Biomass boiler system capable of saving energy and reducing emission

A biomass boiler, energy saving and emission reduction technology, applied in steam boilers, steam generation, combustion methods, etc., can solve problems such as inability to direct combustion, and achieve the effects of preventing moisture condensation, improving drying efficiency, and reducing construction land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

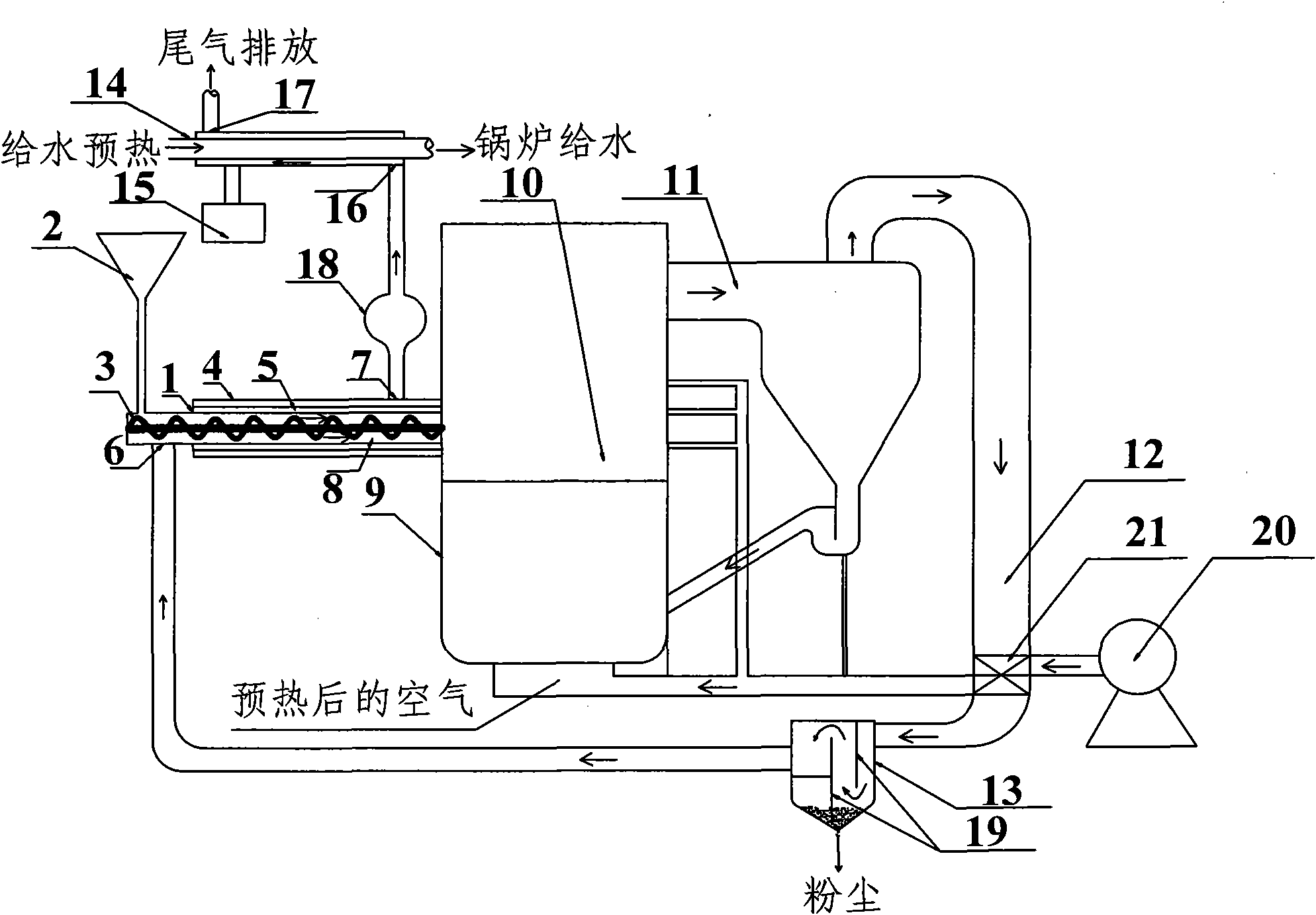

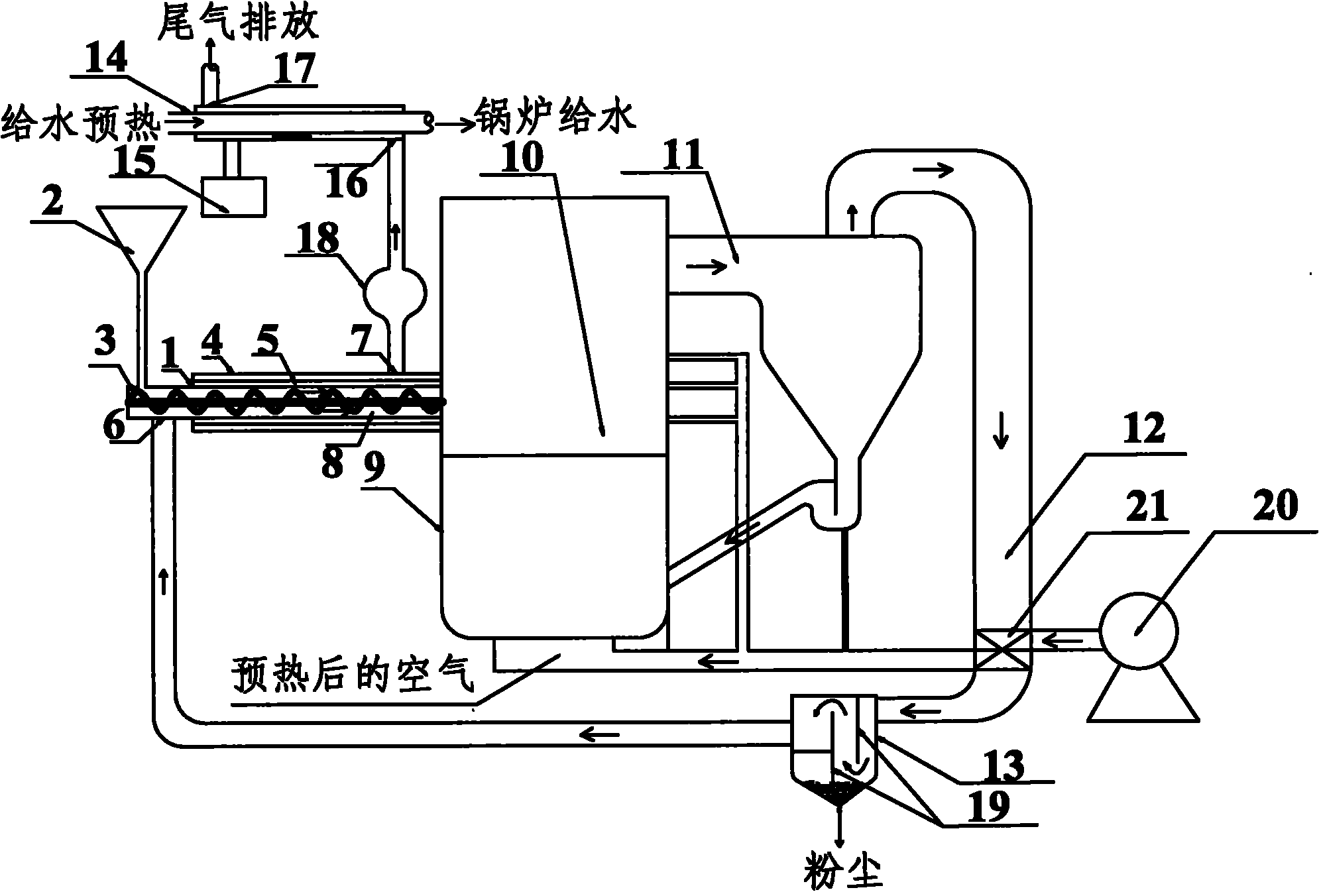

[0025] Such as figure 1 As shown, the energy-saving and emission-reducing biomass boiler system includes a drying feeding device 1, a furnace body 9, an air preheater 21 and a feed water preheating device 14, and the drying feeding device 1 includes a screw feeder 3 and a rotary dryer 4. The screw feeder 3 is placed in the drying chamber 8 of the rotary dryer 4. The furnace body 9 includes a furnace 10 and a combustion chamber 11 connected to each other. The furnace 10 is provided with a material inlet, and the material of the screw feeder 3 The output end is located at the material inlet, a waste gas outlet 7 is provided above the end of the rotary dryer 4 close to the material inlet, the top of the combustion chamber 11 is connected to one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com