Roller for mixed row cutting tooth coal winning machine

A shearer drum and mixed row technology, applied in cutting machinery, earthwork drilling and other directions, can solve the problems of insufficient rock breaking capacity, poor coal loading effect, unsuitable use, etc., and achieve wide practicability and coal breaking capacity. The effect of improving and loading coal is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

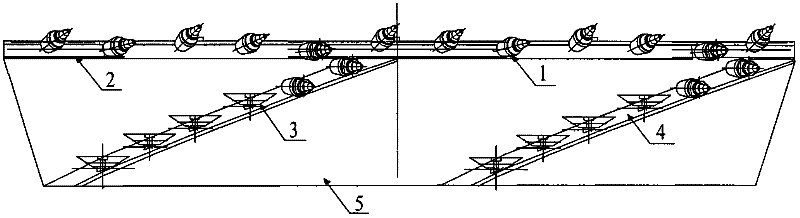

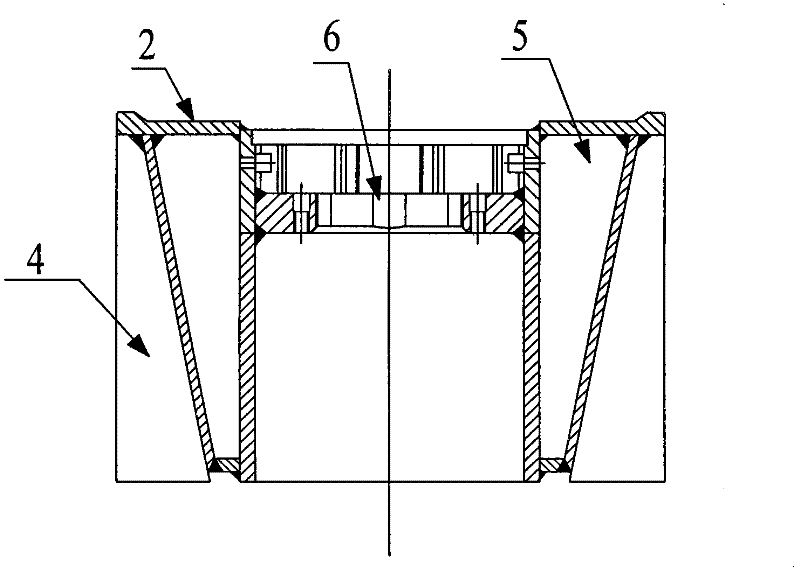

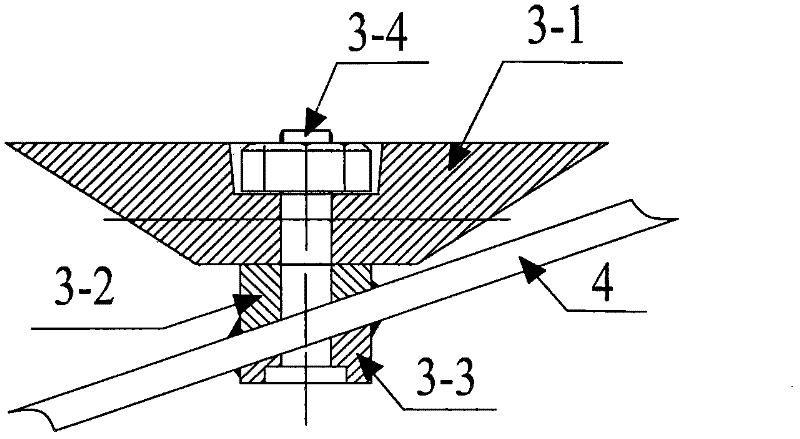

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0012] The mixed row pick shearer drum of the present invention comprises a pick pick 1, an end disc 2, a disc cutter device 3, a variable-diameter spiral blade 4, a cylinder hub 5, and a square connecting sleeve 6, and the disc cutter device includes a disc cutter Tooth 3-1, upper coupling block 3-2, lower coupling block 3-3, bolt 3-4. The pick-shaped picks 1 are arranged in a checkerboard pattern, and are welded to the end plate 2 through the pick-shaped tooth seat; the barrel hub 5 is an inverted trapezoidal structure, the diameter of the side close to the end plate 2 is larger, and the diameter of the goaf side is smaller; the end plate 2 The end face is L-shaped, welded on the trapezoidal structure of the hub 5. The diameter of the variable-diameter helical blade 4 gradually changes, the diameter of the end plate 2 side is smaller, and the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com