Thin coal seam shearer and its chute type coal retaining mechanism

A technology for shearer and thin coal seam, which is applied in cutting machinery, slitting machinery, earth-moving drilling and other directions, can solve the problem that the height of the drum coal-loading blade is reduced, the effect cannot be achieved, and the arc-shaped coal baffle has a large requirement. and other problems to achieve the effect of improving the effect of coal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

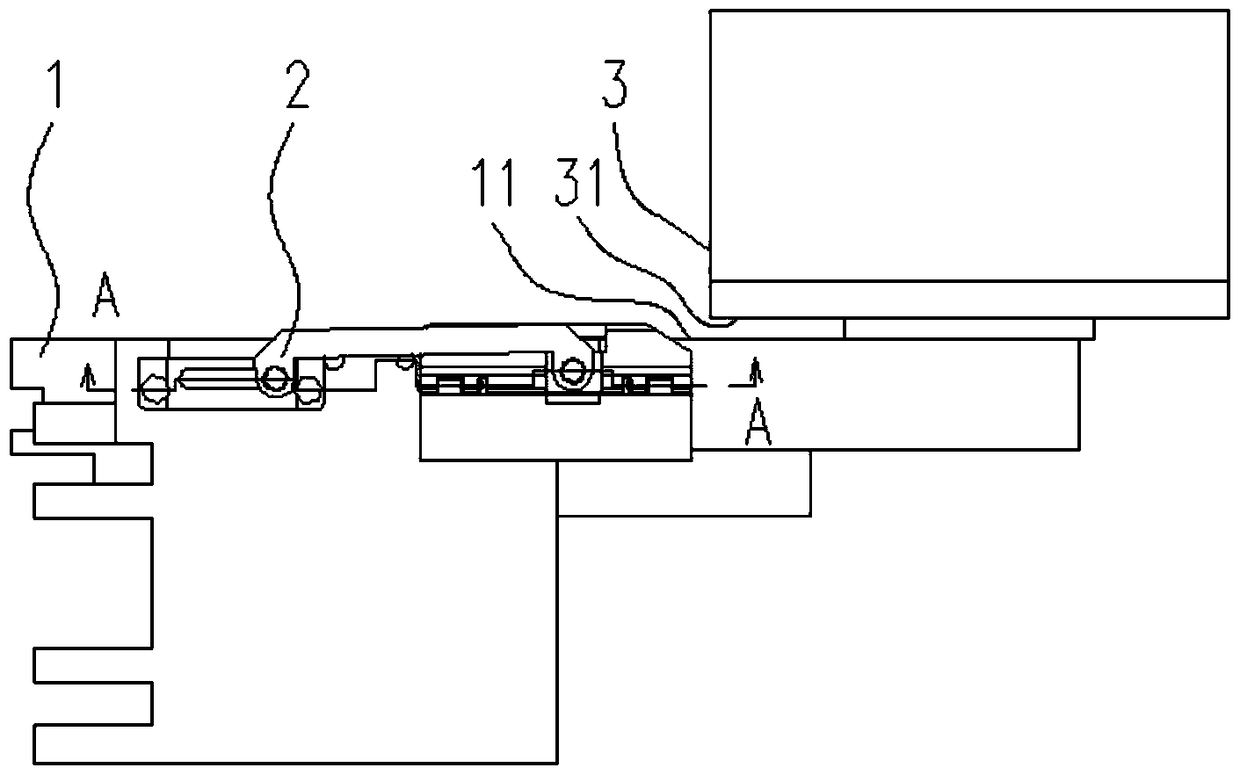

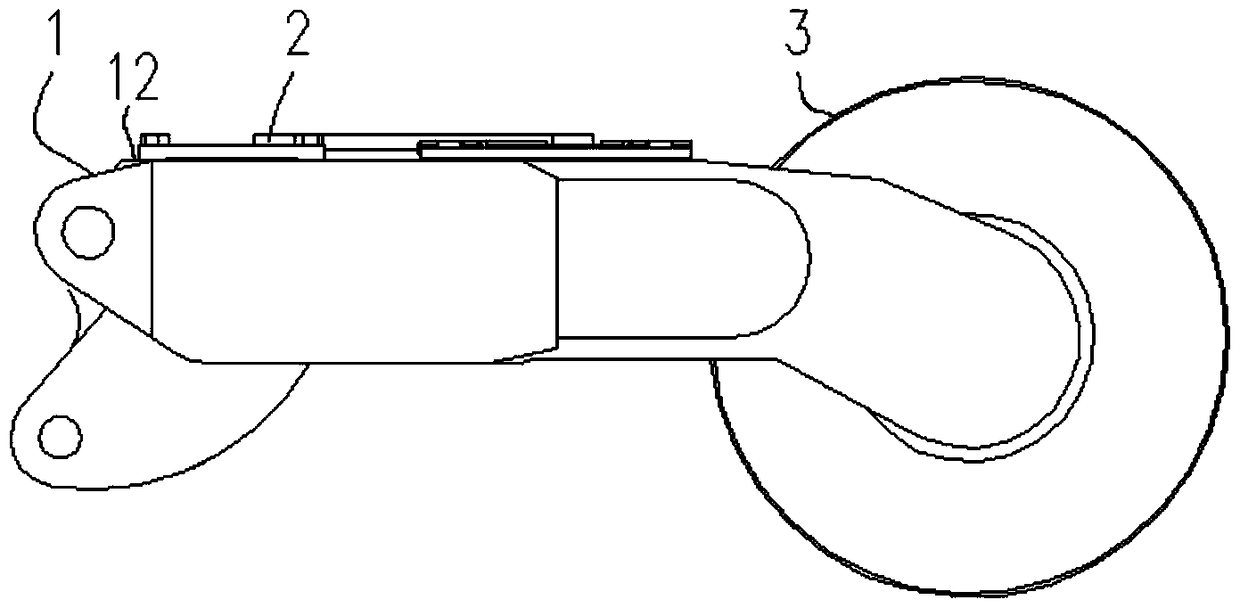

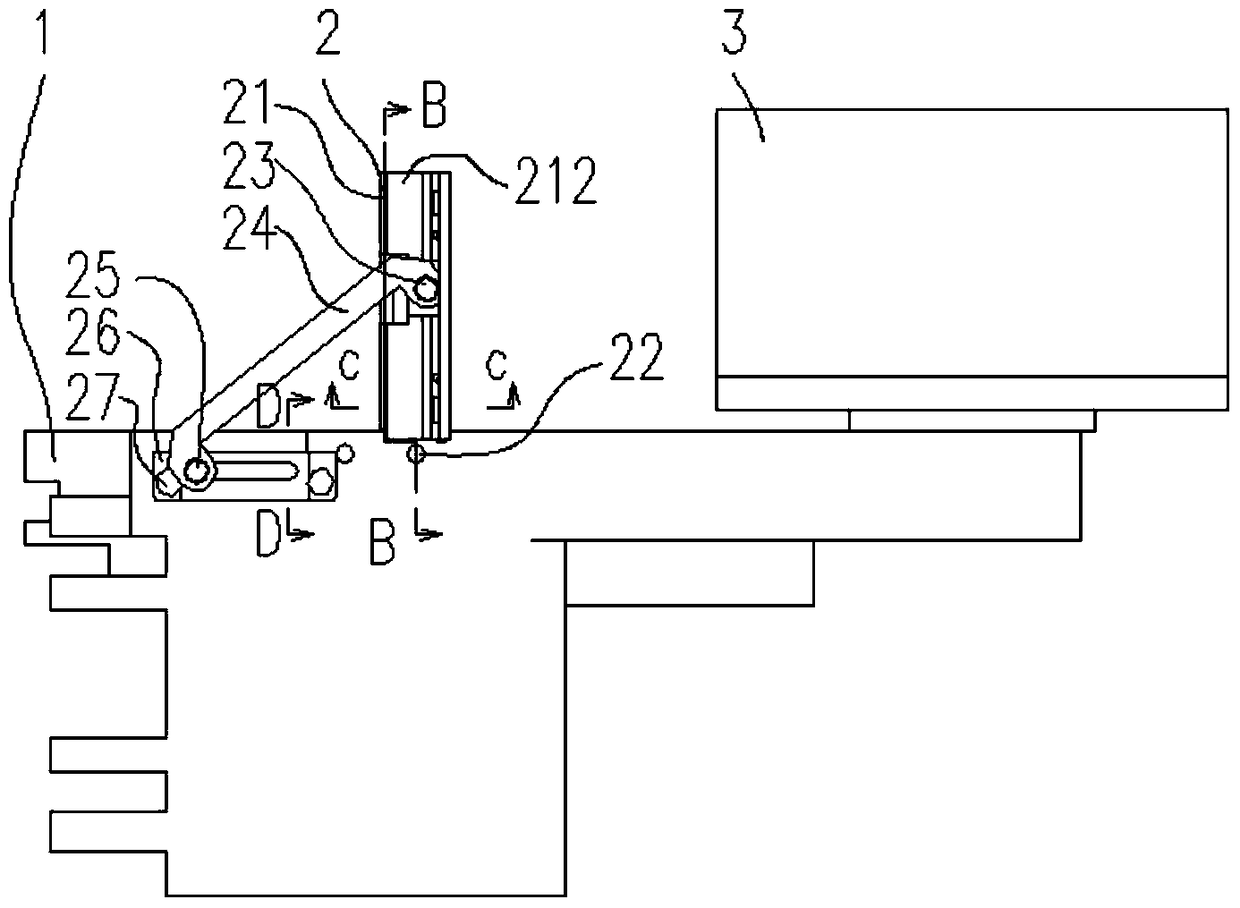

[0061] see Figure 1 to Figure 7 , The present invention discloses a thin coal seam shearer and its chute type coal retaining mechanism. The thin coal seam shearer includes a rocker arm 1 , a chute type coal retainer 2 and a drum 3 .

[0062] The rocker arm 1 includes a rocker arm housing, and the rocker arm housing includes a rocker arm end surface 11 , a rocker arm top surface 12 , and a housing coal discharge groove 13 ; the drum 3 includes a drum end face 31 . The chute-type coal retaining mechanism 2 includes a main coal retaining plate 21, a pin shaft 22, a large retaining pin 23, a connecting rod 24, a chute pin 25, a chute plate 26, a screw pin 27, an auxiliary coal retaining plate 28, and a small pin shaft 29. The second pin shaft 22'.

[0063] The main coal retaining plate 21 of the chute-type coal retaining mechanism 2 is arranged in the gap formed between the end face 31 of the drum and the end face 11 of the rocker arm. The main coal retaining plate 21 does not a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com