Material packaging method and device for laterally transferring full material bags

A packaging method and full bag technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of long longitudinal transfer distance of full bags, sliding friction of full bags, etc., so as to shorten the transfer distance and avoid sliding. The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

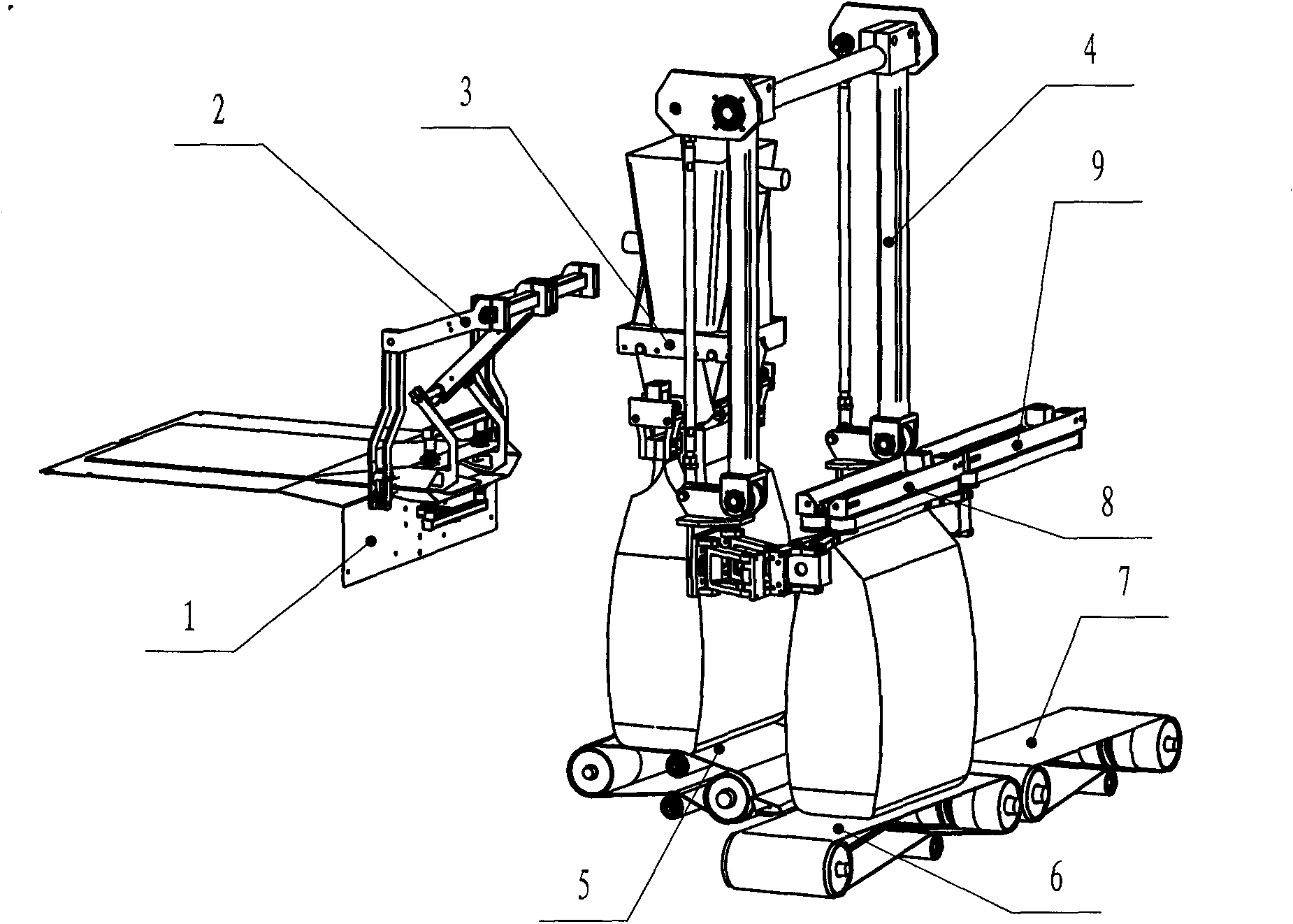

[0034] The specific embodiment of the present invention sees Figure 1 to Figure 11 , the material packaging method of laterally moving the full material bag comprises the following process steps:

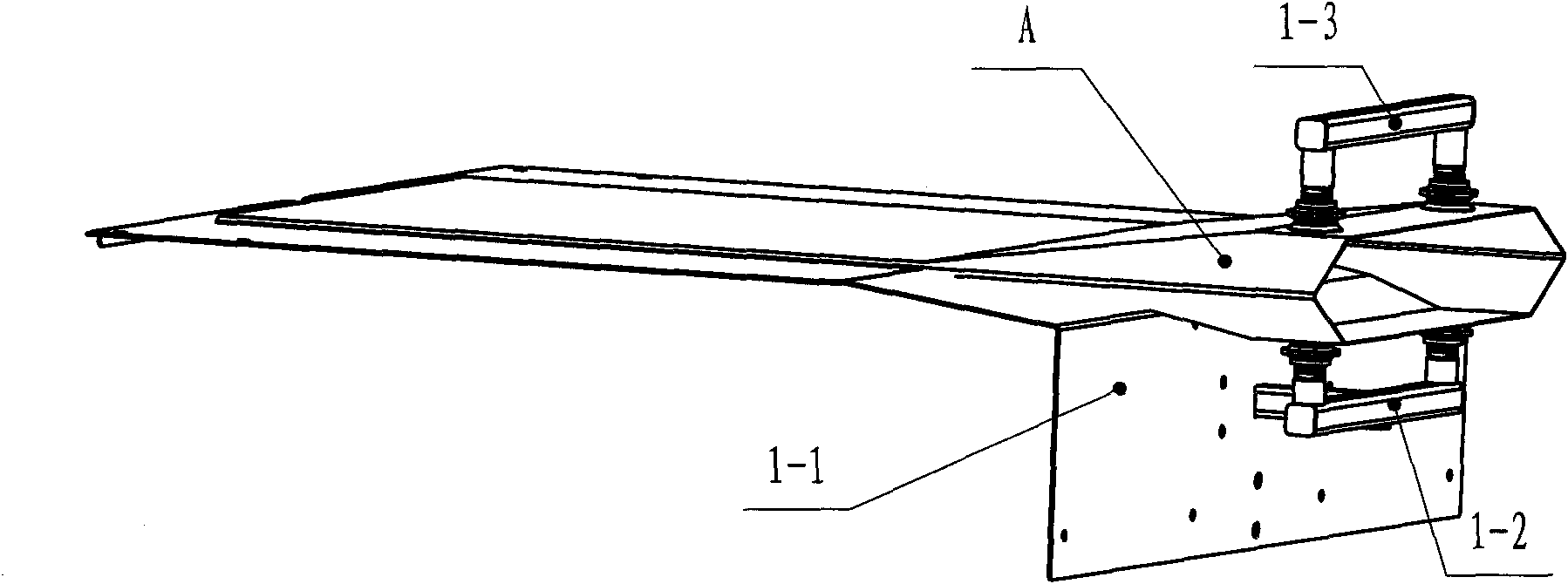

[0035] (1) Opening the bag opening: the upper suction cup (1-3) that can move up and down and the fixed lower suction cup (1-2) will be placed horizontally on the opening of the empty bag (A) on the pallet (1-1) open to the appropriate size;

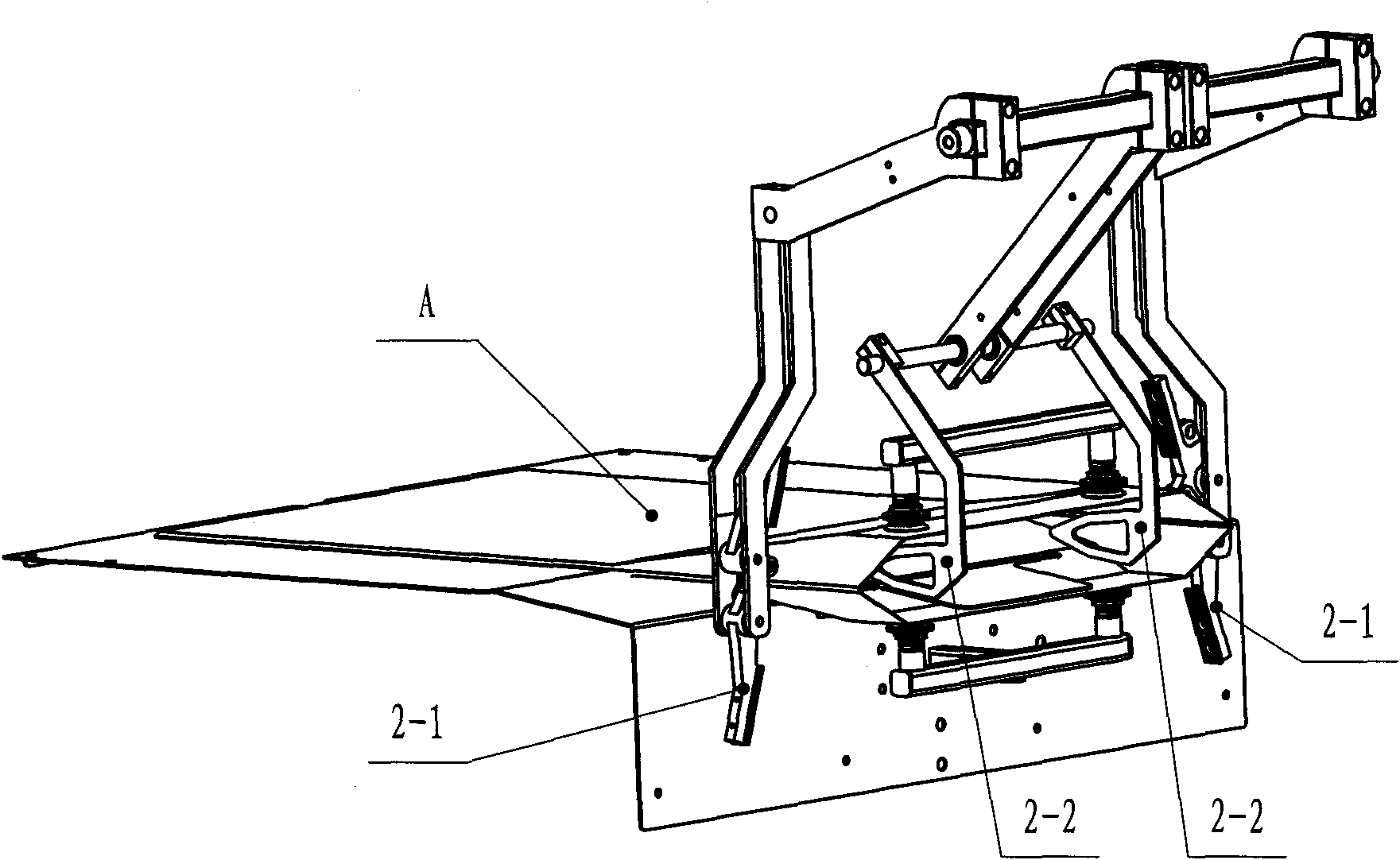

[0036] (2), take out the empty bag: the brace plate (2-2) of width slightly smaller than the opening of the bag mouth is inserted in the bag mouth of the empty bag (A) that opens, and the bagging handles (2-1) on the left and right sides are closed, Clamp the left and right sides of the empty bag (A), leaving an appropriate distance between the bagging handle (2-1) and the mouth of the bag;

[0037] (3) Empty bag: the upper suction cup (1-3) and the lower suction cup (1-2) loosen the empty bag (A), and the bagging mechanism (2) swings at an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com