Double-motor U-shaped cutting portion of thin seam mining machine

A technology for shearer cutting part and thin coal seam, which is applied in the direction of cutting machinery, speed/torque control of multiple motors, earth square drilling, etc. Cut hard coal and other problems to achieve the effect of increasing cutting power, good coal loading effect, and improving coal loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

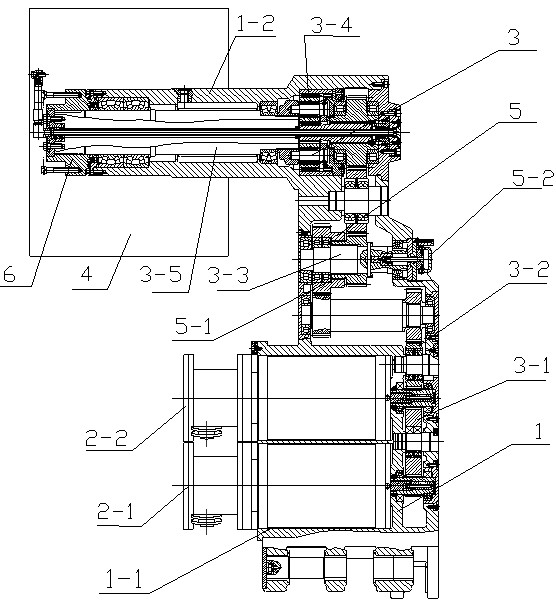

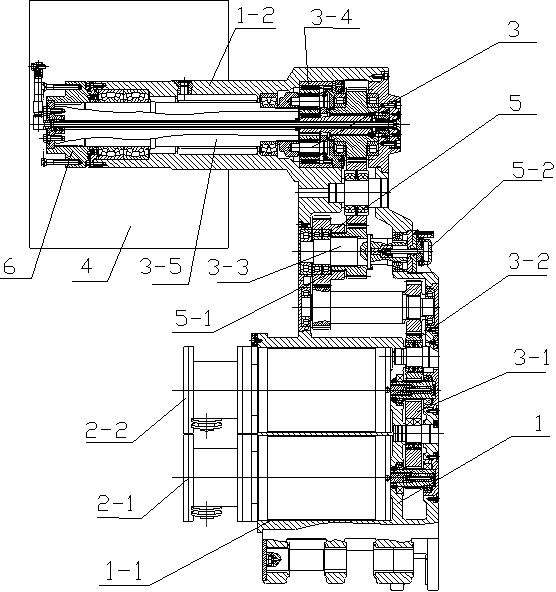

[0010] The cutting part of the double-motor U-shaped thin coal seam shearer of the present invention is mainly composed of a rocker arm housing 1, a first cutting motor 2-1, a second cutting motor 2-2, a rocking arm reduction box 3, and a cutting drum 4, the rocker arm housing 1 includes a motor installation cavity 1-1 and a rocker arm reducer output shaft installation cavity 1-2 arranged in parallel, the output shaft installation cavity 1-2 of the rocker arm reducer is elongated, The length of the slender rocker reducer output shaft installation chamber 1-2 is 830mm, and the outer diameter is 350mm. The motor installation chamber 1-1 is on the same side as the rocker arm reducer output shaft installation chamber 1-2, and the outline forms a U shape; the first cutting motor 2-1 and the second cutting motor 2-2 are installed side by side on the In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com