Full-life sling capable of being monitored and maintained

A full-life, sling technology, applied to bridge parts, bridges, buildings, etc., can solve problems such as high energy consumption, inability to accurately know the internal state of the sling, and environmental protection, and achieve the effect of restoring the normal state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

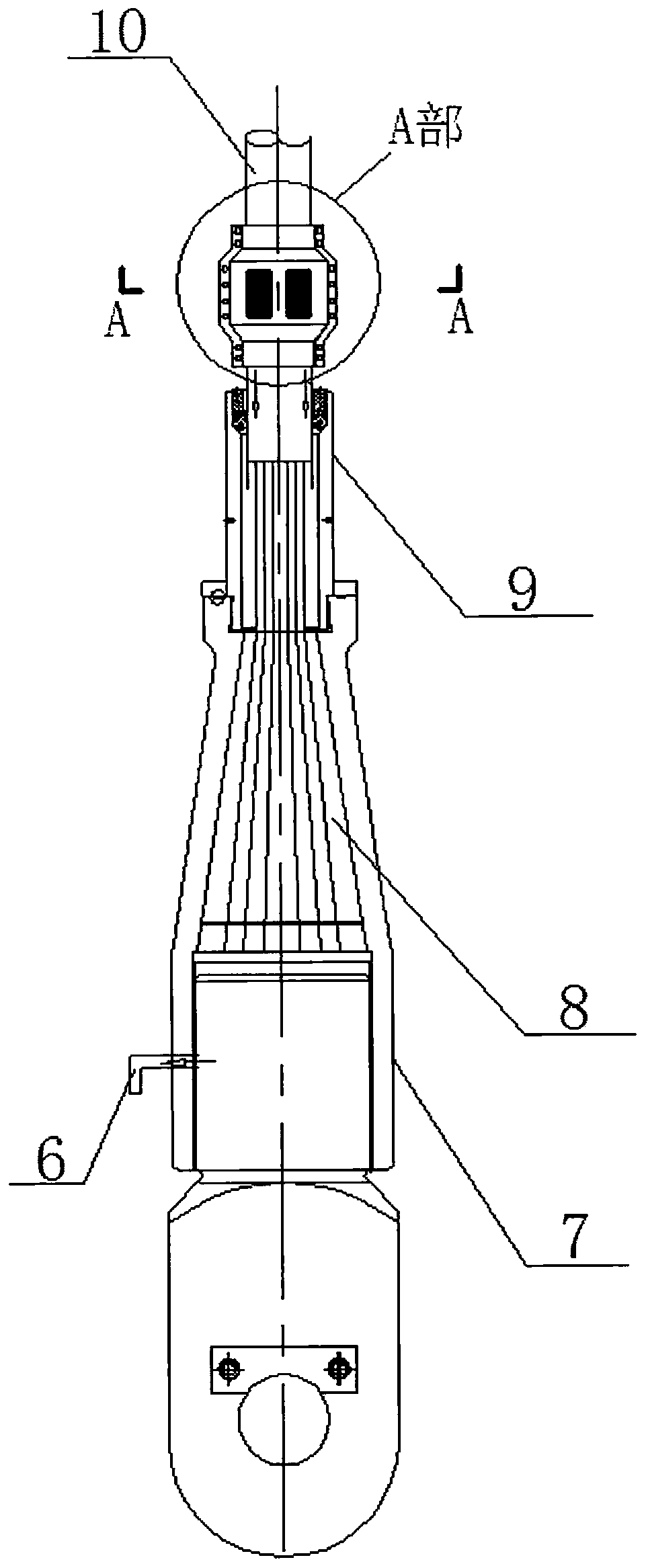

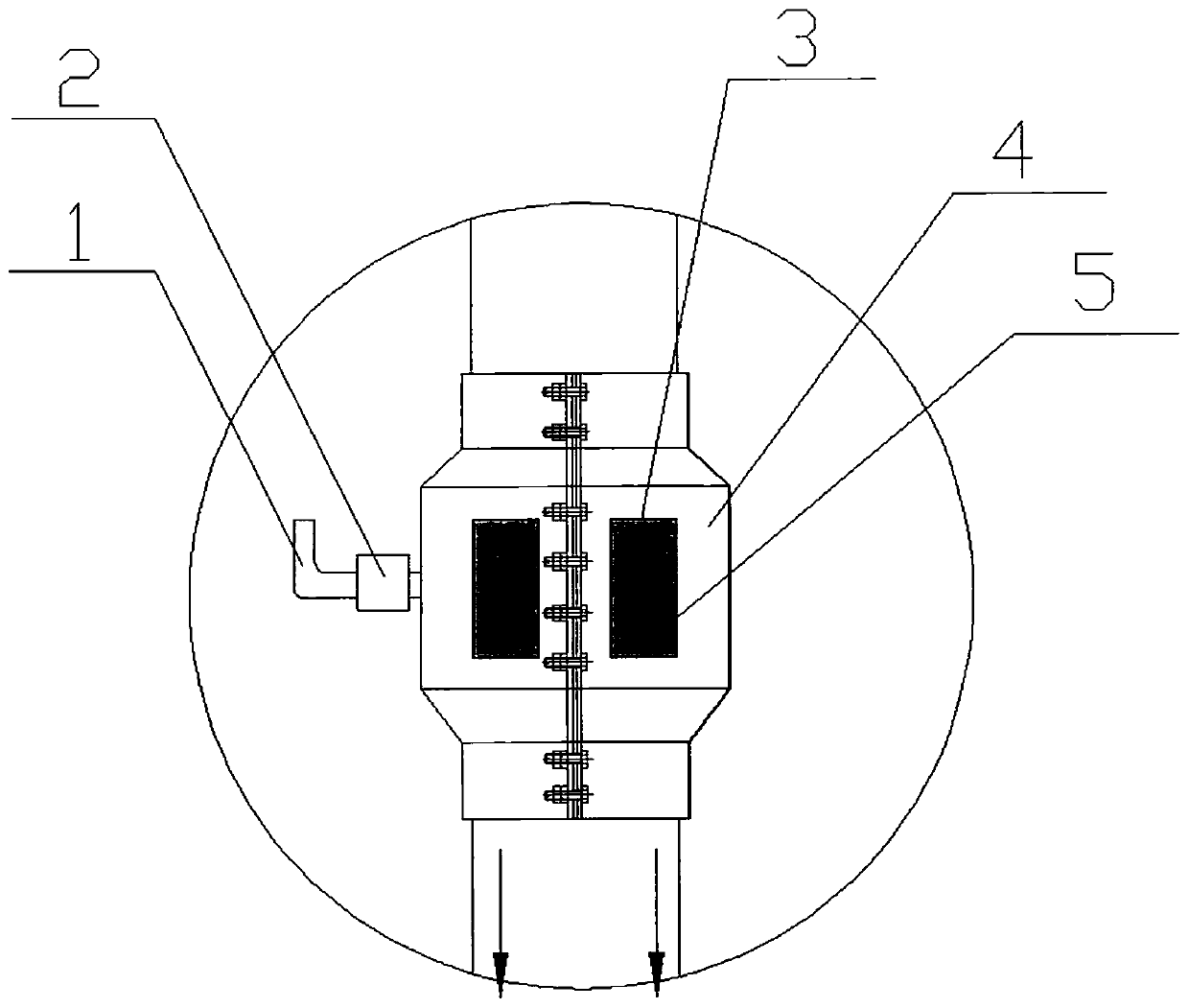

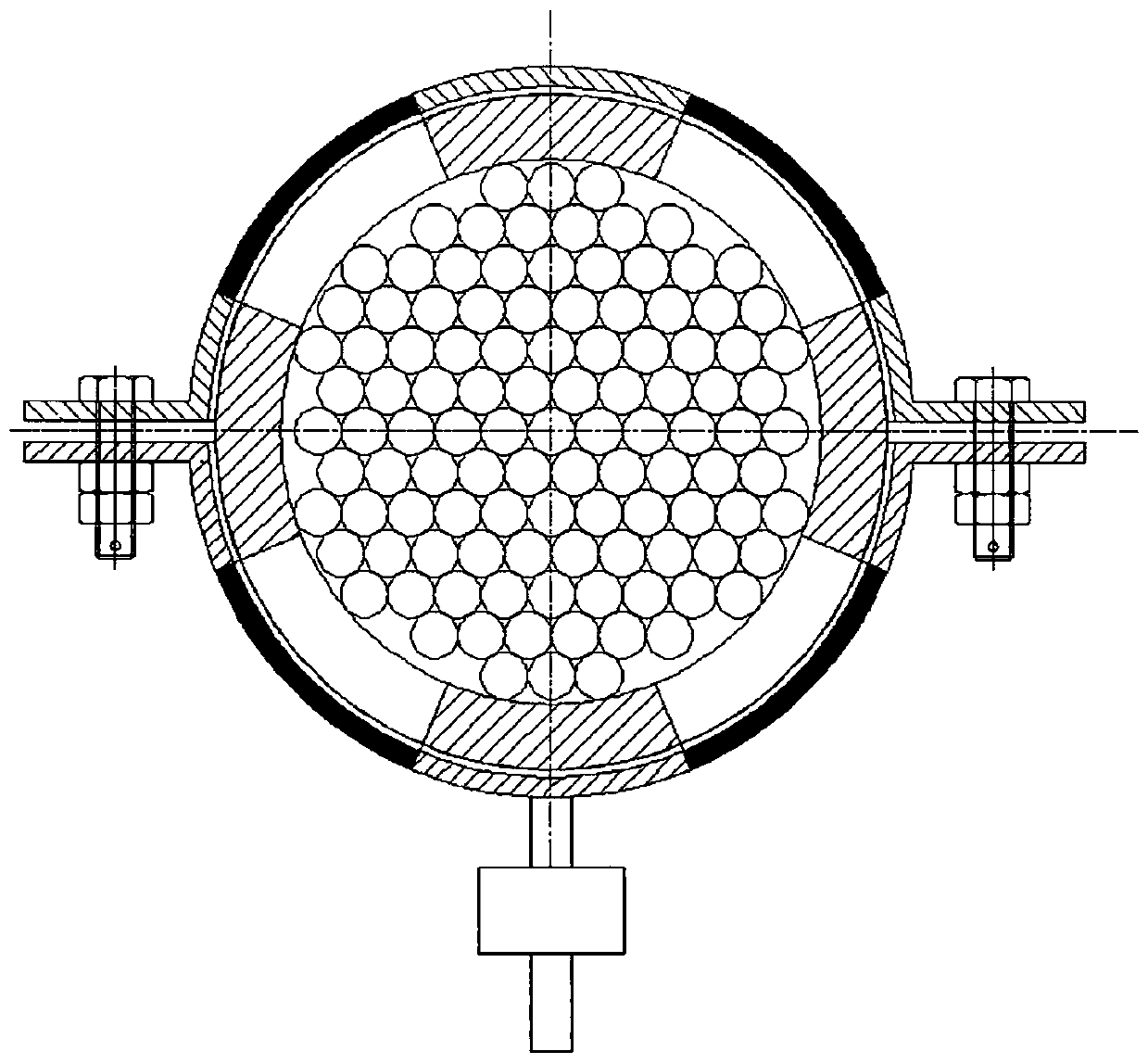

[0015] Such as figure 1 , 2 , 3, a monitorable and maintainable full-life sling in this embodiment includes a cable body 10, a sling sheath 4, a connecting cylinder 9 and a lower anchor cup 7, and the connecting cylinder 10 is fixed on the lower anchor cup 7 The upper end of the cable body 10 passes through the connecting cylinder 9 and is anchored in the lower anchor cup 7, the sling sheath 4 is arranged on the outer periphery of the cable body above the connecting cylinder 9, and the sling sheath 7 and the connecting cylinder 9 are separated by 30- 40 dm, the cable body 10 wrapped in the sling sheath 4 is partially stripped of the polyethylene sheath to expose the exposed steel wire bundles, and the gap formed between the steel wire bundles in the cable body is used as the dry air circulation gap D1.

[0016] Specifically, the steel wire b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com