Venturi nozzle

A Venturi nozzle and nozzle technology, which is applied in the use of liquid separation agent, nuclear engineering, and separation of dispersed particles, can solve problems such as unstable performance, decreased filtration efficiency, and leakage of mixed gas, and achieves convenient operation, simple structure, Practical effect

Active Publication Date: 2014-02-12

718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

View PDF3 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The different positions of the two suction ports of the Venturi nozzle described in US5017331 result in different negative pressures. When the processing capacity of the Venturi nozzle changes, especially when the flow rate decreases, that is, when the gas velocity in the throat decreases, the suction with higher pressure will The liquid port not only cannot absorb liquid, but also causes the leakage of the mixed gas, resulting in a decrease in filtration efficiency and unstable performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

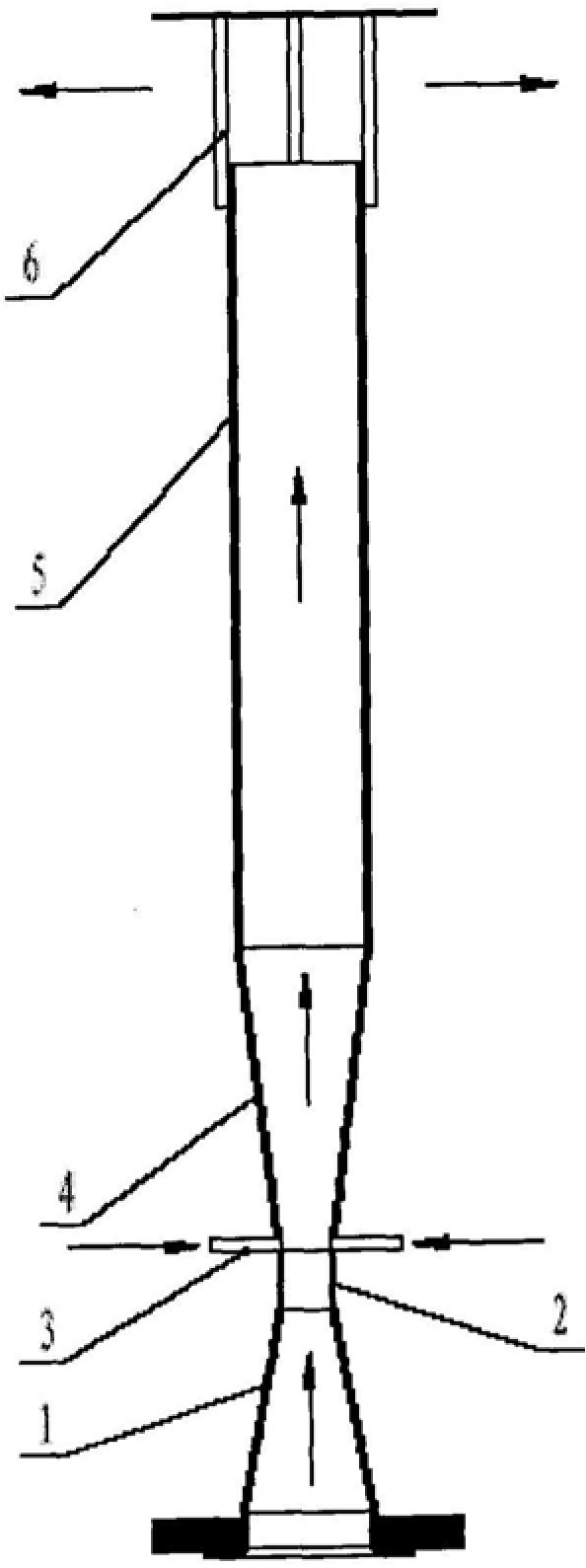

The invention relates to a venturi nozzle, comprising a nozzle body, a liquid suction pipe and a baffle plate, and peripheral equipment includes a gas pipe, a tank body and a washing liquid; wherein the nozzle body is composed of a shrinking pipe, a throat pipe, an expanding pipe and a straight pipe section from bottom to top. It consists of a uniformly distributed liquid suction port at the intersection of the expansion pipe and the throat pipe. The liquid suction port is welded with the liquid suction pipe, and the baffle is connected to the upper part of the straight pipe section through the strut. The liquid level of the washing liquid in the tank is higher than the height of the suction pipe; the invention actively sucks the liquid into the suction pipe through negative pressure, so that the dust particles and the washing liquid droplets are fully mixed, thereby achieving the dust removal effect, and no additional power device is required. The gas and the washing liquid are fully mixed, the structure is concise, the operation is convenient, and the practicability is strong.

Description

Venturi nozzle technical field The invention relates to a Venturi nozzle, which is applied to the dust removal of harmful mixed gas and belongs to the field of mechanical structures. Background technique In the containment scrubbing and filtering discharge device of nuclear power plants, in order to remove dust from the harmful mixed gas discharged from the overpressure of the containment, it is necessary to install a gas filter device; the main function of the gas filter device is the Venturi nozzle, and the current Venturi nozzle structure It is more complex, requires active operation, cannot be applied to radioactive environments, and cannot meet high requirements for use. Venturi tube dust collector described in ZL03204250.7, the dust collector consists of a gas-water separator constituting the main body of the venturi tube, a shrinkage tube connected to the gas-water separator, and nozzles and water supply pipelines arranged inside and outside the shrink tube and so...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D47/10G21F9/02

Inventor 付嫚覃亮徐月赵宁冯海波张彬张纪领黄永生

Owner 718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com