Right-angle turning scraper conveyor and rotary disc mechanism thereof

A technology of right-angle turning and turntable mechanism, which is applied in the direction of conveyors, conveyor objects, cleaning devices, etc., can solve the problems of high requirements for end brackets, unfavorable equipment maintenance, and poor working environment, so as to improve the safety production environment and benefit The effect of roof management and power consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the following describes the technical solutions of the present invention clearly and completely with reference to the accompanying drawings. Based on the embodiments of the present application, those of ordinary skill in the art Other similar embodiments obtained without creative work shall fall within the protection scope of this application. In addition, the directional terms mentioned in the following embodiments, such as "up", "down", "left", "right", etc. are only the directions with reference to the drawings. Therefore, the directional terms used are used to illustrate rather than limit the text. invent.

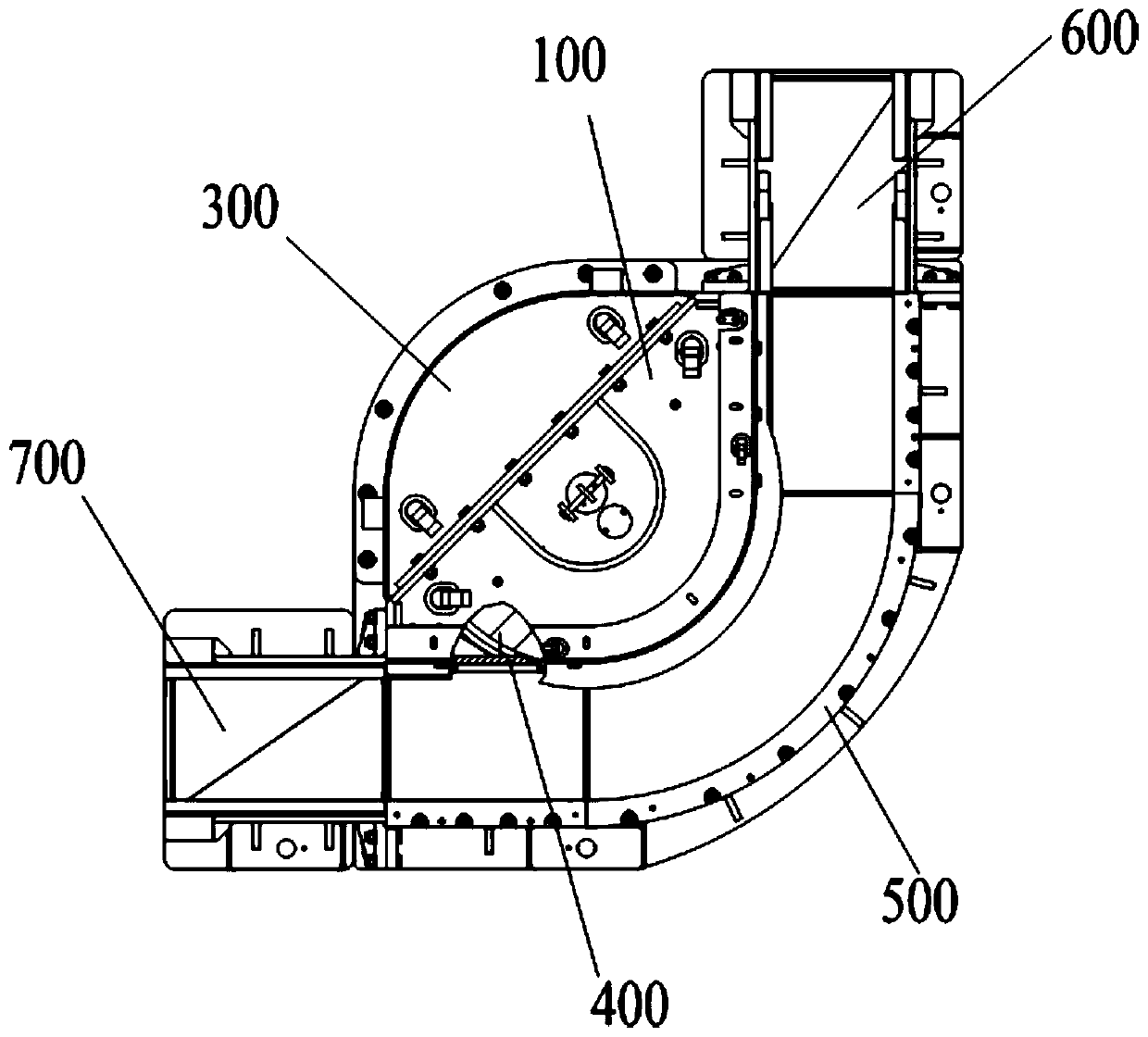

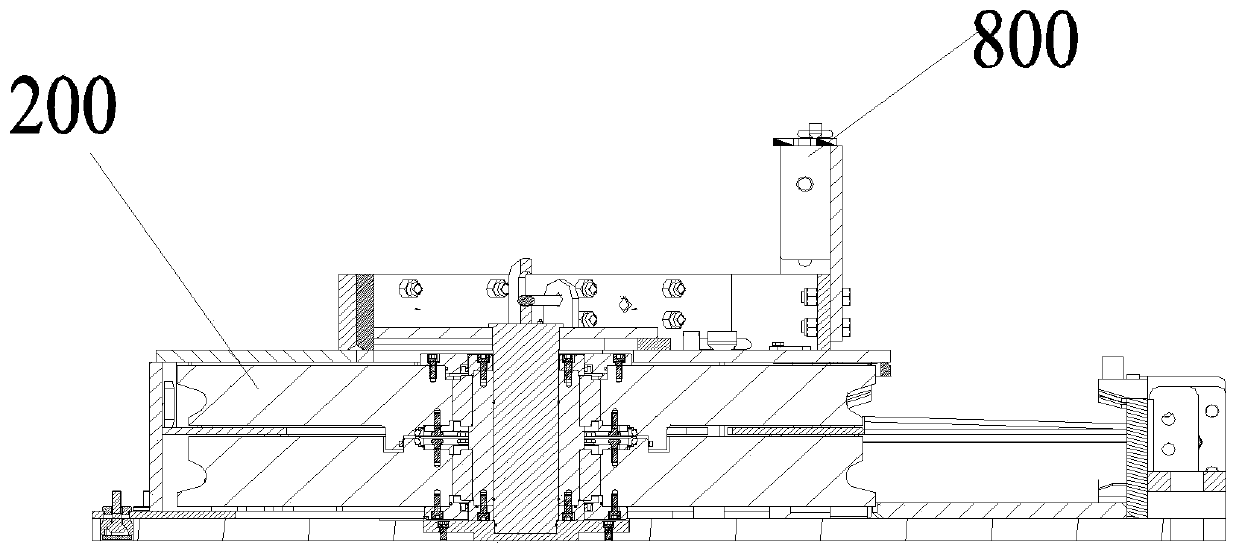

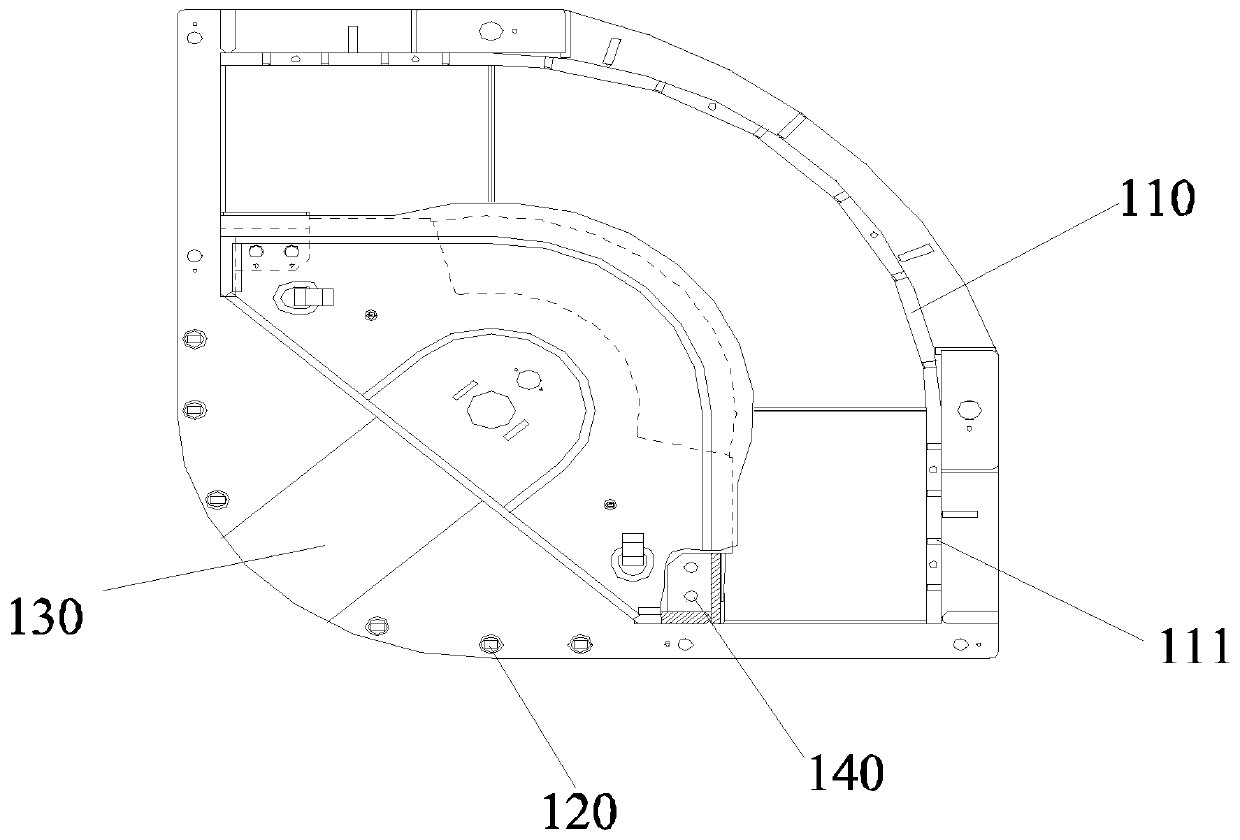

[0034] A turntable mechanism of a right-angle turning scraper, its structure is as follows Figure 1-2 As shown, it includes a turntable box 100, a turntable assembly 200, a turntable guard plate 300, a guide block 400, a movable upper edge 500, a turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com