PCB surface dust removal and static elimination equipment

A PCB board and static electricity elimination technology, applied in the direction of static electricity, electrical components, printed circuit secondary treatment, etc., can solve problems such as printing defects, foreign matter stuck on the surface of the PCB board, harmful static emission, etc., to achieve high work efficiency and eliminate static electricity Speed, the effect of eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

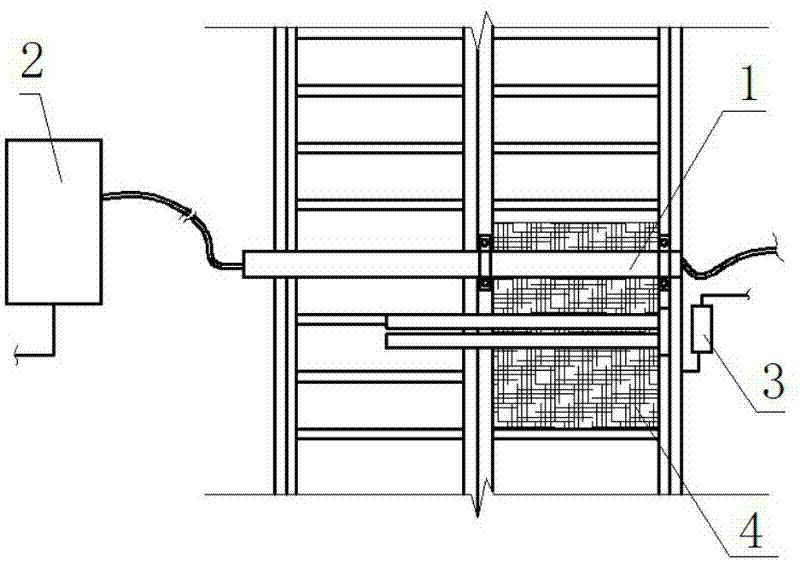

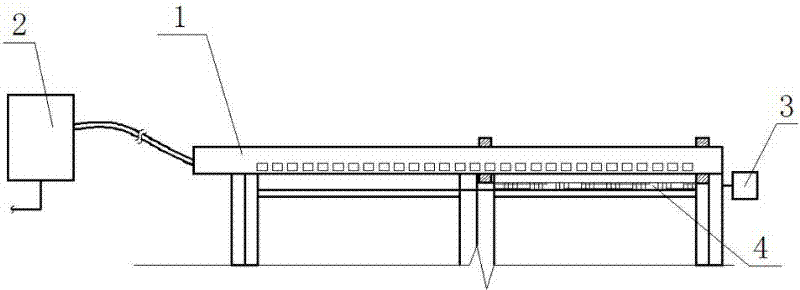

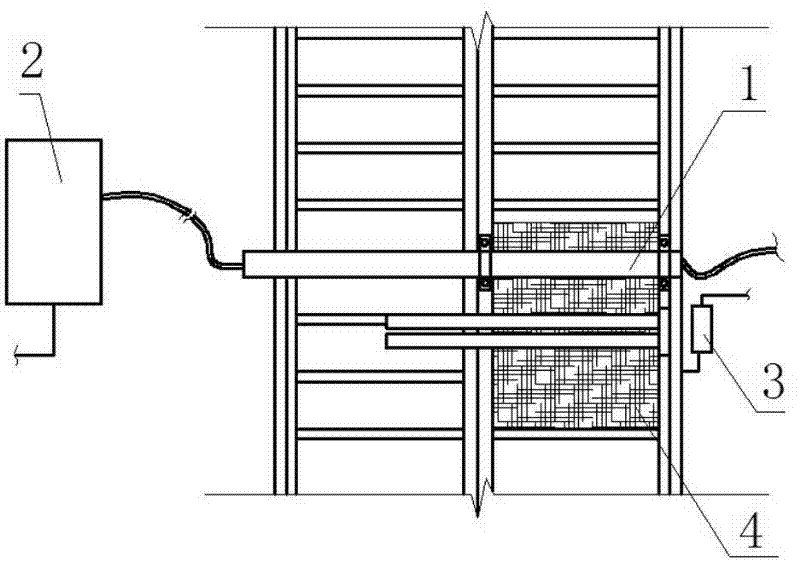

[0019] As shown in the figure, a kind of PCB board surface dedusting and static electricity elimination equipment includes a conveying device for conveying PCB board 4. The conveying device is provided with guide rails, and rollers are arranged between the guide rails. PCB board 4 passes through the rollers. The rotation of the shaft is transmitted forward.

[0020] The top of described guide rail is provided with ion air knife 1, and its tuyere is arranged downwards, and ion air knife is connected 2 with high voltage generator, and PCB board 4 passes below the tuyere from air knife.

[0021] Described conveying device is provided with inductor 3, and inductor 3 is located at the front end of conveying device, and when PCB board passes inductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com