A high-speed cutting longwall mining method for thin and medium-thick coal seams

A mining method and technology for thick coal seams, which are used in surface mining, earth-moving drilling, underground mining, etc., can solve problems such as occupation of manpower and operation time, asynchronous coal cutting and equipment maintenance operations, and low cutting speed. The effect of the start-up rate and continuous operation time, the optimization of the production takt time sequence, and the improvement of the propulsion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The equipment used in the specific embodiment of the present invention is well known to those skilled in the field of coal mining technology, and can be obtained by purchasing.

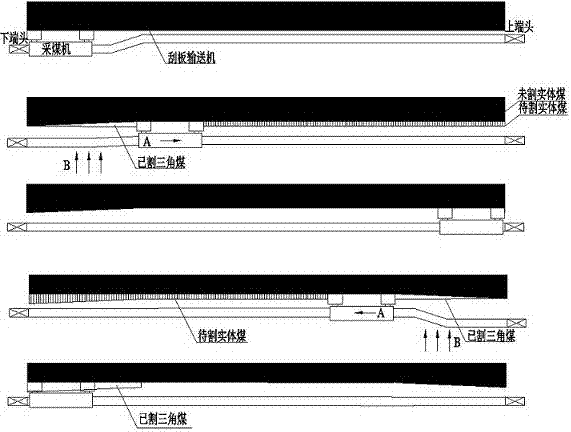

[0028] like figure 1 As shown, arrow A indicates the coal cutting driving direction of the shearer, and arrow B indicates the moving scraper conveyor, " "Represents solid coal," "Indicates the solid coal to be cut. After the coal shearer cuts the coal to the lower end, it goes up in the opposite direction and cuts the triangular coal along the curved section of the scraper conveyor. When it reaches the straight section of the scraper conveyor, the shearer continues to cut coal until it reaches the upper end The cutting depth is half of the normal cutting depth (about 400-500mm). The speed of the shearer is the maximum coal cutting speed, which is 15-40m / min. Move the scraper conveyor straight, do not return to cut the triangular coal, and leave the triangular coal at the lower end of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com