Intelligent full-automatic vacuum tea packing machine

A fully automatic and intelligent technology, applied in packaging, transportation packaging, multiple packages, etc., can solve the problems of inconvenient to carry, low packaging efficiency, slow packaging speed, etc., and achieve the effect of saving labor and labor, convenient installation and placement, The effect of high packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

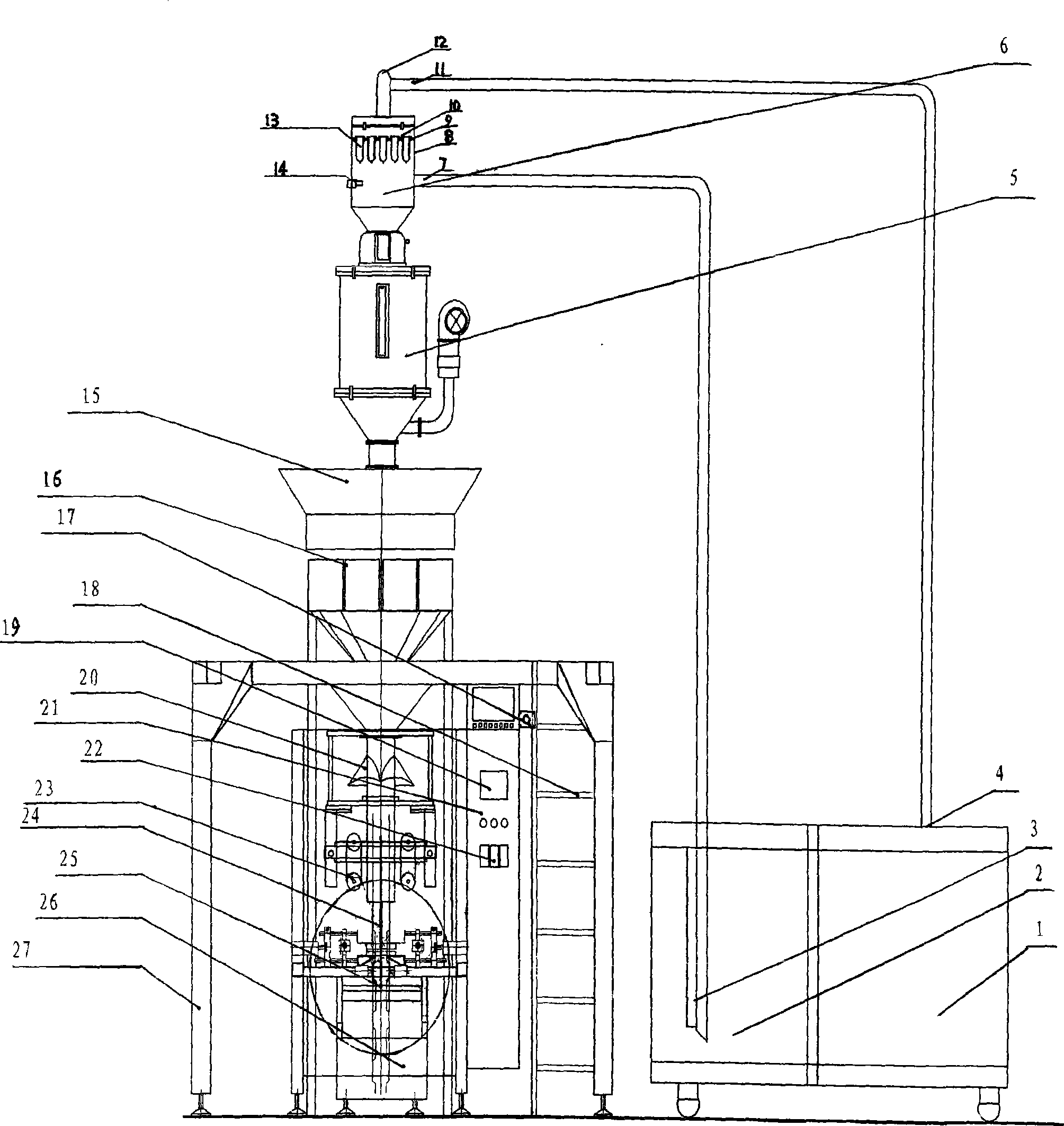

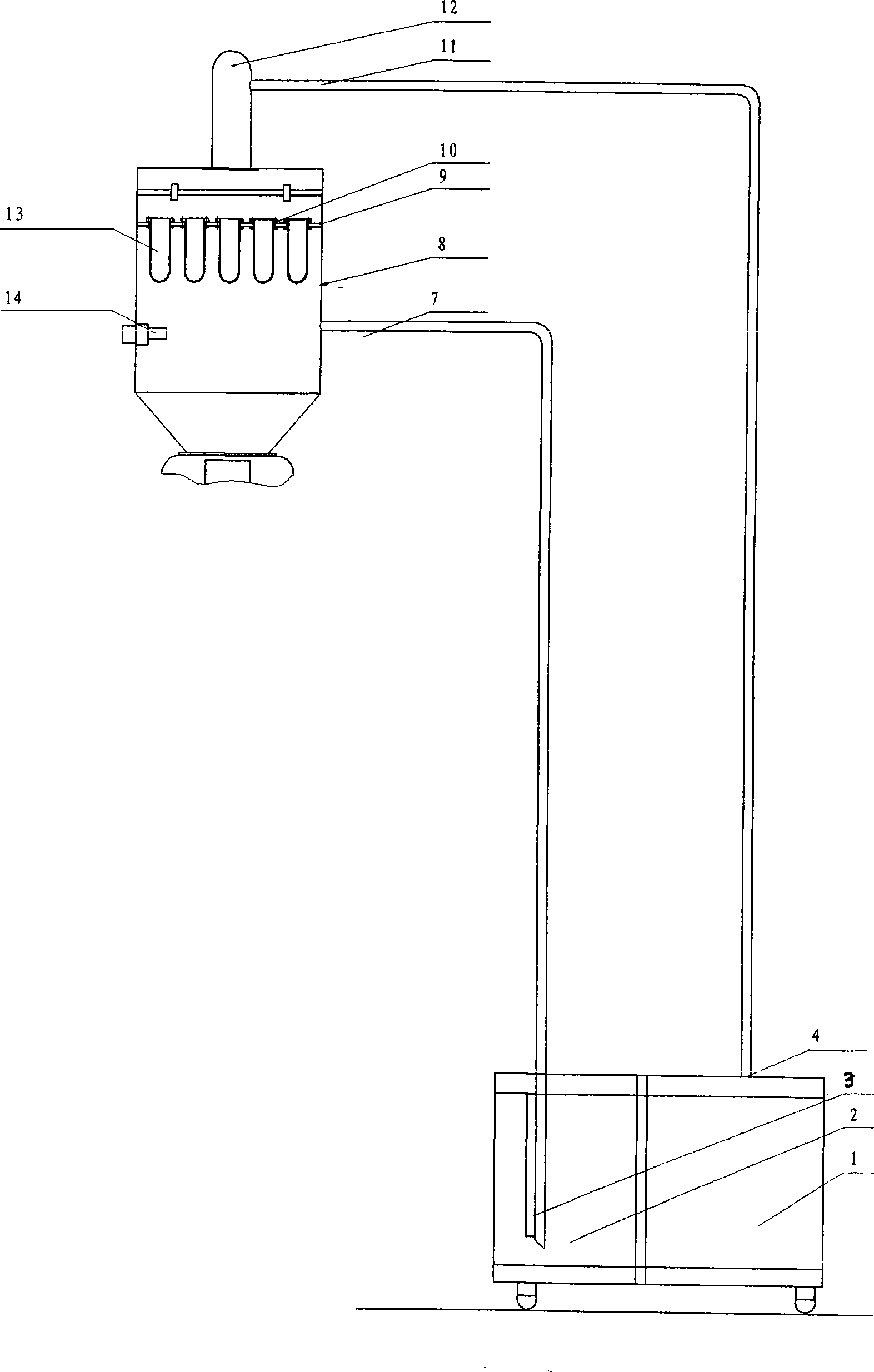

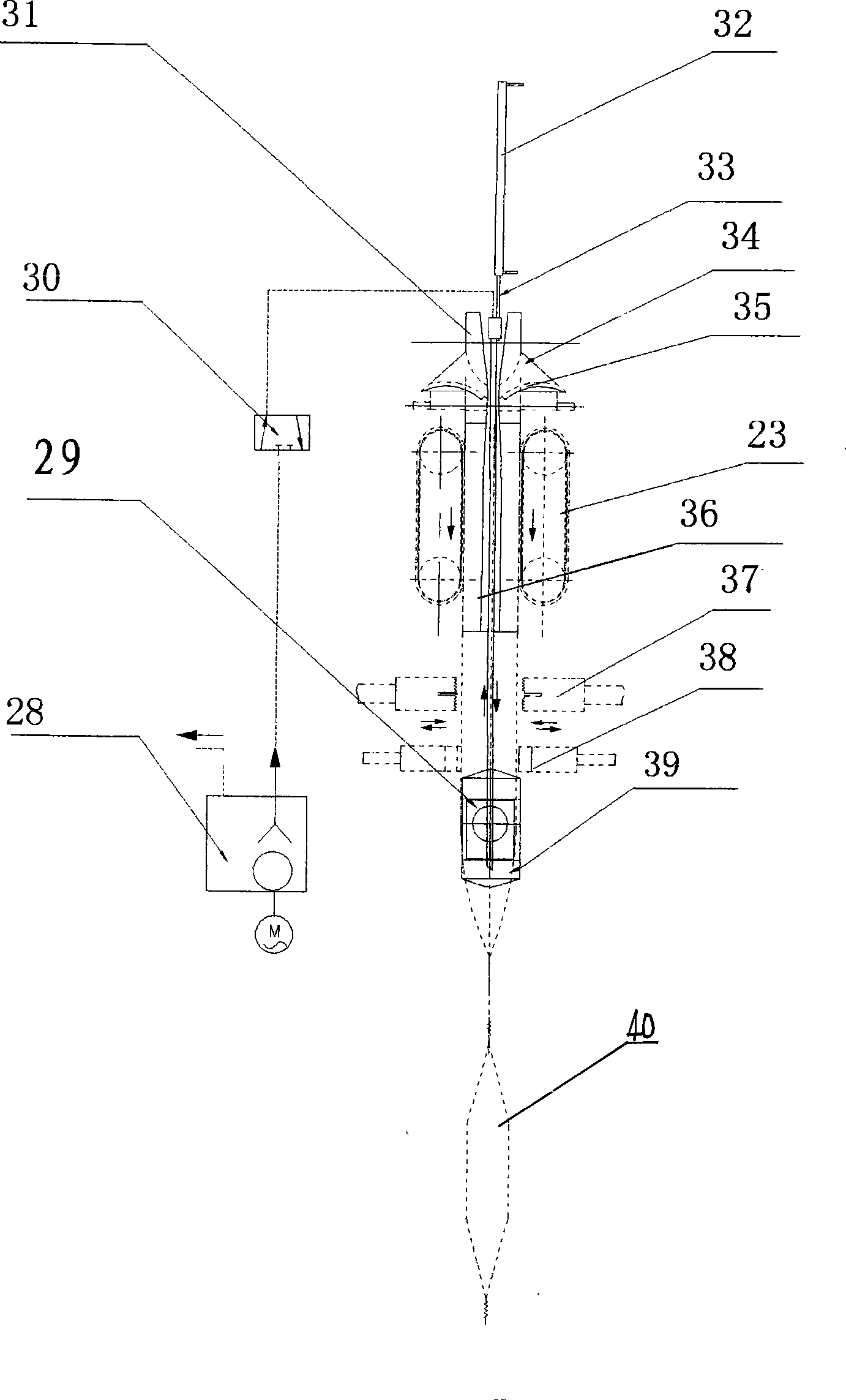

[0011] Such as figure 1 As shown, an intelligent automatic vacuum tea packaging machine mainly consists of a platform support 27, a storage hopper 15 and a weighing device. The intelligent automatic vacuum tea packaging machine includes a vacuum feeding drying device and an automatic vacuum packaging device. The present invention is composed of a vacuum feeding and drying device, a weighing device, a platform support, a storage hopper, an automatic vacuum packaging device, an angle inserting device, a packing bag box type shaping device, an electric control cabinet 21 and a finished product conveyor 26. The suction machine and barrel of the vacuum feeding and drying device are located on one side of the platform support, and the vacuum tank of the vacuum feeding and drying device is equipped with a dryer, a storage hopper, a weighing device, an automatic vacuum packaging device and a finished product conveyor. , the finished product conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com