Auxiliary coal charging device of thin seam coal mining machine

A coal mining machine and thin coal seam technology, applied in the direction of earthwork drilling and cutting machinery, etc., can solve the problems of easily damaged machinery and equipment, increase traction resistance, etc., achieve the effect of simple operation, convenient use, and enhanced coal loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

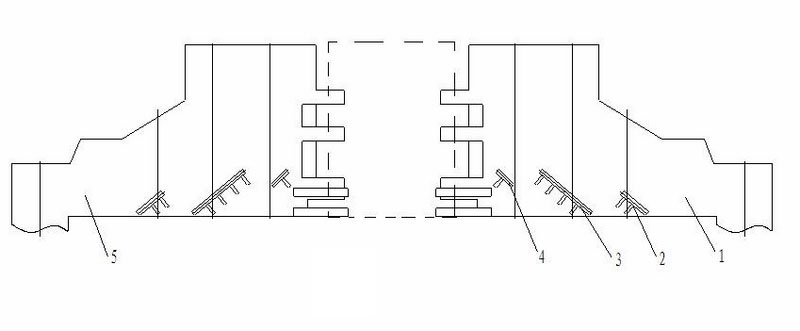

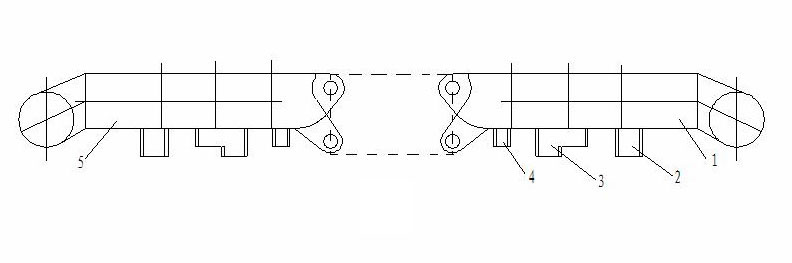

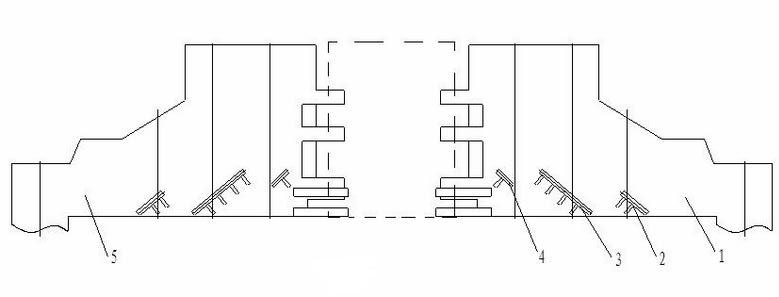

[0010] figure 1 figure 2 Among them, an auxiliary coal loading device for a thin coal seam shearer is mainly composed of the right rocker arm 1 of the shearer, the coal plow I2, the coal plow II3, the coal plow III4 and the left rocker arm 5 of the coal shearer. Coal plow I2, coal plow II3 and coal plow III4 are symmetrically and evenly distributed under the right rocker arm 1 of the shearer and the left rocker arm 5 of the coal shearer in turn. The coal plow I2 is made of a steel plate and two The coal plow II3 is composed of a steel plate and four reinforcement ribs, the coal plow III4 is composed of a steel plate and a reinforcement rib, and the coal plow I2, coal plow II3 and Coal plow III4 is respectively connected with the right rocker arm 1 of the coal shearer and the left rocker arm 5 of the coal shearer at 35°. The left rocker arm 5 of the machine is on a straight line, the top surfaces of the coal plower II3 and the coal plower III4 are on a straight line, the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com