Deflectable cutting device of coal mining machine

A technology for a coal shearer and a body, which is applied in the field of cutting machinery, can solve the problems of poor coal charging effect, low production efficiency, and impenetrable bottom plate of the shearer, and achieves improved coal charging effect, high productivity, and realization of productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

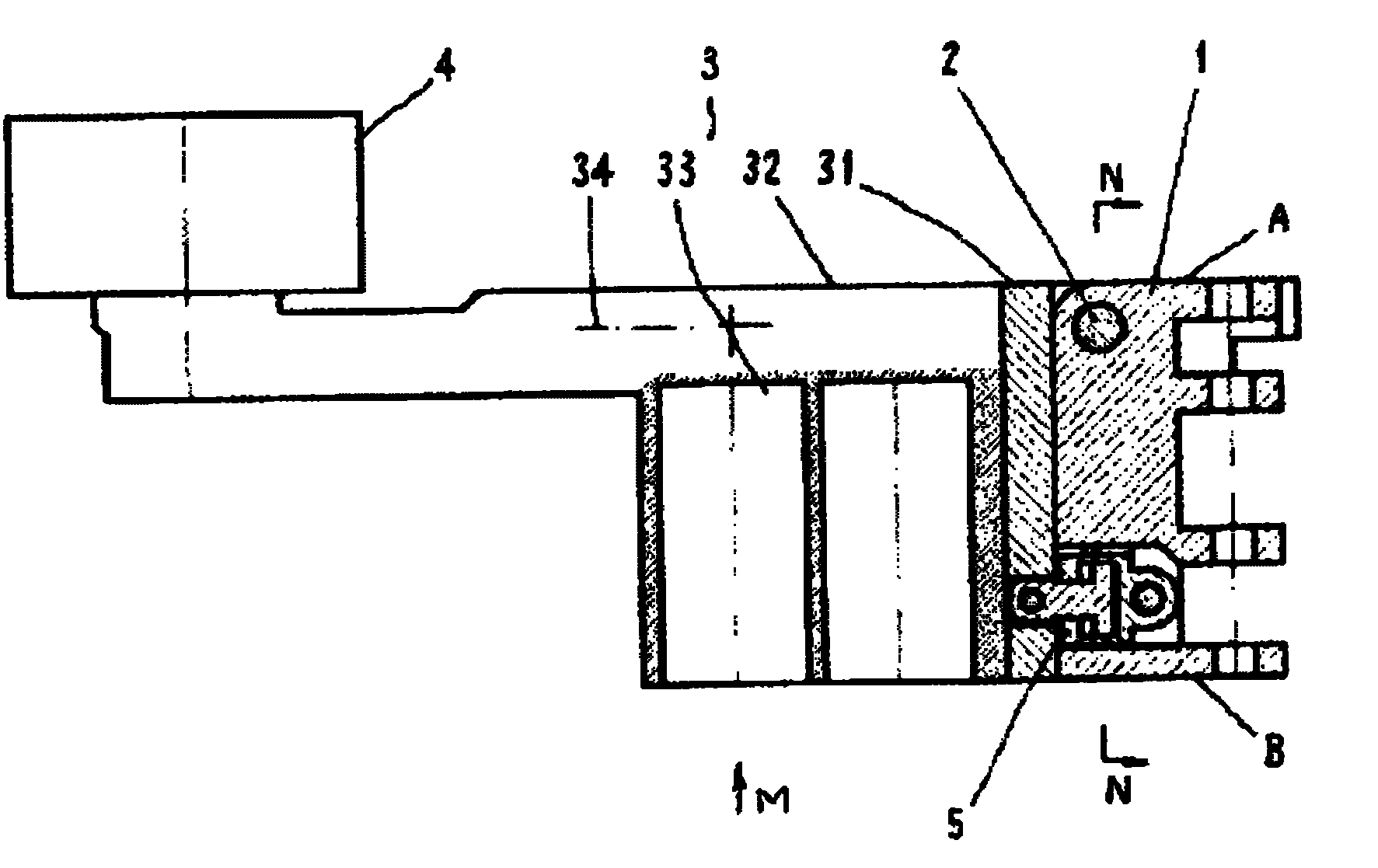

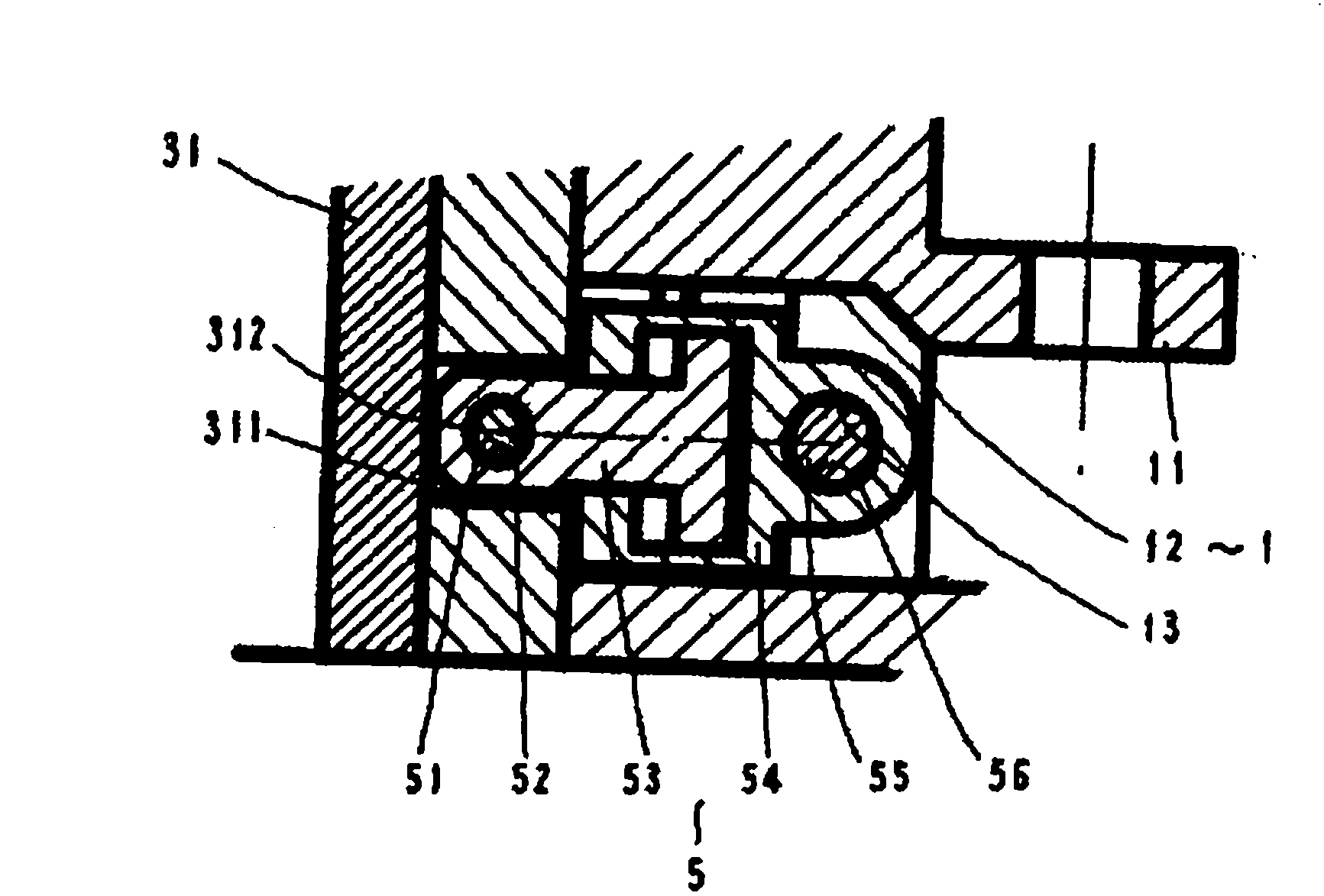

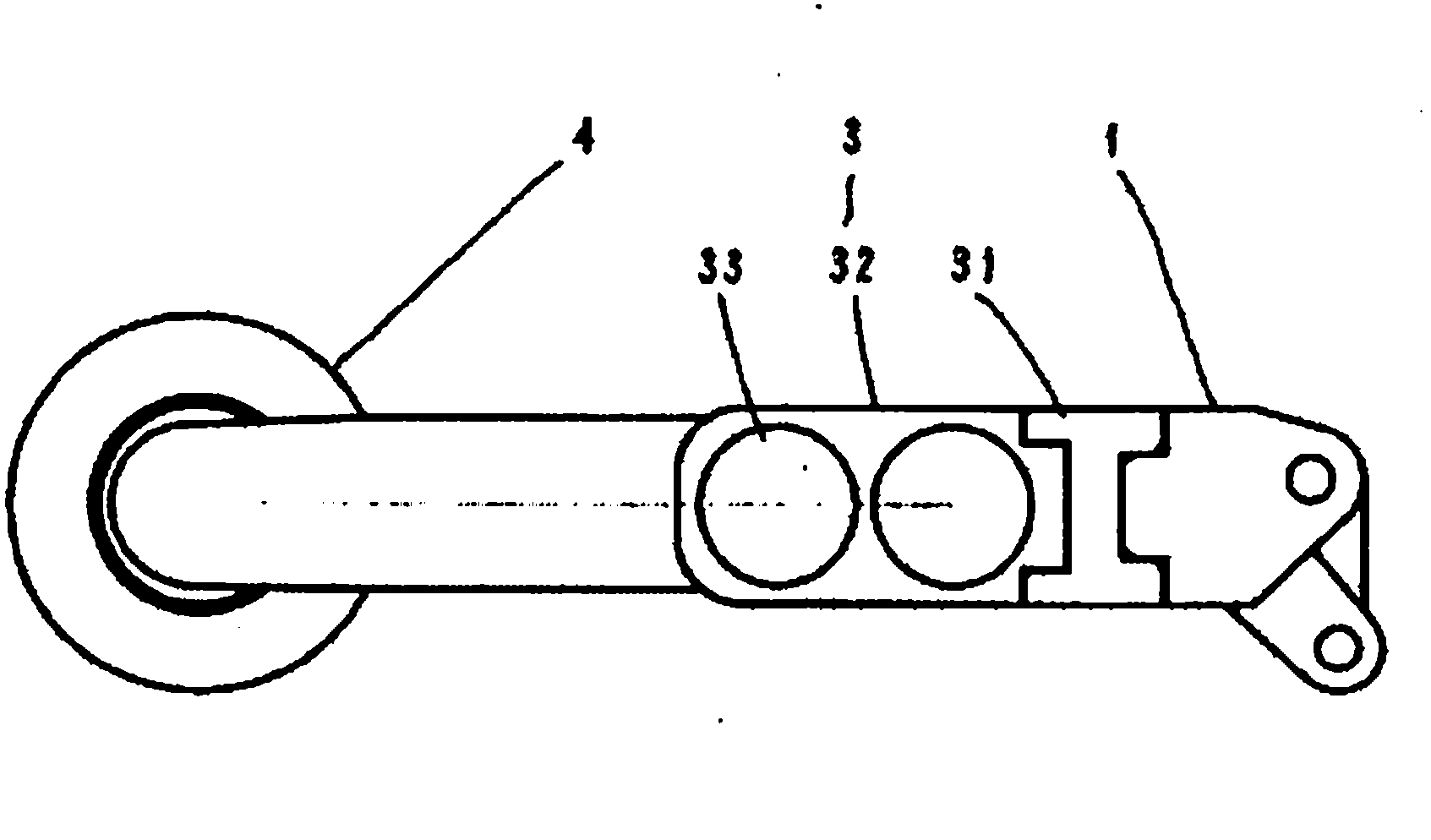

[0016] refer to figure 1 , 3 , The deflectable cutting device of the shearer includes a transition frame 1, a vertical shaft 2, a rocker arm assembly 3, a drum 4, an oil cylinder assembly 5 and a fuselage.

[0017] Transition frame 1 is one of the components of the unique cutting device of the present invention, wherein:

[0018] The near fuselage tail end structure of support body 11 is identical or similar to existing cutting device end structure, is stretched out in tail (near fuselage one end) by several lugs, offers through hole on each lug, this group The through hole and the fuselage support opening are jointly pierced with a rotating shaft, thereby forming a structure in which the end of the transition frame 1 near the fuselage is hinged to the fuselage, and realizes the function of the cutting device rotating with the drum 4 relative to the fuselage;

[0019] The other end of the transition frame 1 frame body 11 relative to one end of the fuselage---the head end, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com