Pipeline type high wind speed double charged area electro coagulation device

A high wind speed, electrocoagulation technology, applied in the fields of cement, metallurgy, and mining, can solve the problems of increased investment, large floor area, and increased number of electric fields, etc., to achieve the effect of improved dust removal effect, convenient improvement, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The relevant technical contents not mentioned below can adopt or learn from the prior art.

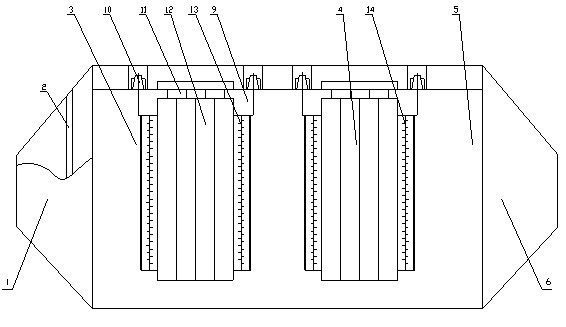

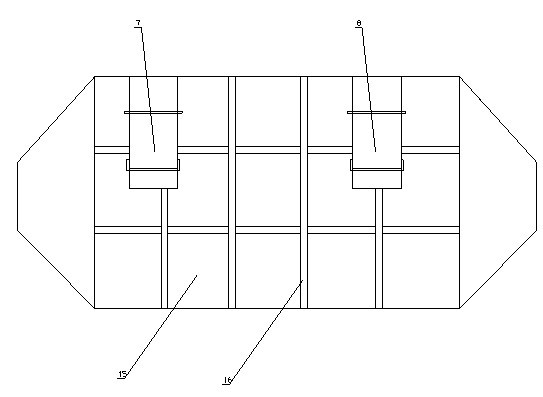

[0033] Refer to attached figure 1 , 2 , a pipeline type high wind speed double charging area electrocoagulation device, the pipe type high wind speed double charging area electrocoagulation device is provided with a flue gas inlet 1 and an outlet 6 at both ends of the shell 15 respectively.

[0034] The size of the shell 15 is 10m×4.5m, the side plate is made of steel plate with a thickness of 12mm, and the airflow distribution area 2 is arranged at the front, and the airflow distribution area is composed of a 200×200mm airflow guide plate.

[0035] The flue gas inlet 1 and outlet 6 are bell mouths, the inner diameter of the bell mouth is tapered from the shell to the port direction, and the outer port of the bell mouth is matched with the pipe.

[0036] The front portion of the housing 15 is provided with an air flow distribution plate with a through hole, and its structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com