IC full-automatic method for testing brede and full-automatic holding tray type machine for testing brede

A fully automatic, taping machine technology, applied in packaging automatic control, semiconductor/solid-state device testing/measurement, conveyors, etc., can solve problems such as low production efficiency, low packaging quality, and single specifications, and reduce manufacturing costs , machine structure simplification, delivery efficiency and detection efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

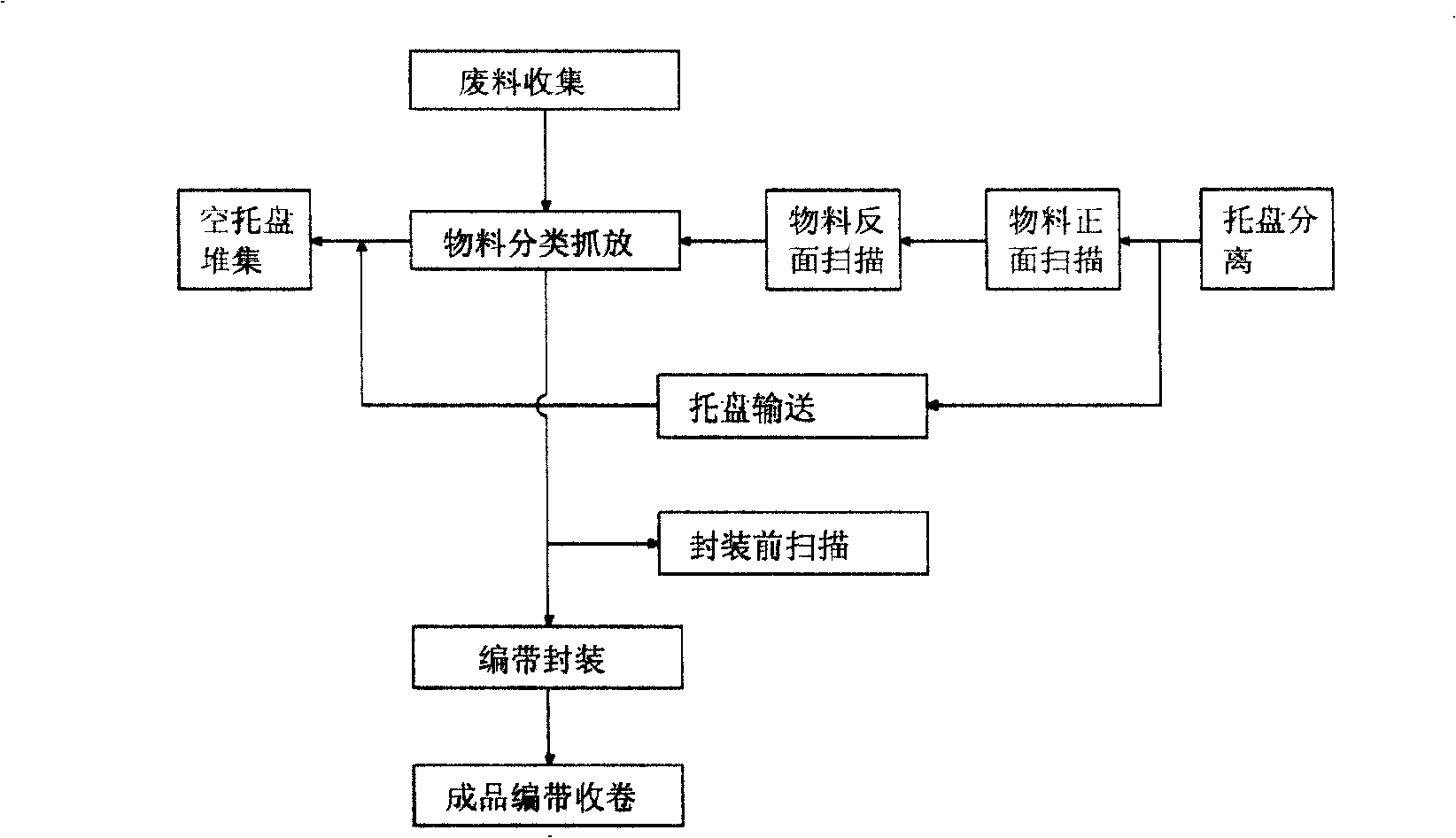

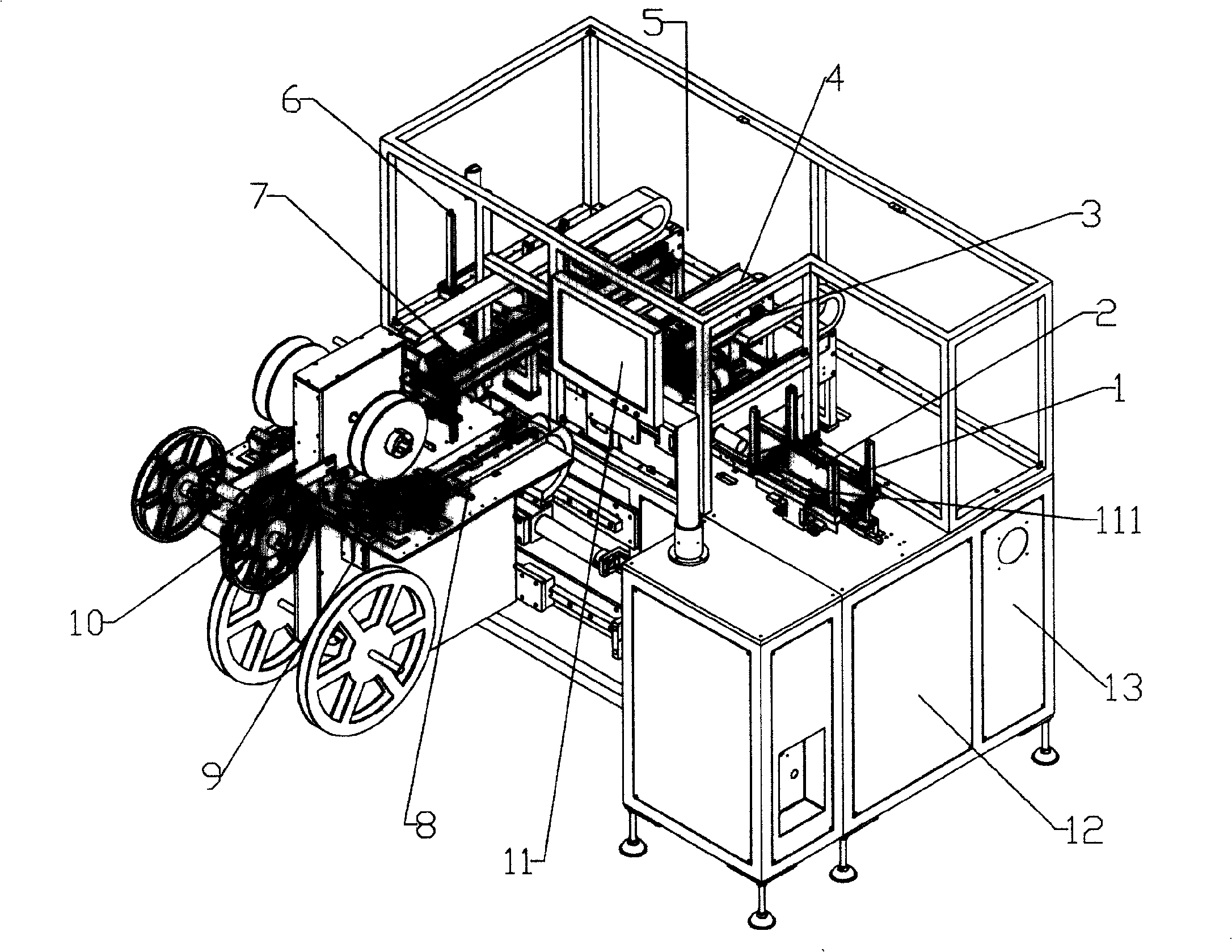

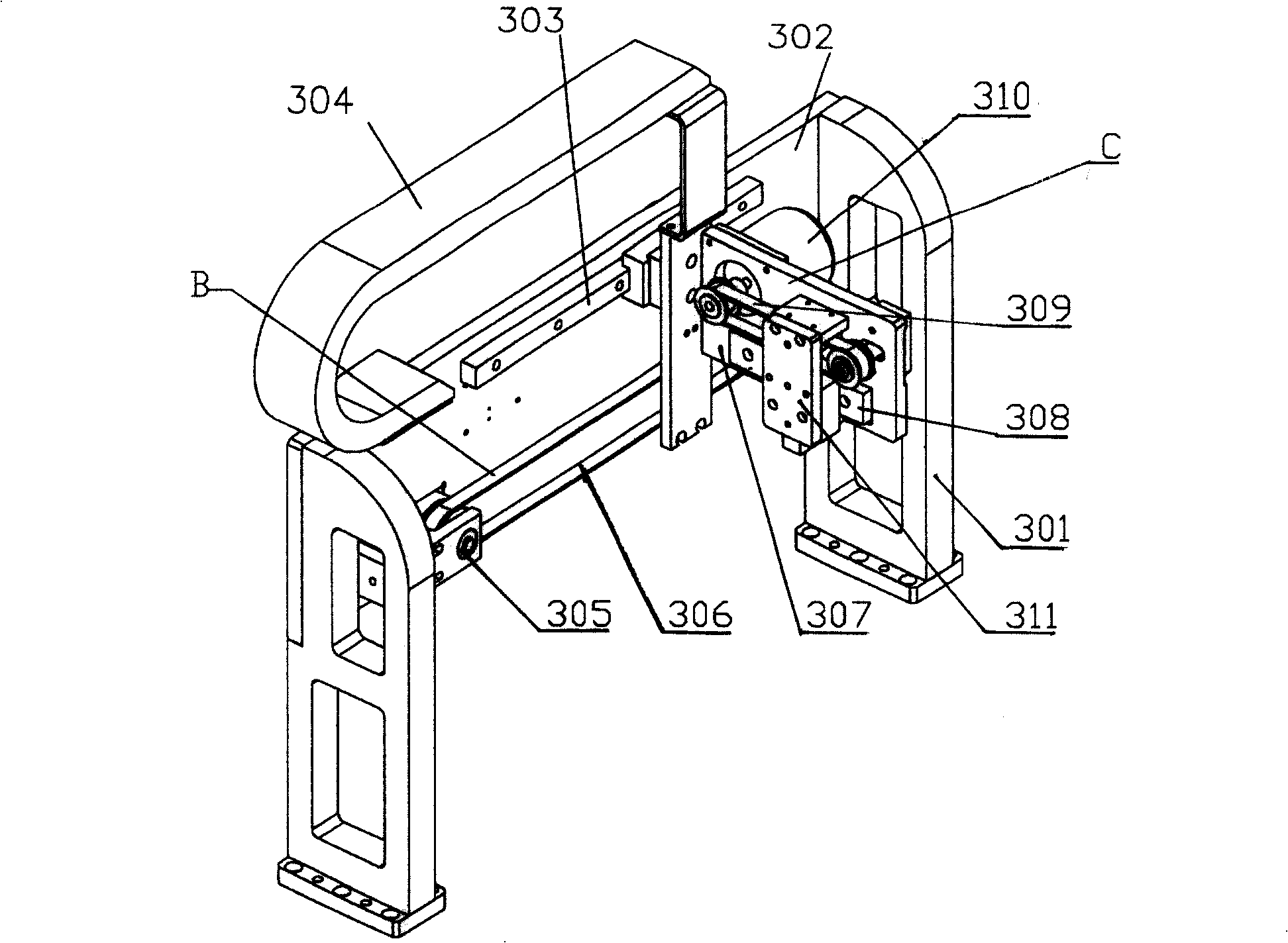

[0044] The present invention is a kind of IC full-automatic pallet detection taping machine, such as figure 2 , 6 , 7, and 8, the machine is mainly composed of a pallet separation device 1, a pallet conveying device 2, a front scanning device 3, a reverse scanning device 4, a waste collection device 5, an empty pallet collection device 6, a sorting pick and place device 7, and a tape It is composed of packaging device 8, product specification quick conversion device 9, product braiding and winding device 10, display screen 11, PC control system 12, electrical control system 13 and so on. The pallet conveying device 2 is placed below the inner sides of the two parallel pallet conveying rails 111, and the pallet is pushed forward by the pushing heads 202, 204, 208 of the pallet conveying device on the slideway between the two pallet conveying rails 111. The pallet conveying device 2 conveys the pallet to the pallet separating device 1 in the front and to the empty pallet stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com