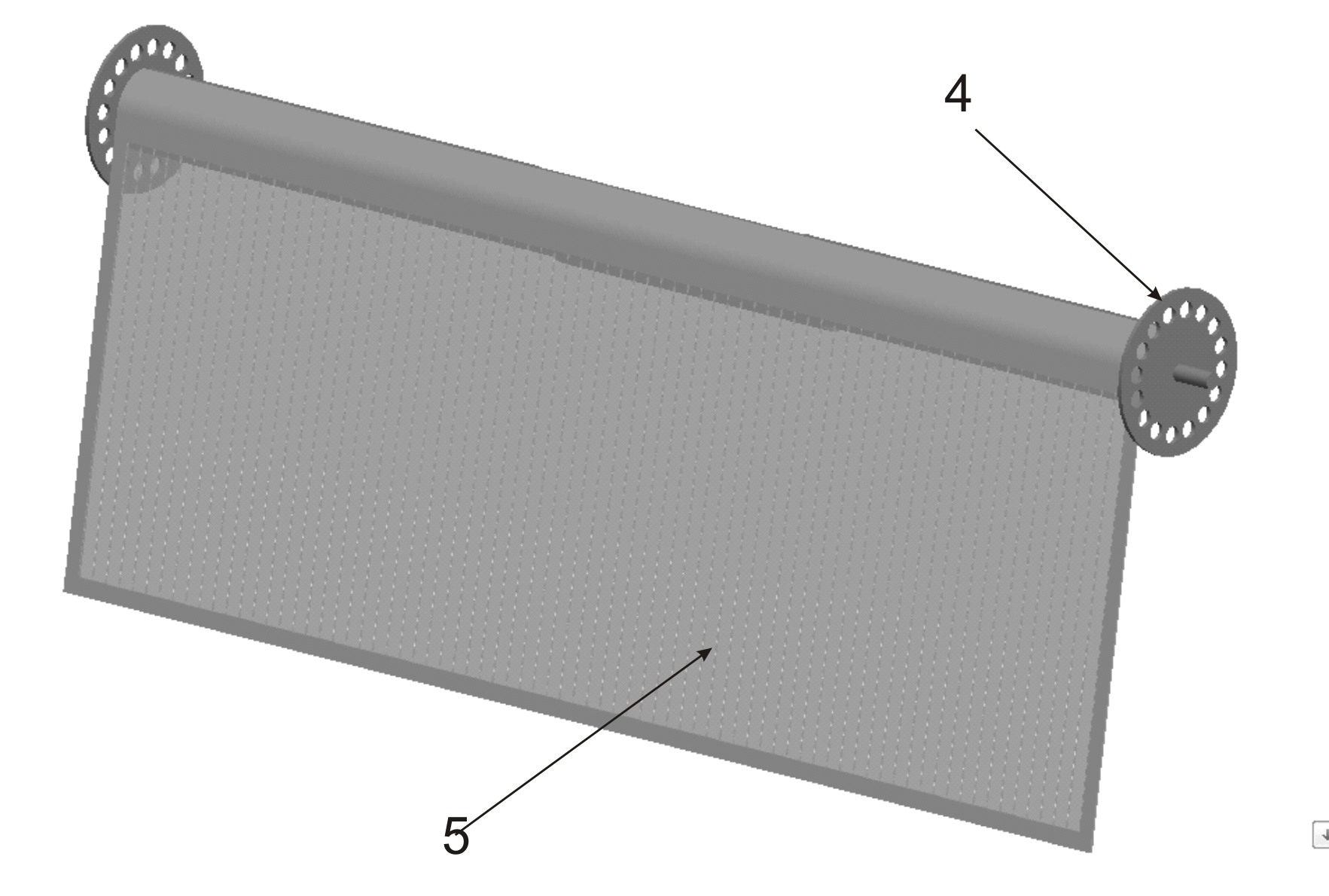

[0024] Embodiment 1: When installing the lift-type soft LED display screen, Figure 4 , install drivers, signal processing and other devices inside the main drum (4); figure 2 , after cutting the LED flexible light strip described in the present invention into the required length, buckle the male buckle (2) of one LED flexible light strip with the female buckle (3) of another LED flexible light strip, Do like this and snap to desired width, trim perimeter as desired. Figure 7 , Use U-shaped fixture (17) to fix the horizontal flat steel (14) on the back side of the assembled lift-type soft LED display, and the U-shaped fixture (17) and lift-type soft LED display are pasted with glue. Vertical flat steel (12) is welded on horizontal flat steel (14) with cold welding process. The lifting bearing (16) and the inverted figure-of-eight rope clamp (15) are installed in the position of the junction of the vertical flat steel (12) and the horizontal flat steel (14). Finally, after...

Embodiment 2

[0027] Embodiment two: Figure 4 , install drivers, signal processing and other devices inside the main drum (4); figure 2 , 3 , after cutting the LED flexible light strip described in the present invention into the required length, buckle the male buckle (2) of one LED flexible light strip with the female buckle (3) of another LED flexible light strip, According to this, buckle to the required width, then decorate the periphery according to the required, and finally fix it on the main roller (4) with beading strips, thus making a small mobile lifting soft LED display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com