Full-automatic case packing machine

A cartoning machine, fully automatic technology, applied in the direction of packaging, transport packaging, transportation and packaging, etc., can solve the problems of unrealistic product packing, large external dimensions, and unsuitable for small-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

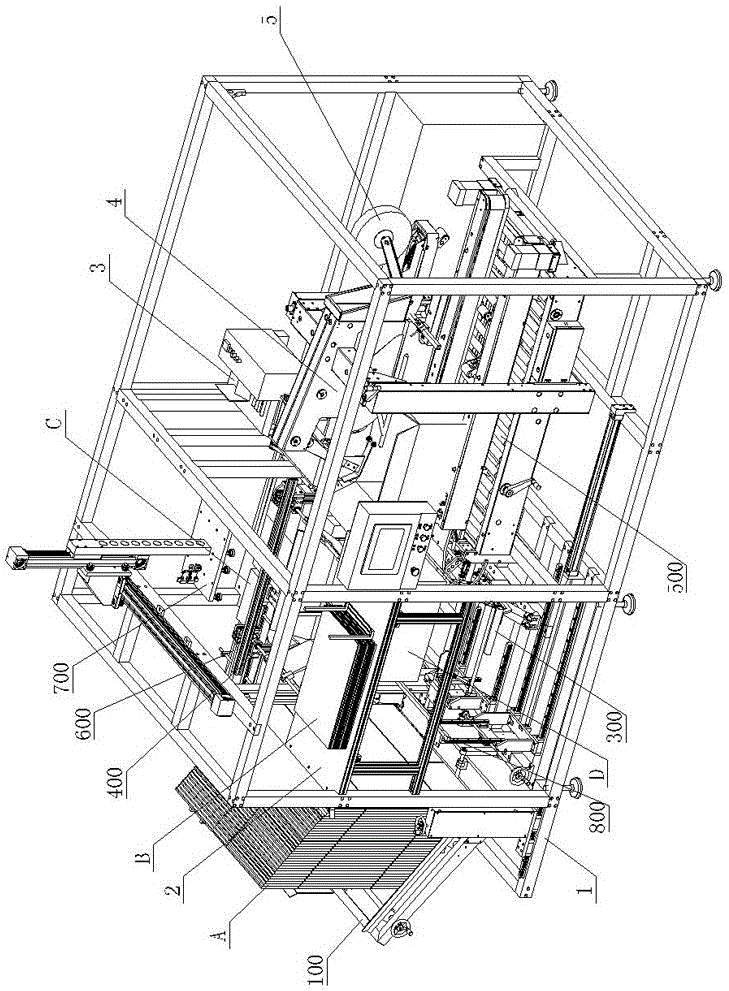

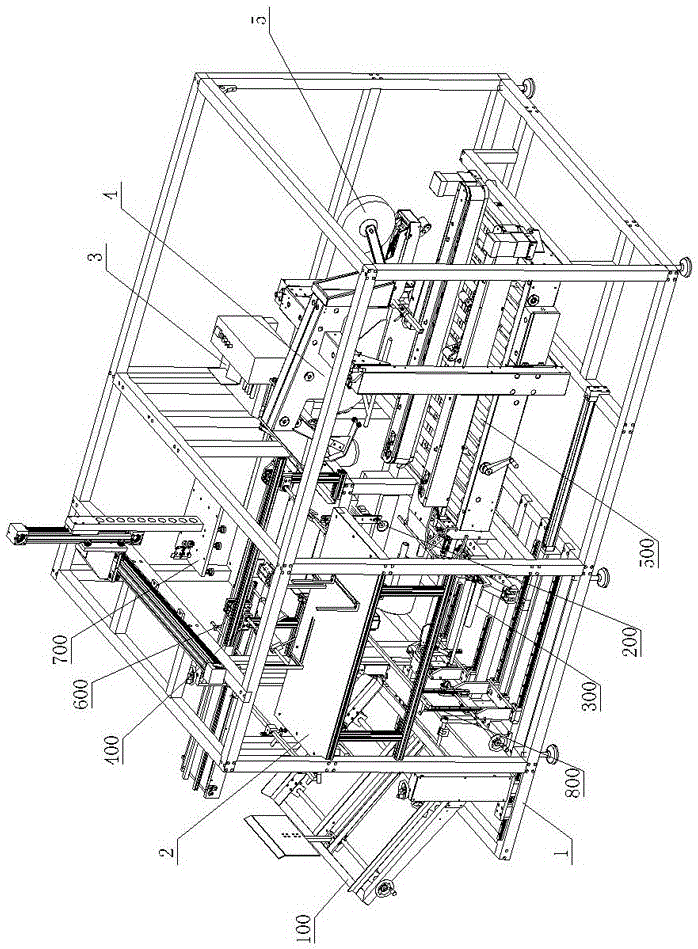

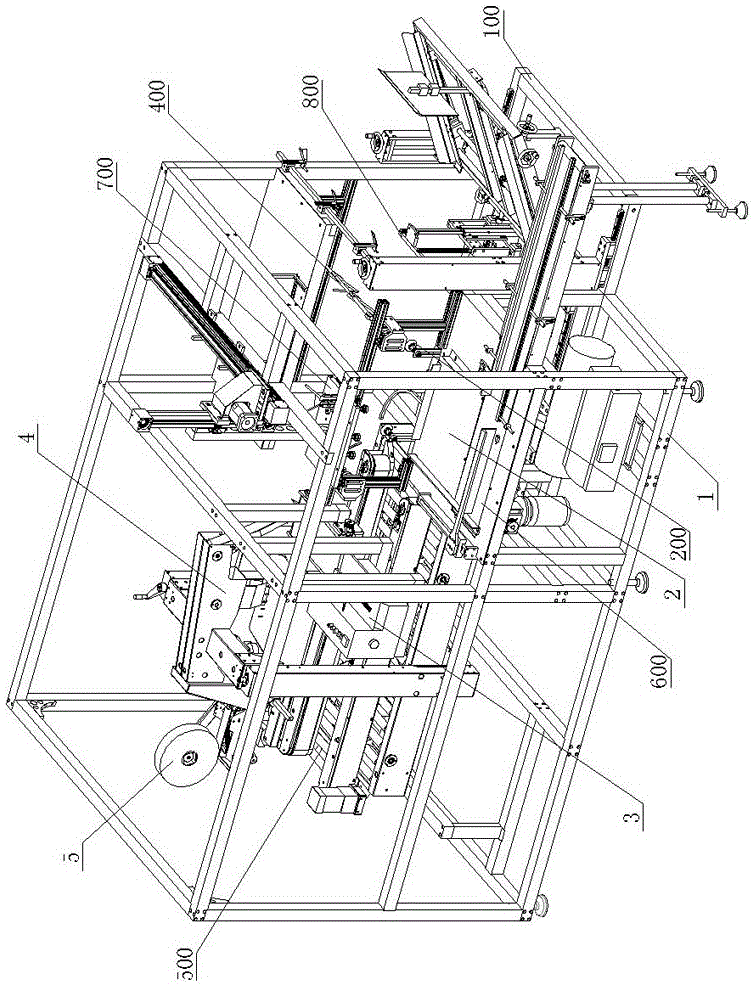

[0039] Such as Figure 1-3 As shown, the fully automatic case packing machine of the present invention has a frame 1 and a case packing station D arranged in the center, and a bin part 100, a suction box part 200, a tongue part 300, and a tongue opening part are arranged around the case packing station D. The component 400 and the sealing station 500, the bin component 100 is located at the rear side of the packing station D for stacking and storing the packing cases A, and the suction box part 200 is located on the right side of the packing station D for sucking and opening the packing cases, The closing tongue part 300 is located at the bottom of the packing station D and is used to close the bottom of the packing case and hold the packing case closed at the bottom of the case. The tongue opening part 400 is located at the top of the packing station D and is used to open the mouth of the packing case. 500 is located on the front side of the packing station D and is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com