Drilling and planing part of thin coal seam drilling and planing combined coal mining machine

A coal shearer and thin coal seam technology, which is applied in the drilling and planing department and the cutting work field, can solve the problems of not being able to better meet the needs of coal mine production, low recovery rate of coal mine resources, and low mining efficiency, so as to shorten the length of the fuselage , Improve mining efficiency and avoid chain breaking accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

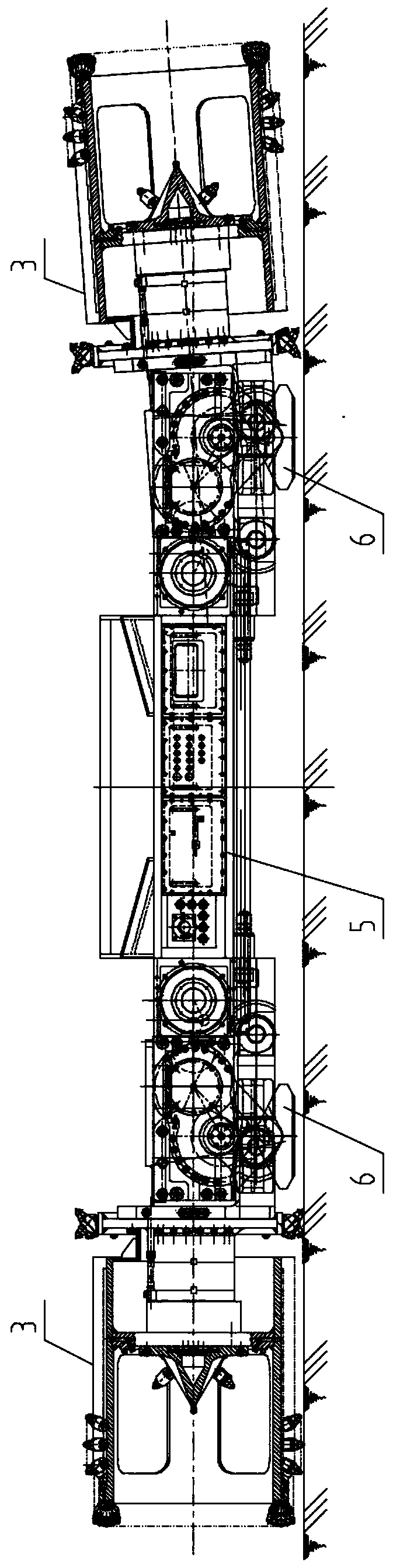

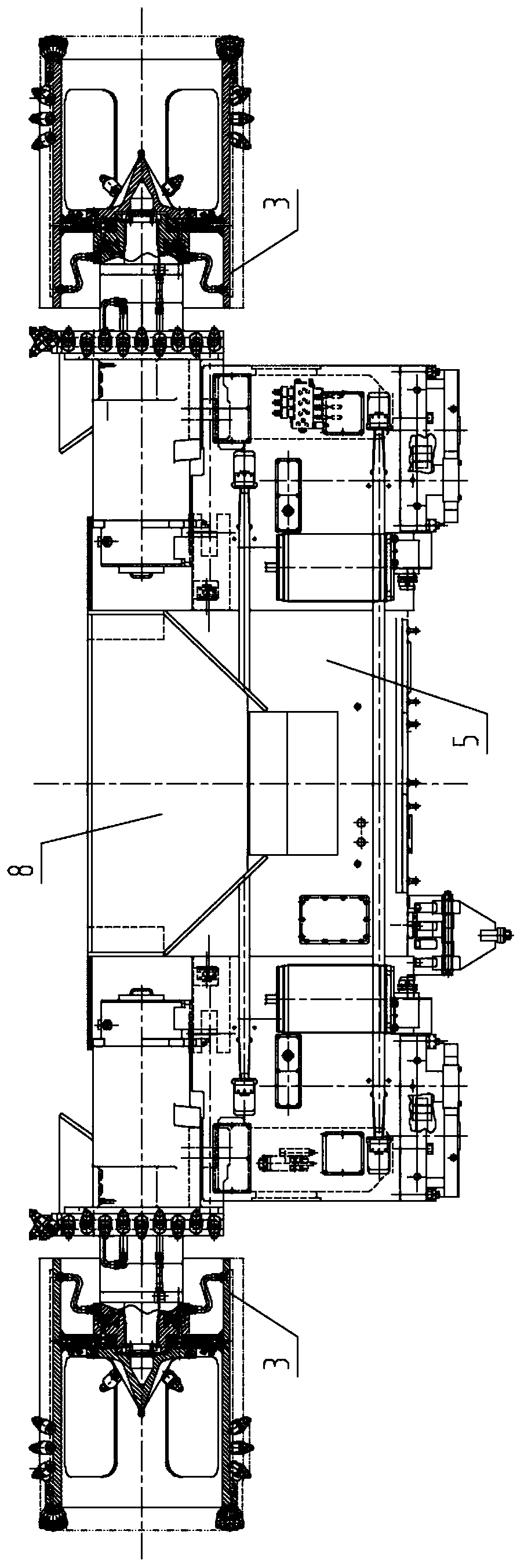

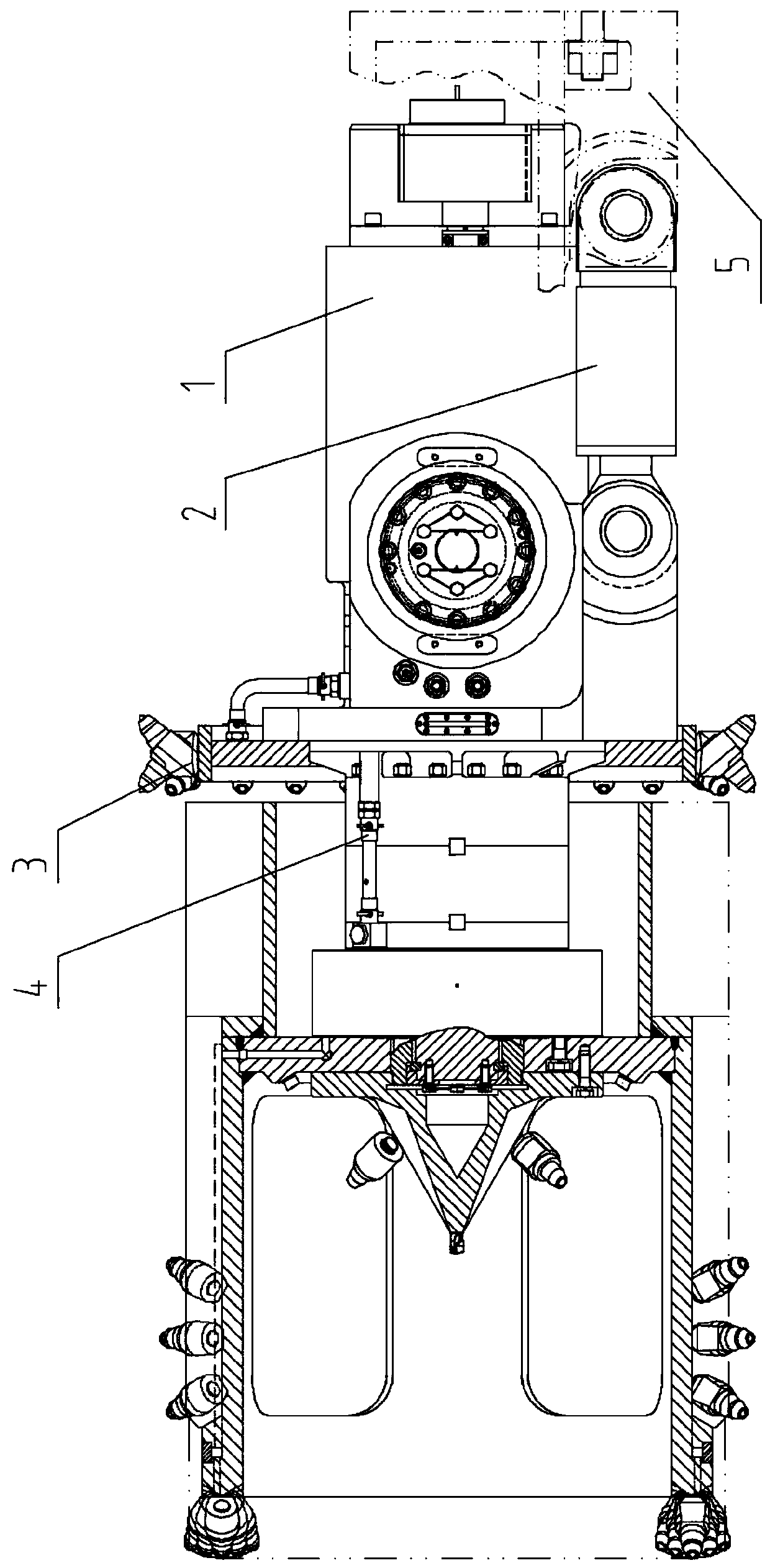

[0040] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 1 The left and right directions are described as the front and rear directions).

[0041] Such as figure 1 , Figure 5 As shown, the thin coal seam drilling and planing combined shearer includes a shearer fixed box 5 installed on a scraper conveyor 7 through a sliding shoe 6, as shown in FIG. figure 2 As shown, the thin coal seam drilling and planing combined coal shearer drilling and planing part is symmetrically arranged in two sets with respect to the shearer fixed box 5, and the two sets of thin coal seam drilling and planing combined coal shearer drilling and planing parts are arranged in the front and rear directions of the central axis. Installed on the side of the shearer fixed box 5 facing the coal seam, two sets of thin coal seam drilling and planing combined coal shearer drilling and planing parts are respectively installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com