Building garbage crusher

A technology of construction waste and pulverizer, which is applied in the direction of grain processing, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of low waste utilization rate, environmental pollution, and lack of pertinence, so as to improve waste utilization rate and reduce production Low cost and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

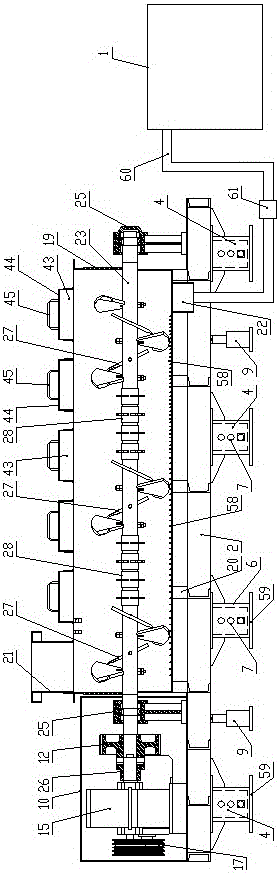

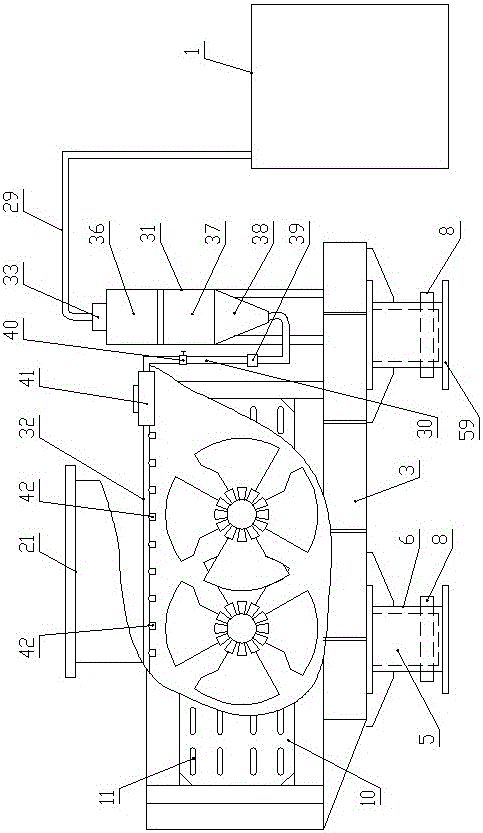

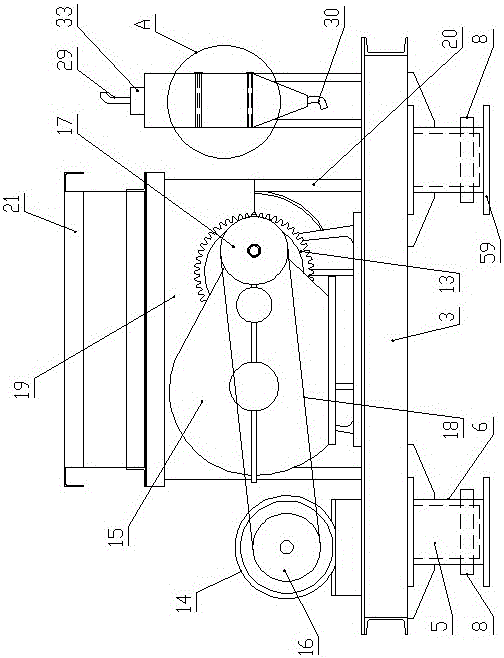

[0030] Such as Figure 1-9 As shown, a construction waste pulverizer of the present invention includes a frame, a power drive system is provided at the left end of the frame, and the power output end of the power drive system is connected with a material crushing system located on the right side of the power drive system. The system is fixed on the frame, which is equipped with an automatic spraying and dust suppression system located in front of the material crushing system feeding place. The spraying part of the automatic spraying and dust suppression system is located in the material crushing system, and a sedimentation tank is installed on one side of the frame. 1.

[0031] The frame includes two longitudinal beams 2 parallel to each other. The two longitudinal beams 2 are arranged along the left and right horizontal directions. A number of beams 3 are evenly spaced between the two longitudinal beams 2 along the length direction. The lower surfaces of the two longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com