Deep bending roll dust remover

A technology of dust removal device and deep roll bending, which is applied in the direction of dust removal, chemical instruments and methods, cleaning methods and utensils, etc. It can solve the problems of affecting the ambient air quality, endangering the health of nearby personnel, and affecting the surface quality of hot-rolled coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

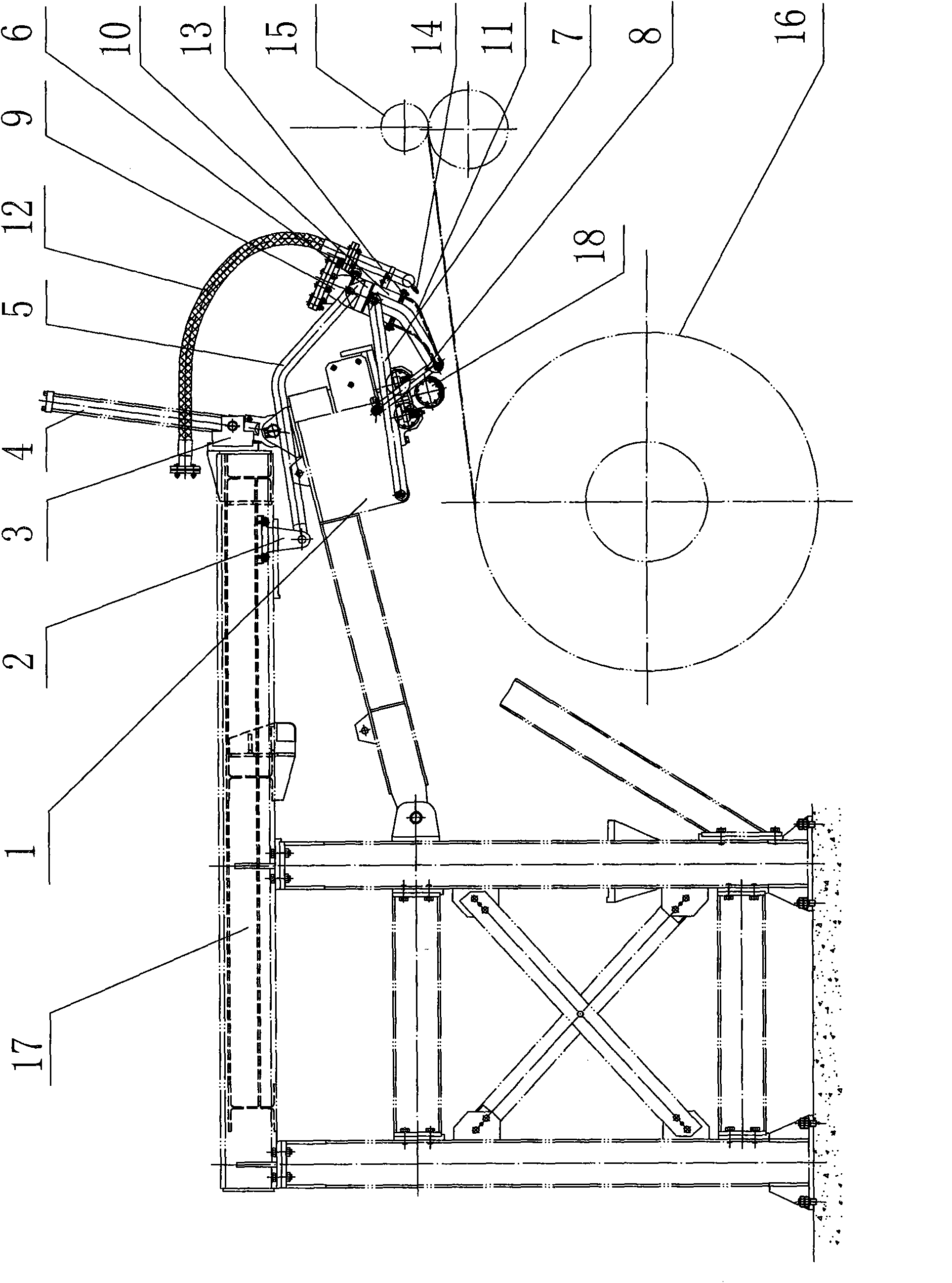

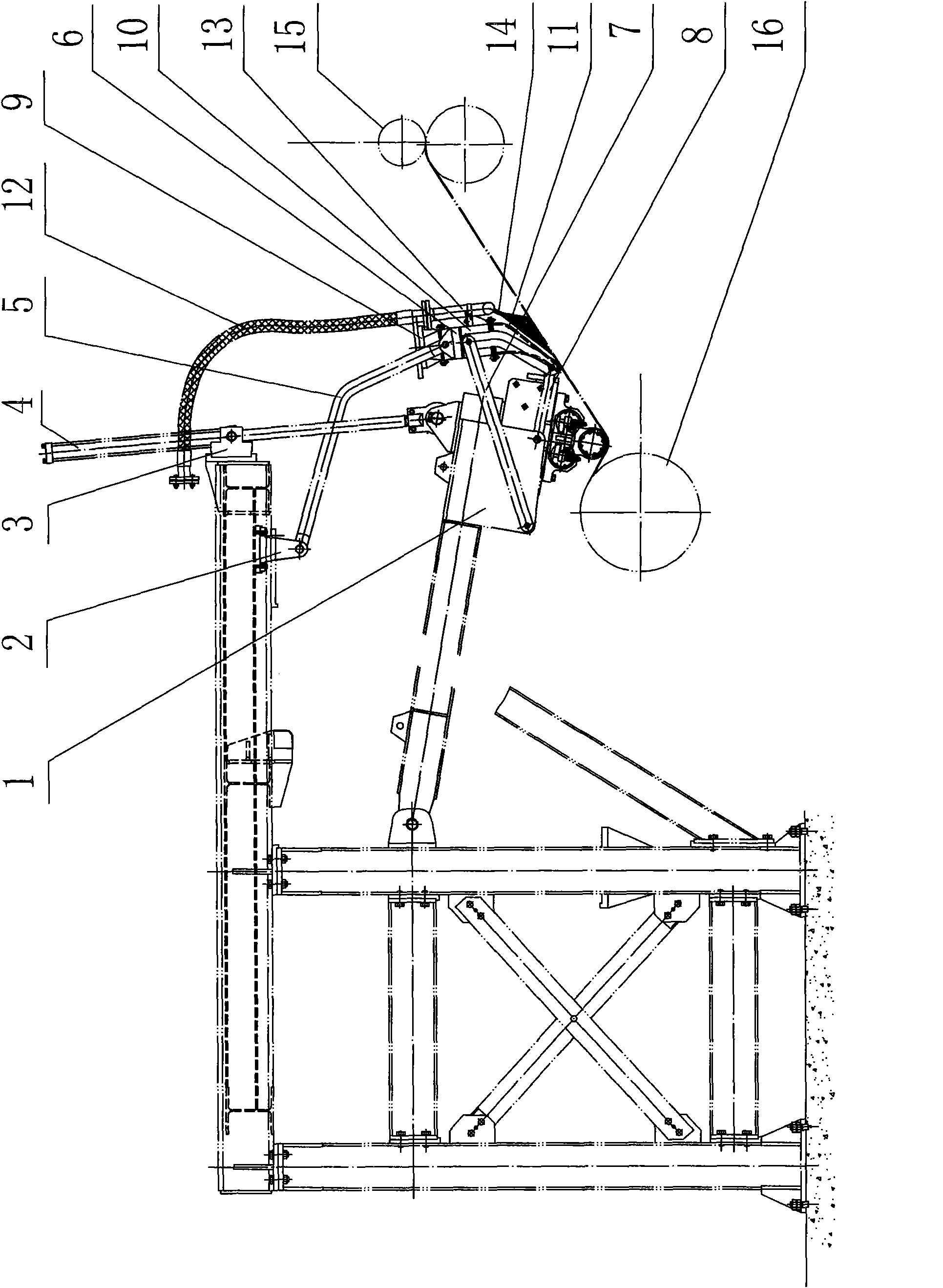

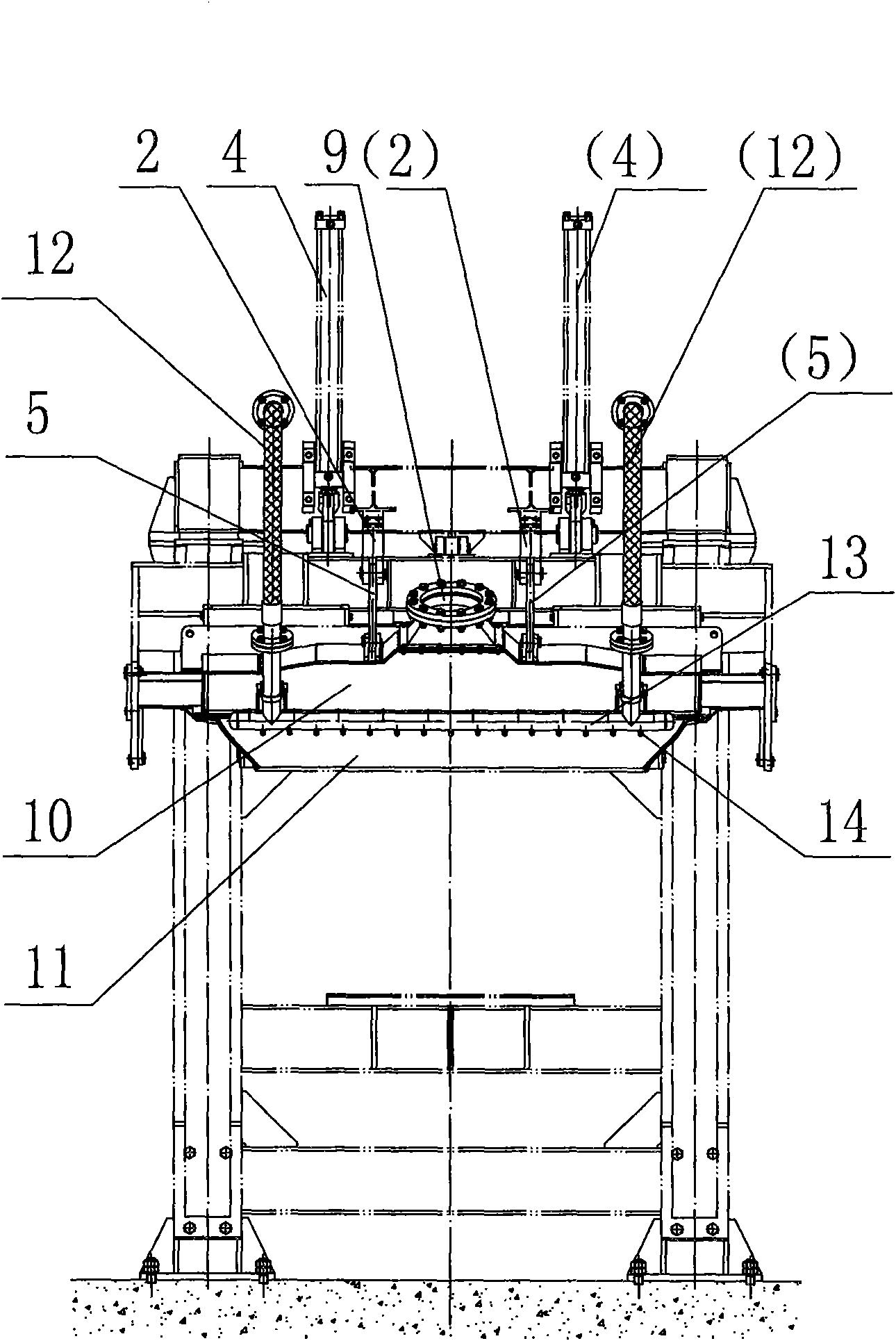

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the deep bending roller dust removal device includes the first connecting rod support 2, the first connecting rod 5, the blowing and suction dust removal device 6, the second connecting rod 7, and the third connecting rod 8; the left end of the first connecting rod 5 Hinged with the first connecting rod support 2 ( figure 1 The left side in the picture is left, the right side is right, and the left and right direction is the moving direction of the strip steel; the inside of the paper is the front, and the viewer is the back), the first connecting rod support 2 is fixed on the support frame 17 of the deep bending roller device, the second The right end of a connecting rod 5 is hinged with the upper part of the blowing-suction dust removal device 6; The middle part of the dust removal device 6 is hinged; the left end of the third connecting rod 8 is hinged with the right part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com