Circulating air path device of biomass boiler

A biomass boiler and circulating air technology, applied in the combustion method, block/powder fuel preparation, block/powder supply/distribution, etc., can solve energy waste, low energy utilization rate, thermal pollution of surrounding environment, etc. problems, to achieve the effect of reducing investment costs, simple structure, and providing energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

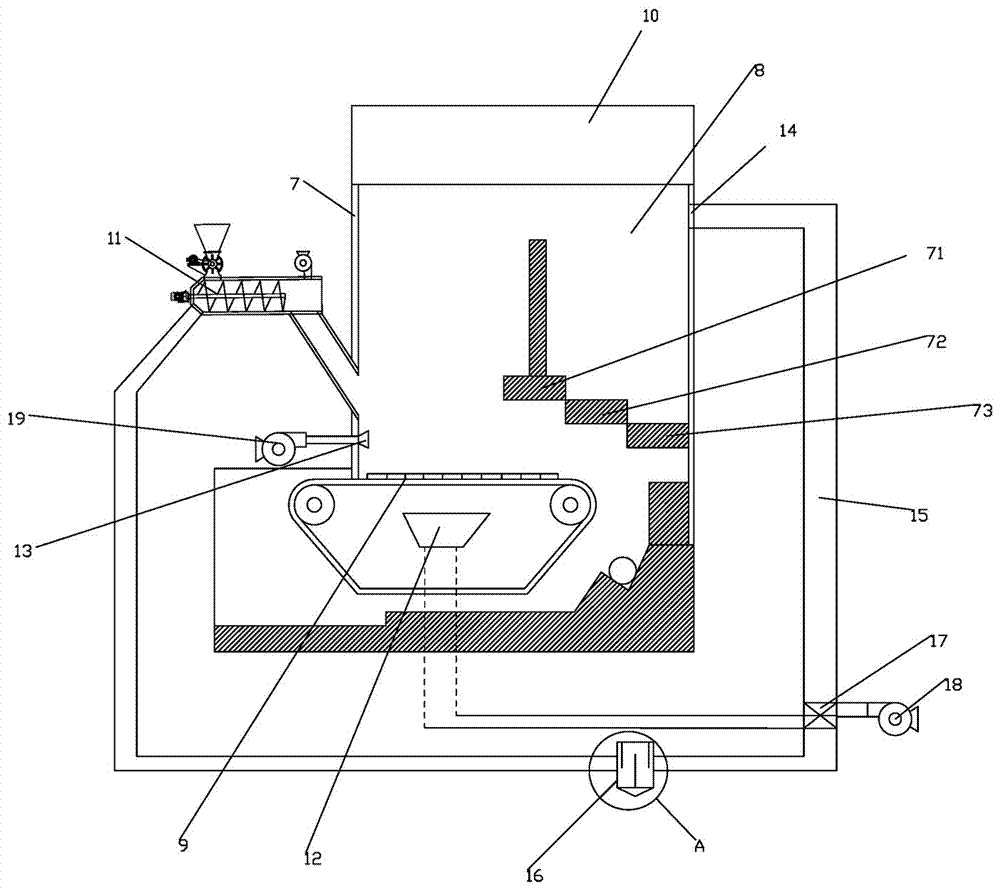

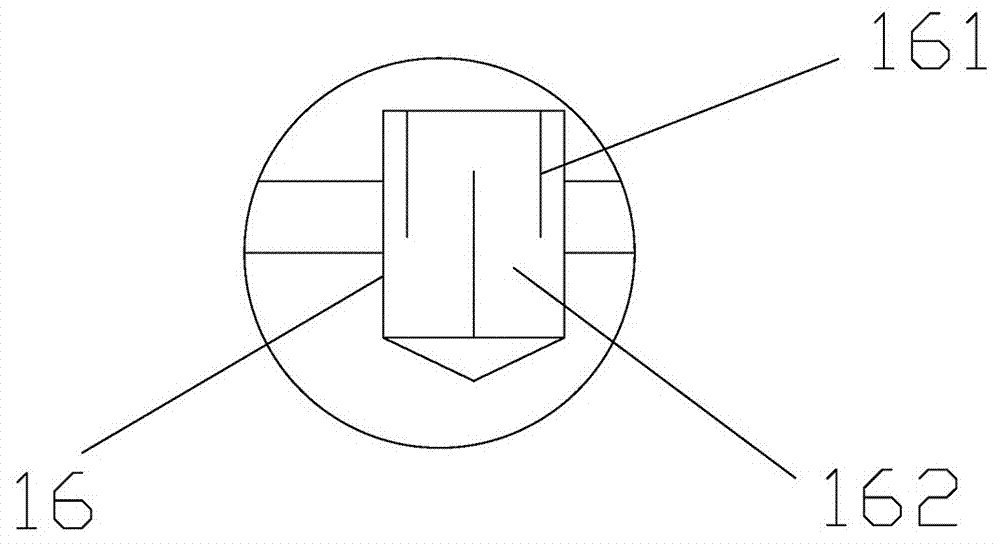

[0023] Example 1: Reference figure 1 and figure 2 , a circulating air path device for a biomass boiler, comprising a furnace body 7, a combustion chamber 8 disposed inside the furnace body 7, a moving grate 9 disposed at the bottom of the combustion chamber 8, and a feeding device disposed at the movable grate 9 11. The drum 10 arranged above the combustion chamber 8, the first air inlet chamber 12 arranged below the moving grate 9, and the second air inlet chamber arranged between the discharge port of the feeding device 11 and the moving grate 13 and the smoke outlet 14 arranged on the combustion chamber 8, the smoke outlet 14 is connected with a flue gas pipe 15, the other end of the flue gas pipe 15 is connected to the inlet of the dust collector 16, and the outlet of the dust collector 16 is connected through a pipeline To the feeding device 11 to dry the material, the flue gas pipeline 15 is provided with an air preheater 17 that utilizes the flue gas in the pipeline t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com