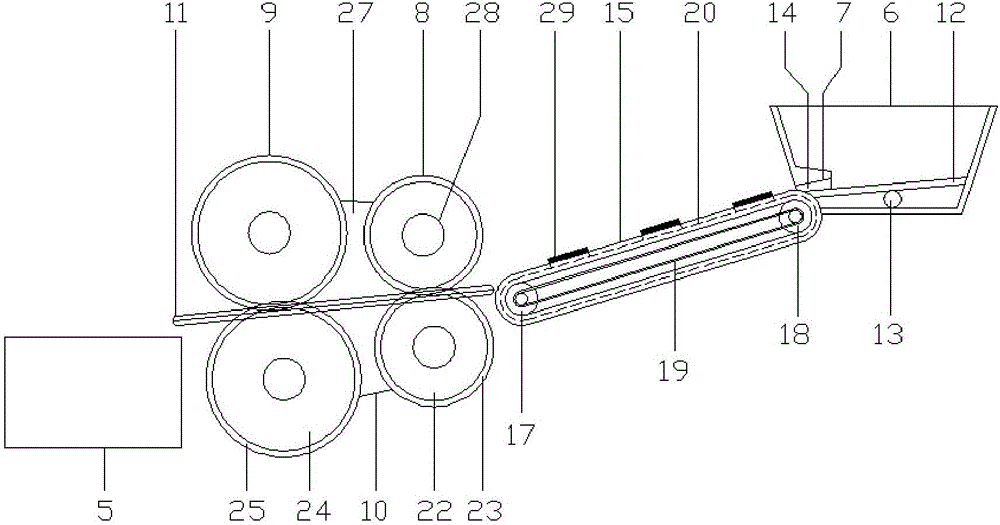

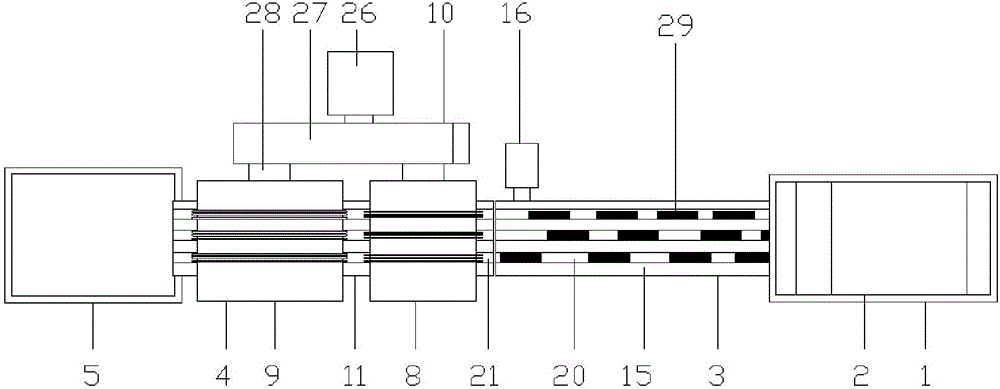

Bamboo rolling and crushing machine

The technology of a crusher and crushing mechanism, which is applied in the direction of wood processing equipment and manufacturing tools, can solve the problems of inconspicuous effect, cumbersome research and observation, loss of activity, etc., and achieve the effect of novel structure, convenient use, and reduced loss of bamboo kun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

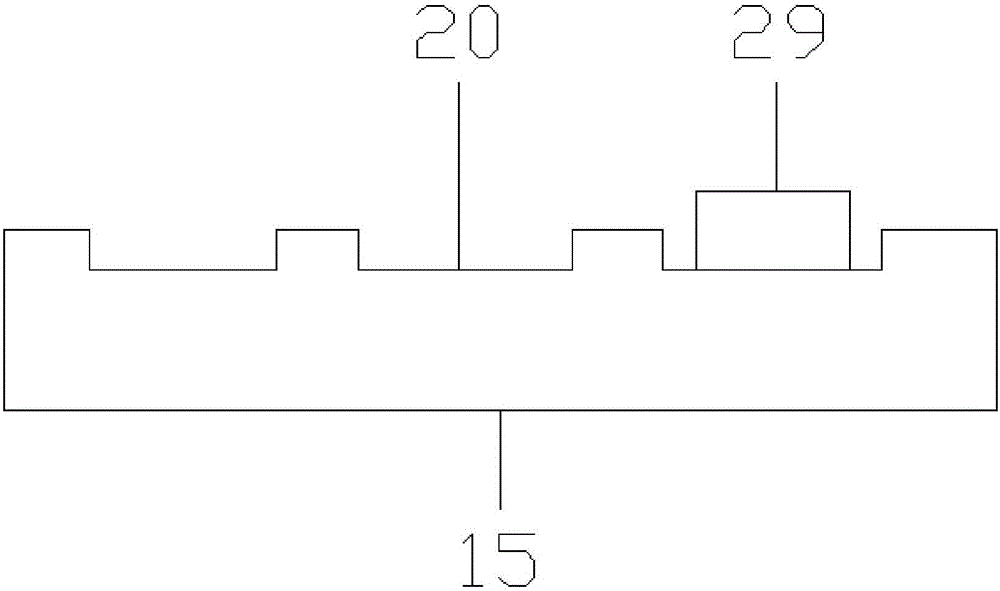

[0039] The user uses the present invention, a kind of bamboo rolling crusher. When the user is using it, the standard bamboo chips to be crushed are poured into the vibrating table inside the feeding hopper through the feeding port, and the vibrating motor inside is energized to generate vibration. The standard bamboo pieces on the vibrating table vibrate, so that the standard bamboo pieces change their direction or position on the vibrating table. When the standard bamboo pieces are in the same direction as the outlet when vibrating, the vibrating standard bamboo pieces enter the conveyor belt through the discharge hole. In the conveying trough, the geared motor on the conveying device drives the driving wheel to rotate, and the driving wheel drives the driven wheel to rotate through the chain, so that the conveyor belt on the driving wheel and the driven wheel moves towards the direction of the crushing device. When the conveyor belt moves to the crushing device , so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com