Cutting part of a thin coal seam bottom-clearing drum shearer

A technology for the cutting part and thin coal seam of a coal shearer, which is applied to cutting machinery, earthwork drilling, cutting machinery, etc. It can solve the problem of reduced strength of planetary mechanism gears and bearing life, failure to effectively improve the coal loading effect, and Problems such as poor adaptability to changes in coal seam thickness can achieve the effects of reducing center distance, improving assembly efficiency and interchangeability, and improving coal loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

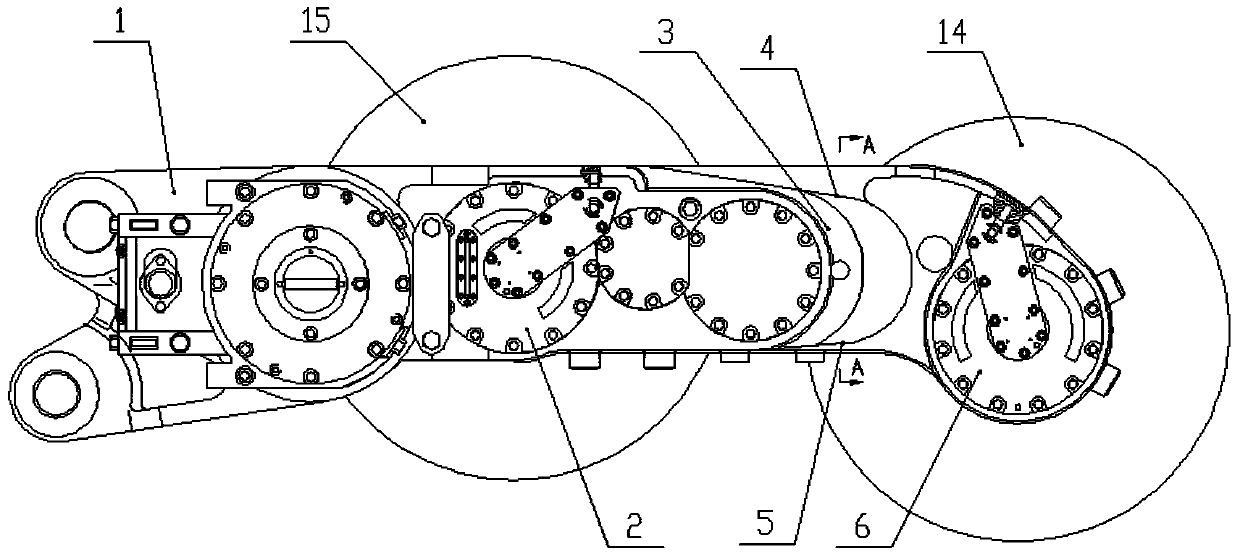

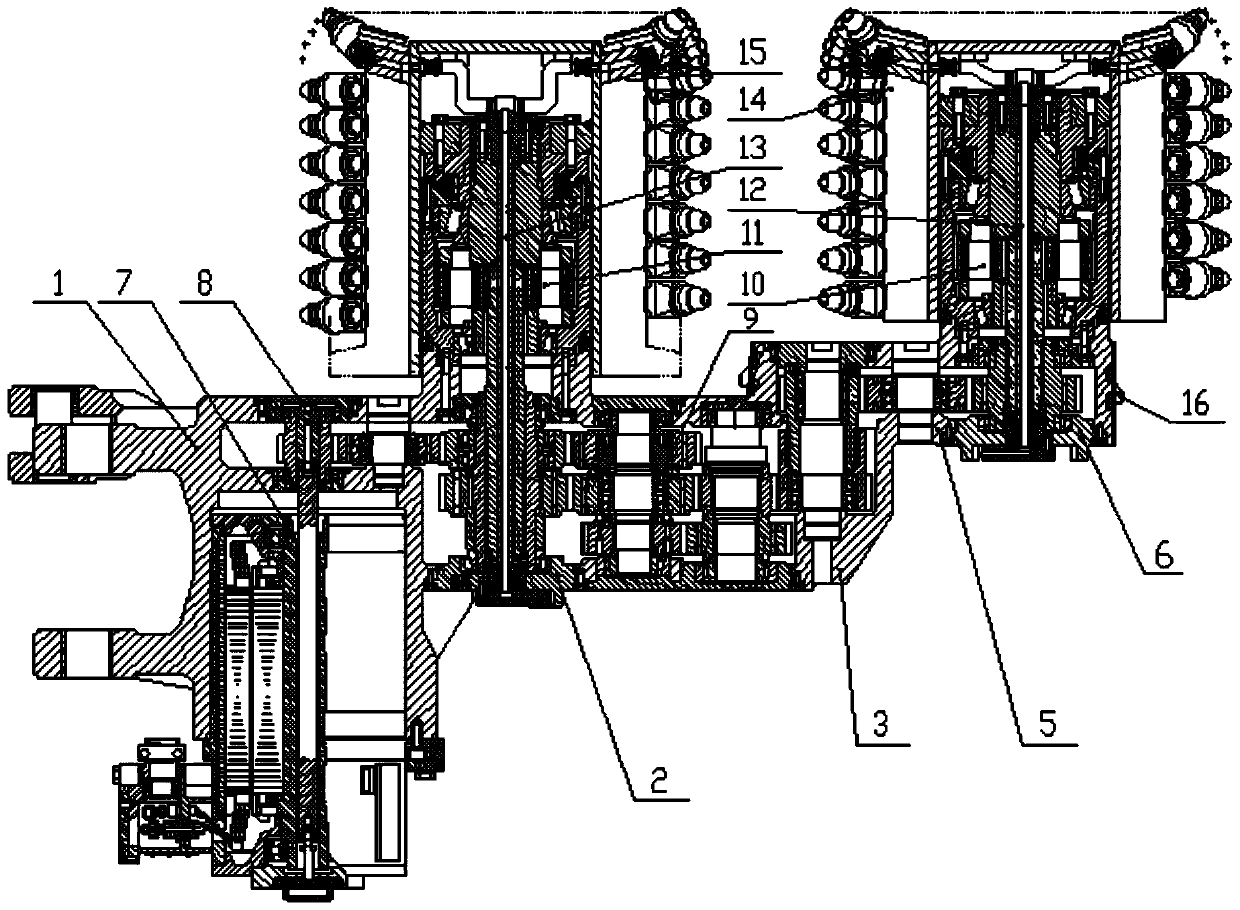

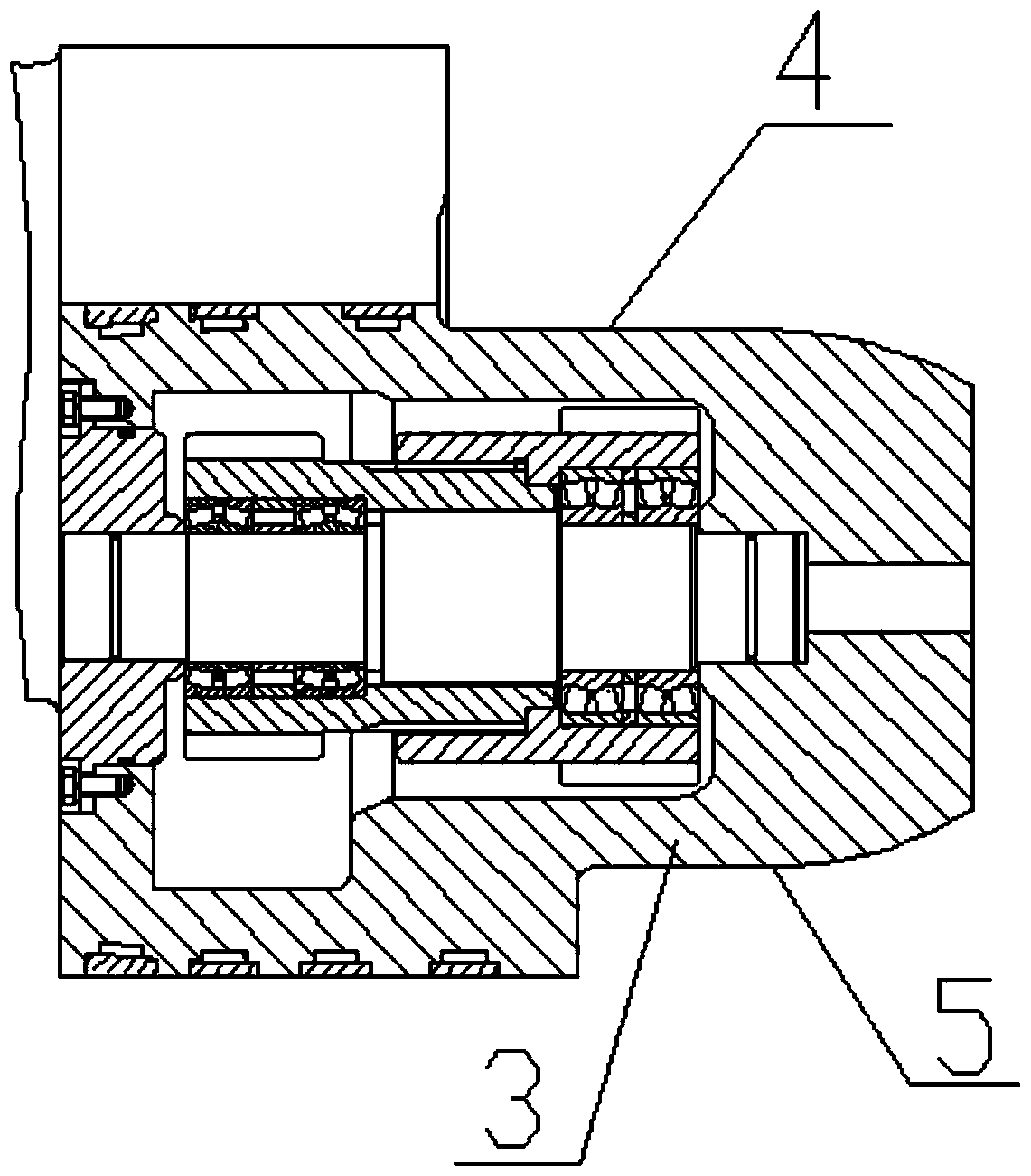

[0019] Such as Figure 1 to Figure 5 As shown, a cutting section of a thin coal seam clearing type drum shearer includes a cutting section housing 1, a cutting motor 7, a clutch 8, a straight tooth transmission system 9, a first cutting drum 14, a second cutting drum Cutting cylinder 15, first planetary mechanism 10 and second planetary mechanism 11, described cutting motor 7, clutch 8 and spur-tooth transmission system 9 are all arranged in the inner cavity of cutting part housing 1, and cutting motor 7 The output power is transmitted to the spur gear transmission system 9 by the clutch 8, and after being decelerated and divided by the spur gear transmission system 9, it is respectively transmitted to the first planetary mechanism 10 and the second planetary mechanism 11, and then through the first planetary mechanism 10 and the second planetary mechanism 11 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com